Architecture magazine

Summary of the requests:

-You guess my design appropriate, if the need arise to scale upward even further.

-How can I improve conditions of potential competition in the data record.

I work in the research of catalyst, where I support about 100 scientists, which includes the construction of automated test systems. I have a joint Bachelor's degree and 5 years experience professional in electronics and software engineering, including 3 years is LabVIEW Development.

I can bounce around ideas of electronics on the site, but as I am the only software person, I was hoping that some of you might take 10 minutes and my general software architecture review.

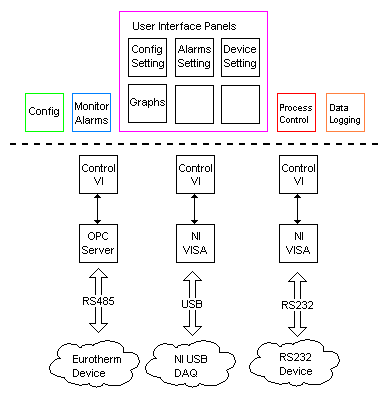

The platforms have usually several pieces of fixed material, usually in the form of:

-Hardware DAQ USB of NOR

-Eurotherm controllers (Controller Mini8, 2000 series, 3000 series) on RS232, RS485 or TCP.

-The material is not relevant, because I communicate with them through OCP

-Other instruments RS232/RS485, communicate through NI VISA.

-Other USB instruments, communicate via directx or device drivers, and al.

An execution will generally last more than 12 hours, and so they need be sure to leave unattended. Generally, this is in the form of hardware locking mechanisms, because I do not trust do not lock down the computers. In addition, it means error real manipulation in software rather than appear an error message on screen

I love my modular software designs and abstract (although never to excess). Each hardware device is handled in its own class data structure; The values are read, stamped and recorded in a shift register. Values are constantly compared to safe operating limits. The only time where an external level, or senior VI is called from the controller is a configuration during initialization data structure. Actions can be sent to the device controller via a queue. If a value is outside the safe operating conditions, special condition is sent to an alarm handler via a queue.

Fortunately, experience can often be arranged in a sequence of steps configurable user. This takes the form of an array of clusters. The cluster instance stores set values for temperatures, dwell time, States of the device and so on. When a sequence step is advanced, the set values are powered by queues to each device controller. It all works fine and dandy.

A higher level than, the test runs can be put on hold a user will put a sample in the rigging, log on to the system, create a sequence of the series of tests and let him get on with it. I would also add sequences and execution conditions are recorded on the disc, so if the PC crash, things can become operational quickly.

Regarding the interface user; That's it, that is. None of the screws in the user interface deal with the operation of the platform. Changes to the user interface are written to the data structure of file config, directly on the device controllers, Manager of alarm or a controller of various processes. The readings of the displayed user interface have a set update rate, which queries data of each device controller

At the request of scientists, all data that may be stored, is recorded at a frequency set by the user. Once the log file reaches a number of lines, it is closed and incremented file name continues. This is why they can be imported into excel, or to relieve pressure on a computer, data processing. Each iteration of newspapers, data are queried from everywhere where the readings are taken.

I think I have a stable, reliable and safe way to build platforms, but I remain unsatisfied with my methods I've tried to present data to the user and save the data. Given that the data is either read from a number of sources, I want a good way to keep reasonably synchronized data. (Reasonable being less than 50 ms) Temperatures, pH levels, pressures, motorized actuators and mass flow controllers fluctuate enough that an accuracy of more than a few hundred Hertz will count (though oversampling and smoothing occur inside the controller of the data of / on the device).

My current method creates a temporary Notifier and adding to the front of the queue. On the next iteration of the device, he's jumped out of the queue and the last value in the buffer is returned by the notifier to the calling function. I support this action engine; because as there is no easy way to tell when to take a reading, whenever the controller of the machine took a reading, it was necessary to update the engine of the action. I'm still unhappy with my method under querying data, because I can't guarantee that the new values have been updated in the device controllers when the section of data logging queries data. This can even cause the same value to be connected. (Race condition) This problem still persists with a motor of action.

Just a few ideas:

* time stamp each reading

* Instead of logging the time stamp of the file, you can trigger an old flag 'data' or similar. I think that the Protocol of the OPC has a flag that indicates how new and recent is any value. Maybe you want to copy from this standard.

