NI 9205 of i/o data acquisition

I use 4 channels Ni9205 of DIFF mode. When I did the test with the generator voltage, I have sons only entered the channel 1 (AI0, AI8) and channel 4 (AI4 and AI12), however the data I loggered shows a weired problem. Channel 2 and channel 3 showed the same profile as the signal of channel 1, only the Channel 4 is different because I have applied a different voltage. The scale seemed well loggered, channels 1 to 4 have given values that should not be.

Hello again.

I had a quick glance at this and it seems that ghosting is the question. As a quick fix, you can wire all of the channels not used to the ground. The earth pin is named "COM" (to the public) and there's pin 17.

I think you see only the ghosts because signals that you are running a test, in which the 9205 tries to scan all channels. When you start working with the contributions actual and reasonable size tensions that the 9205 should be determined between the connected and not connected channels and read that the connected channels.

If the problem persists, I recommend that you take a look at this article:

http://digital.NI.com/public.nsf/allkb/B9BCDFD960C06B9186256A37007490CD

I hope that helped, good luck with your application!

Tags: NI Hardware

Similar Questions

-

Sample clock dependence with small signals data acquisition

Hi all

I use a NOR-9205 on a NOR-cDAQ-9184 and noticing some interesting dependencies of waveform on my sampling rate selected. It seems that small changes in the sample clock frequency have a significant impact on the measured waveform.

Quick background, I am in a position a signal with a ripple of mV ~ 10 with V 1.6 bias. I'm not interested in DC, only the AC signal but the NOR-9205 has only DC coupling. The application is a circuit where I expect simulations noise past the circuit must be greater than the higher noise frequencies. In the waveforms attached the background plot is the applied signal, and the top graph is the signal arising after that the signal was mostly annihilated. The two waveforms are measured with the NOR-9205.

I am aware that this measure is less than the precision of the NOR-9205, which has a maximum precision of ~ 3 mV in his +/-5V range. However, if I can't at least on the basis of shape which is good enough for me. I'm also now pretty curious that data acquisition is actually to create this

My best idea, is that it is a product of internal multiplexing of the 9205 with the DAC.

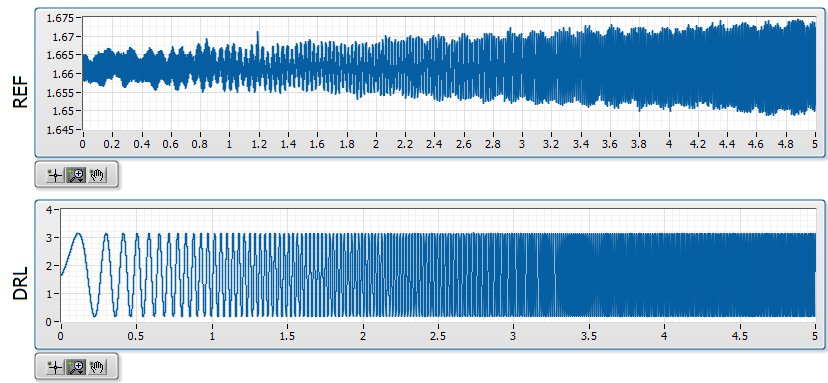

The first plot shows the waveform at 20 000 Hz, which is what I expected:

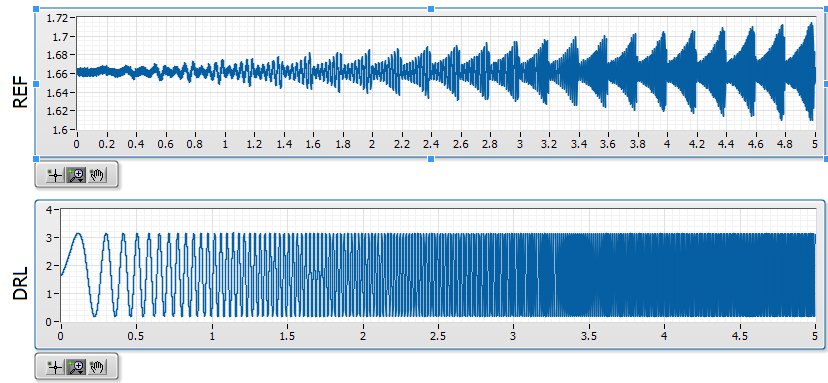

The second shows the waveform at 20 001 Hz, which seems to be modulated with a backup sawtooth:

The waveform looks as expected for 20 000, 20003, 20004, 20005, 20008, 20009, 20010 and Hz 20011. The waveform looks like modulated to 20001, 20002, 20006 and Hz 20007.

