e/s digital simultaneous read/write channel

Hello

In the VI attached labview 8.5, I try to write data to a digital i/o port and at the same time monitoring the status of this port. I think that this should be possible, but I don't know how to code. If it possible, I would like to know what I'm doing wrong to my VI.

I thank in advance all those who watch my code.

Azim

Azim,

Thanks for posting your question on the Forums of NOR. It sounds like what you are wanting to do is the comparison of hardware. This is only possible with our boards PXI-6551 and PXI-6552. An option for you is for wire you to the digital output to another digital line and then measure your signal on the other digital line. I have attached three files, two examples of the expedition, we do a digital writing and the other a numeric reading. The third file (Digital Input Output) is a combination of writing a digital port and then followed another port. All you have to do is wire ports to one another.

Tags: NI Hardware

Similar Questions

-

Hello

I need to order a relay so I have to use labwindows to create a project CVI and Test Stand.I call tried to use the Write.Dig.Chan to find examples in CVI, but it doesn't work!

Could you help me please modify this code to call from test and generate the 5V.

I'm using Labwindows CVI 2010, 2010 testbed and NI PCI-6220.

Kind regards

Hello

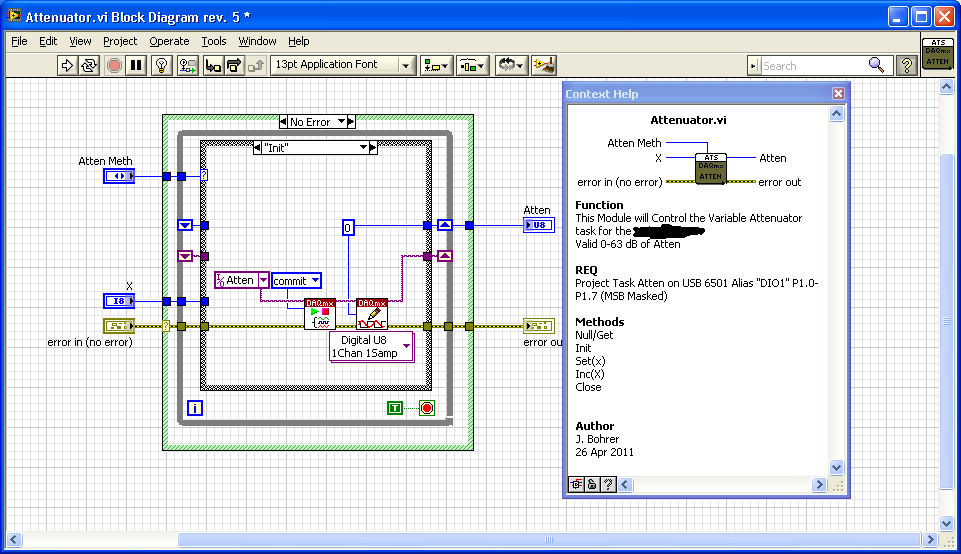

Thank you for answering me. I solved my problem. I did it with the functional and the adapter for Labview it seems to be easier. The picture shows the the VI that works effectively

Kind regards

-

PXI-5122 and PXI-6259 read 2 channels simultaneously

There is a single PXI-5122 digitizer card and a PXI-6259 DAQ card in our PXI system, we use Labview and TestStand (model Batch) to test the multiplication Board simultaneously, sometimes up to 8 boards are tested. We have some problems, such as the results of the tests is not reliable and sometimes blocking of Labview. Everything works fine when test single board. Thus, we feel that multiply causing this problem of acquisition of string data. It's great, if someone has the same problem and we can share the knowledge. My question is as follows:

1. If two channels have been configured, read the two channel simultaneous cause blocking of the system or data damaged?

"lu niScope WDT.vi" is reentrant, we can use two Subvi to call the "niScope Read WDT.vi' access the two channels simultaneously.

2. If we set up a channel in another channel is reading the data, this situation will cause the search system or corrupt data.

Concerning

Samuel

Hi Samuel,.

