NI USB - 6212 BNC analog input impedance matching

I just ordered a case NOR USB - 6212 BNC DAQ (should be delivered soon). I want to use to measure HV signals using a probe of high voltage of 1/1000 I have.

Now, datasheet of the probe (not a lot of info) says it has an impedance imput 100MOhm. I suppose that it consists of a simple resisitve divider, and if the ratio is 1/1000, I wait so to have a 99.9MOhm resistance in series with a 0.1MOhm resistance. However, the data sheet also specify that the probe is designed to be connected to an oscilloscope with an impedance of 1MOhm. As this input impedance is very low compared to the low value of the separator of resistance resistance, so I guess that the real resistance at the level of the sensor values 99.9MOhm and 0.11MOhm (to obtain the 0.99 and 0.1MOhm when it is connected to the oscilloscope for 1mW).

Therefore, given that the impedance of the USB-6212 according to the datasheet, the analog input is > 10GOhm, I expect to measure higher to true alternative voltages when connected to the acquisition of data from 10%. This assumption has a meaning?

What would be the best way to get around this? Do a calibration and correct the values acquired in LabVIEW code? Or should I add precision 1MOhm resistance at the same time to the acquisition of input data to decrease its resistance to entry to the value expected by the probe?

Thanks for your help!

Since you have a range of 1000: 1 I guess you also need bandwidth (I have a TEK 6015 A  ), so you need based on the impedance input, a complex value, means he must not only watch but also the ability to input resistance (1 M). demarcation of the field probes have usually some elements of toppings to match the probe and the input scope. RTFM of the help of the probe

), so you need based on the impedance input, a complex value, means he must not only watch but also the ability to input resistance (1 M). demarcation of the field probes have usually some elements of toppings to match the probe and the input scope. RTFM of the help of the probe

BUT a more serious point is that with your probe, you have a very high resistance. And if you look in the specification of the 6212 you will find on page 2 by mistake ppm in logarithmic scale graph! and even 100 k source impedance it not shown.

So I'm afraid that a simple 1 M on the DAQ entry can work if you're only measuring DC, and only if you use a channel on the acquisition of data. A workaround is an amplifier separate buffer with an impedance of good entry corresponding to the specification of your probe and a low output impedance.

Tags: NI Hardware

Similar Questions

-

Can I feed 12VDC in a USB - 6212 BNC?

I want to follow a circuit that alternates between 0 and 12 VDC. The voltage level will be always equal to 0 or 12VDC.

I can feed this tension in one of the channels I my USB - 6212 BNC or going to fry something if I do. AI channels on the unit are only rated to +/-10V. I don't like to get an accurate reading of the voltage. I just want to see if the signal is high or low.

Thank you!

Hello

Here's the surge card for this map:

Surge protection (HAVE <0..31>, AI SENSE)

Device on... ±30 V for up to two pins of I

Device disabled... ± 20 V for up to two pins of IMy max current during the surge of input pin of ±20 State / I

So you can integrate 12VDC into your Board and not with precision the measure, but you should be in form do not damage the card. If you can turn the voltage down or use an external circuit to reduce the voltage in the specification of the Council, it would be better to ensure proper operation and extend the life of the Board of Directors to the extent.

-

Can't see the rise on a USB 6212 BNC channel time

Hello

I use an acquisition of data NI USB 6212 BNC to monitor the rise time. A single channel (AO0) is used to define a voltage all followed another channel (AI1). The problem I have is that I'm not able to see the rise on AI1 time, only a jump to the specified voltage.

I started to edit one of the material examples. Initially, I have connected the two channels via a BNC connector to BNC cable but thought I better with a simple circuit. I set up a resistance on a model and connected my channels accordingly with crocodile clips. Unfortunately, the result remained the same and all I see is a jump to the previous setting in tension (usually 0) to the new I entered with a infinite slope (vertical line).

I am fairly new to DAQ and plan to work with it for a while. The simple circuit will be expanded considerably in filter tests and other applications, but for now, I have to get the basics. I would appreciate help, that you can offer; only currently, my thoughts are if this could be a sampling problem (I put it to 400000 above) and if I may add a ceiling to slow things down. I want to get this to work, however, so I could develop by looking at rates of filters and sweep of the go-around.

