measure and order through producer/consumer

Hello people,

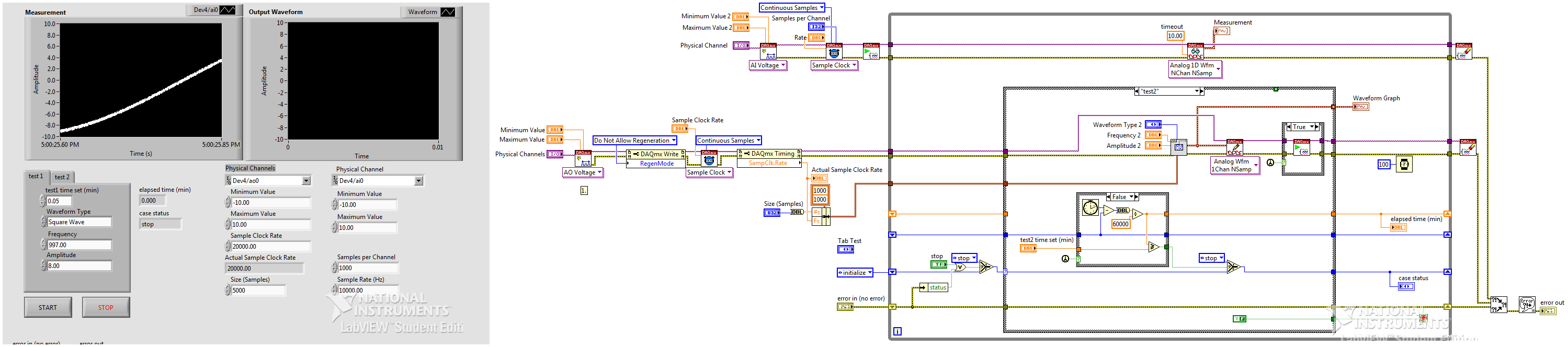

IAM trying to conduct a projekt automated, to test an actuator.

It must measure signals, process them and also has to create the actuator control signals.

So far no problem... But it must also operate 3 ditch or several rounds of tests that each has different ControlSignals.

(example: Test1 - enter: 40VSin (40 Hz), Test2 - entry: Triangle, Test 3 - input: 100Vsin (100 Hz))

It seems always not difficult enough, but as a beginner of LabView, I m having a lot of trouble to find the right Structure to achieve all this. normally I use SPS systems, but this time to Labview

Had a few trys a hav downloaded to them.

But the Structure of producer/consumer makes problems. It does not give all the ProducerLoop signals. :/

Is there a way to outher Labview programming more effective on this problem?

4 I'm sorry the bad English

Greetings

State machine...

Tags: NI Software

Similar Questions

-

Producer/consumer or master/slave, acquisition, control, analysis and recording of data

Hi all

I have NEITHER cDaq-9188 and its modules NI 9214 (thermocouple), NI 9203 (HAVE current) and NI 9263 (AO tension). I need to measure the temperature and pressure, and according to these data, I need a frequency converter to drive a compressor control. I've developed acquisition, analysis and recording program by the use of the state machine, the design of producer/consumer model and I have no doubt about their. They all work very well. Now, I need to add a control program in their. The problem is that I need to check the compressor with feedback from temperature data permanently, but I do not necessarily all the data acquired and permanently from the results of the analyses. For example, I need to record data once in 30 seconds. Which model desing should I use for this task?

Edit: I was not able to find examples of advanced program relevant to the design of master-slave model. If you know where to find them, could you write in this thread please?

The declarant buffer not data. Do only the queues. A new notification replaces the old value if she is ever read or not. You would be loss of data with the notifiers if the loop of consumers with a notification utility cannot keep up with the data that they fade.

What I show all the data buffers through the queue in the loop of the producer. The queue of the consumer removes all data and do stuff with him (such as logging) if the elapsed time is over. What is the problem with that? That is what for (imstuck) described in his message.