You shouldn't have any difficulty to read several channels on your 5122 or between your 5122 and your 6259. You receive an error message when your test is blocked? What happens when your test is not reliable? Are you incorrect data and if so what is the data vs expected data acquired? You should be able to set both your channels in a single task, which would be using a read niScope WDT.vi to be used by the device. You are working from example or have you developed your own code? What version of the driver NOR Scope and NI-DAQmx driver do you use? You can find the driver version number in the measurement and Automation Explorer under the software section.

What kind of test are you running? Your PXI chassis is controlled by a computer or by an on-board controller? Evolution of the rate of acquisition has an effect on your program?

-

How to read / write several channels at a time target real PXI with a Board of 6259

On a PXI real-time target, I was able to access more of a channel at a time. The attached example illustrates the problem, when the second analog read occurs, I get a 'resource is reserved error '. It is my first challenge in real time and do not know how to proceed. In the end, I need to read three channels of analog input and analog output channel in the loop in real time. Thanks for any help.

Yes. You need to put the two analog inputs in a single task. There is only a single clock for reading of the analog inputs. If you use it for a task, this clock is reserved and the other task cannot use it.

That means connecting it to an analog output channel must do with it? If the ai0 is not connected to anything, why you try to read it?

The reason why you see something on this channel, it is that you see the residual value in reading the other analog input channel. When you have an open circuit, the amplifier may not load or unload by another value, if you see a ghost of the other channel. The entry for the land of analog unused thread and you'll see that the reading is zero or very close.

-

A better way to make a continuous read/write on a NOR-6008

Hello

I use a USB of NOR-6008 module and have a loop of the software configuration where I acquire analog signals, digital signals, then, then put a digital high or low and repeat. I use digital multiplex outside the material so that I can use 6 of the analog inputs to read 12 signals. The digital inputs that I have are connected to the buttons on a panel that are used for the entry instead of the screen of the computer of the user. My loop is also to build a buffer zone of all the signals on the analog and digital lines that I read in so I can on average and this process elsewhere in the program.

The question that I am running is because this loop is very slow and on the final product is performed on a touch screen, XP Embedded PC and just this acquisition loop begins again as much CPU as the rest of my program. I would say that drops of loops on 4 or 5 cycles per second, which means that my update of 2 multiplex signals or longer than a second time. I would really like to better performance and does not use as much of my CPU resources.

I use a way simple enough to make the loop of the acquisition, by setting the parameters I, reading, deleting the task, defining the parameters DI, read, erase the task and then by setting the parameters, write about it and delete the task, which gives a slight delay and repeat.

Any thoughts on a better way to start the read/write that what I'm doing?

I have attached the code examples in the loop of the acquisition that I use.

Thank you!

First of all, the best plan is to move the chain DAQmx before the loop to create and use a start DAQmx, then write in the loop, then clear once the loop ends. This configuration must be done once, not every time you write the channel. This should speed things up considerably.

-

has triggered the numerical sequence of read/write

Hello

I'm pretty sure it's impossible to do in Labview, but thought I would ask the question just in case:

On a digital falling edge I need to define a digital line on a highest PCI-6224 and a low, then read sixteen lines as a port. Output high and low lines should change status then and sixteen lines should be read again.

The process is repeated on the edges of successive falls. The time between edges may be as short as 11 microseconds (90kHz).

We have currently a program written in C++ to do this job, but I want to create something a little more friendly and have virtually no C++ experience myself.

Thank you.

Hi Simon,.

I have an idea how to do that using the DAQmx card. This has not been tested, but I think it should work with just a few tricks with DAQmx. There are three tasks that will be required:

Meter output

==============This should be a task redeclenchables meter. Take a look at the example in the example finder LabVIEW under Hardware Input/Ouput > DAQmx > generating digital pulses > Gen dig Pulse Train-finishes-redeclenchables.

1. This should generate two pulse whenever the external trigger is received so your 11us impulses are the trigger for this task.

2. these impulses are then for each reading of digital lines:Rising edge - changed lines to enable

Falling edge - read data.By making these large enough pulse (> 140ns) that will take care of the running lines.

3. the gap between pulses must be long enough for any delay required between the readings.

Digital output

==============It must be a regenerative continuous power - see example material entry and exit > DAQmx > digital generation > Cont writing Dig Ext Clock.vi - Port.

