Conversion rates for simultaneous data acquisition

I use a Mech multifunction data acquisition. / s/SMU-6366. The maximum sampling frequency for the analog inputs is 2 MHz. Is the time of actual conversion of CDA always 0.5µs, or t - it change with the evolution of the sampling frequency? Can I set the time of the conversion? Reading, looks with peripheral multiplex, you can set convert it clock and the sample separately clock. What is with simultaneous data acquisition?

Hi Daniel K..

It is a big question. I wonder if you get any errant behaviour - your card is not up samples as you hope?

Here is some information that might help you:

Wikipedia: successive approximations ADC

I'm not sure exactly what happens, but dare a guess time digitizing ADC does not vary with the frequency of sampling. And it will also be more than 0.5 US - it is more than likely faster than that.

I hope this helps. Good luck with your application!

Tags: NI Hardware

Similar Questions

-

Where are the guidelines on how to interface custom for LabVIEW data acquisition equipment?

I have a need to do some very specialized data acquisition that may require special hardware for the building. I would still use LabVIEW as the front end and maybe even wear parts of the interface of the final product. However, I can't find the documentation. Where is that is kept? I've seen references to a number of generic protocols, no links back to the details, which may be appropriate. The data are a band high bandwidth, but bursty with sampling frequency up to 40 MHz and events that lasts about 100 milliseconds. Can anyone recommend various methods would be most suitable for this application?

You can use the instrument driver model and guidelines.

http://www.NI.com/white-paper/3271/en/

Use google to search not for OR

I searched

national instruments instrument driver guidelines

-

Laptop HP 15-ac118tu: pilot unavilable for PCI Data Acquisition and Signal Processing controller

Hello

I use Windows 7 Ultimate Hp Notebook model ac118tu. In Device Manager, it shows the yellow mark to the Acquisition of ICP data and Signal Processing controller (the name that appears twice). What is the use of this controller?

Yellow mark means that I need to install the driver for this. Please share the link to the installation of this driver.

Secondly, I want the drivers for the webcam as well. Please share.

Hello:

You need the driver for this device...

This package contains the driver which allows Intel platform dynamic and thermal firmware setting. Intel platform dynamic and thermal environment information system temperature and power use for the heat of the system

protection to work properly. This package is provided for the laptop models running a supported operating system.File name: sp71638.exe

For the webcam you just install this software.

This package contains the CyberLink YouCam software for laptops models and operating systems. CyberLink YouCam is an application webcam that allows users to capture images and video from a web camera and apply visual effects for video and captured images.

File name: sp71830.exe

-

choice of the model of design for data acquisition system

Hi all

I have a problem on the selection of the model design / architecture for a data acquisition system.

Here are the details of the desired system:

There are data acquisition hardware and I need to use by looking at the settings on the user interface.

the period of data acquisition, channel list to analyze must be selected on the user interface. In addition, there are many interactions with the user interface. for example if the user selects a channel to add scanlist, I need to activate and make it visible to others on the user interface.

When the user completes the channel selection, then he will press the button to start the data acquisition. Then, I also need to show the values scanned on a graph in real time and save them in a txt file.

I know that I can not use producer consumer model here. because the data acquisition loop should wait for the settings to scan channels. and it works on a given period by the user. If the loop of user interface makes higher then loop (loop data acquisition) of consumption. This means that queue will be bigger, larger. If I use notifier this will be some data loss comes from the user interface.

y at - it an idea about it? is there any model of design suitable for this case?

Thanks in advance

Best regards

Veli BAYAR

Software for embedded systems and hardware engineer

Veli,

I recommend the model producer/consumer with some modifications.

You might need three loops. I can't tell for sure from your brief description.

The loop of the User Interface responds to the user for configuration entries and start/stop of acquisition. The parameters and commands are passed to the Data Acquisition loop via a queue. In this loop is a machine States that slowed, Configuration, Acquisition and stop States (and perhaps others). The data is sent to the processing loop through another line. The processing loop performs any data processing, displays the data from the user, and records to file. A registrant can be used to send the Stop command or stop the loop of the UI for other loops. If the amount of treatment is minimal and the time of writing files are not too long, the functions of processing loop might be able to happen in the case of the UI loop timeout structure of the event. This makes things a little easier, but is not as flexible when changes need to be made.