The other alternative is that you put the timer into the loop of the producer. Have the Boolean value TimehasElapsed drive a deal structure this place only the data if the time is over. In this case, only some data gets queued, and consumer loop removes all data as it gets and it opens a session.

-

Hello!

I noticed that the continuous measurement and a project in LabVIEW 2012 Logging using chains instead of enums and orders from the queue. I wonder if there is a good reason for it?

Kind regards

Anguel

First, string vs enum debate is probably the version of LabVIEW vim vs emacs. There are good arguments on both sides, and I doubt that there is always a "winner".

A brief summary of our reasoning for the current state of the project examples:

- We used enums for the state machine because it is self-contained. A state machine will never tell himself to enter a State, he does not know. Knowing (as the programmer) all possible States with the help of an enum allows you to enlist the compiler in order to help us avoid mistakes to change the time (because you can't quite out an enum and LabVIEW can be said if you are not covering all cases to a structure of the case, etc..).

Enums provide greater protection and rigidity by ensuring all withdrew at the time of publishing. This is often the 'default' recommendation that we do.

- We used strings for messages in queue manager because the producer of message and the message handler could be independent processes that are reused or traded. Channels avoid the need for the compiler to be able to connect the orders and push this responsibility to the programmer. This allows you to develop some sub-components independently as long as you agree to a series of channel commands that you can manage - you need not to share a file 'messages.ctl' or 'states.ctl '. It is conceivable a loop of message management a message it does not, how you can decide to either silently ignore it or will trigger an error (as we do in the model). The strings make it also easier if you want to swap the queues of LabVIEW outside by a TCP implementation for network vacilitate or intra-Processuse communication where the other end may or may not be written in LabVIEW.

Channels to provide more flexibility (that is, you can add new commands to an existing via plugins system, you can pass parameters as part of the string, etc.) at the expense of pushing her potential errors at run time and to put more responsibility on the programmer.

- The actor's gifts frame a 3rd option - using classes such as messages. For me, it combines many of the advantages of these two enumerations (strictly typed, change errors) and strings (flexible and scalable), but with the disadvantage of being somewhat less transparent (you understand OO, be comfortable to navigate through a multitude of screws, legacy of understanding, etc.).

I don't know there are other reasons, others to the breast OR had or seen as we validated models and examples of projects in-house, but here are my reasons. We know that we can not design for each situation there - our goal is to get useful models against new users to make them aware of what well thought LabVIEW programs are similar to experienced users know their applications better and I hope they do not hesitate to change what we provide or create their own designs, when they feel it's necessary. (On a side note, please share what you come up with - a community of experts sharing models would be really useful to us all LabVIEW users).

Best regards

Simon

- We used enums for the state machine because it is self-contained. A state machine will never tell himself to enter a State, he does not know. Knowing (as the programmer) all possible States with the help of an enum allows you to enlist the compiler in order to help us avoid mistakes to change the time (because you can't quite out an enum and LabVIEW can be said if you are not covering all cases to a structure of the case, etc..).

-

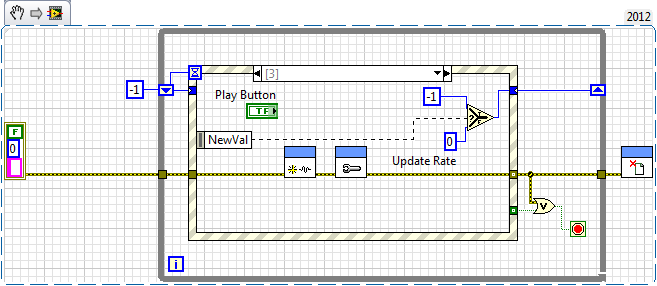

First try the producer consumer Architecture: continuous play and dynamically update settings.

Hello

I am currently working with two instruments; an Agilent E3646A and a NI 6212 BNC. My goal is to have the 6212 continuously take measures according to predefined parameters while the E3646A parameters can be continuously updated. This combination simple instrument aims to help me learn the manual architecture; continuous measurement, output dynamic controls and instruments more will be added in the future.