I enclose my screws in the hope that they will help you decipher the problem. Have tried different combinations on DAQ Read and Write with single or multiple and 1DB/Waveform channel, although I'm pretty green in their functioning, without success.

In hoping to hear talk about you,

Yusif NurizadeYusif Nurizade,

What type of signal you generate on the AO line? The default value in the output array is a single element zero. That didn't exactly have a rise time!

To measure rise times sampling on the line frequency should be fast enough to get samples of several over the course of the rising part of the measured waveform.

The signal on the AO line will always be in the steps from one value to another. This is the way of working with D/A converters. 6212 specifications indicate a speed of 5 V / us. If two successive samples were 0 to 10 v it would take exit 4 move us from one value to another. Same samplng HAVE it line 400 kech. / s, you would get no more than an intermediate value and would not be able to measure the rise time.

Try putting an R - C circuit with a time constant on the order of milliseconds between connections AO and AI. You should be able to measure it.

Lynn

-

PCI 6221 analog input impedance?

Hello

I have a card PCI-6221, I know the impedance of an analogic imput?

Thank you.

Hello

As shown here, when the device is turned on, more than 10GOhm in parallel with 100pF

-

Digital and analog inputs simultaneously - NI USB-6009 and NI USB-6212 - ANSI C

Hello

I'm reading at all times and at the same time analog and digital inputs. Digital and analog samples must be sampled at the same clock and acquisition should be started (triggered?) at the same time (I don't want, after some time, analog reception more digital samples - the opposite is also true).

I found an example (in C source code) "National Instruments\NI-DAQ\Examples\DAQmx ANSI C\Synchronization\Multi-Function\ContAI-Read dig Chan" and tried to run with two USB cards: NI USB-6009 and NI USB-6212. Unfortunately, the two results by mistake, as described below:

DAQmx error: the requested value is not supported for this property value.

Property: DAQmx_SampTimingType

You asked: DAQmx_Val_SampClk

You can select: DAQmx_Val_OnDemandTask name: _unnamedTask<1>

State code:-200077

End of the program, press the Enter key to exit-Is it possible sync analog and digital acquisition in the paintings?

-If so, how?

Thank you

Hello tcbusatta,

Two of these modules, USB = 6008 and USB-6212, support only timed software inputs and digital outputs. This means that you cannot define material timing (like finished sampling or continuous) for these modules. Digital lines can be retrieved or written once to each call DAQmx read.

This means that you will not be able to get any type of synchronization tight between the analogue and digital channels. You will need a Board such as the NI USB-6341 in order to synchronize the AI and DI closely.

-

USB-6212: software problem timed task of analog input

Hi all

I have unexpected behavior using a USB-6212.

The code example shows that when I run in sequence two analog DAQmx to task, material entry first a timed, the second software timed, it happens that the first readings of data are all wrong and have the same value for all channels.

The labour code is the following:

GetCtrlVal(panelHandle, PANEL_HW, &Switch); if (Switch) { // // First Task: read 10 rows of values with hardware timing // DAQmxCreateTask("", &htAI); DAQmxCreateAIVoltageChan (htAI, MX_DEV_AI, "", DAQmx_Val_NRSE, -10.0, 10.0, DAQmx_Val_Volts, ""); DAQmxCfgSampClkTiming(htAI,"", SAMPLE_RATE, DAQmx_Val_Rising, DAQmx_Val_ContSamps, 1000); DAQmxRegisterEveryNSamplesEvent (htAI, DAQmx_Val_Acquired_Into_Buffer, SAMPLE_RATE, 0, RefreshCB, NULL); DAQmxStartTask(htAI); Delay(1.0); DAQmxStopTask(htAI); DAQmxClearTask(htAI); } // // Second Task:read 10 rows of values with software timing // DAQmxCreateTask("", &htAI); DAQmxCreateAIVoltageChan(htAI, MX_DEV_AI, "", DAQmx_Val_NRSE, -10.0, 10.0, DAQmx_Val_Volts, ""); DAQmxStartTask(htAI); for (i=1; i<=10; i++) { DAQmxReadAnalogF64(htAI, 1.0, 10.0, DAQmx_Val_GroupByChannel, AcqVoltRow, HW_AI_CHANNELS, &read, 0); SetTableCellRangeVals (panelHandle,PANEL_SOFT, MakeRect(i, 1, 1, HW_AI_CHANNELS), AcqVoltRow, VAL_ROW_MAJOR); Delay(0.1); } DAQmxStopTask(htAI); DAQmxClearTask(htAI);A picture is worth a thousand words: analog inputs have been connected to a network of resistance have known values.

