Calculate the intensity calculation of labview code

How to calculate the intensity calculation of an in terms of no. labview code. operations? Also please guide me how to find the number of fixed and floating point indicates the operations.

Thank you

As far as I know, there is no tool to explicitly measure the number of operations performed under the hood. An option that could give you a more general overview of the complexity of your code using the VI Analyzer Toolkit. There are many tests that may give you some guidance on performance issues. I would check these items:

http://www.NI.com/white-paper/3588/en/

http://zone.NI.com/reference/en-XX/help/371361K-01/lvvianalyzerhelp/complexity_metrics_tests/

http://zone.NI.com/reference/en-XX/help/371361K-01/lvvianalyzerhelp/vi_metrics_tests/

Tags: NI Software

Similar Questions

-

How Apple Watch to know or to calculate the intensity of my workouts?

Hi all

I used my Apple Watch now since some time in combination with the application of activity for different types of workouts such as running etc and I am curious about the watch or the activity app knows the intensity of a workout as a race.

The rate watch or app works just like a similar race or does it somehow make a difference if a race is more or less "hard"?

I am interested in this because I think that there is a difference if you go on a relaxed atmosphere, 10km run, or if you for example one very hard works on a mountain. Can watch it / app don't know if you use for example up the Hill?

I was recently on a very relaxed ran about 10 km with my girlfriend. After such a race I feel very exhausted, but the activity app still said I burned some calories. Now another day I went to a really hard and fast race up a hill which was a lot however shorter, only about 6km. In this case the activity app said I burned fewer calories than on race relaxed and I really can't believe that run if I work very hard compared to a relaxed atmosphere.

That's why I wanted to know how it actually works and hope someone can answer me.

Thank you and best regards,

Thomas

Hi Thomas

When follow you an activity using the application of the training session and specify a type of activity, your watch uses the most appropriate sensors and data sources to estimate the outcome of this workout.

For example, when you save a run in the open air:

- If you also take your iPhone along (with compatible Bluetooth and location Services), your watch can access the GPS of the iPhone data when estimating the PACE and distance.

- If you do not take your iPhone along, the watch relies on data from the accelerometer in the estimate of the PACE and distance.

- Data from the heart rate sensor is used during the estimation of the Active Calories, including calculations which are adapted to different activity types.

Calibrate your watch helps improve the accuracy of the different estimates made by the activity and workout app app. More information and instructions for calibration of your watch are available via the link below.

Estimates of the results will also depend on your personal information. To verify that this is correct - and update over time:

- On your iPhone, in the application of the watch, go to: My Watch tab > health > edit - tap and adjust the settings, then press on in fact.

More information:

Calibrate your Apple Watch for better accuracy of training and activity - Apple Support

-

Exchange of data between the internal and external labview code

Sorry for a simple question.

I have a TestStand sequence that uses units/tests written in LabVIEW. The sequence is extermnally began with a stand alone LabVIEW program. I need to establish simple exchanges of information between units of the sequence LabVIEW and LabVIEW external code.

Information are simple strings will eventually be sent in both directions.

Please advice what commumnication path needs to be implemented.

Unfortunately, arttempts to search OR site Internet (or Internet) result in a large number of irrelevant information. Probably, I can't shape appropriate keywords. There is therefore a need for your help.

Thank you

_Y_ wrote:

[...] It takes by presenting some initial information (e.g. username) in the sequence [...]Use a Message from the user interface of query for the data (data available in the user interface, executing sequence requires it).

_Y_ wrote:

[...] and view the status of intermediate/final level in the user interface.Use a Message from the user interface to transmit these data to the display (data available in the execution of sequences, Which requires it)

Norbert

EDIT: Btw, you should use TestStand user to nicks track management. This gives you more options and security than some custom stuff implemented in the user interface.

-

Why the activity of the screen or the screen updated slows labview code?

Hello

I use the Labview for quite a long time. recently I discovered that updates screen slows down execution of code. is it possible that I can eliminate the delay I get due to the screen updaes or changes?

-

Open built in the workspace Addons in LabVIEW application using the API

I do Veristand project who uses a lot o custom code for additional features (database Custom logging, several preconfigured stimulus profile running on action of the user, custom logging datafile, customized SCADA-like display of the State of the system (pipes, valves, pumps, etc.)). On any other user of hand interface for the control of the program must be simple, because operators use (the only options, no change in operation) and similar to the previous system solution (which was HMI, touch screen with multiple monitors).

