incorrect thermocouple reading

I have an NI PXI-1033 with an NI TB-2709 block and I'm under Labview 9. I'm just trying to read the temperature with a thermocouple to any of the eight channels. Unfortunately, when I look at the reading of the measure and menu task Automation Explorer value fluctuates all about the difference from peak to Valley about 50 degrees C. I tested the thermocouple on a multimeter and it gives a good reading. What's wrong. Help, please.

Once I updated the chassis ground to the shield of the input cable that the noise went away.

Tags: NI Software

Similar Questions

-

NOR-4351 incorrect Thermocouple readings

Had had problems of expierencing with our boards of NOR-4351, we have several and the only work is done without knowing why.

I took a Board of Directors and setting up a new system with a new installation of windows XP SP3. I then installed TDAQ744.

He installed, then XP recognized the device and install its drivers.

Then, I set the properties of the 4351 for a TBX68T accessory.

Then, I created a virtual channel to measure a thermocouple type j to channel 11, which is RM correctly.

I put the refrence to user at 25deg C.

I then had 23.899 ° c and it woudlnt change such as the thermocuple has been heated or cooled.

I tried changin the ref built in, and then the reading went to 2800 or almost.

I repeated with a different 4351, same problem.

I changed the TBX68T with a CB68T

My guess is a problem with TDAQ744, I can wipe the system and startover and install 7.2

Very disappointed that we have made to buy these cards a few years ago that in-kind for them drop that left us in this impasse.

Finally had the chance to install another system. Even found a replacement cable, or it turns out the problem. It was damaged enough to cause problems intermittly.

-

Thermocouple reading (w / Source built-in CJC) only works on the random strings of CBS

I'm using LabVIEW 8.2.1, a card PCI-6255 and a block of connection SCB-68. I have a Type K thermocouple with a calibrator thermocouple which I'm trying to measure. It is the problem, first, using the attached VI, I tried to read this TC with AI0. Whenever I have use AI0 I get error saying THAT integrated CSF is not available. When I use another channel, this error disappears. The second problem, when I use a different channel than the AI0, I am only able to read Treasury on random channels correctly. For example, it works on AI13 to AI15. For channels that does NOT work, I am able to see the correct voltage thanks to MAX, but DID read TC VI not for any reason any gives an accurate reading.

Nobody knows why, I wouldn't be able to use AI0, and why I only use certain channels for this TC? This is absolutely insane and I tried swapping the CBS, the map of the DAC and cables. I also reinstalled drivers and LabVIEW.

Please help this is driving me crazy!

Thank you

BKB,

The CCM should be configured for differential. Following quote found here http://digital.ni.com/public.nsf/allkb/96B996BAD82A84E9862570690066B03F

«If you configure the switches on the SCB-68 to allow the probe on single-ended channel 0 (I 0) rather than differential has channel 0 (HERE 0 and AI 8), you cannot use a task of temperature DAQmx.»

-

thermocouple reading limited to a value

Hello

I'm new here and don't know much about Labview.

T type thermocouples are connected to the SCXI-1000 chassis with 1102 module and 1303. I use 20 channels and 12 are left open. For open channels, the Labview program is around 139oC. However, the temperature measured in these busy channels cannot exceed this temperature, no matter how hot I heated the test surface.

Is it because of the Labview program or the resistance of the inside of the 1303 or any other possible reason?

Thank you very much.

Hi Johnrally,

By '139oC' do you mean 139 ° C, 1390 ° C or something else?

1390 ° C is well outside the range of type T temperature thermocouples according to NIST. However, it is close to the upper limit for the thermocouples of type k are you sure that your program is to specify the correct thermocouple type?

If this does not answer your question, thanks to post a code snippet to show how your program. Also, I recommend double-checking the SCXI configuration in MAX, to make sure the SCXI-1303 module is configured correctly (and it is not configured as an SCXI-1300 module).

Brad

-

Strange thermocouple at the time reads high

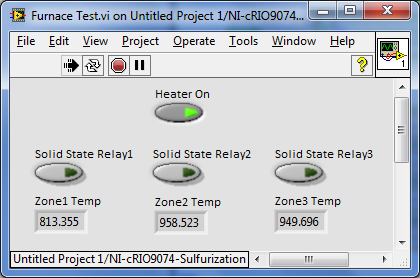

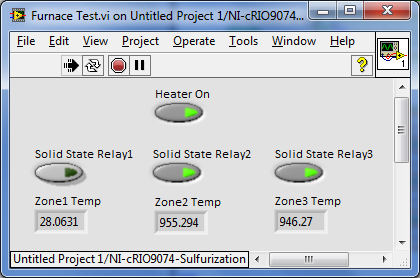

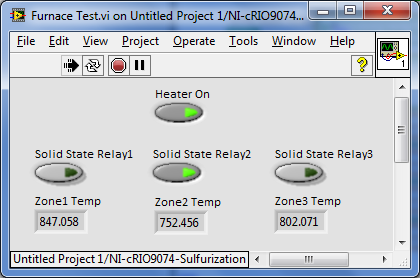

I have a problem my thermocouples to high playing time. I have a cRIO 9074 with a connected to 3 K type thermocouples 9211 thermocouple module. Thermocouples monitoring 3 heat zones from a giant furnace, in which areas can be activated and deactivated with the help of a relay. When activated, the thermocouples read the temperature normally up to 800 ° C. However, when it goes beyond 800 degrees, it can seem to read normally, but when you place radiator different relay on or off, the thermocouple reading significantly changes a few times. This does not happen below 800 C see attached photos and assume that the first photo is the right base temperature:

When I joined the first box to an external drive thermocouple with its own digital screen, I don't see this radical change when switching of the relay on and outside. It has remained relatively constant.

Why I see such a big change with the 9211 module? I'm not process the signal somehow, just a direct reading, and the module itself is configured to play the K type thermocouples. The heater contactor and thermocouples are relatively far.

Any help is appreciated.

Linus

Hi Craig,.

Yes, I could solve this problem. a LabVIEW engineer suggested this solution and it worked. See Section 3 (Nonreferenced) floating measurement of Sources at this link:

http://www.NI.com/white-paper/3344/en/#toc3

The source of the problem was instrumentation amplifier input bias currents, causing the voltage level of the floating source to be moved out of reach. I need to add polarization resistors to provide a path of DC since the instrumentation amplifier inputs to the instrumentation amplifier ground and anchor this voltage level at a few references. I followed resistors in FIgure 10 and added two 100 kOhm for each of my thermocouples. Since then, I have much more fluctuating readings.Hope this helps,

Linus

-

Incorrect SCXI all the playback channels after running for more than 30 minutes

I have a SCXI-1001 module. I use a thermocouple module (1102, breakout box 1300), input analog (off 2, map of 1100, 1300 in small groups), analog output (1124 map, 1325 breakout) and a relay (card 1160, breakout 1324). I'm using labview 2009. I created my channels manually to read all channels, I need about 1 task for entries of thermocouple and analog, 1 analog and 1 for task task for the output relay (total 3 tasks). Each task comes into contact with the SCXI area in a different section of a timed sequence. I read all my channels with precision for 30 minutes but then all of a sudden they stop reading accurately and all thermocouples read the same incorrect value as well as all analog input channels. I can't change the output channels either.

The problem occurs more quickly if I increase the clock frequency. There are no errors showing when this problem occurs.

What is an interaction of hardware failure or a software.

Any help would be greatly appreciated. I also need to resolve this issue quickly because it is delaying the test.

Thanks for your help

Tim

Thank you all for your response. I managed to solve the problem. It was a problem with the start of the task and to connect the clocks for different tasks. I've included only a single task to start my unstable code in the source code as for posed multiple startup tasks. However, I started my slave tasks (analog and digital outputs) before starting my master's work (analougue entered). This seems to have solved the problem. I intend to go more far by adding clocks at 2 slave atsks and linking them to the task of master.

I used the sequence as part of documentation. Each links to sequence number to another sheet that I have has a flowchart to say what is each part. As you say there is no need to put in a sequence and do so limit labviews own data stream. I'll remove the sequences and put my documentation on the codes in the code directly because it is made in the examples of labview.

Thank you for your help

Tim

-

Scaling of voltage of the thermocouple before voltage to temperature conversion

Hello

I have a module of data USB-6211 acquisition entry with Labview 8.6, and I will measure temperatures using a type R thermocouple. Because this thermocouple voltages are very small (about 0-20 mV), I'll use an external amplifier (50 x gain) to transform the signal to 0-1 V, then read the entries using the module of data acquisition.

At this point, I can divide the signal by my (x 50) gain and use inverse polynomials for thermocouples of type R (published online: http://www.omega.com/temperature/z/pdf/z198-201.pdf) to convert pressure into a temperature.

