Digitizer PXI-5105

Hello

I send the same question last Friday.

The scanner we use is an error occurred.

We use the wondows computer 8, running the program Max.

The error code is 200313 self-test occurred.

Hi derives1,

Here are some steps you can take for troubleshooting:

-Try the card 5105 in another location in your chassis or even in a different chassis, to ensure that it is not a problem of chassis.

-Make sure the version of NI SCOPE you are using is compatible. You can update to the latest version, make sure just that you check the compatibility. http://search.NI.com/nisearch/app/main/p/bot/no/AP/tech/lang/en/PG/1/SN/ssnav:NDR/q/NI%20scope/

-Force Windows to re - detect the device and driver. To do this in the Windows Device Manager to remove the device, and then click Action > search for new devices re - detect the hardware.

Error-200313 from the PXI-5105 often results in an RMA number (Return Merchandise Authorization) to repair the unit. Try the above steps, and if the card still gives you the same error then create a service request, then you can work more closely with an Applications Engineer to start the RMA process.

In addition, I can't find the post you mentioned last Friday, but we ask as a policy forums OR you post once on a problem. This will keep things like organizaed as possible!

Tags: NI Hardware

Similar Questions

-

error "device could not be calibrated" to PXI-5105

Hello

I want to calibrate my PXI-5105. But I get an error in MAX and a calibration vi. I tried to install NO-SCOPE 4.1.3 on PXI, but that does not solve the problem. I have labview time real 13.0.1 installed. I enclose the error messages.

See you soon,.

Syed

Syed,

So there is not a lot of good information on this error. Automatic calibration works by connecting a known signal that is embedded in the digitizer at the ADC and to adapt the constants and phase shift. The 234107 error means that there is a problem with this calibration signal or the signal to the ADC path, etc. This known signal is calibrated during the external calibration and since your device is off external calibration (calibration necessary since February 2011), the problem is probably the calibration signal drifted too far from its known value.

To resolve this problem, you will need to send the jury in external calibration, and I would recommend National instruments, send it because if there is a problem with the hardware with the Commission, we might be able to solve this problem, as well as of him have calibrated.

I hope this helps.

-Nathan

-

I am setting up test bench and just add a PXI-5105 card to my chassis SMU-1078.

I currently have NO-SCOPE 14.1 installed on my PC host and target RT.

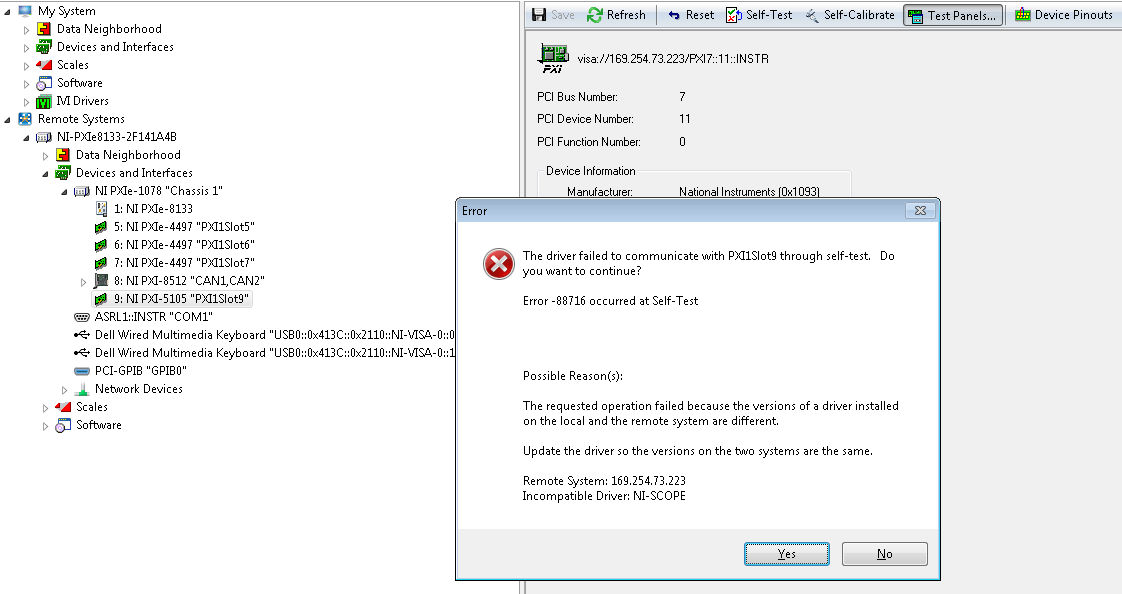

When I try to run the Test panels in MAX, I get the following error:

