control solenoids

trying really hard to find information on how to control a relay. I am quite new to LabView program development and have kind of a problem. I have a system that requires control of the solenoid valves. I have three exits relay to drive solenoids to select one of the three levels of pressure. Is there someone who could give me some advice on where to start? I have fpga and real-time module.i use crio, modules or 9477,9425.

Hello

-What are you looking for?

Kees

Tags: NI Hardware

Similar Questions

-

control solenoids with USB-6525

Hi, I'm new to Labview and try to use a USB-6525 control six independent valves. They'll be turning on and off at different frequencies to control a cell infusion system. I drew a diagram that allows me to program schedules that the CRDD is closed and open. The routine is inside a while loop to repeat until a given time has elapsed. I can duplicate this six times to allow each valve must operate independently. But I would like to trigger all tasks at the same time. How do I synchronize loops so they all start at the same time? Simply put all the loops inside a conditional loop, or it will run the tasks in the order?

Thank you

your synchronizeyour can while loops with the help of tax filers, please see the attachment.

Barros (Certified Developer partner)

-

lets stop the loop parralle notification

Hello

Everyone

I created several loops producer/connsumer.

A loop producer is business event that hold value control change of FP and then send queue consumer loop (solenoid)

The other separate producer loop is to NEITHER 9213 display Temp data, I use another loop of consumer to acquire the data of NI9213

I don't know if I can use notification to stop the two pairs of earrings.

I hope that when I click on stop the whole process in PF button, then, the True value is sent to the notification. The NI 9213 producer loop then get this message to stop the loop. Now, stop process only control solenoid buttonhole since this button is in the structure of the event.

I tried the notification. When I put wait notification NI 9213 looping, this loopkeep wait any notification and doesnot monitor temporary data

Thank you

-

Hello everyone.

I need to design a system where it is supposed to control two solenoid valves (for gas of 5 l/min flow), a thermocouple and a moisture sensor. I have a few questions with respect to the foregoing:

1. what valves would be ideal to achieve flow rates of gas of 5 l/min.

2. is if possible to use NI - USB-6009 to control via PC or some other hardware DAQ system the above would be better

3. what additional devices are required in the above configuration

I'm looking for some preliminary information that could help me get started with the aforementioned project. Any help would be greatly appreciated.

Deepak

(1) do not know...

2) the 6009 will be have limits, no hardware timing for cardiac control loops, can not read TCs, if it's a school or a University project, take a look at the myRio. I'm not shure if it can read the TC directly, but you can easily connect an i2C / SPI TC IC conditioner.

(3) you will need some vor to power external power valves and a pilot valve (at least a transistor and a diode) -

Hey everybody

I designed the system pressure (dp cell) with a variety of 8 ports each of what solenoid. What I'm trying to do is to control the valve through labview so the open 1 stay open for 30 seconds in time, then close and another is open and so on. I have attached the plug of the valves. I use with NOR: 9203 and neither Cdaq-9178: 9472.

The valves are normally closed and the liquid flowing through them is silicone oil.

I tried to look at the different examples, but I got confused.

I would be grateful of any advice or suggestion that you give. (I started using labview just a few weeks ago).

Best regards

Rajab

-

Error 33180 - controlling a solenoid with FieldPoint

I use a LabView program to control a solenoid, giving an entry of 100 and 0 in the adjacent parts of a sequence of flat, using a writing FP (polymorphic) .vi and a constant Point IO FieldPoint for measurement of e/s. In the measurement and Automation Explorer, I can handle the cFP-PWM-520 module, successfully, giving 0 to 100 entries, but the solenoid does click not. The valve works physically, as I've tested before. When the LabVIEW program reached the part of the solenoid of the sequence of flat, he stops at the vi FP writing and gives me an error 33180 (the amount of data provided does not match the number of data elements required or the number of channels to deal with). I don't understand what that means or how it relates to the electrovalve. I joined the program (LabVIEW, 13).

Hello ksinks,

It seems that you have defined 0 to 100 as the index of your matrix constant as opposed to the real value in the table. in the constant matrix, the left field should remain as '0' If you try to pass a single value (because the tables are indexed from zero) and the value in gray on the right should be defined as 0 or 100 (or any value that you want to be passed in). Please try it and let me know if it works!

-

Best configuration for the control of solenoid valve

Hi all

I'm really new with everything regarding controllers or the relay so that any help would be much appreciated.