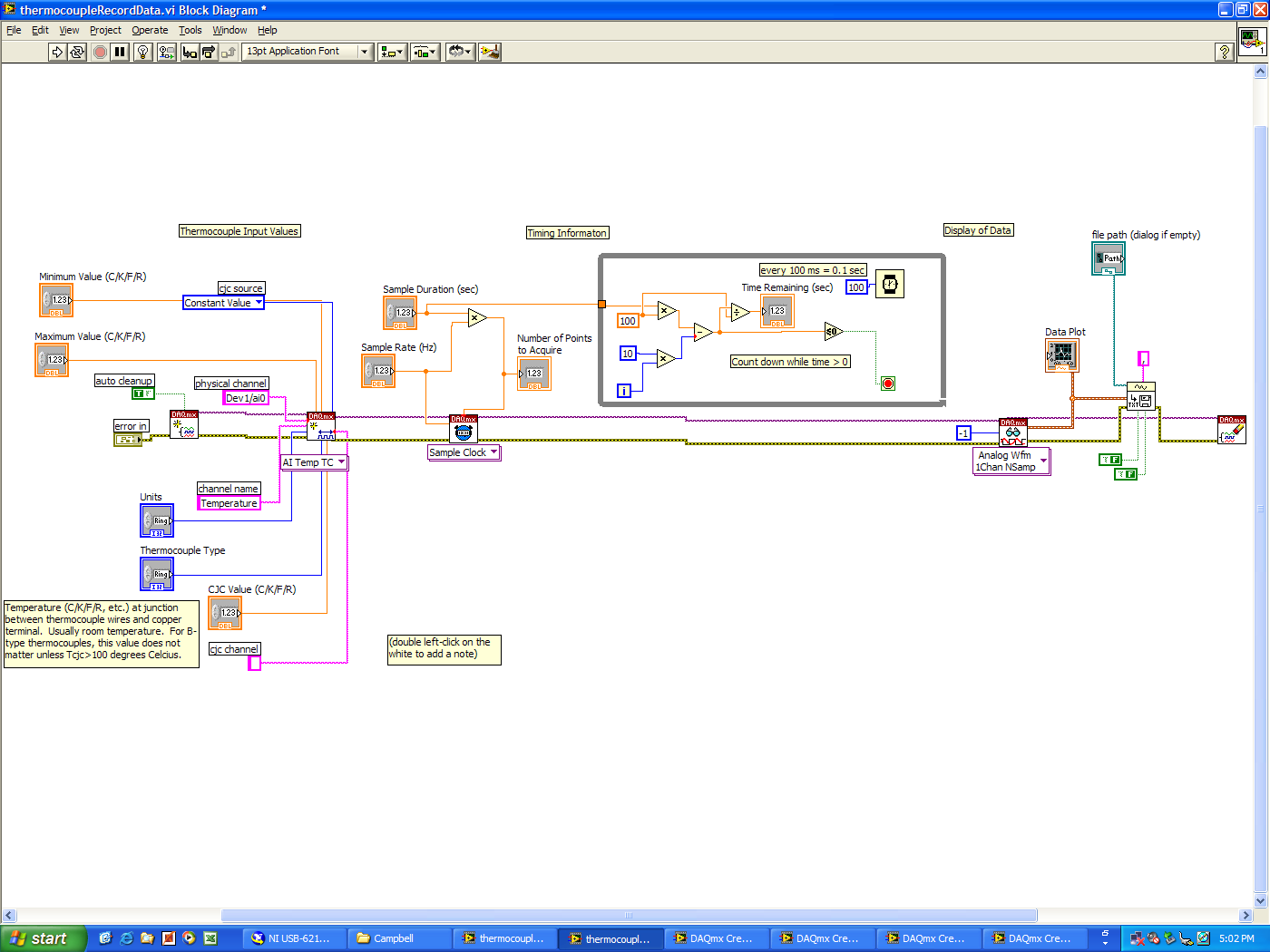

However, I noticed that Labview has built in thermocouple modules. There is a stage of creation of task, and the task is sent to a module that allows me to specify the thermocouple type, value CJC etc, then a sample clock, then a sampler with analog wafeform (see below). I would use this structure, rather than coding in polynomials. However, I can't find a way to divide my my (x 50) gain input voltage in order to give the thermocouple module reasonable voltage values.

Is there a simple way to do this, or I'm better just a coding in polynomials?

Thank you!

Amplify the signal, read the voltage, then divide by 50.

No need to code polynomials. Search for pallets for the Subvi convert Thermocouple Reading.VI

-

NEITHER USB 6008 tension problem reading

Hello

I am trying to program a USB-6008 on a mac. When I connect to the input to analog 5V output I get a reading of 3.67volts, while on an osscilascope, I read a 5volts voltage. Is this normal? Need to load resistors? Also, I get the same effect with the release of tensions for the analog output.

Hi Zepp2,

Thanks for your post. The pins are you connect together on your device? Depending on the type of connection you have the wiring may not be quite right.

I found a few documents online which hopefully should help you:

Field of connection for analog signals: http://zone.ni.com/devzone/cda/tut/p/id/3344

USB-6008/6009 Getting incorrect voltage reading: http://digital.ni.com/public.nsf/allkb/95CC0CB11D7DF3D18625712E000C4ABD?OpenDocument

Input analog USB-6008/6009 reads about - 1.4V Offset: http://digital.ni.com/public.nsf/websearch/E687933C5694AB00862570BD00593CA3?OpenDocument

Please let me know if one of them will help out you.