I've already posted on a similar, but more complicated configuration (http://forums.ni.com/t5/Instrument-Control-GPIB-Serial/Split-second-lag-when-controlling-two-instrum... and was advised to try the producer consumer Architecture.) I found the documentation on the website (http://www.ni.com/white-paper/3023/en/, https://decibel.ni.com/content/docs/DOC-2431), searched the forums and built my own VI. While my first attempt at a producer consumer Architecture has solved some of the problems I had when I posted on the subject, however, new questions have been raised regarding the reading and adoption of the VI.

I am currently able to run the VI and update the settings on the device. Previously, I'd get a freeze while the instrument has been updated and could not switch settings until it was done. This has been resolved, although that reading updates only when a parameter has been updated, although it is outside the structure of the event. In addition, the Stop button does not in any context. I also got occasional mistakes on the part of Deqeue, but the major part of the sentence is error-200279 'A tried to read samples that are no longer available' to DAQmx Read. I realize that there is a problem in my loop of producer but have not been able to find a way to solve it.

This is my first attempt at a producer consumer Architecture and already I can see that it is a powerful tool. I read as much as I could and looked at examples, but should have some problems at the beginning. Would be very grateful of any advice so I can take full advantage of the architecture.

Hope to hear from you,

Yusif Nurizade

You're going to overflow this buffer, unless the events are generated faster than "sample rate/number of samples. Period. Nothing could be simpler.

You don't need a local to stop your curls.

Try something like this attachment. I simply moved the structure of the event in its own loop dedicated since it had nothing to do with acquiring data at all.

Data acquisition loop stops very well when you destroy the task and destrying the stops of power queue (sending the default values of the queue for the power control) for EXAMPLE, to ADD a group of setting 'Safe shutdown' to a 'package' and it wire to the Center terminal (Prototype).

-

Producer-consumer - acquire and analyze different number of samples

Hello

I do some application which allows to acquire data with DAQmx with sample rate 50000 samples/s loops producer-consumer.

In the loop of the producer I have DAQmx Read function that reads 2500 samples in each loop literation. I send these data to the loop of consumers through queues.

The consumer loop I need to analyze the data, but to do what I need a second data part od (50000 samples). Unfortunately the queue gives only 2500 samples in a loop of producer literation, and the next literation queue fills with another 2500 samples.

I want to read only 2500 samples of data acquisition, because in the loop of the producer I graph which shows me real signal acquisition, and I have a quick refresh of graph (50000/2500 = 20 times per second). But in the loop of consumer I need of 50000 samples to analyze. I can't lose all the data, everything must be analyzed.

What should I do?

Concerning

Kacper

Do not stop the loop based on 50 000 samples. Only stop it when the program is supposed to stop.

Use a case structure in the loop based on the question if the 50 000 samples were acquired to determine whether to add to the table, or add the new information to the table and remove the oldest data in the table.

-

Producer-consumer mode, PDM and Acquisition journal continues

I created a VI based on events to control the parameters of data acquisition. I created a queue of producer-consumer in TDMS file in the loop of the consumer.

Question 1: Why should I get DAQmx TASK through each defined event? If I don't, I get error task DAQmx.

Question 2: I need the QUEUE of each event? If I don't I get error in the file close TDMS (consumer loop)

Question 3: When I look at the data file, I get manily in the near TDMS file loop of consumer-related. Since there is no element in the QUEUE why should - I get this error.

Please advice.

Thank you

This is certainly not how I would like to start to create a Soft Front Panel for a task to HAVE. Leave to file logging asside for now (appearing, it is actually very easy to add later.)

As food for thought - and because that create a FPS really involves a slightly different thought where you started I whip a 'start' of a FPS. It also shows how to create a simple API around a 'resource Module. (Just a natural extension of a "motor action - if you haven read the nugget of community is always a good read.") http://forums.ni.com/t5/LabVIEW/Community-Nugget-4-08-2007-Action-Engines/m-p/503801)

What I compressed is not complete - but you should get an idea of what to expand and where. You could even have there more faster here than when you are now.