I'm not sure that there is a type of design for this exact configuration, but it is essentially a combination of the models Design of producer/consumer (data) and producer/consumer (events).

Lynn

-

I just installed Win7 Pro x 86 on my Z600 workstation. It was an upgrade to Windows XP Pro. I'm missing the driver for PCI Data Acquisition and processing of the Signal and Hardlock USB 1.02 controller in Device Manager. Can someone help me find these drivers. I looked on the page of Support/Drivers for this model, but could not find anything.

Hello

You can get assistance on the HP Enterprise Business Forum since you have a professional worktsation.

-

Hi, it is impossible for the moment to install the driver for PCI Data Acquisition and Signal Processing.

I downloaded the driver from Intel, and it did not work... I found a version of this site for windows 8.1 unupdated and it does not work.

A little help?

Thank you!

Hello:

It could be one of two different drivers.

Try this one first, and then restart the PC.

This package contains the Intel Chipset Installation utility. This utility allows the operating system to show the correct name for the Intel hardware that is installed in the Microsoft Windows Device Manager. This package is provided for the laptop models running a supported operating system.

FTP://ftp.HP.com/pub/SoftPaq/sp75501-76000/sp75561.exe

If this does not work, try this one...

This package contains the driver which allows Intel platform dynamic and thermal firmware setting. Intel platform dynamic and thermal environment information system temperature and power use for the thermal protection of the system to work properly. This package is provided for the laptop models running a supported operating system.

-

HP laptop - 15-ac022ne: pci of data acquisition and signal processing controller

I have this laptop HP - 15-ac022ne and I got windows 8, evrything has not been totally perfect until I upgraded to windows 10, wireless function no longer works, tried to install the driver and update, it was succsessfully installed in the machine to say, but still not working and PCI data acquisition and signal processing controller driver is missing tried to download the chip set on the driver support page, does not, tried to update the driver through the Device Manager and the message can not find a driver for the device of said...

Please I need help...

Hello:

You need this driver for pci data acquisition and signal processing controller.

-

Pci L512 and sigmal treatment data acquisition controller driver?

Just reinstalled a L512 and now I can not find a driver for «pci data acquisition» and treatment sigmal controller

I had the same problem on a T510 and I have not found a solution to this

I am running XP SP3.

Anyone who can help?

Got the fra Lenovo solution. Its Intel Turbo boost, which is missing.

Use one of these

Edge: http://www-307.ibm.com/pc/support/site.wss/document.do?lndocid=MIGR-74348

T410: http://www-307.ibm.com/pc/support/site.wss/document.do?lndocid=MIGR-74434

-

PCI data acquisition and Signal controller and SM Bus controller drivers are not installed

My laptop is Toshiba satellite L305 with Intel Pentium (R) Dual CPU T3200 2 GHz / 2 GHz.

Rescently that he has been upgraded to Windows Vista Ultimate Edition, 32-bit operating system. Since then, my USB device wireless to connect to the internet is not worked. The Device Manager displays a yellow! Select this option for PCI Data Acquisition and Signal controller and the Bus controller. The details for the two area said that pilots are not kept.

How can I get these drivers. I'll appreciate your help, thank you.

Carlos

http://www.CSD.Toshiba.com/cgi-bin/TAIS/support/JSP/home.jsp

Toshiba support at the above link

http://www.CSD.Toshiba.com/cgi-bin/TAIS/support/JSP/home.jsp?NAV=download

Toshiba Driver download at the link above

http://laptopforums.Toshiba.com/

Toshiba laptop Forums at the link above

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Access the site of the manufacturer of your laptop to the link above > drivers and downloads Section > key in your model number > look for the latest Vista drivers > download/install them.

The computer you are using now if you have an Internet connection with the other > download / save drivers > copy them into Flash Drive > transfer / install on another computer/laptop.

See you soon.

Mick Murphy - Microsoft partner

-

data form for the opening of the conversion rate

Hello

I am trying to create a data form for entry of conversion rates. For example in the given line below, I want to create a data form to convert USD to euro and I want to enter into 1.05742 via the data form. I do not know how to select USD and EUR custom 1 and custom 2 members. where can I see this option?