Kind regards

-

Two measures of different thermocouples 1303

Hi all

I use a SCXI-1303 module and a module SCXI-1102 and SCXI-1000 chassis. The plan is to measure the temperature using thermocouples type T. 1303 modules (I have 3 of them) are completely new, and I pulled out of the box and put them on my 1102. I was testing my thermocouples to ensure they all worked when I noticed a difference in temperature between some of the thermocouples. When I started using AI16 (0-15 was already in use) temperature readings began to appear about 4 degrees below all other temperatures. Most of the thermocouples read 21 c, which is good, but those channels AI16-19 (I'm not plus far only 19), have been reading of 16 C. So I swapped the thermocouples, who had read the right temperature (from AI15) set AI16 and he showed the same offset of 4 degrees, so should not be a thermocouple problem. I put the 1303 on another module of 1102 and I swapped the 1303 modules, I had the same problem each time. The polarization resistance came in 1303 modules, so I have not tested with them. I get the same temperature difference using "integrated" and "constant" for the source of the CJC. I can hardly believe that it's a hardware problem, scxi-1303 1102 both had the same result. So I was hoping there is something else here I'm missing. I looked in the forums and not found anything quite like my problem. I read the manuals but have not encountered anything that would explain this.

Please let me know if you need more information,

Thank you

Jim

Well, I feel stupid. When you use the wizard daq, you must specify the type of thermocouple for each channel. I've had several channel sent to the type of thermocouple wrong without realizing it. Switching the appropriate type, made them of course work.

Heh, sorry for the useless post

Jim

-

Help. Temp for voltage conversion.

I'm currently trying to find a best way to calibrate the thermocouple read outs. I would like to be able to enter any temp for all TC and labView output the corresponding voltage. So I was hoping someone would have a way to make this temp for voltage conversion. Example if I want to do 250 C I need 10.153 mV how labView could be made to calculate this.

This will allow you to enter the temperature you want for the simulation and corresponding voltage.

-

problems syncing multifunction with PCI-6229

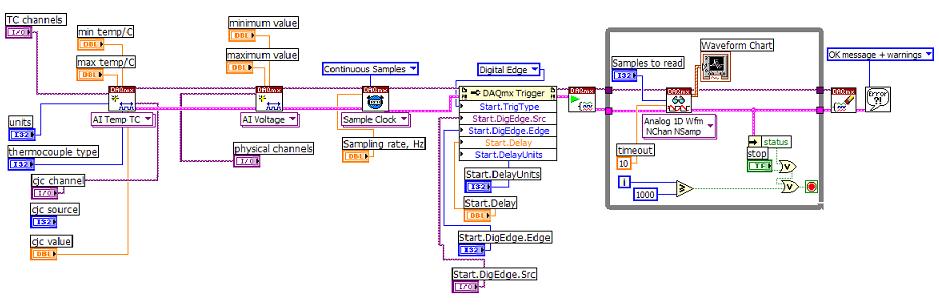

Hi, I use PCI-6229 and LabVIEW 8.0 for synchronized of the thermocouples and voltage measurements. The diagram is attached here. Here are my questions:

(1) with the analog inputs of TC is ranked very first and followed with inputs analog voltage, as shown in the diagram, it works fine. But once the tension AIs are placed first and followed with AIs for thermocouples, thermocouple reading makes no sense, for example telling 25 deg C, the program shows strong fluctuating temperature 10-80 deg C.

(2) the delay time using DAQmx Trigger, here I put the Start.Delay = 2, Start.DelayUnits = ticks. And sampling rate = 1000 Hz for sample clock VI. Then, is equal to 2 X (1/1000 second) delay time = 2ms? If no deadline is set, which is the time between the trigger signal and actural reading? Will it be the time device resolution 50 ns?

All entries would be very appreciated.

Hi Matt11,

(1) the order that you specify strings in your task will affect the order of scanning. In other words, when you add the channels voltage before channels of temperature, the material can enjoy the tension or s channels followed by the string (s) temperature. Since the 6229 is multiplexed, it comes to each channel sequentially switching in a single ADC. In your case, it seems that the tension on the ADC to measure voltage not had time to resolve completely prior to taking the measure of temperature. We refer to this sometimes as ghosts in extreme cases where the value measured on channel b mimics the tension on the channel.

I think that you have found that you can get this by adding the TC task first. You could probably also get the same result by allowing more break-in between channels on your scan list. You can set the time between the channels with a Timing DAQmx property node (you can set the property is the clock frequency convert, which is the opposite of a waiting time). For slow sampling rates, sets DAQmx convert a default clock rate up to a minimum of 1/14 US (on the x 622). If your overall sample rate is less than 1/14 us (about 71 kHz) then you should have room to lower the clock rate to convert more of this if you wish to allow more time to settle between the channels.

I'm a little surprised that you see errors because of it (generally, the problem comes from a signal source of high imepdance measure or when sampling at higher rates), but then again, the temperature measurement would be very sensitive to small voltage fluctuations since you deal with thermocouple voltages at room temperature. Given the order of scanning affects your measure the problem is almost certainly introduced leaving not enough time for the ADC to settle after reading your string tension.

(2) ticks means actually timebase tick rather than the graduations to sample. The minimum is always 2, but this match 2 graduations of 20 MHz (100 ns) time base from which the sample clock (unless you choose otherwise or specify a sampling rate less than 20 MHz / 2 ^ 32), instead of 2 graduations of the 1 kHz sample clock (2 ms). In fact the trigger is probably performed asynchronously at the base of your time, if you are anywhere between the graduations of 1-2 the basis of delay time (50-100 ns) according to the relative phase of the trigger to the time base. If no time limit is set, the default value according to me is still 2 ticks which is the minimum that allows hardware (you can check on your own by reading the property node if you wish).