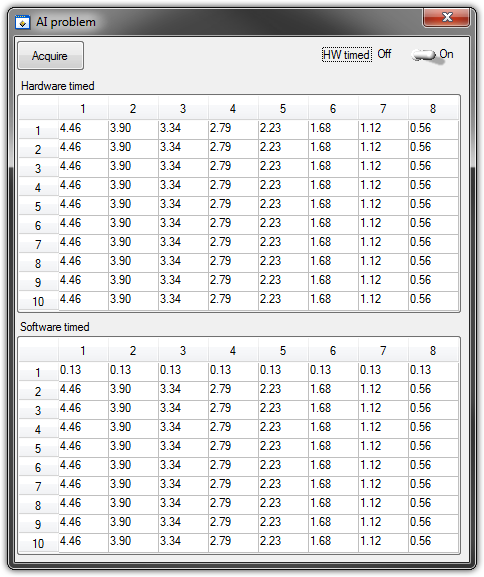

The upper table contains timed material acquisitions, the lower the software timed readings... as you can see it the first line is the set of values of 0.13, totally wrong

If the task of timed acquisition of software runs without the earlier (in my demo, that this can be achieved by the switch at the top right), the readings are correct!

Y at - it something I am doing wrong?

I also tried to run the program on USB-6009, but it seems to work properly.

[LabWindows/CVI 2010 SP1 - driver OR-DAQmx 9.4 - Windows 7 x 64]

This problem was corrected by NOR-DAQmx 9.5

324044 NOR USB-621 x task HAVE request returns incorrect data after erasing a task HAVE stamped

-

NI USB - 6259 BNC DAQ: analog input signal cross on the question

Hello

I use the NI USB-6259 BNC DAQ unit to acquire a four-channel analog signal, and I'm having a problem with a signal that affect others. The circuit, I am running is:

I have a wire connected to a battery (two AA batteries at ~1.5V), which then feeds the signal cable to a BNC cable, which feeds an analog BNC of data acquisition channel. The field of NBC feeds to another wire, which is attached to a conductive plate. The idea is this: when I touch the wire connected to the battery for the metal plate, I complete the circuit and thus get a binary not anything at all about 3V. When I tested with an osciloscope using two channels (each earth connection to the metal plate) I get independent steps whenever I touch any of the sons of the respective batteries to the metal plate (i.e. it works as expected). However, when I use it with data acquisition, whenever I touch a wire, I get a response in all other channels (3 others), even if their respective sons does not touch the metal plate.

No one knows why this happens, and how I might be able to stop this 'cross-talk '?

Thank you

Veritas

I see, and you're right. This request will have trouble with crosstalk. Luckily the ground channel thing should help you.

Configure your DAQ to collect twice as many channels as you need. Connect your wires in the odd channels and short circuit (ground) the entries of those even.

Now when you scan the channels it will always technically crosstalk, but it will come from a channel to the ground so that there will be nothing to interfere with your measurements.

At least that's the theory.

-

Generation and acquisition of analog signals simultaneously on USB-6212

Hello, I am novice programmer DAQ trying to create (what I think is) something very simple.

I use a box NI USB-6212 and LabVIEW 8.5 is trying to generate a pulse train analog while recording a simultaneous analog input.

My first question is, is it possible?