* In this case, I would just read the data via a notifier of broadcasting all the time instead of notification of recall temproary. The journal (or other) just browse the list of notifiers and takes the most recent value.

Felix

Tags: NI Software

Similar Questions

-

IPAD app magazine subsription quite

IPad app Maclean's magazine to quit smoking. Updated app, now impossible to download issue. MacLeans does not recognize my address, send back me to Apple.

How to restore subscription?

EDDD change you, by chance, your Apple ID recently? You will need to identify yourself with the old ID, if so.

Otherwise, Contact App Store support directly. Start with the link contact us at the bottom of this page.

View, change or cancel your subscription:

-

Hallo, ich habe eine question zur Diashow in «Fotos» Wie kann ich bei "Magazin" die Anzahl der Bilder pro Dia change? Vielen Dank und beste Grüße

P.S.: Bin bei der Software auf dem current Stand

bei den Diaschauen kann man gar nichts change away. Folge der Folien und die Anzahl der Bilder ist fest programmiert. Man muss sie einfach so nehmen wie sie kommen und das Beste draus machen.

-

HOW to view pages in pairs beside? In a digital magazine-style layout (type istudio)

I desperately need to know HOW to display pages side by side, so I can create a digital magazine. view the pages vertically does not see a magazine or a flipbook. I need a layout like istudio. Help, please! Thank you!!

I don't think that there is. I really want to know, too.

-

App Store, Architecture of Plugin, legal, etc.

Hello

We have two or three question about what is allowed by the policies of Apple.

We intend to build application 'customer base' which will target devices mobile apple. This customer base should contain all the logic basis for access to specific material on the devices, communication skills, features common etc... and it will be published in your App Store. Basic customer contain no business logic.

This customer base should take advantage of the plugin architecture in order to have a business running logic. This business logic will be very very light, because all the real logic is on our cloud services and/or site.

The idea is therefore to build the customer base is solid, which should be used by our customers and the function or the project, customer base must download appropriate to our server plugin.

IMPORTANT: These plugins will contain ONLY LIGHT BUSINESS LOGIC, AND user interface that requires NO physical resources and features, other than permitted by basic client app.

The idea behind it is to shorten our efforts to develop, fix, put our demand of our customers.

This type of architecture is allowed by the policies of Apple?

Kind regards

Hello Rony8620,

You only asked a question--nd the answer is a firm no.

-

Can I mirror my iPad on TV or Mac computer magazine? Thank you very much!

I have a lot of magazines on my iPad (iPad Pro 9.87), some purchased through iTunes, others through Zinio.

Not all can be read on a computer. If I could mirror magazine (most with a small print) on a TV, it would be useful. Can it be done?

Thank you very much

Wexmall

If your TV has an HDMI port, you can easily get an adapter and you will see your iPad on your TV screen (you must also set the entry to the corresponding HDMI port).

-

Hello guys.

I'm looking on the web for some time to learn about the architecture used on iOS as the type of file system, the system management process and memory management system.

Can anyone help me to get some documents.

Thank you in advance.

If I were you, I would like to ask here Developer Forums

-

I got the Firefox version just before the new 8. The icon of the new version has a circle with a cross bar. The application does not open. I want back my old version. How?

From Firefox 4, Mac must have an Intel x 86 processor; your system is Mac PPC.

The good news is that Firefox 3.6.24 supports still the PPC Mac architecture. The bad news is that the support for Firefox 3.6.x series is likely to end in the first quarter of 2012.

- System requirements: Firefox 3.6.x

- Download Firefox 3.6.24: https://www.mozilla.org/en-US/firefox/all-older.html

You can try the TenFourFox third-party product that supports the PPC Macs. Firefox 8 version of TenFourFox is available. The product is based on versions of Firefox released. All support is provided by the developer, not by this site:

- Homepage: http://www.floodgap.com/software/tenfourfox/

- The developer's blog: http://tenfourfox.blogspot.com/

- VERY IMPORTANT; read this: https://code.google.com/p/tenfourfox/wiki/PluginsNoLongerSupported

If this answer solved your problem, please click 'Solved It' next to this response when connected to the forum.