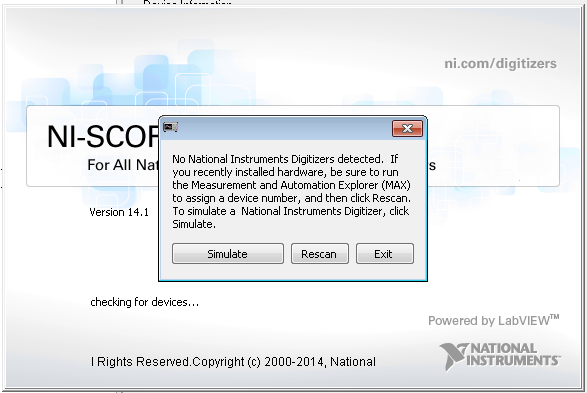

If I try to launch SFP-OR-Scope, it does not detect the card of the scope:

The map seems to indicate as normal in my remote systems in MAX.

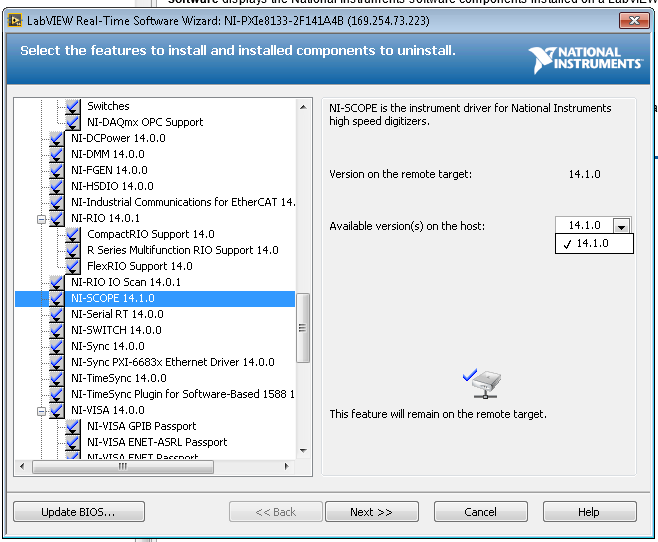

For the host, the Installation of NOR-SCOPE includes:

- Configuration support 14.1

- 14.1 development support

- 14.1.1 duration

For the target RT, Installation of range OR watch as 14.1.0.

I even checked in the feature add/software for the remote system see if a driver incompatibility was actually present:

I have also confirmed in the Readme that PXI-5105 is supported OR-SCOPE 14.1.

I'm kind of dead in the water on other ideas to investigate on concerning the system is behaving properly with the new card. Other ways suggested for study?

I continued to play with setting up more and find my VI has been targeted my Windows host instead of the goal of the RT. I'm nowable to see my map of scope 5105 now through Labview + RTM. Thank you for tolerating a newbie.

-

Extract and save all the channels of the PXI-5105 with 4 M of edge detection... Help!

Dear collegaues!

Please help me to improve my request, exhibit attached and sorry for my English.

So my task is to extract and save all the channels (eight) of the PXI-5105 with 4 M of detection of peaks and sample rate 4 M with loop 1 sec...

Entered all my channels are wiring detectors NaI with 0, 5... 1 microsec pulse (really) width and 0 kHz at not more than 40 kHz freq.

Why I chose the registration of 4 M and the sampling frequency of 4 M namely? Answer is that I tested previously PXI-5105 40 kHz generator and pulse width 0.5 microsec. It works great and detection of peaks indicate 40000 pulses/s for me. If I set lower than 4M record and sample rate of 4 M, it is without work. In my honest opinion record 4 M and the frequency of sampling of 4 M are parameters very min.

In the detection of peaks time present only 6 working channels... When I connected to diagram more 6 "detector.vi peak" - I see the error "...". out of memory... ».

Advise me please, what needs to be done to it, it's all working well.