An approach like that can really help when you go to unwind the problems as you mentioned in your code when you are unable to move around the information that the GUI can't really do use anyway and not IS NOT NECESSARY at this level. the guys from 'Computer Science' will use terms such as 'Hide data', "Functional Abstraction" and "Encapsulation".

The capture below is meant to tease the project so that others can get the idea of code - (sorry no LAVA TDC today!

)

) -

You want to know the NI-VISA order in measurement and Automation Explorer

Hello

I use measure and Explorer of automation to connect my equipment through LAN and it works well.

But this device does not detect my code VBA with Ni-VISA. I want to know how the software (measurement and Automation Explorer) generates the connection and reading the message of compression inside the unit.

It's my code. I check the read back value if it is "100 connection accepted."

----

Public Function VNAconnection() As Boolean

= stat viOpenDefaultRM (defaultRM)

msDly (1000)

Stat = viOpen (defaultRM, ' TCPIP0::10.85.148.60::5000: OCKET ", VI_NULL, 20000, NETWORK" ')

OCKET ", VI_NULL, 20000, NETWORK" ')

msDly (1000)

= stat viSetAttribute (RÉÉS, VI_ATTR_TMO_VALUE, 15000)

msDly (1000)

Feedbk = Space (80)

status ("Waiting for connection VNA")

= stat viBufRead (NETWORK feedbk, Len (feedbk), Actual_Length)

If InStr (left (feedbk, Actual_Length), "accepted") = 0 ThenMsgBox "error has occurred. Ethernet connection not accepted! »

NETWORK viCloseviClose defaultRM

VNAconnection = False

Exit Function

End If

End FunctionThank you

Michelle,

I found I need to add viWritebuff to * IDN, equipment, then he will answer a message accepted.

Thank you

Xin

-

acquisition and recording of analog data with producer consumer model

Someone on this forum, in a separate last week discussion, suggested that I use the producer model consumer data acq. My ultimate goal is to acquire analog channels 1-4 continuous data, display graphical band style and save the data on the boot disk when the user presses the 'Start Saving' button (and will continue to display recorder cards). Economy will stop when the user presses the button "Stop Saving" but strip map will continue to operate.

My attempt to use the producer-consumer model is attached (LV 8.5 only). It does not work. I have not tried to implement for recording user controls - just trying to make simple continuous display and save (1 channel) at this stage, using this model. VI runs, but the graphic Strip is never updated with the actual data, and the data file that is saved has zero byte inside.

Thank you.

WCR,

Looked at your code, and you are right. It won't work.

Take a look at this example:

http://decibel.NI.com/content/docs/doc-2431

The VI of the acquisition must be inserted in the loop of the producer. In addition, you must tell him how many samples for (otherwise, it will get 0).

-

overflow memory for the producer consumer

I'm trying to save data from 4 ports to 40.96 Mhz. using a producer consumer architecture and a PCIe NI 6527 B using an external clock.

I inherited code which works for 2 ports. I tried to add additional ports and changed the size of the data to the DAQ.mx queue and data. Launch the program several times, reach conflicting error messages after less than 2 seconds from the beginning:

Error 200284: Some or all of the requested samples are not yet acquired. [...] To make available samples more quickly, increase your sampling rate

200361 error: Overflow memory device on board. Due to the limitations of system and/or the bandwidth of the bus, the driver could not read the device fast enough to follow the flow of the unit. Reduce your sampling rate.

What is a race condition between the error messages, a problem of timing of start or something else?

I approach, how to debug these types of problems? How can I determine what is causing the error? I can't single step through because I'm at the wheel of sampling with an external clock.

Running on labview 2012 Windows XP on the machine who's 3.17 GB of ram.