These points should be compatible between different driver versions, with the exception that DAQmx chose by default convert rate differently in earlier versions of 7.4. Select the conversion rate is a compromise between the settling of deadlines and the channels are sampled how "simultaneously" on the MULTIPLEXED Board. The final result in point 7.4 of DAQmx was a compromise apparently arbitrary add 10 US for the minimum conversion period and use this as the maximum by default between the channels. The user can of course always set the clock to convert to all what best fits their application (in your case, you might want to allow a settlement more between each channel).

Best regards

-

invoke the node (screw in a parallel work library)

Hi all

I'm evaluating a temperature probe. For this I must watch the thermocouple readings. Thermocouple is attached to the FP-TC-120 of temperature module. Moreover, I have to acquire data from the optical spectrum analyzer. I use 3650.VI to monitor the temperature and 86140 B Capture of Trace_Screen .llb (2) o trace data of OSA.

I try to use Invoke node VI for Spectrum Analyzer trace data. For this, I specified the path to the necessary file as an input for the code. The problem is that the necessary VI (write Trace to File.VI) is within a Bachelor of law. folder and need codes to operate completely.

It is when I run the code (and when the condition of stability is met) the computer asks me to save data of Spectrum Analyzer in a file called trace.csv. When I press ok, it simply registers an empty file with a header (Power (dbm) wavelength (nm)). Apparently it works in parallel with the other VI. How can I make use of the VIs within a .llb file with call node VI or should I use another VI to combine temperature monitor VI VI of tracing data.The second problem is with the temperature stability criterion. In the attached VI, I check if the thermocouple reading is within the range of stability of 0.8 degree 900 seconds. I want to change that. I have

you want to check the stability of the temperature by comparing the final data with the previous ones. Y at - there no specific VI which should be used to check fluctuations of waveforms?Thank you very much

Deniz says:

Now, I struggle with timing. The problem is that if I put a timer inside a case structure, it disables the time VI

This is not what is actually happening. What is happening is that the loop must wait until the delay function is completed before you can continue to the next iteration. There are several ways to solve this problem. Here are 2:

- Instead of having a time delay within the structure of the case, use a shift register to keep track of the last time a trace has been captured. If the time is greater than or equal to 1 minute and you are supposed to be captured, and then do the capture and reset the timer. Thus, the structure of the case would be headed by 2 conditions rather than 1. It is a relatively simple change.

- Place trace capture in a separate and independent loop. The case structure would be as is inside this independent loop. You must use a property node or a local as a flag variable, so that the trace capture can be triggered. For example, you must create an indicator of the output of the or less? function so that you can read the value in the other loop.

I recommend method 1.

PS, I just noticed that the "Trace Xfer" VI has already incorporated in writing in a spreadsheet file . As it is, you will get a dialog box asking you for a file name. You can either:

- Delete the entry in the worksheet in the "Trace Xfer" VI file as you do in your top-level code.

- Delete the entry in the worksheet of your first level VI file and add a path control to the "Trace Xfer" VI and past in the path to the file you want to write.

-

Como puedo medir con temperatura a termopar in una tarjeta 6221

Necesito UN medir con temperatura a termopar, so the 9172 con el uso blocks 9211 mide pero cuando acerco una punta caliente temperatura disminuye in place of increase. Don't jerk the 66221 no puedomedir. Necesito UN medir con realidad the 6221 are para una clase y son las tarjetas than I have.

Normal 0 false false false fr X-NONE X-NONE MicrosoftInternetExplorer4 / * Style Definitions * / table. MsoNormalTable {mso-style-name : « Table Normal » ; mso-tstyle-rowband-taille : 0 ; mso-tstyle-colband-taille : 0 ; mso-style-noshow:yes ; mso-style-priorité : 99 ; mso-style-qformat:yes ; mso-style-parent : » « ;" mso-rembourrage-alt : 0 à 5.4pt 0 à 5.4pt ; mso-para-marge-top : 0 ; mso-para-marge-droit : 0 ; mso-para-marge-bas : 10.0pt ; mso-para-marge-left : 0 ; ligne-hauteur : 115 % ; mso-pagination : widow-orphelin ; police-taille : 11.0pt ; famille de police : « Calibri », « sans-serif » ; mso-ascii-font-family : Calibri ; mso-ascii-theme-font : minor-latin ; mso-fareast-font-family : « Times New Roman » ; mso-fareast-theme-font : minor-fareast ; mso-hansi-font-family : Calibri ; mso-hansi-theme-font : minor-latin ;}

Hola diegoseuret, el blocks 9211 esta specially designed para medir termopares asi what no debe darte problema este ago includes todo el acondicionamiento Señal necessary. Aqui lo mas more likely than are el termopar este conectado al dreams, asi as simplemente debes of invertir el termopar (por lo general Los termopares el rojo es el negativo).

