Data acquisition tool NOR-DAQmx with Matlab R2012a

Hello

I'm trying to control NI USB-6211 of Matlab 2012 using NOR-DAQmx Data Acquisition tool:

http://zone.NI.com/DevZone/CDA/tut/p/ID/3005

I'm working on win7 64 bit. And I see the device AND Measurement & Automation Explorer.

The tool does not work: DAQ_Demo_Browser do nothing. And I got the error "unexpected or unbalanced parenthesis or support" of AcqNUpdates_nonUI.m

What is the problem?

Thank you and best regards,

Arthur Shulkin

Hi Arthur,.

Tools OR DAQmx for Acquisition of data with the Software Inc. MATLAB® from The Mathworks, supports up to the 2008 version of the MATLAB® software. In order to use our products DAQ Multifunction with MATLAB® software, you could get back to 2008 or earlier, or instead use the Data Acquisition Toolbox provided by The Mathworks, Inc.

Another option would be to import your ".m" files in a node MathScript in LabVIEW and use the functions of NOR-DAQmx everything in the LabVIEW development environment. For more information on the Module LabVIEW MathScript, you can consult the information available on this link:

Inside of the LabVIEW MathScript RT Module

MATLAB® is a registered trademark of The MathWorks, Inc.

Katie

Tags: NI Hardware

Similar Questions

-

Portable data acquisition support ICP (IEPE) with external excitation source

I work towards the acquisition of a force sensor data Peizoelectric (ICP) with 0 - 5v output and his own excitement of current constant.

Please suggest materials DAQ recommended for these sensors. (We usually use PCI (6229) or the DAQ hardware (9215) compact for static load cells.)

In addition, the LV point of view, is the process to acquire HAVE preamplificatrices such different force ICP sensor of the static load with 0 - 5v output cell?

your thoughts?

-

Hi all that I use NI DAQ 9188 and I have integrated the NI 9205 module to it.

In the NI 9205 data sheet, it is written that he has 250 k s/s ( http://www.ni.com/datasheet/pdf/en/ds-190 )

It is written in the data of NI 9188 sheet that it has 127 samples / slot ( http://www.ni.com/pdf/manuals/370086a.pdf )

(1) so, what is the difference between these two samples?

(2) where will be the memory of data. That is to say where the samples is recorded through which we read it by LabView software

Thank you

-Naga

A few details:

When acquiring, DAQmx will automatically transfer data from your device (in this case 9205/9188) in memory on your computer. As long as there is room in this buffer, daqmx will transfer data. When you call DAQmx Read, it will return that stamp on your computer data. The size of this buffer can be set or queried via the Buffer DAQmx-> Input.BufSize property property node. You must configure your LabVIEW application to read from this buffer before it fills up. I make this distinction because it means have you strictly need a loop that reads 127 samples each 0.0005 seconds. You can read a lot less often if you read larger blocks of data. Simply ensure that you are pulling the data from the buffer as fast hardware is producing data (for the 9205, it tops out at 250 ksps / s).

I hope this helps,

Dan

-

What is the oldest version of measurement and Automation Explorer that can be used with Windows7 32 bit? My USB-6009 is considered by the windows Device Manager, but it will not identify MAX 8.6. Do I need a later version?

In this post, Adnan (CLA) says you must use DAQmx 9.0.2. Have you tried this, or just the most recent version?

-

is possible to use either usb 6353 map with Matlab 2010A

Hello

On a bought a NIUSB 6353 map, but in my computer don't I i the 2010 version of Matlab. Is there a way to control this version of this map with MATLAB

Thanks in advance

Hello

And thanks for posting here.

Please write in English if you post here. Otherwise, post on the french forum.

NI USB-6353 using the DAQmx driver, it must be used with Matlab.

You will find several links from the NI USB-6353 by clicking here.

And presents an additional link showing you how to use your device with Matlab: Introduction to NOR-DAQmx with Matlab tools

Kind regards

-

Hi all

I installed the latest versions of NOR-DAQmx and NOR-DAQmx base software. I would use the tools NOR-DAQmx (like on the video tutorial: http://zone.ni.com/devzone/cda/tut/p/id/5370) but I can not find the software (screenshot attached) tools. Anyone know what's the problem?