Actual spending; 2005; January; Periodic report; [None]; [None]; AverageRate; [ICP no]; USD; EUR; [None]; [None]; 1.05742

I'm new to HFM and any help will be appreciated.

Thank youThis looks good to me. C1 will be USD and C2 will be EUR entity will be [none]. Choose USD and EUR in C1 and C2, make sure to change the 'Selector' drop-down list on the form of "currency".

-

motion control for vertical actuator and data acquisition

Hello

I am a researcher (a branch of civil engineering) geotechnical engineering and I have very little knowledge about the acquisition of control and data motion, so would need a lot of help from the experts OR. I have only knowledge base on these 2 aspects based on my reading of some materials on the Web site of NOR and youtube videos, so I hope that you bare with me

. Here are my questions:

. Here are my questions:I am trying to build an actuator which will be used to push a probe (a penetrometer with a load cell to measure the resistance of a soil sample), resembling the concept, photography in the attached file. I need to have these criteria for my system:

(1) actuator, which can push the probe at speeds between 0.01 mm/s - 300 mm/s with precision and move the probe cyclically (upwards and downwards) in the vertical direction

(2) load expected on the probe into the ground range: 0.02kN - 6 kN.

(3) necessary to get the load cell load data and the speed of the probe.4) able to control the actuator to a PC (speed and posotion) and monitor data from transducers and data log time even the transducers.

Guess my beginners is that I will need:

For orders:

(1) software - LabVIEW and NOR-motion assistant(2) controller - NI PCI-7342

(3) driver/amplifier - analogue servo AKD Drive

(4) motor - motor brushless servo AKM

For the acquisition:

(1) software - based LabVIEW development systems(2) amplifiers or other device - no idea what type on the conditioning of signals

(3) data acquisition device - no idea what type

Since I'm a beginner, is - that someone might recommend components (hardware and software) for the control and data acquisition. I'm on a tight budget, so I thankful if someone could help me to recommend components good enough to build my system.

Thanks for your help.

At these rates, you will need to run the sensor for the cDAQ. You can configure the analog output on the Tritex nationally on the position. There is an adjustable filter that you can set in order to get a clean enough to 300 Hz signal. When you learn about the Tritex, make sure that let you them know what comms and e/s that you want to use. If I remember, not all options have worked together. The analog output may need to be my, but you can put a resistance through the acquisition of input data to get the voltage instead. I don't remember all the details. You should really not too much on the Tritex/LabVIEW side. You will send your movement parameters (beginning of end of race, speed, position, accel, cut), and if you cycle (I believe you) or simply running in a loop. You could also just be able to use the functions of jog. When you get close to knowing exaclty what you need, PM me and I'm sure we can work something out with the drivers. You need only the basics. In fact, you could probably do this all your movements via digital and analog i/o.

-

data acquisition won't taste at the specified rate

Material: C - DAQ 9178, AI 9239, inside a servo and an encoder potentiometer module

Setup: I use the 9239 to measure the angular position of my servo and encoder of trees by streaming came pressure pot of the servo and my encoder. I put the sampling frequency on the DAQmx - Schedule VI to 100 Hz.

Problem: I don't think that my DAQ is sampling data at 100 Hz because my VI registers more than 10 000 data points for a 10 second test. In addition, every time I have save my data in a text file, the vector of time my test data resets after a number of iterations.

To debug, I tried the following configuration:

I've defined the sampling frequency of 100 Hz (or is that s/s?), the samples per channel (size of buffer for continuous mode) at 2000 samples, number of samples per channel up to 10 and loop milliseconds timer on my VI at 10 m accordingly, data acquisition would send 100 samples per second (or 1 sample every 10 ms) on my PC buffer (which could store 20 X that amount). Then LabVIEW would read up to 10 samples per loop iteration (which is itself ~ 100 Hz) and work with these 10 samples inside the loop. However, since the loop is operating close to the sampling frequency of data acquisition, then LV should only work with 1 sample each iteration of the loop (100 Hz / 100 Hz)-not the 10-sample-max that I specified.