Ahora con the 6221 cambia a poco no dado than esta no tiene el acondicionamiento Señal what needs para UN termopar.

Básicamente para leer well Señal del termopar tienes than linealizarla, amplificarla y punta fria compensation apply.

Para linealizar Señal básicamente ordered sacar el polinomio from las tablas as del termopar, o well there you could be useful some screws como el to convert thermocouple reading.

Aunque el 6221 tiene buena puedes poner resolución amplificarla para an OPAMP Panel al principio como para increase el valor y tener una mejor resolución.

Sue en punta fria tienes as conocer temperatura ambiente para y restar el voltaje para temperatura ambiente puedes usar como el LM35 sensor. Y is este valor o con you can get the table a cuando match y restarlo o meter el valor en el VI to convert thermocouple reading.

In following links are described with a little more detail:

Packaging for Thermocouples of signals required

Take measurements of temperature Thermocouple

Measure the temperature with a Thermocouple or RTD

Paintings of the thermoelectric voltages for all Types of thermocouples

Saludos

-

Hi all

I'm working on an application of temperature. I take the thermocouple reading from a device of FP-TC-120.

I want that reading of thermocouple to stay in the range of 1 degree accuracy, for example for 10 minutes. To do this, I wrote the attached VI. (Target value and time required temperature are entered in VI.) The problem is that I want that time to be reset to zero when the value of the temperature falls out of scope. In the application, I wrote that it resets the little matter that the reading of thermocouple. The problem has something to do with the structure of the case? (I tried to use while loop, but I had trouble getting the thermocouple inside the loop of reading)

Thank you

Deniz

The way you have it, the timer resets whenever the front panel boolean is true. You have absolutely no connection with the thermocouple reading being within the range or not. A simple solution is shown below.

-

Valid select Spry of State does not

Hi all

This is my first post. I searched for an answer but can't find anything that matched my problem. I have a few spry validation boxes on my page, and all but one will not work correctly. The one in question is spryselect1 ("spryEquipLoc"). For some reason any (which I can't understand) this field will display the selectRequiredState even after a selection has been made. Thanks in advance for any help. Here is the code (sorry, that I couldn't see how to format the code in the post):

< ! DOCTYPE html PUBLIC "-//W3C//DTD XHTML 1.0 Transitional / / IN" "http://www.w3.org/TR/xhtml1/DTD/xhtml1-transitional.dtd" > ""

" < html xmlns =" http://www.w3.org/1999/xhtml ">

< head >

< script src = "SpryAssets/SpryValidationTextField.js" type = "text/javascript" > < / script > "

< script src = "SpryAssets/SpryValidationSelect.js" type = "text/javascript" > < / script > "

< script src = "SpryAssets/SpryValidationTextarea.js" type = "text/javascript" > < / script > "

< script src = "javascripts/Calendar.js" type = "text/javascript" > < / script > "

<!-< script src = "javascripts/datetimepicker_css.js" > < / script >->

< script type = "text/javascript" >

categories of var = [];

categories [list of "departures"] = ["Hardware problem", 'Issue of the newspaper', 'Operator error', 'Question media', 'Question of Satellite', 'Problem program', 'Problem of Playlist', "Issue Promo"]

categories ["equipment issue"] = ["Digibeta deck", "recorder XDCAM', 'Monitor', 'Chyron', 'Switch', 'Media port',"Downstream manipulator", 'Asset base PC',"Device server", 'Fast X PC game', 'Receiver Satellite', 'Video server', 'wall of Miranda", "Crispen automation", 'Vertigo X-Play'];

categories ['Log question'] = [' incompatibility of Log/list of reading ', 'Journal strobe', 'Journal calendar heavy ',' wrong time', "bad start time ',' events deleted"];

categories ['operator error'] = ['operator name1', 'Name2 operator', "Operator Name3"];

categories ["media question"] = ['Damaged care', 'Missing media', 'Dublist not received', 'Bad media file', 'Snipe Question', 'Question Bug', ' Audio ',' out of synchronized ", Audio or deformed cutting ',' Audio too low ',' Embedded credits of missing '];

categories ['question Satellite'] = [' Black we air ', 'Failure of Signal', 'Sun down', 'Subtitle', 'problem Audio","Transmitter partner"];

categories ['program question'] = ['Program the light ',' heavy ',' Incorrect program', 'Incorrect material ID', 'Replaced Programme', "Incorrect segment lengths", "Embedded crédits"];

categories ["Playlist issue"] is ["light Playlist', 'Heavy Playlist', 'Playlist loaded Incorrect', 'bad reading source'];.