Since I'm new to this, I use the DAQ assistant in LabVIEW. I can acquire a signal, I can also generate the desired signal, but I can't seem to operate simultaneously.

I have been successful in obtaining my program to work with both USB-6212, but I have to be able to do this with a single.

I have attached the block diagram and vi, I hope that's easy to answer the question, even if my research so far has left me empty handed.

Any help would be greatly appreciated!

Jon L

Hi Jon,

Well, first of all welcome to the DAQ programming! I took a peek at your code and published it with a device simulation very well, so I ran with the PCI 6251 card in my computer and he did not also get errors. Could you post the error code you get?

If I could figure out what is your error, I would say you encounter errors of buffer because it is too much overhead in the DAQ to wizards in the face of data rates. My suggestion would be to use the example called "Multi-Function Synch AI - AO.vi. This program can be found in the Finder for example of NOR (see Help"find examples in LabVIEW). "" It appears in the input and output material"DAQmx ' synchronization ' Multi-Function.

Can you give that a try and let me know how it goes? Thank you!

-

Several analog inputs seem to change any of the other (details DAQ: 2120 BNC and 6062E)

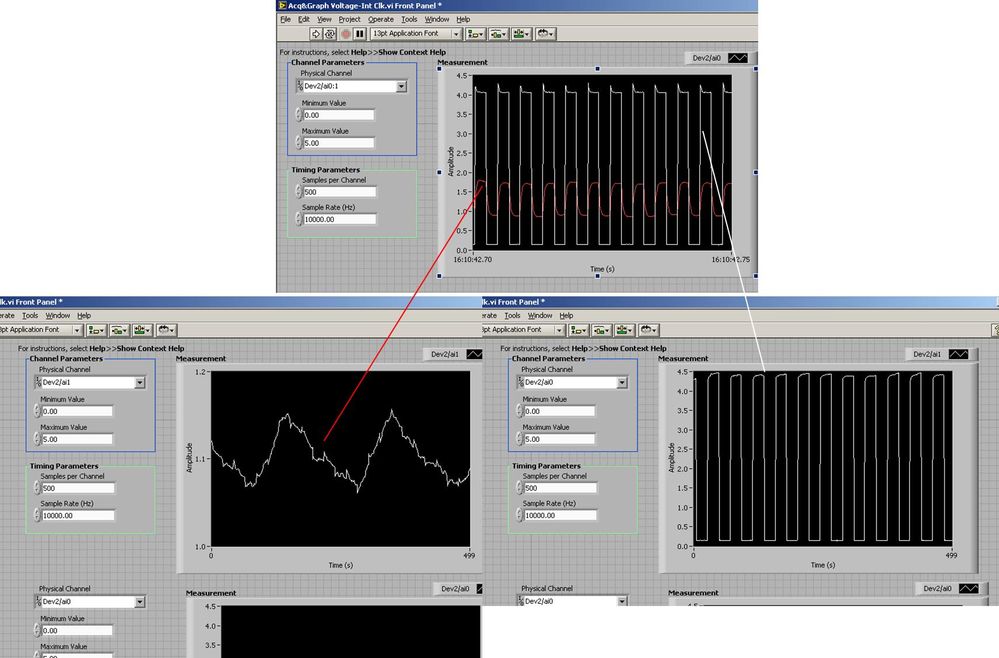

I use the BNC 2120 DAQ board connected to the data acquisition card 6062E to record two analog inputs. An entry is connected to ai0 and the other at ai1. Example vi: "Acq & graph int clk tension" has been used to measure the two entries with the value read NChan NSamp vi (channels being dev2 / ai0:1). The output is the top graph in the image. However, this seemed a bit strange to me that one of them should be modulating with a different frequency. When I record both entered individually (two in low pictures) they are indeed different since the entries shown in the top graph.

Why this would be the case, and how can I overcome this to measure the real signals?

Thank you!

The E series card takes the samples as soon as possible. Thus, for example,.

If you have 16 analog input channels but you only read of

channel 0 and 1, the map will show the channels 0 and 1 right

After and then wait 14 'ticks '. What's that little run-in

the origin of the afterglow.