-

Unable to trigger pxi-5105 exported signal pxi-4461

Hello

I use a chassis PXI-1033 with a PXI-4461 (daq) in slot 2 and 4-PXI-5105 in slots 3-6. I want to use the 4461 to export a reference trigger signal to of the 5105, but when I try to run my program I get the following error:

Error-89126 occurred at DAQmx Read (Analog DBL 1Chan 1Samp) .vi:1

Possible reasons:

Trigger line asked could not be booked because it is already in use.

Property: RefTrig.OutputTerm

Property: RefTrig.Pulse.Polarity

Target unit: PXI1Slot2Task name: _unnamedTask<89>

The Subvi I use to export the signal is built off an example I found. At the moment it is only under the scope of my code mode (I'll take care of the datalog part later). I'm not sure what I'm doing wrong, any help is greatly appreciated.

Thank you

John

Hi John,.

T Clk select a PXI_Trig lines used to deliver pulses of synchronization between devices. Since that you configure T - Clk before configuring the signal to destination, the driver doesn't know that you plan to use PXI_Trig0 to export the reference trigger. I guess that's to select PXI_Trig0 as the line to book the pulse of synchronization.

I recommend that you try to export the signal to one of the other lines PXI_Trig - this should I hope to correct the problem but keep inform us if it is not. Thanks for posting and have a great weekend!

-John

-

PXI-5105 clipping voltage to ~ 19V

The PXI-5105 should be able to measure voltages of Ridge Crest of 30 V. I have a set of 3, 9V batteries to give me a total of 27 volts through a resistance. PXI clips this tension about 19V however. I confirmed with a multimeter I have 27 volts. I have a value of 1 Mohm input impedance.

Thanks for any help.

Hi cuxcrider,

The maximum range of 30 V on the 5105 is a peak to peak voltage, which means that the higher voltage, it can measure compared to ground (0 V) is + 15 V, except if you apply a DC offset, which unfortunately cannot be done on the 5105 OR. Generally, you will see a little higher than the specified value rail voltage, but generally you shouldn't play in this region because you may cause damage to the Board of Directors and measures out of spec. hope this helps,

-

Problem of delay time PXI-5105

Hello

I'm running the PXI-5105 (@ 60Msa/s/ch 12 bit 8Ch) using the attached VI. I put it to trigger off channel 0 to 1V. When I put in a sinusoidal waveform of cycle 5, it seems that the scope triggers too late and I only see 4 of 5 cycles. I confirmed this by generating a sinisoid of increasing amplitude across a PXI-5412 and again once the waveform has been truncated, as if there is a delay after that relaxation hit. (btw, I have an oscilloscope running in parallel and the waveforms appear perfectly here)

Why this is happening any help would be really appreciated.

Thank you!

Actually - problem solved.

When I played with him I had inadvertently set it to DC coupling. Coupling AC fixed.

-

How can I display an analog input for the PXI-5105 on LabVIEW?

Hi all

I am very very new to LabVIEW and I started to tinker with it. I use the version of LabVIEW 2010 SP1 on Windows 7 OS. I also have the chassis NI SMU-1073 with SMU-6361 and PXI-5105 modules and the chassis is connected to my PC via PCI. I became familiar with the devices and trying to see some analog signals to one of the channels on the PXI-5105 module in a graph in LabVIEW.

I would appreciate your help.

Hello Henokview!

I would like to read through these tutorials to understand the steps of programming of the NOR-SCOPE, NOR-DAQmx. After reading these links below, you will be able to understand how to connect the output of a readfunction to a chart or table.

DAQmx

http://www.NI.com/white-paper/5434/en

OR-SCOPE

http://www.NI.com/white-paper/3382/en

Best regards

Jonas

-

How we control the gain of the digitizer PXI-5102 factor?

Dear Sir, I have a question on the gain settings in the wfmInfo structure that is returned when you use fetch or read functions. Dose it be determined by the digitizer (internal) automatically when you set the attenuation range and vertical probe? How he determined? Thank you very much for your help.

Double post. See the answer here.

-

PXI-5105 resolution not quite as expected.

I have a system with the guidance of PXI5105, and I use it to sample a signal on beach of 30V (+/-15V), 1megaohm input impedance, 1megasamples by the second sampling rate.

The PXI5105 has a resolution of 12 bits, so I expect to see the steps in the quantification of 30V / (2 ^ 12) = 7.32mV

Acquisition of a stationary signal, the noise extends over 7 discrete levels, so spans 6 quantization steps (see file attached .jpg)

Ranges of noise on 52mV (it goes from-16 to + 36mV), so measured quantification step is 52 / 6 = 8.66mV

I'm missing something obvious here. Why the difference between calculated and measured resolution?