1. the clock source should be set by right-clicking on the source control. Select i/o filtering name and then check the box advanced terminals. You can then select him appropriates the in-house production of counters.

2. you need to set the clock for the front edge.

3. the entrepreneurs that the buffer with two outputs that we require for example 10 and 01 and then sending a pulse to the clock pass effectively between the two.

Digital input

=============This should be a task of standard continuous input as in the example of the input and output material > DAQmx > digital measures > Cont read Dig channel-Ext Clk.vi

1. set up the VI of timing almost identical to the output task. Same source, but this time on the front clock down.

2 do with the data you want!

Overall program

===============The main consideration is that you should start the meter output last as soon as it runs other can start synchronization of data.

I hope this helps and is clear enough. I would like to know if it makes sense or if you would like more information or even no matter what assistance this program construction.

Kind regards

-

I'm looking for TDMS files as a way to save disk space for long trials.

I have trouble finding a clear tutorial on how to write several channels (but I think I got including this one), but more specifically, how to read several channels on a sort of a waveform graph. My research did not give much.

Is there a better data format to use?

Rick

Talk wrote:

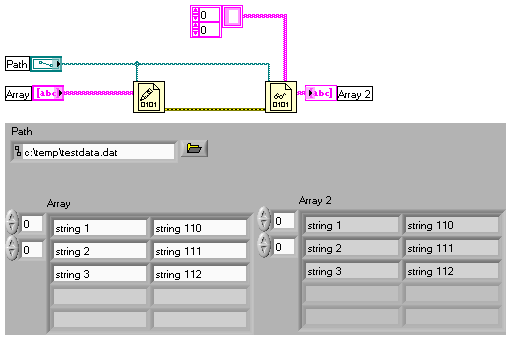

So if I understand well to do a PDM read function for each registered channel?

No. one is the reading of many channels. In this case it receives all channels waveform data in the data group measured. You could also provide an array of channel names if you want to be more specific. But all channels from a single reading must be of the same data type. That's why the other two readings are separated.

-

Read/write port DAQmx questions

Environment

Windows XP SP3

LabView 7.1

NOR-DAQmx 8.7.1

(2) PCI-DIO-96 cards

I'm trying to move from the level of registry TDAQ programming DAQmx and give me an "intensive" in mx. I'm not sure about a few things.

I need to put in place 20 channels/tasks that will run a mix of single, large port (8-bit) bed and written. Some will be handshaking (82 c 55 mode 1) and some no handshake (82 c 55 mode 0).

The plan is to create all tasks during an initialization routine and save the names of global tasks. I open the task after creation and use the globals during the main part of the program execution, when I make the reads/writes on the port. The body can run for hours at a time. When the main is closed, the stop routiine close all tasks to exit ahead.

Regarding the task creation/destruction - is it safe to create tasks and leave them open, or should they be created and destroyed every time that a write is performed?

Regarding the port reads/writes, I suppose that when a port single read/write is made, there is no established buffer. Is this correct? Specifically, if I use the method above and leave task open, is it possible saturation of buffer or something similar to happen?

TIA

Charlie

Regret - Yes, you said 7.1 - I can't keep back away, but here is a screenshot

And - the task is saved outside of LabVIEW, so it's not really 'Open' or 'Closed', even when programmatically, create and destroy jobs. Tasks exist or do not exist. If they exist and have no errors, they can be run.

Tampons are to move data to and from the device. For static DIO, this isn't a problem. You CAN run into problems with a task of acquiring buttons if it acquires data as soon as you read the data, but you can work around this by starting and stopping the task properly.

-

a speed of read/write DAQ card mode change will reach 200K

HEY, man,

I have a project needs to test two points I name them point A and point B, the first time, I should point A 5V DC input, voltage inductive test point B, sencodly, give point B 5V DC input and inductive point test output voltage, this means and two analog ports must read and write sharing mode , and the test speed must be 100 KB, if I have a 200 KB data acquisition card, can the speed of read/write mode change reach 100 KB for an analog port? or, please give your suggest for my this kind of situation, thank you.

Hi API,.

I see that you are trying to measure voltages using a single channel at a time on a data acquisition card.

Unfortunately, you cannot change the inputs to the outputs or vice versa on a map of data acquisition, they are static.