Ideally, I would like to understand this problem so that I can configure the measure in a stable way that I can count on the basic shape of the wave. Has anyone seen something similar?

-

I get upgraded my laptop (HP for laptop - 15-r224tx) for Windows 10 but I can't find the driver for the controller of PCI Data Acquisition and Signal Processing. Please help me find the right one.

Thank you!

You are the very welcome.

It is the latest version of the W10 driver for this card model... see if this solves the problem, if you have not already installed this driver.

This package contains the installation package driver for the controller wireless LAN Realtek RTL8723BE/RTL8188EE in the laptop models running a supported operating system.

File name: sp72517.exe

-

PCI Data Acquisition and Signal Processing controller driver

I installed win 8.1x64 on my HP Probook 450 G2, but miss me the driver of PCI Data Acquisition and Signal Processing controller.

Can you please help?

Thank you

Leontina

Hello:

Please see if installing the Intel Chipset driver installs this device.

https://Downloadcenter.Intel.com/Detail_Desc.aspx?DwnldID=20775 & lang = eng & ProdId = 816

-

I just installed Win7 Pro x 86 on my Z600 workstation. It was an upgrade to Windows XP Pro. I'm missing the driver for PCI Data Acquisition and processing of the Signal and Hardlock USB 1.02 controller in Device Manager. Can someone help me find these drivers. I looked on the page of Support/Drivers for this model, but could not find anything.

Hello

You can get assistance on the HP Enterprise Business Forum since you have a professional worktsation.

-

Hello

Need driver for PCI and Signal Processing controller HP 240 G4-328TX Data Acquisition

Can anyone provide me please the link for download it for windows 10

Thank you

Hello:

See if this driver works...

-

Hi, it is impossible for the moment to install the driver for PCI Data Acquisition and Signal Processing.

I downloaded the driver from Intel, and it did not work... I found a version of this site for windows 8.1 unupdated and it does not work.

A little help?

Thank you!

Hello:

It could be one of two different drivers.

Try this one first, and then restart the PC.

This package contains the Intel Chipset Installation utility. This utility allows the operating system to show the correct name for the Intel hardware that is installed in the Microsoft Windows Device Manager. This package is provided for the laptop models running a supported operating system.

FTP://ftp.HP.com/pub/SoftPaq/sp75501-76000/sp75561.exe

If this does not work, try this one...

This package contains the driver which allows Intel platform dynamic and thermal firmware setting. Intel platform dynamic and thermal environment information system temperature and power use for the thermal protection of the system to work properly. This package is provided for the laptop models running a supported operating system.

-

Hi team,

I just install windows 7 edition integral and peripheral Bluetooth windows 8.1 is not be detectable, when I search for problem that I came across this PCI data acquisition and Signal Processing controller driver is missing and a unknown device driver missing shownup in my result of troubleshooting. Please help me

Please find the screenshot for your reference

Thank you

Hello:

See if these drivers work...

CQI PCI controller:

This package contains the driver which allows Intel platform dynamic and thermal firmware setting. Intel platform dynamic and thermal environment information system temperature and power use for the heat of the system

protection to work properly. This package is provided for the laptop models running a supported operating system.File name: sp71638.exe

Bluetooth:

This package contains the installation package driver for Realtek bluetooth in the laptop models running a supported operating system.

File name: sp71288.exe

Unknown dev:

This package provides the HP 3D DriveGuard software (HP ProtectSmart Hard Drive Protection) for the laptop models running a supported operating system. HP 3D DriveGuard software protects the drive hard by parking the heads if cell phone accidentally falls, or is suddenly struck by another object.

File name: sp71811.exe

-

15 - r235ne: SM bus controller / IBD DATA Acquisition and Signal Processing controller

Hello team

I am facing problem in finding the right driver for material below.

1 SM bus controller

2 IBD DATA acquisition and Signal Processing controller

kindly help

concerning

NASIR

Hi, Nguyen:

Download and install the Intel chipset installation utility and restart the PC.

The 2nd driver down on the left is the automatic installation file.

-

Data acquisition reading incorrect when you use a loop

Hello

I wrote a simple VI (00, 01, 10, and 11) output to a circuit connected with 4 resistors. Based on what value the ciruit receives, it passes current through a particular resistance. It is again entered in Labview and traced.

The problem is when I send a particular value (i.e the 00, 01 and 10 and 11) and get that back, it's okay. But when I send and receive the consectively connected via the loop counter, they are incorrect (not synchronized with the number of the loop).

I made sure that circuit works very well. It has something to do with the loop synnchronization, reset, value compensation, etc. can be.

Please Guide...