My only thought is that resolution is not linear in voltage range. I expect there are a few non-linearity, but didn't expect so much.

Fill the void in my knowledge!

Hi Bandit,

The gap you see is due to the fact that the input range effective from Ridge to ridge of the Board of Directors is not exactly 30V. The overall increase in analog front end that lies between your input signal and the ADC has initial inaccuracies and can also drift over time and temperature. These effects can be minimized but never completely eliminated. As a result, we design boards to have a peak-to-peak input nominal range is slightly larger than the ideal ranges specified in the data sheet. This ensures that the jury will never less that ideal beach, even though the gain of slightly derivatives (this way you can always be assured that if you use the 30Vpp range and put you in a 30Vpp signal you will never saturate CDA which results in a loss of the signal information). The 5105 has an internal calibration of precision voltage generator which is then used to calibrate data at the scale that you are returned. This results in a slight reduction in resolution (increase of the voltage/ADC code) as you have seen, but the tension you be returned is always exact specification of precision AC / DC published in the data sheet. If you know that the resolution calibrated, it is possible to get this information from the output of cluster "wfm info" from the "Fetch (poly) .vi niScope" when you use the vi in a mode of extraction of binary data. Sorry for the confusion and hope this helps.

Kind regards

-Matt

-

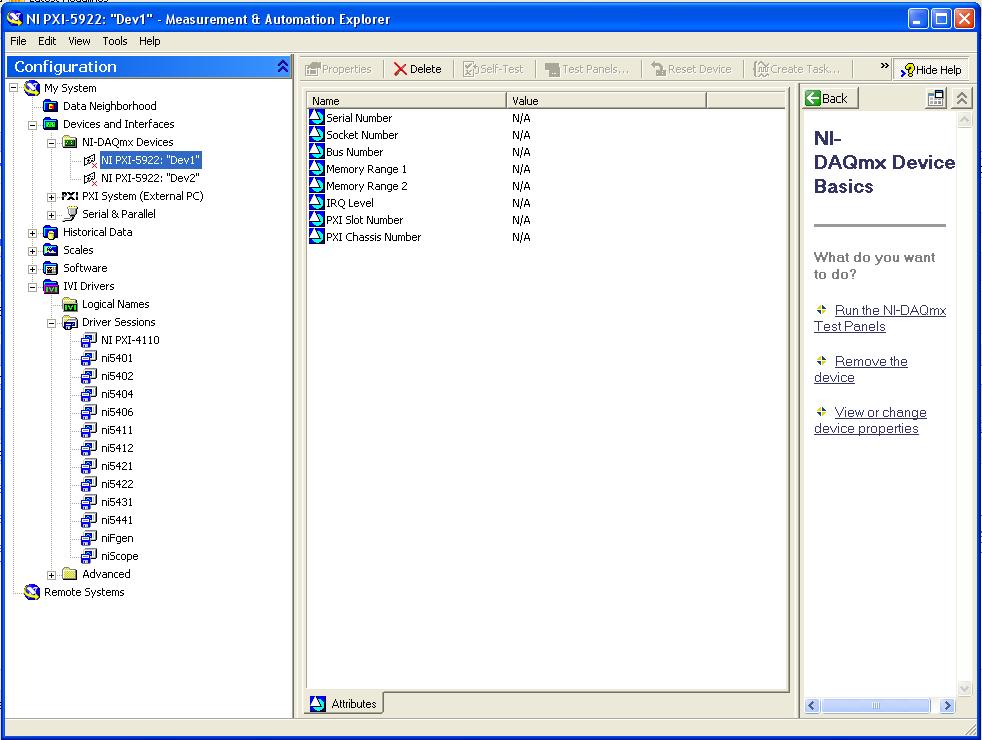

Try to recognize the digitizer PXI-5922

I've only been using LabVIEW for about a day now, so everything is more or less still new for me. I worked for most of the startup guide to become familiar with the program. Right now I am so he can recognize a NOR-DAQmx device. This device has been used before (but not by me), so I'm sure that everything must be properly installed. One thing I noticed, is that when I turn on the chassis, the LEDs on the digitizer do not turn with it. I came across this while trying to find possible solutions, http://www.ni.com/pdf/manuals/371133m.pdf in the troubleshooting guide, there is a section for this problem. It points me to the measurement and Automation Explorer to try to reset and self-test of the device. The problem is, once I get to it I'm greeted by this

Maybe I'm just on a step since I've only used this program and material for the day, but could someone put it in an entry. Thank you.