Try to reduce the size of your buffer. In fact, simply leave the calendar DAQmx unwired. The size of the buffer must be large enough by default. And then also try to read less data at a time, as data instead of data 500ms 10ms. What I suspect here, it's that the DAQmx buffer is too large and therefore must use the hard drive for part of the buffer, to slow things down a lot.

Other notes here:

1. do not use the time-out to stop your loop of consumer. Your producer should send an order of a certain type to your consumption by telling it to stop. In this case, I would use an empty array. And then, you must release the queue after the loop of the consumer.

2. you want a constant FALSE to Append Array/String input size of the binary file write. This will remove the 2 I32s at the beginning of each table that you write. Eelle are here to tell the size of the table being written. But since you are just data flow, I doubt that you care about those.

3. instead of the entire setup of producer/consumer, have you considered using just the DAQmx Configure Logging VI do DAQmx stream directly to a TDMS file for you? Makes things much faster and much easier on you.

-

events producer consumer with notifiers

Dear users of LabView,

I would like to ask your advice on my project (see the attachment of files). For the beginning, I did only the "backbone" of my project, that's what you can see in my VI. My project will have the following features:

-Start and stop action possibly (and also plot data to the chart and saving the data to the file)--> here is some time a loop to record data ranging from DAQmx (USB6009) and another while loop with rates of different loop to rise in voltage output amplifier of the magnet.

-During the measurement, or if the system is idle, the user is able to read files of measured data and evaluate the measured data, etc... (so there will be more features...)

I decided to use producer consumer structure with events and the authors of notifications, and I also use the dynamic user event to be able to communicate to the consumer with the producer (where I have my machine of the State as in a shift register).

Please comment on my VI, what do you think? Maybe I should use the state machine (the shift with the pole of the State Register) in the lower loop? I could also use up queues of the notifier, but since I send only orders and the values of the parameters (not streaming broadband data) I guess that the declarant is fine?

Thanks for the tips!

The code you posted looks like a good start. The architecture is very similar to the measurement sample continuous project comes with LabVIEW 2012.

A few things I noticed:

- I would usually use queues instead of filers (unless you want to manage only the last command and not all orders in the order they are received).

- You don't need the registry change in the top loop (structure of the event). You inadvertently send a length of measure and other commands parameter since you replace only the command. Probably, this is no problem for now but could be a problem later.

- I think the user events are a great way to manage cases of judgment where the consumer is able to report to the producer that the application must exit loop (this is how we do in the sample project).

- Your case 'Init' confuses me a little. It is read length control measure and send a user event in the event that, in the structure turn immediately place a measure command. Once I see a control in a loop of consumer as it hurts a bit uncomfortable. Why not have the value "start_measurement" to change event read the length of measure command and send it as part of his message to the consumption loop. Then the loop of the consumer can Init and self talk to start the measurement.

- You may need to rethink your strategy mistake in the case of the measure. Currently you do not stop a loop if an error occurs, and allows you to keep the error between iterations of the loop information shift registers. Therefore, if an error occurs in one of these loops you can never hear about it.

- In general, using the error state as the main way to stop a loop from consumers is a bad practice. I'd rather see a "Shutdown" command which causes the consumer to stop loop. It is more scalable and less likely to be triggered by the accident.

Good luck with the rest of your application.

~ Simon

-

Continuously measure and write waveform using PDM

Hi all

I'm doing my thesis by using Labview 2010 (since this is the only version currently available in University

). I need to read and save data from the microphone (currently to simulate a signal because I need to make the program work first) then save and analise IT (has not reached this point yet). I tried to use the structure of the event in order to record and then play tdms files. But unfortunately it saves only a small piece, then I inserted while loop, so it will record continuously but the program is not responding after registration, I push and I can only manually close the toolbar it. Please does someone could help me or suggest that something since I'm not very good for Labview and any comment is welcome. Here's what I've done so now. I tried searching forums for a similar solution but did not find anything useful (some had a much newer version so I could not open). Thank you.