Change your DAQ assistant that reads to be 1 sample on request.

Right now it is set for continuous samples. And 10 samples at 10 Hz. Then it runs and starts. The next iteration, you send a new digital out, but the wait for 4 seconds. When you read again, you get the next 10 samples that are put into the buffer of data acquisition, but now 40 samples have actually entered the DAQ buffer. In time your DAQ buffer will be finally complete and raise an error. In the meantime, you will continually read data continues to become more tainted by the iteration.

-

Is it possible to change the name of data acquisition device?

Hi all

Is it possible to change the name of device of data acquisition in a pragmatic way?

I wish I had at the beginning, when I start the data acquisition control a name that my .net program assigns to the DAQ card. Is this possible?

Thank you

Virginia

Ashly thanks!

Virginia

-

motion control for vertical actuator and data acquisition

Hello

I am a researcher (a branch of civil engineering) geotechnical engineering and I have very little knowledge about the acquisition of control and data motion, so would need a lot of help from the experts OR. I have only knowledge base on these 2 aspects based on my reading of some materials on the Web site of NOR and youtube videos, so I hope that you bare with me

. Here are my questions:

. Here are my questions:I am trying to build an actuator which will be used to push a probe (a penetrometer with a load cell to measure the resistance of a soil sample), resembling the concept, photography in the attached file. I need to have these criteria for my system:

(1) actuator, which can push the probe at speeds between 0.01 mm/s - 300 mm/s with precision and move the probe cyclically (upwards and downwards) in the vertical direction

(2) load expected on the probe into the ground range: 0.02kN - 6 kN.

(3) necessary to get the load cell load data and the speed of the probe.4) able to control the actuator to a PC (speed and posotion) and monitor data from transducers and data log time even the transducers.

Guess my beginners is that I will need:

For orders:

(1) software - LabVIEW and NOR-motion assistant(2) controller - NI PCI-7342

(3) driver/amplifier - analogue servo AKD Drive

(4) motor - motor brushless servo AKM

For the acquisition:

(1) software - based LabVIEW development systems(2) amplifiers or other device - no idea what type on the conditioning of signals

(3) data acquisition device - no idea what type

Since I'm a beginner, is - that someone might recommend components (hardware and software) for the control and data acquisition. I'm on a tight budget, so I thankful if someone could help me to recommend components good enough to build my system.

Thanks for your help.

At these rates, you will need to run the sensor for the cDAQ. You can configure the analog output on the Tritex nationally on the position. There is an adjustable filter that you can set in order to get a clean enough to 300 Hz signal. When you learn about the Tritex, make sure that let you them know what comms and e/s that you want to use. If I remember, not all options have worked together. The analog output may need to be my, but you can put a resistance through the acquisition of input data to get the voltage instead. I don't remember all the details. You should really not too much on the Tritex/LabVIEW side. You will send your movement parameters (beginning of end of race, speed, position, accel, cut), and if you cycle (I believe you) or simply running in a loop. You could also just be able to use the functions of jog. When you get close to knowing exaclty what you need, PM me and I'm sure we can work something out with the drivers. You need only the basics. In fact, you could probably do this all your movements via digital and analog i/o.

-

data acquisition won't taste at the specified rate

Material: C - DAQ 9178, AI 9239, inside a servo and an encoder potentiometer module

Setup: I use the 9239 to measure the angular position of my servo and encoder of trees by streaming came pressure pot of the servo and my encoder. I put the sampling frequency on the DAQmx - Schedule VI to 100 Hz.

Problem: I don't think that my DAQ is sampling data at 100 Hz because my VI registers more than 10 000 data points for a 10 second test. In addition, every time I have save my data in a text file, the vector of time my test data resets after a number of iterations.

To debug, I tried the following configuration:

I've defined the sampling frequency of 100 Hz (or is that s/s?), the samples per channel (size of buffer for continuous mode) at 2000 samples, number of samples per channel up to 10 and loop milliseconds timer on my VI at 10 m accordingly, data acquisition would send 100 samples per second (or 1 sample every 10 ms) on my PC buffer (which could store 20 X that amount). Then LabVIEW would read up to 10 samples per loop iteration (which is itself ~ 100 Hz) and work with these 10 samples inside the loop. However, since the loop is operating close to the sampling frequency of data acquisition, then LV should only work with 1 sample each iteration of the loop (100 Hz / 100 Hz)-not the 10-sample-max that I specified.

However, I stumbled on "error-200279: the application is not able to cope with the acquisition of material" when I ran the program. Why?