Thank you!

Hello Joonasmikkola,

You should be able to have the DAQmx Base and DAQmx installed on the same PC (I have both in my other computer).

Could you open measurement and Automation Explorer, expand the software tab, check if you see list of NOR-DAQmx?

If it is not, I'll try to repair OR DAQmx of Windows Control Panel > add/remove program > National Instruments > NOR-DAQmx and do a repair on the pilot.

-

Data acquisition in LabView for other suppliers DAQ cards that NEITHER

Hello

I am a beginner in LabView programming. I have a 32 channels base PCI card DAQ (i.e. PCI-1602 of the manufacturer, ICPDAS) and I want it to interface with Labview 8.5.

So how cards DAQ in Labview 8.5, which are manufactured by other suppliers that NEITHER? Should I DAQmx (or some other driver) for that?

What are the other drivers/components required to access of data PCI-1602 (device) of LabView 8.5 acquisition card?

(1602-PCI card driver are installed in my win XP and dispalyed in Device Manager).

Please provide some tutorial above mentioned the problem to interface.

Please guide me in this regard. Thank you

Waqar123 wrote:

Hello

I am a beginner in LabView programming. I have a 32 channels base PCI card DAQ (i.e. PCI-1602 of the manufacturer, ICPDAS) and I want it to interface with Labview 8.5.

So how cards DAQ in Labview 8.5, which are manufactured by other suppliers that NEITHER? Should I DAQmx (or some other driver) for that? You will need the drivers from the manufacturer, of the Board of Directors. In your case, "ICPDAS.

What are the other drivers/components required to access of data PCI-1602 (device) of LabView 8.5 acquisition card? Same as above.

(1602-PCI card driver are installed in my win XP and dispalyed in Device Manager). Ok. Then take you care of my 2 answers above.

Please provide some tutorial above mentioned the problem to interface. To learn more about LabVIEW, I suggest that you try to watch some of these tutorials.

Please guide me in this regard. Thank you

According to what you do with the DAQ cards, they can do the job however, from experience, there are some functions that I could achieve with the cards NOR that I couldn't with 3rd-party maufacturers. This does not mean that this is your case. However, it is worth noting that it took me a while to understand why the code has worked with a single data acquisition card (NOR) but not another (Non-OR).

The drivers that you have installed may or may not include examples and code in VI. They may be DLL. If this is the case, you can write LabVIEW "Wrappers" around these functions, as it will simplify your life. If the drivers are in the form of DLLs, and there are no examples of LabvIEW or available VI, you must read on node library function call.

R

-

not able to write the data through data acquisition

Hello

In fact, I need to send a code word (text file) from the program matlab through my data acquisition (OR-USB-6215). my program (transmitter.vi [case structure: page2]) attached below has a problem to do the task. whenever I run the program it gives me an error like

Error-200479 occurred at DAQmx start Task.vi:2

Possible reasons:

Measurements: Specified Operation cannot be performed during execution of the task.

Task name: _unnamedTask<84>

At the moment I don't see output in my oscilloscope. But, if I highlight my performance I observe my samples on the oscilloscope with the following error message

200288 error has occurred in the DAQmx write (analog 1-d 1Chan NSamp DBL) .vi:3

Possible reasons:Measurements: Attempted to write a sample beyond the final sample generated. The build is stopped, so the sample specified by the combination of the position and the offset is never available.

Hi Raja,

What I did is I moved the 'write DAQmx' outside the while loop. That made the VI in this case is read the file and passing it to a table, and then this table is formatted a waveform to be written to the data acquisition device.

With respect to the way in which the data is read, I don't change anything, it was based on your original code. A good way to know if you write the correct data is to check the chart view in VI.

So the question is, is the graphic display showing the good waveform?