I want to control 5 valves (Web site) with the following characteristics:

Rated voltage: 12 or 24 VDC, available voltage fluctuation: 10% of energy consumption (when 24V nominal voltage): 1.5W (0.06 A)

I want to use LabView to control. In a similar position, I knew I would need a digital camera I/O driver relay and a generator of 24V.

I was thinking of using these:

NEITHER 6501

Relay driver (uln2003)and a 24V generator.

Is it enough to order the valves with LabView or do I need something else?

Thank you very much for your help!

Ilan

Yes, this combination should suffice. The ULN2003 is designed for exactly this type of application, and works well.

Usually in English, we refer to the power supplies when we talk about devices to convert AC line voltages to lower DC voltage.

In addition to LabVIEW, you will need a driver for the USB-6501 DAQ. Under Windows, it will be DAQmx. On Mac or Linux, the dirver is DAQmx Base. The driver is a separate LV facility, although it can occur on the same disks.

Lynn

-

-

Solenoid with labview interface

Hi, I currently have a solenoid valve (NVZ110) with 24 VDC, "+" and "-" terminals) and I:

CFP-DIO-550

CFP-AO-200

CFP-AO-210

PSC-HAVE-112

My question what module should use to open and close the tap? Also, I couldn't find a tutorial on how to create a simple vi to control this valve using LabView. Is there a simple example VI?

As an alternative, you can use the 550 to turn on a mechanical or relay DC coil, whose output contacts could then apply/remove you power AC powered solenoid.

-AK2DM

-

Use of LabView to solenoid in the gas system.

Hello

First of all, I'm new to the LabView program don't know much this program but it can connect and control instrument.

Second, my Adviser want to move the manual system in an automatic system that control through LabView using

the temperature and the pressure is a trigger to open/close the solenoid valve. (starting with the solenoid valve 3-way 2-way and 1 2)

Third, this system starts from scratch; for now, I have an evaluation version of LabView 2010 for the test and temperature/pressure sensor in RS323

which easily connect to LabView.

The problem is which module or equipment to connect the solenoid with LabView?

THK.

I think that the Green wire solenoids ASCO is grounded. Red and black are power. If you use an AC solenoid, you can go from a solid state relay. Static relay more require 3-32 VDC to a few my for the control and the control is isolated from the electrical circuit. There are some DAQ with outputs digital equipment that can drive the input solid state relays.

Lynn

-

Hi, I know there is a lot of info on valves and solenoid valves on the forums, but I'm looking to establish myself a starting point. I need a solenoid (or any faucet that can be controlled, really) that will allow me to open and close the tap fairly quickly (less than 1 second) so I can control the level of the liquid in a container. It will be constantly liquid on one side (the top side of the valve in vertical position), and the valve opens for a short period of time until a few mL are exempt, and then close. I have read a lot about who have need of an acquisition of data, or a relay card, but is it here that I can just plug into the wall to power and then have a usb key or another wire run to my PXI to open and close easily? I have a card 4130,2564,8232,4065,8101 PXI slots.

For example, could just use something like the coleparmer below valve and just supply 24V to the PXI-4130 to open it and then remove tension to close?

http://www.Grainger.com/Grainger/Red-Hat-solenoid-valve-6WTP4?PID=Search

Good, but don't forget a solenoid works using a magnetic field to move a piece of metal--a lower voltage, more current is needed to produce the same field, you just need to make sure that everything you go to interface it can handle the voltage and current (or power, which is simply volts * current pure DC).

-

Output at 120VAC solenoid trigger

Hello

I have 4 120VAC solenoid valves, working in 6.1 watts, requiring only 0.05 ampere. I want to control LabVIEW via a hardware DAQ device.

My doubt is if there are hardware devices out there that give a large part of output to trigger a solenoid ON / OFF?

If NOT, is it possible that I can achieve this?

Thank you.

A device of digital output (DO) is controlled by your PC to put a voltage on and outside. A relay is a switch that uses an electrical input, usually low voltage, but not always and generally low current (such as from a c) to switch a higher voltage or current signal - like your 120VAC to control your solenoid.

-

I'm trying to control a solenoid TTL using a USB 6212 and LabView. I'm new to LabView and don't know if my code is correct. I'm also not sure which way I'm supposed to use. I appreciate all help.