I think you can get the card to wait a certain

number of ticks with a property node. I have attached a screenshot. You

can find the property node in the palette of functions >

Measurement of e/s > NOR-DAQmx > node Timing. Expand it

Property node so there's two entrances. The properties are in

Left click on the node and going more > converted >

Its properties delay units and sampling clock delay and delay that

you want.If the phase is important so the above is not the best

the option because it causes a delay in phase. So, if you need true simultaneous

sampling, then you will need different hardware. The S series is everything

simultaneous sampling.Or, rather than the Delay property and delay units, try the Rate property

find more > converted > rate.If this is not

work either, you can move the second signal source to, say, AI8 and

Connect everyone to the ground. Readings for these, but just do not take into account

the data. In this way the ADC will sag to the ground at the time where that can happen

the second string in the way so that you should not see this frequency

ghosting on the other channel. -

Using the DAQ USB-6009 meter and an analog input voltage at the same time.

Hello

Currently, I'm reading the two channels of voltage with the USB-6009. It happens that one of the channels is the output of a digital coder, and it would be much easier to use it directly to the PFIO entry that is defined as a counter. The problem I am facing right now, it's that I can't use the DAQ Assistant to use the analog voltage to a channel and the digital channel counter at the same time. Once I put the DAQ Assistant to read the input from analogue voltage, I won't be able to add analog inputs. And as I put the DAQ Assistant to use the PFIO as a counter, I can add more entries to read analog voltage is.

I wonder if it is possible to solve this problem using the lower level data blocks? Another solution would be to read two channels in analog input voltage and that the use of Matlab to process data resulting from it, since I was not able to do the counting to work simultaneously with the acquisition in Labview to impulses.

Hope you guys can help out me.

Thanks in advance.

Using a simple wizard of DAQ is incorrect. You need one to acquire analog inputs and one for the meter.

-

LabVIEW think my NI USB-6008 has only analog inputs

I am using an NI USB-6008 box to run a route of analog input and analog output.

If I do a constant material DAQmx channel and out the finger tool and pull down... and it offers me 8 analog inputs on Dev1 and nothing else. I've nothing else connected to this computer, but the box USB-6008. A USB-6008 doesn't even have 8 analog input channels.

I'm a bit confused.

-

How to synchronize the analog input and the output of two different USB data acquisition boards

Hi all

I have two tips very different USB NI USB 6008 case, which I use to acquire the data (analog input) and a USB of NI 9263 is a output analog only site I use to route a signal (in this case a square pulse). The reason why I use the outputs analog 6008 is because I need to deliver negative tension and need the full +/-10 v range.

Looking at similar positions, I'm pretty sure that I can't use an external trigger or a common clock, I also tried to use the timed synchronization of the structures but no cigar.

I'm including a quick vi I whipped showing how the jitters because of the lack of synchronization signal. The OD of the 9263 connects to AI in the 6008 in this example.

I talked to a specialist in the phone and tols me that's not possible.

-

What is the analog input of the NI PCI-6229 impedance?

I am trying to determine the effect of a 12 K resistor that is in series with an analog input of an NI PCI-6229 data acquisition card. Resistance of 12K seems to be part of a RC filter. I have a 0-10 VDC source this supply circuit. What is the impedance of the analog input of the NI PCI-6229 data acquisition card? If it makes any difference, the analog input is connected in differential mode with a 180K resistor to Gnd AI.

Thank you

RWB

Hi, RWB,.

The input impedance is classified in the specifications 10 GOhm. So, the effect of your k 12 resistance should be relatively low. Take care!

-

USB-6211: analog input signal affecting another of the same map AI

Hello

I use the DAQ-nor-6211 map and DAQmx features to read a hammer and a signal of the accelerometer and then use other LabView functions to make the FFT of these analog input signals. However, it seems that the analog inputs where the hammer and the accelerometer are connected generate a kind of noise or influence in other entries of this data that is not connected to any other sensor acquisition board.