). I need to read and save data from the microphone (currently to simulate a signal because I need to make the program work first) then save and analise IT (has not reached this point yet). I tried to use the structure of the event in order to record and then play tdms files. But unfortunately it saves only a small piece, then I inserted while loop, so it will record continuously but the program is not responding after registration, I push and I can only manually close the toolbar it. Please does someone could help me or suggest that something since I'm not very good for Labview and any comment is welcome. Here's what I've done so now. I tried searching forums for a similar solution but did not find anything useful (some had a much newer version so I could not open). Thank you.Hi and welcome to the forums,

The reason why you can not stop the waveform recording or exit the application is because you have the case of the events set to "lock the table until the end of the matter for this event" (in edition events). This means that LabVIEW will not respond to the user until the end of this structure of the event, but because you have the option to press the while loop stop to complete the structure of the event means that you have a blockage and abandon the VI.

The architecture of your application is not ideal - I highly recommend everything that takes a long time to execute within the structure of your event for the above reason (obviously you can uncheck lock as a quick fix Panel). I think I have a look at the design of producer/consumer model (events) (new... > model > frameworks) because it would be more appropriate for your application. You can manage your button presses in the structure of the event and have a state machine in the loop at the bottom for starting, running and stopping of your data acquisition.

The idea is that you don't do very little inside the event structure so it frees up the façade, but the messages (e.g. power acquisition data, quit the application) are managed by another loop.

I don't know if it comes in LabVIEW 2010, but there are examples of projects that include a project in 2012/2013 "continuous measurement and logging" which may be suitable for your application. There are also examples of the State machines and managers of messages queued.

-

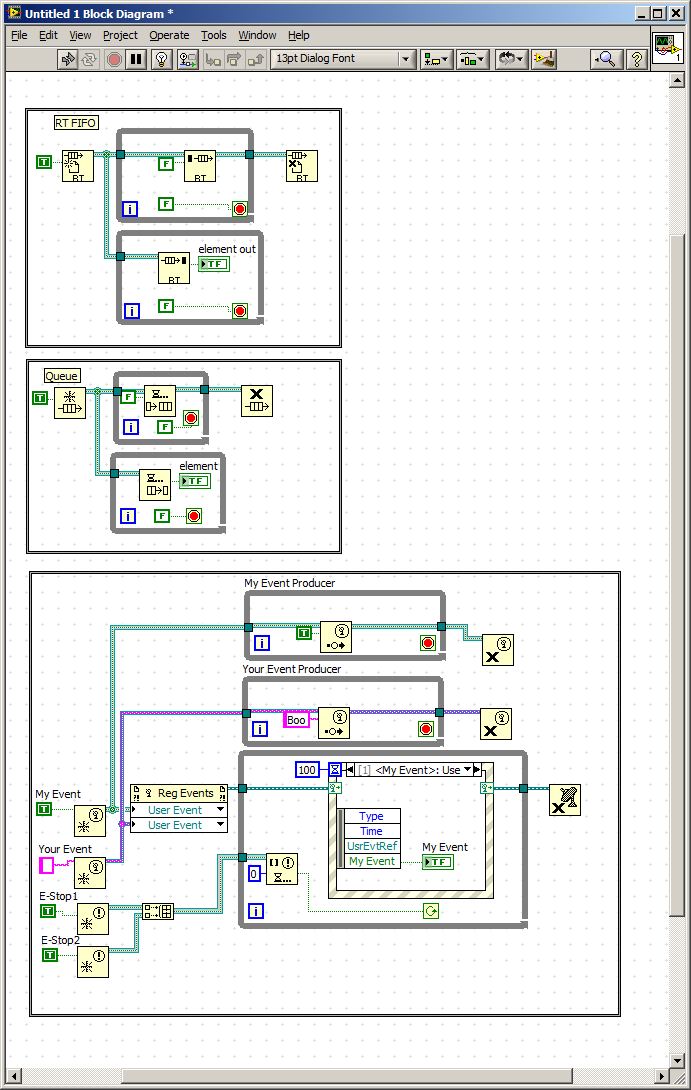

What is the fastest method producer consumer. Queue, RT-FIFO, event

Hi all

Another question completed for the pro:

I recently inherited the labview code that uses RT-FIFO for the transfer mechanism in the architecture of the producer consumer.