-

My computer is not allowing me to use any version of Firefox, after several attempts to download. Simply, I get a message that Firefox is not supported on this architecture, and the Firefox icon in my toolbar now has a circle with a line through it top (cancelled). I hope someone can explain what I need to do to be able to use Firefox once more. Thank you, TC

As you have a PPC or Power Mac the last form of waiver Mozilla to work on the PPC is Firefox 3.6. *

3.6.23 Firefox can be found at http://www.mozilla.com/en-US/firefox/all-older.html

Since you have a PPC Mac, there is this option of third-party for Firefox 7.0.1

http://www.floodgap.com/software/tenfourfox/From Firefox 4.0, a Mac Intel with OS x 10.5 + is required for versions of Mozilla's Firefox. http://www.Mozilla.org/en-us/Firefox/7.0.1/system-requirements/

-

I removed the Intel 32-bit architecture, do I have to re - install OSX EL Cap to get it back?

I removed the Intel 32-bit using a freeware program called monolingual architecture that eliminates essentially irrational language files and architectures to recover from storage space. I didn't know that MS Office for Mac 2011 requires it. I have to re - install OSX EL Cap to get it back?

Yes. You may also need to reinstall Microsoft Word and any other program assigned by monolingual.

Programs such as monolingual should not be used.

-

Cant't open on my bad architecture of Mac OS x 10.5.8 PPC? Only for maybe Intel?

MacOS said something on the wrong architecture and the Firefox icon displays a diagonal line through the icon to slide into the application.

For older Macs that are not considered supported in Firefox 4.0, try TenFourFox for PowerPC in performance Mac 10.4.11 and 10.5.8.

http://www.floodgap.com/software/tenfourfox/ -

You can use credit balance account Apple iTunes to purchase the subscription to the magazine.

I downloaded the app on app store, buy a subscription for one year of the magazine could I use my apple balance on my account, or if I have to enter a credit card?

Yes, you can use iTunes credit to pay subscriptions to magazines.

-

Can I use the account balance in iTunes and add this to purchase subscriptions to magazines.

can you use iTunes account money to pay for subscriptions to magazines? So if my payment of account I select 'none' and do not enter a credit card, would be the payment of the subscription comes from my iTunes account balance?

Unless the magazine says something else, and you aren't a family Organizer in the sharing of family (it cannot use their balance or remove their card from their account), then Yes, your balance will be used

-

This architecture is not supported on install

pc power problem?

http://www.Skype.com/intl/en/get-Skype/on-your-computer/MacOSX/2-8/

Use the above link to PPC. Architecture PPC version 2.8 support.

-

XP Home SP1 - MS Universal Audio Architecture HD audio bus driver installation.

High definition audio bus driver MicroSoft Universal Audio Architecture is required before you install the original audio driver after reinstalled XP Home SP1 operating system, on a Compaq Presario.

I downloaded the MS folder and unpacked in a driver's record, but document text tips are only for a network situation.

Help would be appreciated with a few questions:

(1) is there an easier way to install the UAA driver?

(2) is there a better driver available or other if I install SP2 I downloaded ready to install offline?

(3) I believe that it is not safe to use the internet again as the firewall is not sure in SP1. and

(4) if it is safe to use internet with SP1 which free antivirus could I use?

A simpler way to install MS UAA & the Realtek Audio driver becomes it while one of the Realtek site.

Choose High Definition Audio Codecs, contract, then download the file "Executable":

Maybe you are looking for

-

I downloaded the version 9.0.1 seven times and every time the download indicates that the download went well. However, my computer guard return to 3.6.25 which is a version more old who ask me to update to version 9.0.1. So, I'm in a loop going aroun

-

Need a display driver (s3) for Tecra 8100

I installed Windows XP pro on my tecra 8100 and cannot get a full screen.Someone knows what's the problem? Do I need a new display driver voor the S3 Savage MX, or is it something else?

-

Satellite A100-683: 251 MB partition found - whats for?

Hello I just got a laptop Satellite A100-683.It has 3 partitions, but the 3rd (at the end of the hard drive) is not visible in my computer.In fact, Windows does not recognize its file system. The only thing that windows can say is that it is 251 MB i

-

Why my email is considered the functioning

All of a sudden I can't send or receive e-mail

-

Having a real problem. Just going in circles. Just did a restore and now the connection of the fingerprint reader is apparently spent some password which is not known. The fingerprint is read and recognized, but then it asks me to enter a new passwor