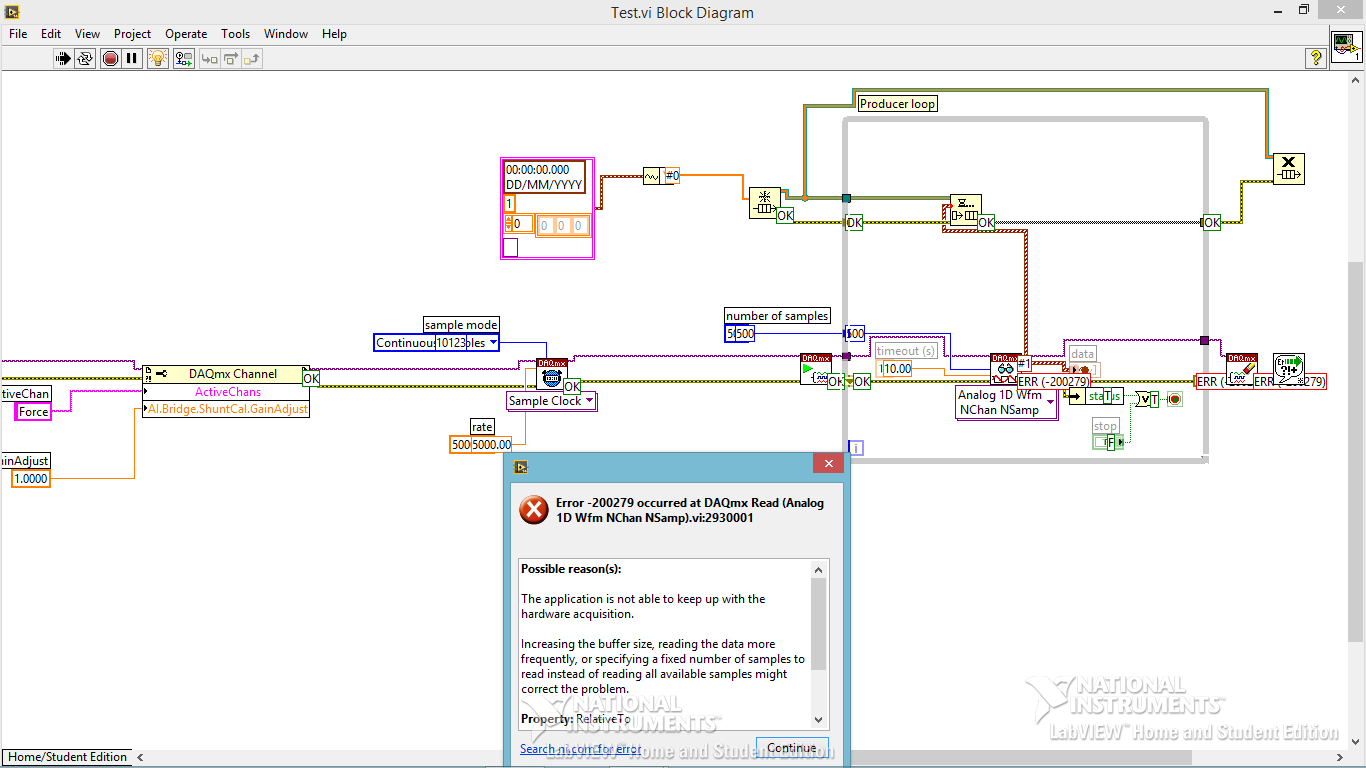

However, I stumbled on "error-200279: the application is not able to cope with the acquisition of material" when I ran the program. Why?

My code and materials should be easily able to cope with data acquisition - at least the way I put it in place

This whole situation wondered my fundamental understanding of data acquisition timing, so I would really appreciate an explanation of exactly how to deliver DAQmx uses data synchronization, why my DAQ sample at 100 Hz, and how can I fix the calendar specified by the user.

Thank you!

aeroAggie wrote:

The C - DAQ 9178 there some minimum sampling rate I will not meet?

It's actually the 9239 that limit your sampling rate. Read the data sheeton page 5 there's available data rates. In short, your data rate allowed is 50kS/s / n, where is goes from 1 to 31. 50 k/31 gives you 1.6kS / s. So, it's the minimum sampling frequency that can be used.