I plan to do LabVIEW custom application for GUI which communicates with the gateway Veristand and target using API functions.

However, I want to implement some already existing in the workspace tools in LabVIEW code, such as monitor of the alarm. There are "Open workspace tool" API functions in the labVIEW Veristand API function list. This function requires the toolpath to workspace as an argument. How can I set path for those built in the workspace tools? I'm not managing to find with the simple search.

You may want to consider this topic

http://forums.NI.com/T5/NI-VeriStand/open-workspace-tool/m-p/2253154

Concerning

-Eric

-

How LabVIEW calculates the Euler Angles of the Direction cosine matrix?

I am looking to clean my block diagram by converting mathematical functions LabVIEW Mathscript; However, I can't know exactly what convention of rotation is used to calculate the Direction cosine matrix Euler angles. Any ideas?

Here is what I use now (see below)... the angle phi is the only one (of three angles) not correct as mathematical LabVIEW functions. I've also attached the .vi illustrating the calculation in two ways.

% calculate the angles of Euler of DCM

% "DCM" is a 3 x 3 direction cosine matrix

Phi = atan ((DCM (2,3)) / (DCM (3.3)));

Theta = acos (DCM (3.3));

lb/po2 = atan2 (DCM (1,3), DCM (2,3));

-

Stupid question, but I cant find it through various research.

How can I calculate the width of the code and relate that back on my sensor units.

If I have a 24 bit ADC with a range of 500mV I get 2.98 mV E-5 steps. How to convert to the engineering units.

Solved the stupid question.

a gain factor for sensor that is (in increments of V/unit)

Then, just multiplied by my calculated voltage code entry.

to get unit/data acquisition engineering bit

=(DAQVoltage range) EU / (bit) *(Sensor Gain)

-

need a script to custom calculation to calculate the standard deviation

need a calculation script customized to calculate the standard deviation of 8 rows, it is a form .pdf variable data entry points will be users using this model as a form.

I can get the average of simple calculation, but struggling with the script for the standard deviation. Any help would be appreciated.

Header 1 Header 2 Header 3 Header 4 Header 5 Heading 6 Heading 7 8 header Header 9 Header 11 sample1Row1 sample2Row1 sample3Row1 sample4Row1 sample5Row1 sample6Row1 sample7Row1 sample8Row1 Average stdDeviation If the formula is not:

StdDev = sqrt (sum (sampleXRow1 - average) ^ 2 / (n-1))

But:

StdDev = sqrt (sum ((sampleXRow1-average) ^ 2) / (n-1))

If the code should be something like this:

var avg = Number(this.getField("AverageRow1").valueAsString); var sum = 0; var n = 0; for (var i=1; i<=8; i++) { var v = this.getField("sample"+i+"Row1").valueAsString; if (v!="") { sum+=Math.pow((Number(v)-avg),2); n++; } } if (n==0 || n==1) event.value = ""; else event.value = Math.sqrt(sum / (n-1)); -

Process of calculation to calculate the value after submit after all validations

Hello

Please help with a possible approach or suggestions for the calculation process.

I have a calculation process after submit I want to calculate its value after that all validations are handled. Because this process of calculating trim is off of the first part of the input string of the user for the P3_USES element. Thus, for example consider; the user selects a value for P3_USES (point list manager) to be "TAC"... BCA... BCA... BCA... 0.CA BC... "CA IT BC. So my calculation process just stripes off the coast of the first portion of the string and computes the value will be "BCA"... BCA... BCA... 0.CA BC... "CA IT BC. It works fine when all postings on the page are placed without cooking.

The problem occurs, then the validation fails on the form. Once the validation fails, the calculation process; already calculates the value and the P3_USES value form element is set to "BCA"... BCA... BCA... 0.CA BC... "CA IT BC. So, here the user solves the problem of validation and sends it again the form, but at this point the value is calculated again but this time that my string is "BCA"... BCA... BCA... 0.CA BC... CA IT BC"which is not correct, because my initial user string entry was"TAC"... BCA... BCA... BCA... 0.CA BC... "CA IT BC.

So my question is how they treat the value of my calculation after all validations. While I can keep the original value of the P3_USES element. I'm using the version of Oracle APEX 4.0 and Oracle 10 g R2 database.

Thank you

Rambeau

Hello

Combine code of calculation and validation?

Perform the calculations in the process?