I've had different experiences in order to check if the problem is with reading the card: put the accelerometer and hit the dog in another table where the DAQ card table was located (to avoid the vibrations on the map and a possible noise), ai1 entry was logged on the differential mode on the dog and the ai4 of entry is connected to the output (z axis) of the accelerometer. The other 2 ai2 and ai3, entries that can also be read by my LabView program, are open (i. e., any other sensor is connected to the card). When the structure where the accelerometer is located is struck by the hammer, the signal of ai2 ("x axis" seen in the first attached document) has a curve (on the time domain) which initialize almost at the same time that the hammer and the a3 of entry has a weak signal, but with the swing as well as the signal of ai4. The document "hammer ai1 + z_axis connected_ _x_axis disconnected ai2 + y_axis ai3 ai4" images that I captured the chart created in LabView. On these graphs, it is possible to check on the FFT the ai3 signal and ai4 has the same behavior (with different intensities), and enlarged figure of time domain image, we can see that the signal of ai2 increase almost at the same time of the signal of the hammer (ai1). The signal picked up by the sensors are probably creating a sort of noise on open entries ai2 and ai3.

Another experiment was conducted to check if the signal from a single entry that may affect the signal read from each other near the entrances: the DAQmx task Create channel had a physical channel has changed: ai3 entry has been modified by ai7 (maintain the same connection mode: differential), and the results are visible on the second attached document. In the graphs obtained in this experiment, it seems that the entrance of the hammer (ai1) affects the signal of input ai2 and ai7, which are not connected. And the ai4 signal does not seem to influence the other inputs, because he has a different curve on the graph of the FFT.

The same experiment was conducted using the CSR connection (change threads and create the DAQmx Channel Configuration), but the results were the same as those found using differential connection.

Finally, if the output of the accelerometer is connected on the ai2, the signal of the other open entries ai4 and ai7 seem to be affected by the signal of the accelerometer on ai2 (last document attached).

Could you tell me if the problem I encounter is caused by the DAQ card with this information that I gave to you? And if the answer is Yes, do you know if there is a way to avoid this noise create in one entry on the other hand, it please?

Thank you

Maybe Ghosting or crosstalk? Just an idea.

-

analog input on USB-6009 - what potentiometer to use for this test?

Hello, I am referring to this video

http://www.YouTube.com/watch?v=rSNRG_Ddl1s

What is the resistance (ohm) the potentiometer used in the film?

Thank you

Luke

They know the author of video ...

Since it is connected to the output of 5V to the DAQ card, you don't want to use too low of a low value.

A pot more of 500 ohm must work safely. Exact value is not critical for this demonstration. Rear wiper terminal must be connected to the analog input, the other two legs go 5Vout and GND.

-AK2DM

Maybe you are looking for

-

Pavilion Entertainment PC dv6: need a new hard drive for the dv6-1230us

My question is about the HP Pavilion Entertainment dv6-1230us PC. Recently, it was abandoned, and since then it has been giving me the following message if poster every time it starts. Not found boot devicePlease install an operating system on your h

-

Screen shows just "wallpaper" at startup; no tasks or icons bar.

At startup, the screen does not show anything other than my wallpaper. There is no icons and the taskbar are not displayed. Strangely, if I get called on Skype it appears, likewise, if I opened a linen of Skype Internet it works too. Any ideas? I use

-

Inspiron 1721 won't recognize hard drive

I replaced new hard drives with virgins, but I cannot now reinstall Vista from the DVD of resettlement because no disk is considered. I updated the BIOS to the latest version available, but still no joy. I took on the readers and, using an external H

-

ORA-03113 "reading" XML of CLOB

HelloI use XMLTable for reading XML to insert data into the DB table. I have:PROCEDURE IMPORT_XML)p_plik VARCHAR2,p_tp_id NUMBER,number of p_commit_po: = 500) ISl_blob_id TERYT_PLIKI.tp_blob_id%type;l_blob BLOB;XMLTYpe l_teryt_xml;L_Name varchar2 (10

-

Failed installation cloud creative

I couldn't install cc., error: Office creative cloud could not be updated. (Error code: 72) Contact Customer Support. Installation stops at 5%.