categories ['Promo question'] = ['Invalid hardware ID', 'Wrong time', 'Snipe Incorrect', 'period of Incorrect snipe', "Promo replaced"];

var nLists = 2; the number of overall selection lists

function fillSelect (currCat, currList) {}

var step = Number(currList.name.replace(/\D/g,"")); "

for (i = step; i < nLists + 1; i ++) {}

document. Forms ['frmOnAirActivity'] ['List' + i]. Length = 1;

document. Forms ['frmOnAirActivity'] ['List' + i]. SelectedIndex = 0;

}

nCat var = categories [currCat];

for (each in developpement) {}

var nOption = document.createElement ('option');

nData var = document.createTextNode (nCat [each]);

nOption.setAttribute ('value', nCat [each]);

nOption.appendChild (nData);

currList.appendChild (nOption);

}

}

function init() {}

fillSelect ('startList', ['frmOnAirActivity'] ['List1'] return)

}

navigator.appName is 'Microsoft Internet Explorer'? attachEvent ("onload", init, false): addEventListener ("load", init, false);

< /script >

< meta http-equiv = "Content-Type" content = text/html"; charset = utf-8 "/ >"

< title > on Air activity form < /title >

< style type = "text/css" >

body, td, th {}

do-family: "Lucida Sans Unicode", "Lucida Grande", without serif.

do-size: 14px;

color: #052F47;

}

{body

background-color: #8E8E8E;

background-image: url();

background-repeat: no-repeat;

}

{#form}

behavior: url (PIE.htc);

do-family: Verdana, Geneva, without serif.

background-repeat: repeat;

do-size: 14px;

padding: 10px;

Width: 660px;

border-radius: 0px 20px 0px 20px;

box-shadow: #666 10px 10px 10px;

border-top-style: none;

border-right-style: outset;

border-bottom-style: outset;

border-left-style: none;

background-color: #589DC6;

float: right;

}

{#wrapper}

margin: auto;

Width: 860px;

}

< / style >

< link href = "SpryAssets/SpryValidationTextField.css" rel = "stylesheet" type = "text/css" / > "

< link href = "SpryAssets/SpryValidationSelect.css" rel = "stylesheet" type = "text/css" / > "

< link href = "SpryAssets/SpryValidationTextarea.css" rel = "stylesheet" type = "text/css" / > "

< link href = "css/Calendar.css" rel = "stylesheet" type = "text/css" / > "

< / head >

< body >

< script type = "text/javascript" >

show and hide sections of a form

function preparePage() {}

document.getElementById("List1").onclick = function() {}

If (document.getElementById("List1").value == 'Question equipment') {}

use the CSS style to show

document.getElementById("Equipment").style.display = 'block ';

document.getElementById("Satellites").style.display = 'none ';

} Else if (document.getElementById("List1").value == 'Satellite question') {}

use the CSS style to show

document.getElementById("Satellites").style.display = 'block ';

document.getElementById("Equipment").style.display = 'none ';

} else {}

hide the div

document.getElementById("Equipment").style.display = 'none ';

document.getElementById("Satellites").style.display = 'none ';

}

};

now he hide on the initial page load.

document.getElementById("Equipment").style.display = 'none ';

document.getElementById("Satellites").style.display = 'none ';

}

Window.OnLoad = function() {}

preparePage();

};

< /script >

< div id = "wrapper" > < img src = "Graphics/banner.png" alt = "Banner" width = "860" height = "84" / > "

< div id = "form" >

< form id = "frmOnAirActivity" name = "frmOnAirActivity" method = "post" action = "" >

< span id = "spryAirdate" >

< label for 'Broadcast' = > release < / label > < br / >

< input type = "Text" id = "Dissemination" tabindex = "1" / >

"< img src =" graphics/cal.gif"onclick =" javascript:showCalendar('Airdate') "style =" cursor: point "/ >

< span class = "textfieldRequiredMsg" > a value is required. </span > < span class = "textfieldInvalidFormatMsg" > Invalid format. </span > < / span > < / p >

< p >

< span id = "spryDiscrepType" >

< label for = "List1" > event category < / label > < br / >

< select name = "List1" id = "List1" tabindex = "2" onchange = "fillSelect (this.value, this.form ['List2'])" >

< option > < / option >

< / select >

< span class = "selectRequiredMsg" > please select an item. </span > < / span >

< /p >

< span id = "spryDiscrepSubType" >

< label for = "List2" > detail < / label > < br / >

< select name = "List2" id = "List2" tabindex = "3" onchange = "fillSelect (this.value, this.form ['List3'])" >

< option > < / option >

< / select >

< span class = "selectRequiredMsg" > please select an item. </span > < / span >

< p >

< div id = "Equipment" >

< span id = "spryEquipLoc" >

< label for = "EquipLoc" > rental equipment < / label > < br / >

< select name = "EquipLoc" id = "EquipLoc" tabindex = "4" >

< option > < / option >

Master Control < option > < / option >

Media Services < option > < / option >

< option > central strip < / option >

< / select >

< span class = "selectRequiredMsg" > please select an item. </span > < / span >

< p >

< span id = "spryEquipID" >

Hardware ID < label for = "EquipID" > < / label > < br / >

< input type = "text" name = "EquipID" id = "EquipID" tabindex = "5" / >

< span class = "textfieldRequiredMsg" > a value is required. </span > < / span >

< / div >

< p >

< div id = "Satellites" >

Satellites of affected < fieldset > < legend >: < / legend >

< table width '424' = >

< b >

< td width = "152" > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_12" / >