My code and materials should be easily able to cope with data acquisition - at least the way I put it in place

This whole situation wondered my fundamental understanding of data acquisition timing, so I would really appreciate an explanation of exactly how to deliver DAQmx uses data synchronization, why my DAQ sample at 100 Hz, and how can I fix the calendar specified by the user.

Thank you!

aeroAggie wrote:

The C - DAQ 9178 there some minimum sampling rate I will not meet?

It's actually the 9239 that limit your sampling rate. Read the data sheeton page 5 there's available data rates. In short, your data rate allowed is 50kS/s / n, where is goes from 1 to 31. 50 k/31 gives you 1.6kS / s. So, it's the minimum sampling frequency that can be used.

-

Digital relay of data acquisition

Hello

I quickly ask you questions. Can I connect several relay digital for single block scb - 68 (data acquisition is: 6321 PCI)?

With Labview, I want to enable or disable each of these relays. Is this technically possible? because never, I have connected several sensors to scb - 68.

Each relay acts as a binary switch to a motor brush continuous (3-12 v and RPM motor voltage: 11.5 krm with weight)< 80="" grams).="" the="" dc="" motors="" will="" receive="" power="" from="" external="" dc="" power="" supply="" unit.="" so="" the="" power="" for="" the="" relays="" (i="" am="" thinking)="" must="" be="" from="" daq.="" but="" i="" know="" daq="" can="" supply="" only="" very="" very="" less="" current.="" i="" am="" trying="" to="" source="" out="" if="" i="" can="" find="" relays="" that="" run="" with="" very="" current="" (which="" could="" be="" supplied="" by="" the="" daq="" itself)="" can="" you="" suggest="" me="" if="" this="" is="" possible?="" and="" also="" any="" information="" or="" source="" for="" the="" required="" digital="" relays="" would="" be="" lot="">

Thank you

MSC

-

DSA maxing out CPU data acquisition

I'm developing an application on a PXI-8196 (Windows XP) controller that uses a card PXI - 4472 DSA to read a single microphone and a FFT signal analysis. I need solve the two frequencies of 36kHz (and), so I've planned for sampling 96 kech. / s. I wrote a simple loop of data acquisition, configuring NI44xx DAQ/read screws using read the string unique at this rate, but when I run it, it immediately pegs my CPU 100% usage. So far, I did have problems with missing samples or the system crashes, but I am a little concerned that only data acquisition uses all my CPU time. Y at - it tricks that I can implement to reduce the CPU load?

I tried to vary the parameter samples per channel - with sizes ranging from 1000 to 48000 samples - buffer but I do not seem likely to reduce the CPU usage. Changing the sampling frequency affects the CPU usage (up to about 40% to 48 ksps / s; ~ 75% 72 ksps / s), though. According to this KB: http://digital.ni.com/public.nsf/allkb/D9DDF9FA02D1C18A86256EBC0016C93D

"A controller Embedded PXI-8176 can compute all the time of the spectra of FFT power on 8 channels for PXI-4472 clocked at 102.4 ksps / s »

so I think with my 8196 I should have no problem at all to read only one channel 96 kech. / s.

Anyone have any suggestions to reduce my CPU Overload? Thank you!

Here is a link to some good information on how to OR-DAQmx 7.4 and later behaves with respect to the use of the processor: Default CPU use with NOR-DAQmx Version 7.4

Maybe you are looking for

-

How to customize the status bar, to see the send/receive status bar

I have TB 24.4.0 on computers both Win 7 and Win Vista.On the installation of Win 7, I can (usually *) see email send/receive progress in the lower-left corner of the status bar (for example "Inbox to check for new messages", then POP3 for my various

-

Satellite P10 - after installing XP, the SD card reader does not exist

I formatted my Satellite P10 and complete nine with XP SP1 installed. Since that time the integrated SD card reader no longer exists in the system (when I insert an SD card it doesn't work). Is this a problem with a driver or what can be the problem?

-

Question of generation of scripts or VI

Hi Experts, I have question about scripts... or maybe that is not . In VBAI there is a feature: Labview code generation. How this feature implemented without scripting? I have Labview 2009 SP1 and tried the generation of code VBAI VI. Is that what th

-

automatic search starts on fast by clicking on

Sometimes, when I'm game and get in a panic situation and quickly, click on my (set to 'r' for run) programmable mouse button, it opens a windows search and of course the search engine is a priority for windows, it minimizes the game and I got a litt

-

Open manage - can be used on a cluster NIC.

The subject is a little weird and don't know where to put it, but here's the situation. I have a Power edge 515. I have two GB NIC. I noticed on my a hostname called idrac-1SNMFP1 DHCP server. I have never see this before. It was just sort of. I pin