I got actually work on my dissertation for my last answer. Thanks if.

-

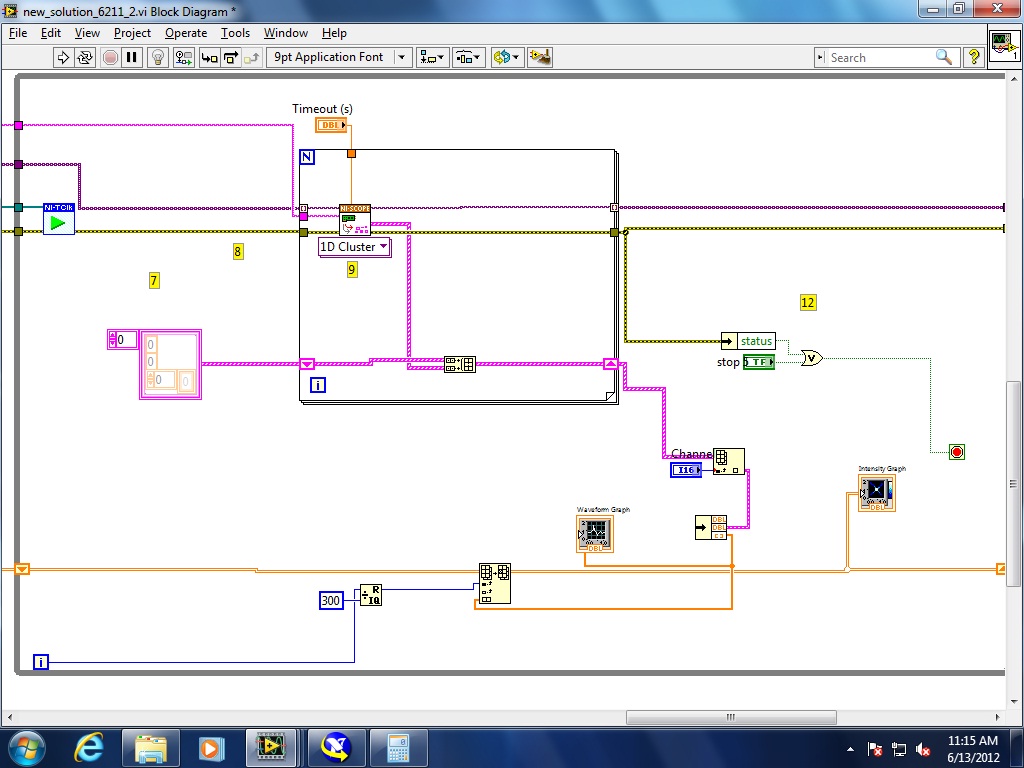

Theoretically, we want the PXI-5105 (digitizer) have 302 record with each record has a 1260 sample (the save operation is inside a while loop) in approximately 30ms, however we have found that for each period (30ms), the PXI5105 only perform about 10 records. It is so wired. I wonder if the operations inside the while loop consume more time (for example 3MS), so that he cannot have 302 records even the PXI-5105 have 60 M/s speed of sampling. Is it true, you can find my labview code and if possible can you give me some suggestion in the most short time of operation of the loop.

Please find attached labview code.

Hi g_l_g_s,

The digitizer PXI-5105 acquires data at the speed that you specify and stores the data in its memory embedded (up to 512 MB). The data is then sent to your computer when the Multi Fetch Cluster.vi is called. In VI that you posted, you are only fetch record during each while the loop iteration. If you want to retrieve 302 records you will need to specify 302 files in the horizontal Timing.vi to configure. For more information about scanners, you might find the DevZone, hereuseful.

To determine the amount of time it takes for each while the loop iteration, you can consider using the structure of code in the example comparison community calendar, which is located here.

-

8.6 of LabView and NOR-Scope 4.0 will not work

I have LabView 8.6 running on a PXI system and am trying to acquire data from a digitizer PXI-5105. I was already running LabView 8.2 and an older version of NOR-Scope. I opted for LV 8.6 and also NO-Scope 4.0 and now I cannot use OR-Scope in my VI. He said search for the file type for each component of NOR-scope that I use in my VI and seeks the .clt files. I can still use soft Panel OR-Scope, but it will not be displayed on the tab like before measure.