Best regards

Faris

-

Simultaneous to the AO and HAVE with the acquisition of data NOR USB 6001/MATLAB Toolbox

I am very new to data acquisition and bought a NI USB 6001 to start to learn. Because I can get free MATLAB through my University, I use Matlab data acquisition Toolkit as the data acquisition software.

My problem is that I get the following error message when I try to generate an AO (an LED voltage) signal and measure a signal I (voltage of a battery of 9V) simultaneously.

ATTENTION: This change is caused in the dump output data queue. Use queueOutputData for the queue data before the start of the object.

Hardware does not support the specified connection. Check the user manual of the device for the valid device routes and pinout.However to measure IA or by generating the AO each by themselves works perfectly well.

My Matlab script looks like this:

daq.getDevices;

s = DAQ.createSession ('or');

s.Rate = 1000;

s.DurationInSeconds = 10;

addAnalogInputChannel (s, 'Dev1', 'ai0', 'Voltage');

addAnalogOutputChannel (s, 'Dev1', 'ao0', 'Voltage');

aoVoltage = 1.8 + 0.1 * sin (linspace (0, 2 * pi, 10000))';

queueOutputData (s, aoVoltage);

s

startBackground (s);

Note that adding the channels HAVE and AO at the session also works, however I get the error mentioned at the start of the session. This is a limitation of my data acquisition hardware (I don't see something like that mentioned in the manual) or do I have to modify the script?

The pins connected for the LED are AO0 (+) and AO GND (-).

The pins connected to the battery are AI0 (+) and (-) AI4. (The problem is still there if I use the reference to the ground for AI)

6001 cannot make simultaneous tasks. Very standard limitation of the low-end hardware... just don't have on board computing resources to handle such things. Even the 621 x boards have only limited multitasking abilities.

Can intensify to a high range data acquisition ($$$) or buy a 2nd a low end and synchronize tasks in software (not as precise calendar). I've done two approaches, one is "best" really depends on demand... If low-cost or high-performance is a priority.

-

DAQmx data acquisition with persistent error of nyquist

Hi, I created a multi channel data acquisition vi (accelerometer 2 and 1 sound pressure) using models for producer. The vi is attached. Thanks to labview 2011. I get the error of nyquist (2 enclosed) when you make a bandpass filter between 50 to 5000Hz. This happens despite having put my sampling rate to 22050Hz. When I checked the output of wave I noticed that the signal has a dt 1 s. The text output to check the result. I could not understand how this is so since I had set the sample rate to 22 k Hz. Any help will be much appreciated. Thank you.

I would do something like that. You must calculate the dt of the set (with the recipricol) sampling frequency and use to initialize the shift registers. This way you only need to change 1 constant if you need to change your sample rate.

-

with Agilent 33522 A data acquisition

Hello everyone

When you use the driver NOR-daqmx (for the acquisition of data with agilent 33522A) what material should I use and configure please (map name)

anything that could help me please

Thank you

The cable surrounded in black looks like a USB-GPIB cable. You can use a NI PCI-GPIB and GPIB cable place for as long as you have a PC with an available PCI slot. If you connect via GPIB, you use DAQmx, as Intens said.

-

Question about the Acquisition continues through NOR-DAQmx

I'm a bit new to NIDAQmx methodology and I was wondering if someone could could give me some advice on accelerating certain measures of tension that I do with a case of DAQ NI USB-6363.

I have a python script that controls and takes measurements with a few pieces of equipment of laboratory by GPIB and also takes measurements in the area of DAQ OR DAQmx via (I use a library wrapper called pylibdaqmx that interfaces with the libraries C native). As I do with the data acquisition unit is 32 k samples at 2 MHz with a differential pair to AI0. An example of code that performs this operation is:

from nidaqmx import AnalogInputTask # set up task & input channeltask = AnalogInputTask() task.create_voltage_channel(phys_channel='Dev1/ai0', terminal='diff', min_val=0., max_val=5.) task.configure_timing_sample_clock(rate=2e6, sample_mode='finite', samples_per_channel=32000) for i in range(number_of_loops): < ... set up/adjust instruments ... > task.start() # returns an array of 32k float64 samples # (same as DAQmxReadAnalogF64 in the C API) data = task.read(32000) task.stop() < ... process data ... > # clear task, release resourcestask.clear()del task< ... etc ... >The code works fine and I can all the 32 k spot samples, but if I want to repeat this step several times in a loop, I start and stop the job every time, which takes some time and is really slow down my overall measure.