Use another element to contain the value 'real '?

Kind regards

Jari

-

Complete mapping and the library of labview code order

I worked with a Schneider Electric M258 Logic Controller (PLC). I already used an Ethernet cable to connect, recognized as a device of TCP/IP network OR max. Recently, I used a Schneider Electric TSX C 485 USB cable to connect via a COMPOTE. This connection is also recognized in NI MAX, as well as the fact that I can actually open a panel of test VISA this way.

I'm looking for help step by step how to use LabVIEW to scan the logical controller for the command codes, it is used to control other instruments (heaters, pistons, etc.), can fill a library in a project, LabVIEW myself with these commands, so that I'll be able to control these instruments from my laptop.

Hello

Unfortunately, there are currently no tools or methods for the analysis of the controllers for control with LabVIEW codes. For a list of commands using the PLC, I reference the manual for the device or contact the manufacturer.

Many instruments are prefabricated screw to control these instruments available on the NI Instrument Driver Network (www.ni.com/idnet) that were created by the manufacturers or other users. I searched for the Schneider Electric M258 Logic Controller (PLC), but sees not all drivers. If you are interested in a person having to create these screw driver for you, we have the Alliance partners who can help you with that. (http://www.ni.com/alliance/)

Once find you the commands from the manual or the manufacturer, you can develop your own screw driver for the device and, if you feel so inclined, download them to idnet. Information on the creation of instrument drivers for devices to use in LabVIEW in the following link.

https://www.NI.com/DevZone/IDnet/development.htm

Good luck with your instrument driver development!

-Eric

-

LabVIEW hangs with in the intensity chart

Twice this morning, LV2010 weighed ("program is not repsonding") when I tried to put a graphic on my front intesity. In one case, I copied the graphic in an example program OR my VI. When I tried to reposition the chart on my forehead panael, LV unresponsive. Same thing happened when I tried again; the second time, I have the graph of the intensity of the palette of tables and graphs. I LV 2010, version 10.0f2 and windows XP. Thank you.

Hello!

The following KnowledgeBase explains why this could happen.

http://digital.NI.com/public.nsf/allkb/9A8FB888BFCED9658625721500434A31

Basically, this table might contain a large amount of data, and when you move, LabVIEW must reorganize all this information in RAM as you move the chart. You can write smaller data, or save all data in a separate table in the table at the end of the execution so you can save it. If you want to view a chart later, simply enter it in a graph.

-

Use several versions of the same material and the same LabVIEW code

Here's my dilemma,

I have many different s NI 9213 (16-channel thermocouple module) that I use in my lab. I only need to use one at a time, but I want to use the same LabVIEW code with each. I use NI MAX to create a task for the NI 9213 I use, but when I plug another 9213 OR in the computer I need to delete the first task and make a second tast with the second 9213 OR.

My question is, is there a way to plug in different s 9213 OR the computer and without having to reconfigure the NI Max tasks? If so, how?

Thank you

Maddie

Just use Concatinate String using the returned device name as well as the names of channel to build complete path name and then DAQmx create channel to add this channel to your task.

-

calculate pixel intensity in an image in black and white

Hi all

First of all, im new to labview. Now, this question may have been asked before, but I'm not quite sure. OK, so I have an avi video that can be allocated by 50 images. I used imaq threshold and a loop for to put a threshold in each image, which makes them black and white. What I want to do is to calculate the percentage of area which is highlightened as white. I thought that I can do by calculating the total number of pixels that have an intensity of 1. I know the black pixels are 0 intensity and I also know the total number of pixels in each image. I tried to use the function to quantify but I couldn't get the desired effect. Then, I tried to use imaq light meter, but still I could not the exact number of pixels with an intensity of 1, only the mean value and the standard deviation of the pixel. I can probably calculate the area that is intense using these two values (mean, st.dev) and simple statistics, I think, but I need more detailed results. Is there a way to get the total number of pixels with intensity of 1 in a black and white setting? Sorry if this question has been asked before, I could not find that a related. Sorry for my bad English as well. Waiting for your answers.

Thank you very much.

The problemwith gregoryj code is that it converts to a table of Boolean number, not a number, the value of this number depends strongly the position of values in the table that are True.

Once you have the array of pixels in the black and white image (all the values 1 or 0), just use Array Sum to get the number of 1.