What I recommend is either using a switch like this: http://sine.ni.com/nips/cds/view/p/lang/en/nid/207130 where you will need a high chassis.

Or, having four channels, 2 inputs and 2 outputs and try to measure it. You should have the necessary speed as well.

If you have any other questions, I'd be happy to answer.

Thank you very much

-

Frequency of calls to control for the FPGA read/write

Hello

I use a cRIO-9076 with a module NI 9476 DO spend some faucets. It is sometimes necessary for faucets with a pulse time down to a few ms of impulse.

The FPGA VI Gets the power tap queries, executes a logic of security, and routes the numerical results for the exits. It gets applications power of the VI on RT target that uses the function ' Read/write FPGA control' interaction programming of the FPGA VI front. The loop on the RT runs with 1 kHz, no iteration is missed. That means, it should be possible to switch the valves with a resolution of 1 ms.

What I see on an oscilloscope, is that the output digital are high for multiples of 50 ms, the system does not reach the valve for example 80 ms pulse or pulses shorter than Ms. 50 is a kind of limitation for calls of "FPGA read/write control"? I tried both options for arbitration, but it does not help.

The best knowledge of the limiting cRIO/module/features or ideas? Thank you in advance.

Karsten

Hi Karsten

You use any time in your FPGA VI?

It is useful to your code by sending as an attachment so that I can have a look.

Kind regards

-

Difficulty using the binary read/write

Hello

The binary read/write function somehow not working properly in my application.

I have one store a 2D strign binary array. When the user closes the application, the application stores the values in table in the Bin file.

N when the application starts, it reads the file and displays its contents on the table.

The system works well if the total size of the content is 3 bytes. But if the size of the content is greater than 3 bytes, the program simply returns a NULL value at first when I read the Bin file.

How to save:

Convert 2D in String table using "Flatten the string" fn and to save in a binary file.

Procedure to read:

read a binary file. convert the output string table 2D using 'string Unflatten ".

I enclose my code here. PLS, have a look at it and let me know the cause of the problem.

Ritesh

I don't understand why you're flattening of a string, a 2D channels table. It's redundant. You seem to be also the substitution of the default big-endian to little endian byte order. You try to save it in a format suitable for other programs on other platforms?

If this is not the case, all you have to do is:

-

ORA-27070: async read/write failed

Hello

10 g R2 on Win server 2008 my faile overlap RMAN backups when:

As yo see RMAN backup finishes but defective during overlap. The file is available and can be connected to the CARRYING by RMAN to write the file. Why can't it overlaps?run 10> { 11> allocate channel t3 type disk; 12> backup as compressed backupset format '\\ASERVER\SAV-DAT\RMAN\INCR\MYDB\df_%d_%T_%s_%p' INCREMENTAL LEVEL 1 database; 13> sql 'alter system switch logfile'; 14> backup as compressed backupset format '\\ASERVER\SAV-DAT\RMAN\INCR\MYDB\al_%d_%T_%s_%p' archivelog all delete input; 15> backup as compressed backupset format '\\ASERVER\SAV-DAT\RMAN\INCR\MYDB\ctl_%d_%T_%s_%p' current controlfile; 16> } 17> host "DIR \\ASERVER\SAV-DAT\RMAN\FULL\MYDB\DF_MYDB*"; 18> crosscheck backup; 19> delete obsolete; 20> delete expired backup of database; 21> 22> Finished backup at 01-SEP-10 Starting backup at 01-SEP-10 channel t3: starting compressed full datafile backupset channel t3: specifying datafile(s) in backupset including current control file in backupset channel t3: starting piece 1 at 01-SEP-10 channel t3: finished piece 1 at 01-SEP-10 piece handle=\\ASERVER\SAV-DAT\RMAN\INCR\MYDB\CTL_MYDB_20100901_98_1 tag=TAG20100901T205836 comment=NONE channel t3: backup set complete, elapsed time: 00:00:03 Finished backup at 01-SEP-10 released channel: t3 host command complete allocated channel: ORA_DISK_1 channel ORA_DISK_1: sid=103 devtype=DISK RMAN-00571: =========================================================== RMAN-00569: =============== ERROR MESSAGE STACK FOLLOWS =============== RMAN-00571: =========================================================== RMAN-03009: failure of crosscheck command on ORA_DISK_1 channel at 09/01/2010 20:59:58 ORA-19501: read error on file "\\ASERVER\SAV-DAT\RMAN\FULL\MYDB\DF_MYDB_20100825_22_1", blockno 1 (blocksize=8192) ORA-27070: async read/write failed OSD-04016: Error queuing an asynchronous I/O request. O/S-Error: (OS 64) Net Work name unavailaible ORA-19501: read error on file "\\ASERVER\SAV-DAT\RMAN\FULL\MYDB\DF_MYDB_20100825_22_1", blockno 256 (blocksize=8192) ORA-27070: async read/write failed OSD-04016: Error queuing an asynchronous I/O request. Recovery Manager complete.