-

cDAQ for the continuous acquisition of data faster

Hello

I've only done very slow with LabVIEW data acquisition and I was wondering what the most fast (conservatively faster I'm not pushing the limits) data acquisition and recording of data possible on compact DAQ hardware? and the advantage of switching to a cRIO of a cDAQ really just for more reliable speed and data acquisition? I am interested on 30kS/s channels more analog input 5.

Thank you very much!

Rates are feasible, and you can stream to disk. It is only when you save in a text file that you need to start to worry about the use of a design of producer/consumer and a queue (in general).

I'd be too concerned about real-time unless you do some kind of control loop where the reactions must be precisely timed (once again, in general).

For very high acquisition rate (high MECH. / s), OR sell scanners that connect with USB in order to have some distance to go before you should start worrying.

-

Code error-200279 for data acquisition

Hi all

I am trying to build a small program of data acquisition, but I get a 200279 error telling me to increase the buffertime. What I am doing wrong?

Andersson wrote:

No, you're right. I don't get the error, I turn off highlight execution.

It seems so. I did not understand why he would come with an error during the audit of the code with the bulb. It seems like what I discovered on www.ni, one can avoid the error of initialization of certain data for the chart.

Not sure if I got it 100% correct however. Here is the link:

http://digital.NI.com/public.nsf/allkb/A647A1BE3DA8336786257AAA0066B45B

I don't have any other loop in the installer. I'm sorry for the confusion with the name 'producer loop. It's the only loop in the code, I deleted the rest to refine the error.

Is the conclusion that the program is good? Or do I have to do something to remove the error?

The table has nothing to do with your error. It's strictly highlight execution.

When you configure a continuous sampling, start the collection of data at a given flow rate. It is so big a configuration of the buffer. There is an article that tells how much room it is exactly, but for the sake of argument, let's say 10 seconds worth of data. In normal execution, your code runs pretty quickly that she is able to empty the buffer as soon as the data are acquired. But when you enable execution of climax, your VI slows down to a crawl so that he can show that you step by step what is happening on each wire. Your data acquisition always occurs in the background. Execution of idle is to take much longer that data are acquired. Within one or more loop iterations, you have filled the buffer and get the error message.

You cannot use point culminating performance when you use a device of data acquisition in this way (or VISA ports either) where data are sent continuously at a speed that is independent of speed, the code is executed.

-

I get upgraded my laptop (HP for laptop - 15-r224tx) for Windows 10 but I can't find the driver for the controller of PCI Data Acquisition and Signal Processing. Please help me find the right one.

Thank you!

You are the very welcome.

It is the latest version of the W10 driver for this card model... see if this solves the problem, if you have not already installed this driver.

This package contains the installation package driver for the controller wireless LAN Realtek RTL8723BE/RTL8188EE in the laptop models running a supported operating system.

File name: sp72517.exe

Maybe you are looking for

-

How can I change the order of photos in the shared album?

Hello I have pictures from multiple sources in a single shared album. Photos are not in order (each device had date and different time). I can change something order these photos? I even tried to delete the shared album, rearrange photos in my album,

-

I recently created my own website at Fat Cow to announce my ebooks. I build my web pages with Microsoft Word 2010 and saving regular htm/html files (unfiltered) and then their FTPing at Fat Cow. Web pages look good on IE, but the latest versions will

-

Hello I'll have a picture with me and I would like to save it to a path. I was able to get the flow of data in this way. QFile qFile("file://" + workingDir+ "/temp.jpg"); if (!qFile.open(QIODevice::WriteOnly)) return; QDataStream out(&qFile); Therefo

-

Hi, can someone help me with a really annoying (and I'm sure a simple to fix) problem? I don't know if it's related to Windows 7 or if it's just my laptop plays up. I recently upgraded to Windows 7 from Visa and whenever I have increase/decrease no

-

How to configure VPN remote access to use a specific Interface and the road

I add a second external connection to an existing system on a 5510 ASA ASA V8.2 with 6.4 AMPS I added the new WAN using another interface (newwan). The intention is to bring more internet traffic on the new road/interface (newwan), but keep our exist