The code was first written in 3-4 years and is currently in LV8.6. It is possible that the reasons for the architectural decision no longer exists.

I am qualified using a producer consumer queued architecture,

I understand the RT-FIFO Architecture.

I started using an architecture based on events from the user.

(I have attached samples of each)

I also see the existence of a priority queue

Each method has its own capabilities and gaps, that hand, nobody knows the relative performance of each method.

(Assuming that the only process)

I would expect RT-FIFO to be faster, there seems to be a version of low characteristic of a standard queue.

What is the perfornace hit to use a coding user-friendly queue more

RT-FIFO description talks about commications between the time-critical and lower priority threads.

Until today, I thought that the queues had the same capacity.

I've included an event method that I commonly use for review by peers and help from other users...

It allows to:

1. several producers with different types of data

2. process 37 production order.

3 allows asynchronous verification of functional notifiers such as stop, start and abort.

4. in a system not real-time, it can include interactions of façade.

What I do not understand on this subject, that's what are overhead or thread priority changes that may occur using this architecture (it solves a lot of problems for me).

Thanks in advance,

Hi Timmar,

Here's a KB article on some frequently asked questions about the RT FIFO: http://digital.ni.com/public.nsf/allkb/7AE7075AF1B2C58486256AED006A029F?OpenDocument

The more relevant question is #4, I posted below.

What is the difference between RT FIFO and queues?

Functionally, RT FIFO and LabVIEW queues are two pads of first in, first out. However, here are the main differences between them:- RT FIFOs run deterministically in LabVIEW and evanescent code queues are not. This comes from the fact that queues use block calls during read/write to the resource shared, while RT FIFOs use non-blocking calls.

- RT FIFO are fixed size while queues develop when items are added to them.

- RT FIFOs will execute the code, even if there are input errors. They can (and will) produce new errors and spread the existing errors.

- Queues work with any type of data, while the data types that can be used with RT FIFOs are limited. Generally any type of data involving allocations of extra memory can be used with RT FIFOs to preserve determinism.

Let us know if you have persistent questions!

Ryan

-

Funky producer/consumer behavior

If it's a weird thing...

I have a loop of producer/consumer taken (especially) of the labview model is based.

For some reason when I click on the button stop to stop the program, instead he wants to run through the case of default (shown in picture) a second time. That is, I run the program, that my event, the event takes place through, I click the button stop, then the event goes smoothly once again and finally stops.

In addition, there are 2 times in my program where I record data, in the beginning where I implemented headers, and after all the data is taken. If I have the program stops after clicking on the stop button, but before the event through even once (there that while loop which is idling until I click on 'accept the level') if I abandon execution, then the previous run data not saved. (Although the 1st write to spreadsheet.vi may be overwriting the previous run data, which might be the reason why he is absent).

What I've done wrong, what makes my program run it twice?

If you are relying on the destruction of the reference of the queue to stop the loop at the bottom, wrap the structure from the bottom case with another structure of case that starts on the Dequeue elements error - use cases existing in the State without error and any special in the case of the error and discontinuing treatment.

-

error 1 to queue in a producer/consumer architecture

Hi all

I use an architecture-based on producer/consumer queue, as shown in the screenshot below (which is a simplified diagram of what I want to do).

As you can see:

1 / in the producer of the loop, I read data from two LV2: map Wafer and HAD current

2 / in the loop of producer, these LV2 are used as output of a sub - VI, called 'Wafer map change. The Subvi, allows the user to change the 'Wafer map' picture indicator located in the loop of consumption, by double clicking it.

3 / when the Subvi has run, it displays the picture indicator updated (Wafer card) and the new 'Course DUT' coordinates.

4 / the two variables are grouped and transformed into a Variant.

5 / the variant is then enqueud in the queue of the 'hand '.