I thought that maybe there is a way to speed up by configuring the task for continuous sample mode and just read from the channel when I want the data, but when I configure the sample for the continuous mode clock and you issue the command of reading, NOR-DAQmx gives me an error saying that the samples are no longer available , and I need to slow the rate of acquisition or increase the size of the buffer. (I'm guessing the API wants to shoot the first 32 k samples in the buffer zone, but they have already been replaced at the time wherever I can playback control).

What I wonder is: How can I configure the task to make the box DAQ acquire samples continuously, but give me only the last 32 samples buffer on demand k? Looks like I'm missing something basic here, maybe some kind of trigger that I need to put in place before reading? It doesn't seem like it should be hard to do, but as I said, I'm kinda a newbie to this.

I understand the implementation of python that I use is not something that is supported by NEITHER, but if someone could give me some examples of how to perform a measure like this in LabView or C (or any other ideas you have to accelerate such action), I can test in these environments and to implement on my own with python.

Thanks in advance!

Toki

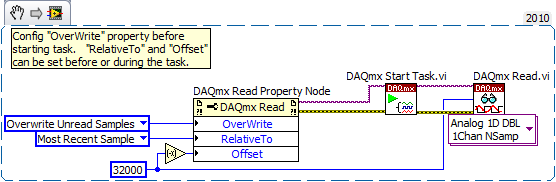

This is something I do a bit, but I can only describe how I would do it in LabVIEW - I'm no help on the details of the C function prototypes or the python wrapper.

In LabVIEW, there are accessed via the 'DAQmx Read property node' properties that help to implement. One is the Mode "crush" which I'm sure must be set before performing the operation. The other pair is known as "RelativeTo" and "Offset" and they allow you to specify what part of the CQI data buffer to read data from. If you the config to "RelativeTo" = 'most recent sample' and 'Offset' =-32000, then whenever you read 32000 samples, they are the very latest 32000 which are already available in the buffer of data acq. Between the readings, the task is free to overwrite the old data indefinitely.

Note that you will need to do this continuous sampling mode and that you can explicitly set a buffer size smaller than the default which will choose DAQmx based on your fast sampling rate.

An excerpt from LV 2010:

-Kevin P

-

Clock and hw external trigger with USB-6210 on Linux with NOR-DAQmx Base?

I have two devices USB-6210 I need to synchronize so that they both collect data exactly at the same time. I was told by support OR I can send the clock off Dev1/PFI4 and have the two USB-6210 s read the clock in through their own PFI0. I also want to trigger data collected for each device by sending a trigger off Dev1/PFI6 and have two devices to receive the signal on PFI2.

All my attempts to try this are filled with error messages and my research online seem to say that's not possible with USB devices on NOR-DAQmx Base 3.4.0f2 on Linux.

I "ve tried using example AI programs and those who do not seem to work either for external clocks. Here is the code I tried:

#include "NIDAQmxBase.h"#include

#define DAQmxErrChk(functionCall) { if( DAQmxFailed(error=(functionCall)) ) { goto Error; } } int main(void){ // Task parameters int32 error = 0; TaskHandle taskHandle = 0; char errBuff[2048]={'\0'}; int32 i; // Channel parameters char chan[] = "Dev1/ai0"; float64 min = -10.0; float64 max = 10.0; // Timing parameters char clockSource[] = "/Dev1/PFI7"; uInt64 samplesPerChan = 1000; float64 sampleRate = 10000.0; // Data read parameters #define bufferSize (uInt32)1000 float64 data[bufferSize]; int32 pointsToRead = bufferSize; int32 pointsRead; float64 timeout = 10.0; printf("Calling CreateTask...\n"); DAQmxErrChk (DAQmxBaseCreateTask("",&taskHandle));printf("Calling CreateAIVoltageChan...\n"); DAQmxErrChk (DAQmxBaseCreateAIVoltageChan(taskHandle,chan,"",DAQmx_Val_Cfg_Default,min,max,DAQmx_Val_Volts,NULL));printf("Calling CfgSampleClkTiming...\n"); DAQmxErrChk (DAQmxBaseCfgSampClkTiming(taskHandle,clockSource,sampleRate,DAQmx_Val_Rising,DAQmx_Val_FiniteSamps,samplesPerChan));printf("Calling StartTask...\n"); DAQmxErrChk (DAQmxBaseStartTask(taskHandle));printf("Calling ReadAnalogF64\n"); DAQmxErrChk (DAQmxBaseReadAnalogF64(taskHandle,pointsToRead,timeout,DAQmx_Val_GroupByChannel,data,bufferSize,&pointsRead,NULL)); printf ("Acquired %d samples\n", pointsRead); // Just print out the first 10 points for (i = 0; i < 10; ++i) printf ("data[%d] = %f\n", i, data[i]); Error: if( DAQmxFailed(error) ) DAQmxBaseGetExtendedErrorInfo(errBuff,2048); if(taskHandle != 0) { DAQmxBaseStopTask (taskHandle); DAQmxBaseClearTask (taskHandle); } if( DAQmxFailed(error) ) printf ("DAQmxBase Error %d: %s\n", error, errBuff); return 0;} When I run the resulting program, I see this:

$. / acquireNScans-ExtClk

The CreateTask call...

Call for CreateAIVoltageChan...

Call for CfgSampleClkTiming...

Error-89136 DAQmxBase:route specified cannot be satisfied, because the hardware does not support it. For example, a clock and a trigger can be imported via one of the PFI lines by using a USB-6210 on Linux with NOR-DAQmx Base? A clock and a trigger exportable via one of the PFI lines?

If so, does anyone have the code example illustrating how to do this, or can you at least tell me the names of the lines ("PFI0/Dev1" or other) so I can try again?

Clues or suggestions would be helpful.

Thank you

-Tom

The clockSource in the example specifies an output rather than an input channel channel. Change source "/ Dev1 / PFI0" solved the problem.

Please close this post.