Hi biomedP,

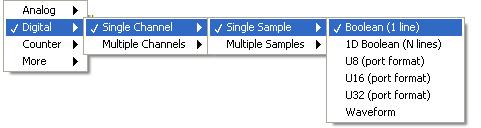

I had a look at your code, and it's a good start, but if you are simply trying to turn the TTL and you don't need a U16 to combat it. If you change your DAQmx, write to boolean (1 line), you can just write a real or fake (power) value to your solenoid.

I don't know to what extent you are in this project, but to develop it further you can also add a sort of loop or some control values. I am attaching a file named "solenoid % 20Control-1_mod [1] revised.vi", which should point you in the right direction.

You can also search in the help files for more information:

Step 1: Go to LabVIEW and go to help.

Step 2: Click on "Find Examples.

Step 3: On the tab browse on the tree table click "Hardware Input and Output" > 'DAQmx' > 'Digital Generation' > 'write dig Chan.vi.

Check out this example, it could solve other problems.

On the channel, just check where the solenoid is plugged into your 6212 and change the input on the VI to match.

Let me know if you have any other questions.

Thanks, Owen.S

-

The relay through time and Total flow control

Hi all

I'm relatively new to Labview and have worked on a great program from lately, which uses a Module with my cDAQ-9178 OR relay SPST 9481 to open and close the 3 different solenoids. The program should open at a specific time and leave it open until a certain amount of flow is passed through them. I already finished the programming to record the total flow through the valves, and after many hours past the forums I found a way and changes in the code that turns on the relay based on the amount of time spent searching, however it turns on the relay and leave them on until the 'period' are filled then pass on the next round. I need to change this option further so that it lights when my "Cycle Start Time" is reached, turns off when reaching the set amount of flow for this cycle and then continues to wait until the next "Cycle Start Time" occurs.

I imagined a way to proceed would be; by eliminating where departures from the clock a new cycle each run and just have it constantly by comparing the time of "Initial start (run)" 'Start' time sequence (when I push the start sequence and actually start to opening the relay). Then change the "delay" to 'Cycle start time' and the (> =) function to a function (=). So now, it begins after the elapsed time is equal to the start time of Cycle. Certainly, this opens the questions, because currently, at the beginning of the cycle the command of the relay begins. So I need make my comparison outside the case 'Cycle' or move the control relay in the case of 'true/false '. However, then I run the question of how to get the software to change the case once he saw to stop the relay.

As you can see, I have about 1 million different things in my head that I played with. Advice or assistance to get me on the right track, or you know of examples would be great! My code is attached below, and I'll post a photo after this post about how I'm taking care to record the total flow. Thank you for your time and help!

Hi M_Blaylock,

You mentioned that you are relatively new to LabVIEW. Are you familiar with some of the debugging tools?

http://www.NI.com/getting-started/LabVIEW-Basics/debug

Turning on climax execution should allow you to see the data flow through your schema. Also, probing the wire just before the input case structure should allow you to see what data is actually trying this case selector. If you get unexpected data, you can probe the front steps to see source these unexpected data.

I hope this helps and good luck with your code!

-

Hello

I have a problem to control the relays i advanced to two loops for the relay a solenoid to control and other control fans. loop of solenoid should work when the fans stop. I am unable to control loops or maybe my developed logic is incorrect. Please, any body help me with this. I am using pxi2586 equipment.

Thank you

Shaik

Maybe you are looking for

-

Satellite Pro P300D-21F - how I wake up from hibernation?

How do I wake up? tried the mobile mouse by pressing different keys. If you press the power button / stop watch computor message was not closed properly.

-

I tried all the stupid solutions here.I'm not running ANY security software. I have no need, so please do not ask me to remove it or disable it.I'm not running Windows Firewall, however; Having never been, I had problems with WF and Skype. Everything

-

Setup Vista Display Driver on Satellite A200 19 L error

After visiting this link, I finally downloaded the driver installation for my laptop! But when he work for install, I got an error message: "Setup nVIDIA didn't find all the drivers that are compatible with your current hardware. Setup will now exit.

-

R52 GUARD RESTORATION after IBM factory records

I just got a new HD for my r52 and using factory restore disks (8) I chose full install at factory and after its all done he just continues initializing restore since the program even if I removed the discs, checked the settings of the bios etc. It d

-

Windows Vista Photo Gallery - change default values

I would like to change the default check mark when printing in the library. The default seems to tick the box 'adapt to the chassis. I would like to make the default value to leave out the check in the box. Sounds easy... but I have not found a way.A