6 / this variant is converted from inside the loop of consumption, and photo indicator is unbundled.

7 / Finally, the map LV2 Wafer is written and the modified photo indicator.

This type of data flow worked earlier, but now I am facing the following error (it's my french translation):

Error 1 occurred: Add an element at the end of the queue in GUI.vi of automatic Test Bench

Possible reasons:

LabVIEW: An input parameter is not valid. For example, if an entry is a path, it may contain a character that is prohibited by the operating system, as? or @.

NOR-488: The command requires a PDC GPIB controller.

I have no idea how it appeared. But now I'm stuck, and I would be grateful if someone can help me with it.

Thank you.

Kind regards

Florian

Your method to allow the judgment seems suspicious. Say that there is an error in the loop of consumption. This stops the loop of consumption and the stop button set to TRUE. But the value of the stop button will not be read until the next iteration of the loop of producer. So if you decide to hit the button on the Insert, the queue was already destroyed, then you will get your error. And all these local variables just shouts "RACE CONDITION" for me.

Get a mechanical action of the Stop button latch when out. It is the default setting for a button. Then place the terminal inside the event (which you already have). A REAL outside this case, wire OR with wire error to stop the loop of the producer.

You need to do is create a command to stop the loop of the consumer. This order will be sent in the case of changing value of stop button. You should probably send this command after the loop of producer, just in case where the loop of producer created an error.

You can also use a node property of the button stop to set the Value property (signs). This will cause the structure of the event to raise. This will cause the producer loop stop if the consumer has an error.

-

best way to handle this situation of producer-consumer

It is, I know a common thing, however, I never really thought about before. I can't post my VI so a description will have to do. It goes without saying, but again, it's producer-consumer architecture. Let's say you have a generator of signals and all the controls that are in a cluster. A value is changed, an event in the loop producer and you compare the old and new values to determine which button has changed the lights. Cool, all good. While I have the tail a State front reading in my loop prodcuer who is corresponding in my loop of consumer. The State of reading front load all the new values in a cluster that is then introduced into a shift register be accessible from anywhere in my code (see here).

Now my question is, what would my next state that I have the tail? If I have a single "send commands to the gen GIS", in my loop of consumer I have again to determine the value that has changed in order to know what order to be sent (because the initial determination of what has changed in the loop of the producer). However, if I have an individual for each order state that I want to send, my business structure will get very large, very fast.

Last option is to have a send order status and just write all the data on the only value of a control change, whether it is new or not (which seems an exaggeration).

Suggestions please?

For situations of this kind, I would not send a 'State' to the consumer. I send a '' command. '' When the consumer receives a command, it determines if this command is executed immediately, or if he completes the task of process and then manages the new command.

With the command I send one or the parameters. For your signal generator parameters would probably be something like a bunch of 'control ID' and 'value '. Control ID would probably be a typedefed enum and value a DBL.

What ever you decide, think, plan and document before code you.

Lynn

Maybe you are looking for

-

Satellite Pro 2100: PCI Wireless card

Install a PCI card Broadcom wireless and need to know where the overhead wires are routed (screen or base) so that I can try and extend one is short of 1 cm-oh and make black and white colors correspond to large and in the?

-

You attempt to add an iCloud account but the iMac is asking password iMac

When I try and add an iCloud, after the seizure of the user and the password account, he then asked the password "iMac". I enter the one associated with the user account on the iMac, but it fails and says the password required is not the password of

-

I was downloading addons for a game on the internet and then later the next time I turned on my computer, it said I was missing the csrss.exe file and so I searched for it looking to see if I somehow accidentally moved and he didn't so I was wonderin

-

I have updated Sony Bridge for latest Mac 3.5, so I can sync the phone and my Mac. The phone is detected-very well, I can't just transfer data between the phone and the computer. I can't move photos from the phone to the computer. I can't move music

-

After installation of sp2 to vista my sound does not work.

I've tried everything. Uninstalling my drivers and re - install but it don't seem to work. any advice on what I should do?