Thank you.Why can't it overlaps?

S/O-error: name of Net work (OS 64) unavailaible

-

Help? the source volume is read-write and can not be disassembled...

I use 10.11.5 on an iMac 21.5 ", end of 2009 and I want to restore the OS X 10.11.5 to HD on an external drive but I get this message" Source volume is read = write and cannot be disassembled, so it cannot be copied from block. " I can find answers do not address El Capitan. Help would be greatly appreciated.

.. .Goldie

You use disk utility's restore feature?

If the HD has a recovery partition, you can make starting in place of the recovery.

Or you can use SuperDuper! (the basic version is free and can copy the entire disk, the paid version allows "smart updates", which copies only files that are different, saving time) running on externally to perform the copy.

-

Tecra A8 DVD don't read/write DVD-R 1-16 x.

Using Sonic Record DLA, Tecra A8 DVD don't read/write DVD-R 1-16 x. Ok work on DVD - R 1-8 x and CD DVD - R 1-16 x has tested successfully on the two recent Toshiba Satellite Pro and HP Office. Have updated the Bios, software DVD-RAM and Sonic DLA.

Hey,.

What exactly do you mean? This means that you can t burn DVD-r with 16 x speed?

In this case, you should check the specifications of your CD/DVD drive. Not all models support this speed of combustion. In addition, I recommend using 8 x only, he speed will give you a better quality of the burned data/average.You must also use different types of media. I believe that your other computers have different drives in order to test different mediums. I have a good experience with Verbatim DVD-R.

-

DVD recorder is not read/write discs DVD-RAM on Satellite A200-1GH

Hello!!

I have the problem as the topic - my DVD drive is not read/write DVD-RAM discs (recorder: HL-DT-ST DVDRAM GSA-T20N). Unfortunately, there is no any drivers (more recent than I've got) for this recorder on the Toshiba, not even site on LG or Microsoft. What should I do?

Greetings

Hello

To be honest, it's quite strange. If the laptop is preinstalled with recovery image, it should work. I tested it on my laptop 5 minutes ago and it works. The DVD-RAM disc is readable and different documents can be saved on the disk too.

Do you use your own installation of OS, or you still have some factory settings?

Maybe you are looking for

-

El Capitan Preview Zoom App problem with PDFs

Hello world After the upgrade to Yosemite to El Capitan (10.11.5), I noticed a strange when behavior you zoom in PDFs with Preview.app. Crossing of a certain zoom level obviously breaks the screen refresh. The window turns white, while the text and t

-

disable the Bluetooth cannot depend on

Bluetooth suddenly turn off and can't turn it on again. Message says bluetooth: bluetooth is not available. Bluetooth PAN is not connected, no bluetooth PAN not found. The wireless keyboard has power. Try restarting com + opt + pr, may not work. Remo

-

Hello I am very happy with the RAZR, but it will not automatically install drivers bluetooth on windows 7. Is there a link to download and install the correct drivers? Thank you Sea

-

error item not taken in charge on the RIO

We have a project involving a RIO and a WSN, that has been put together for my by a value OR added reseller. I can see the RIO and MAX WSN nodes and can connect to everything. When I look at the view of the project, I get a warning on the RIO (yello

-

setting moet naar devising smart card. hoe doe ik dat...

installation e.dentefire 'Aggro' bank account fails note of Pentecost: automatick smart card settings. How to do that. (if possible in Dutch) or call + 31 6 30216539