NET Sat1 < / label > < table >

< td width = "119" > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_16" / >

NET Sat2 < / label > < table >

< td width = "137" > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_20" / >

NET Sat3 < / label > < table >

< /tr >

< b >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_13" / >

NET Sat4 < / label > < table >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_17" / >

NET Sat5 < / label > < table >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_21" / >

NET Sat6 < / label > < table >

< /tr >

< b >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_14" / >

NET Sat7 < / label > < table >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_18" / >

NET Sat8 < / label > < table >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_22" / >

NET Sat9 < / label > < table >

< /tr >

< b >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_15" / >

NET Sat10 < / label > < table >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_19" / >

NET Sat11 < / label > < table >

< td > < label >

< input type = "checkbox" name = "Satellites_" value = "checkbox" id = "Satellites_23" / >

NET Sat12 < / label > < table >

< /tr >

< /table >

< / fieldset >

< / div >

< fieldset >

the legend <>network: < / legend >

< table width '424' = >

< b >

< td width = "152" >

< label >

< input type = "checkbox" name = "Network_1" value = "checkbox" id = "Network_1" / >

Networl_1 < / label >

< table >

< td width = "119" >

< label >

< input type = "checkbox" name = "Network_2" value = "checkbox" id = "Network_2" / >

Network_2 < / label >

< table >

< td width = "137" >

< label >

< input type = "checkbox" name = "Network_3" value = "checkbox" id = "Network_3" / >

Network_3 < / label >

< table >

< /tr >

< /table >

< / fieldset >

< p >

< label for = "OnAirVariance" > on Air Variance < / label >

< input name = "OnAirVariance" type = "checkbox" value = "" / > "

< p >

< span id = "spryDescription" >

< label for = "Description" > Description < / label > < br / >

< name textarea = 'Description' id = cols "Description" = "45" lines = "5" tabindex = "6" > < / textarea >

< span class = "textareaRequiredMsg" > a value is required. </span > < / span >

< p >

< span id = "spryResolution" >

< label for 'Résolution' = > actions < / label > < br / >

< name textarea = 'Resolution' id = cols 'Resolution' = "45" lines = "5" tabindex = "7" > < / textarea >

< span class = "textareaRequiredMsg" > a value is required. </span > < / span > < / p >

< / make >

< / div >

< / div >

< script type = "text/javascript" >

var sprytextfield1 = new Spry.Widget.ValidationTextField ("spryAirdate", "date", {validateOn: ["blur"], useCharacterMasking:true, format: "mm/dd/yyyy"});

var sprytextfield2 = new Spry.Widget.ValidationTextField ("spryEquipID", "none", {validateOn:["blur"]});})

var spryselect1 = new Spry.Widget.ValidationSelect ("spryEquipLoc", {validateOn:["blur"]});})

var spryselect2 = new Spry.Widget.ValidationSelect ("spryDiscrepType", {validateOn:["blur"]});})

var spryselect3 = new Spry.Widget.ValidationSelect ("spryDiscrepSubType", {validateOn:["blur"]});})

var sprytextarea1 = new Spry.Widget.ValidationTextarea ("spryDescription", {validateOn:["blur"]});})

var sprytextarea2 = new Spry.Widget.ValidationTextarea ("spryResolution", {validateOn:["blur"]});})

< /script >

< / body >

< / html >

Corrected it by specifying the number of points for each option in my select as follows:

Please select an item.

Found the info here:

http://labs.Adobe.com/technologies/Spry/articles/select_overview/index.html

Maybe you are looking for

-

Using the Structure of the event in a Machine of State Enum

Hello! I'm new to labview(~10 months). I tried my best to search on the forum/net but didn't have an explanation.I simplified the code to show the problem. I'm using Labview 2013 worm 13.0f2 (32 bit). The "EventStructure_Trigger_in_EnumStateMachine.v

-

Hello I want to build the app to get a random number between 200 and 250 How can I do in labview nots I have labview 9 Thank you

-

-Need to uninstall for Vista Ultimate Upgrade - HOW? This question has been posted before, but I don't see an answer to the problem. I just reinstall Vista after replacing a failed hard drive - new clean install.When I try to run my upgrade: Home Pre

-

How to deselect "always" in the choice of the ringtone

Hello. In the menu sounds and notifications-> ringtone for phone calls, I select "forever" to search with the ringtone file Commander, and now I can't see the list of ringtones installed in the phone. How can cancel selection 'forever '? Thank you.

-

Problem: folder my documents will show images No miniature icon pictures so you can see what the photo is recently sent mobile back fixed hard drive and this problem occurred. I tried clicking on display to change the size of thumbnails, but without