-

Sample clock dependence with small signals data acquisition

Hi all

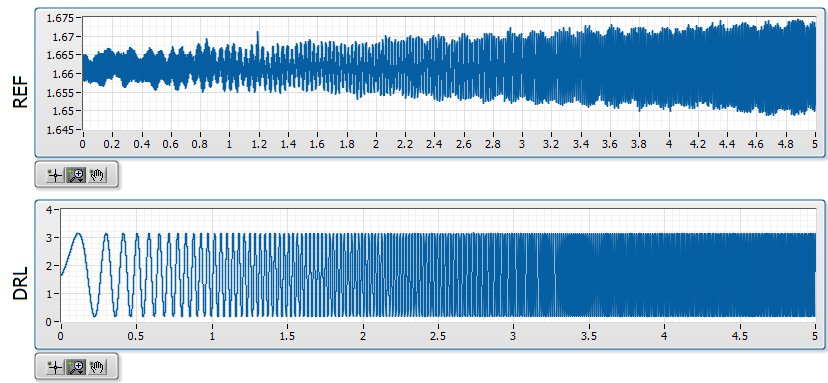

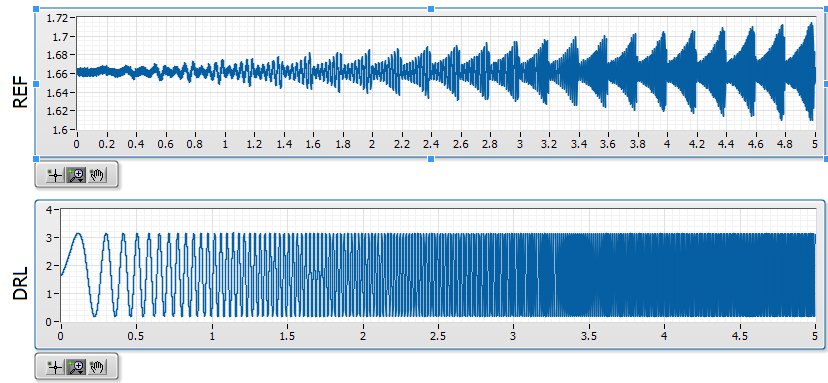

I use a NOR-9205 on a NOR-cDAQ-9184 and noticing some interesting dependencies of waveform on my sampling rate selected. It seems that small changes in the sample clock frequency have a significant impact on the measured waveform.

Quick background, I am in a position a signal with a ripple of mV ~ 10 with V 1.6 bias. I'm not interested in DC, only the AC signal but the NOR-9205 has only DC coupling. The application is a circuit where I expect simulations noise past the circuit must be greater than the higher noise frequencies. In the waveforms attached the background plot is the applied signal, and the top graph is the signal arising after that the signal was mostly annihilated. The two waveforms are measured with the NOR-9205.

I am aware that this measure is less than the precision of the NOR-9205, which has a maximum precision of ~ 3 mV in his +/-5V range. However, if I can't at least on the basis of shape which is good enough for me. I'm also now pretty curious that data acquisition is actually to create this

My best idea, is that it is a product of internal multiplexing of the 9205 with the DAC.

The first plot shows the waveform at 20 000 Hz, which is what I expected:

The second shows the waveform at 20 001 Hz, which seems to be modulated with a backup sawtooth:

The waveform looks as expected for 20 000, 20003, 20004, 20005, 20008, 20009, 20010 and Hz 20011. The waveform looks like modulated to 20001, 20002, 20006 and Hz 20007.

Ideally, I would like to understand this problem so that I can configure the measure in a stable way that I can count on the basic shape of the wave. Has anyone seen something similar?

-

Measurement of low-cost input analog (4-20mA) with data acquisition

Hello

I would like to have a very low cost measurement system loop which I can plug in my laptop current:

I have a load, which is connected to a circuit of air conditioning/signal booster, which output a 4-20mA. I want to measure this current loop signal.

An idea for the lowest cost system? I think that the most NOR DAQ are too expensive and too exaggerated.

I have LabVIEW.

Use of remote sensing current low-value resistance, then measure the fall of voltage through it with the help of an acquisition of data 6008/6009? They have about $150.

You will probably need to amplify current-sense with a MAX4372 or similar resistance to achieve a result that allows you to use a reasonable scale on data acquisition. I measure the current through our products in almost all of our equipment to test in this way. The size of the resistance of meaning as a result. The 6008 is accurate enough, but it is not the fastest nor well presented. But starting at $ 150, they are hard to beat.

Maybe you are looking for

-

I have a group called Group1 in my address book with 30 names. I want to create another group of Group 2, which is exactly the same as group1, but with 1 missing name. Is there an easy way to do it?

-

Port program COM in Visual C++ on Windows XP

I have a Dell optiplex 745 running Windows XP and I'm trying to communicate with a device connected via RS232 on a DB9. I have Visual C++ 6.0, and I want to write and set baud rate. Can what functions I use?

-

Request album not showing my pictures

I recently changed phones and moved my 32 GB of my Xperia old card to my new. I use ES File Explorer to manage the files that I know the ' s and off "locations of files, etc." My album application installed on my new phone (I had galleries and Xperia

-

Removal of metallic ink on photo

I am currently editing an image of art I scanned and loaded into Photoshop.So the problem is that the image was made using a metallic ink of a gel like grey marker to a copic marker pen and the program is unable to distinguish between the two colors.

-

How to change the headphone port #?

ENV: Oracle 10 g 2, RHEL 64 bit on ASM (10gr 2):Current listening port is 1521. I was asked to change it to 10526 (please don't ask why :-)).)I tried to change the port number in the listener.ora file, then restarting the listener, but the I start ge