Lynn

-

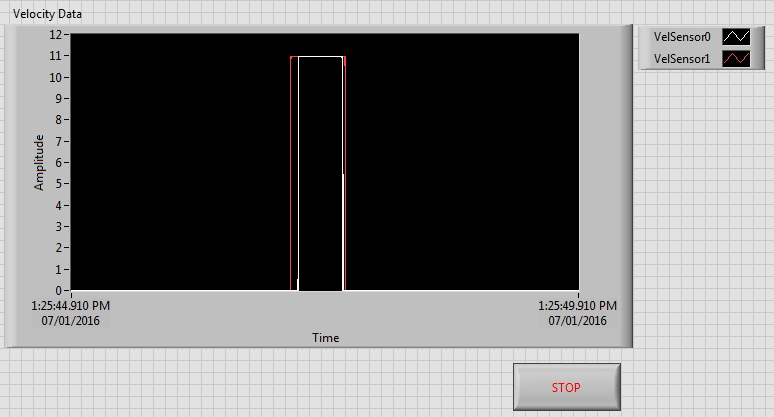

Calculate the speed of the target by using photoelectric sensors 2

I use 2 photoelectric sensors mounted parallel to each other. As the target passes in front of the sensor, the signal of output voltage goes from 0V to 10V. Because I know that the distance between the sensors, I need to use the difference of rise time of the signal between the sensors to calculate speeds. I can do that when I export the data to excel, but I would do it automatically into my LabVIEW code.

The data of my sensors are the type of waveform. I can extract the waveform (t0, dt, Y) components using 'Get waveform components' and then look for the timestamp for each value using t0, dt and index value. I need to calculate the timestamp of each sensor once the signal passes to 10V (Y = 10V). I can't extract the components of waveform for signals from sensors (seems to only be able to extract the components for a sensor) and once I extracted components, setting up my calculation of the speed. I think I need a case structure to save the timestamp, once the signal hits first 10V (if Y = 10V save timestamp; if Y = 0V continue indexing of values).

Any suggestions on the extraction of components of form of wave or indexation of values and calculation speed are greatly appreciated! The code I wrote to collect signals is attached.

Thank you very much

Alberto M.

Here is a sample of the signals of the sensor showing the difference of signal rise time.

1. you must use the finished sample mode and read all samples. To match what you have, I would use 10 k samples. That would be 5 seconds worth of data. This eliminates the need for the while loop and gives you the full waveforms.

2. just use the base trigger level detection VI (in the Signal Processing-> measures of waveform-> palette of Waveform Monitoring) to get the time for every rising edge. Then it's a simple subtraction and divide.

In addition, if you want to make things even easier, you could have used a camera with a meter of A - B. Then the meter gives you just the time difference directly.

-

How to calculate the execution time of a SCTL in FPGA VI?

Hello

Can someone guide me that how to calculate the execution time of a SCTL for an iteration in the FPGA VI?

Thank you and best regards,

Rashid

Hello r,.

A SCTL will always run in a beat the clock it has been linked to. So, if you use a 40 MHz clock, this loop will run in 25 ns. If the code cannot complete in that, or if it requires two graduations of the watch to do the calculation, your code does not compile, then you have the guarantee that this will always be how long it takes this piece of code to run.

Maybe you are looking for

-

Is there a way to save all my tabs at once and transfer them to another computer?

No, I'm not talking about having to first laboriously click each tab, bookmarking them, following the instructions to transfer your Favorites file and them by clicking on each bookmark to reopen your tabs. I wonder about a one click way to save all m

-

Connection Bluetooth 4.0 iPhone 4 with IOS 7

Hey guys, sorry for my bad English, but I'm Spanish, I have a problem, I recently bought a Smartband (Master Kaos) and when I tried to connect this with my Iphone 4 SmartBand it does not, because the Smartband has bluetooth 4.0 and my Ihpone have blu

-

USB recovery is not partition properly and will not plant recover.

Started a thread here but apparently only for American models http://forums.Toshiba.com/T5/system-...t/false#M24453

-

Lost icon volume - Satellite C660 running Windows 7

I was wondering if someone could help me with a little annoying problem... I have a Toshiba Satellite C660 running Windows 7, since working I could use the function button to turn the sound off, I lost the icon for the volume control on the taskbar..

-

On top I get this message after the recent Microsoft updates. I have my original Windows 7 Home Premium paper. By other posts, I downloaded MGADiag and posted my results below. Please notify. Thank you Diagnostic report (1.9.0027.0):-----------------