OR-SCOPE compatibility with LabVIEW

You need an older version of NOR-Scope or a more recent version of LabVIEW.

-

Hello

I want to use PXI-5105 on SMU 1071 chassis for strain measurment by conneting the strain gauge by the to 5105 wheatstone bridge circuit using BNC cables. I'm using Labview for the same thing.

(i) I get the variable noise (0,008 to 0.010 V) with no connection to the input channel.

(ii) I'm unable to balance / minimise the noise to zero by subtracting signal from one channel to another (differential input).

Data acquisition parameters:

Input voltage: 5V by DC power supply

All cables used are sheathed in copper cables

Sampling rate: 5ms / s

Number of samples to read: 2000

We worked on the reduction of noise for a long time. Any help will be much appreciated.

Thank you

Vinod

Hi Vinod,

Keep in mind the accuracy of the unit 5105 is specified to +/-2mV.

Also, you can check that your device has been calibrated on the outside and in his external calibration cycle.

When I watched a 5105 digital signal in a similar setup to yours, I saw the same kind of (about) + / 2mV noise. I don't think this is unexpected. Especially if you let the front end of your digitizer not completed, it could recover the additional ambient noise.

Why you choose to use this scanner for a measurement of the strain gauge? There are several other products OR Lane County and specifically designed for measures of constraint. Here are a few resources:

Strain with gauges

http://zone.NI.com/DevZone/CDA/tut/p/ID/3642

SMU-43xx Bridge Module Product Pages

http://sine.NI.com/NIPs/CDs/view/p/lang/en/NID/208288

Dynamic signal acquisition board

http://forums.NI.com/T5/dynamic-signal-acquisition/BD-p/100

-Andrew

-

PXI SFP 5105 configured Vs Acquisition VI

Hello

I recently started to use the NI PXI-5105 cards, I need to capture (noise level<20KHz) on="" top="" of="" my="" dc="" signal,="" i="" used="" software="" front="" panel="" to="" capture rising="" edge="" of="" an="" analog="" signal i="" was="" able="" to="" capture="" signal="" when="" it="" meets="" my="" trigger="" requirements="" same="" as="" configured="" acguisition="" example="" vi="" also="" vi="" recommended="" input="" signal freq="" ="" is="" 100khz,="" what="" changes="" i="" need="" to="" do="" in="" order="" to="" make="" this="" vi="" to="" trigger="" when="" the="" noise="" level="" on="" my="" dc="" signal="" exceeds="" certain="" point="" can="" anyone="" please="" help="" me="" with="" this="">

Thanks in advance!

Hey djo.

If I understand your description, the best sounds of relaxation as it can be a trigger of hysteresis with coupling AC trigger in order to eliminate the effects of your DC signal. You will then be able to adjust the amplitude of the noise that you are looking for as the level to which you want to trigger off. You can find information about the options available with the help of scanners trigger high speed OR under Fundamentals > trigger.

Maybe you are looking for

-

Reset my MacBook Pro to factory

I have a MacBook Pro in early 2011. OS X El Capitan10.11.3. How can I re - set it to factory settings? Or some Tips for helping him run a little faster. Thanks in advance.

-

A2DP quality is not high quality

I have a newer Toshiba Bluetooth Stack and a capable v2.0 Bluetooth dongle. I use a headset Nokia BH-604. Low quality, bitrate settings is correct, 201 Kbps. But the standard and high quality (also the auto settings) parameters use the same flow rate

-

Office Pro L7680 about 4 years old - suddenly blue is not printing at all. Equip the new Blue cartridge, did not help. Diagnostic shows no no blue print.

-

Having problems installing of software and drivers for HP Deskjet 9800

I uninstalled my HP Deskjet 9800 because I have too many problems with it. I use Windows XP. I went to hp.com and download the software and drivers for this printer. The software and drivers simply go to my folder of the downloaded files. How can I

-

blue screen error and the memory of dumping

Dear all, Beyond 20 days before my knees worked well, with any problem. OS: win 7 home. recently I updated all the patches update.that time Windows first problem started in the MSE. Error: Session "Microsoft Security customer OOBE" stopped because of