NI9213 Thermocouple measurement noise AC

I use a cRio with various thermocouple C-Modules NI9213. For my application, I need thermocouples not be safe and be very close (same body) sources and AC cables. When I read the thermocouple values that are close to the AC cables, I see noise sinusoidal structure in different frequencies (according to my sampling frequency). I use high-resolution scanning engine (mode high speed gave a louder signal). I would appreciate any help on this matter. Should I ground my cRio in a particular way? My last resort will be to sample at a higher frequency and the average of the values (assuming 60 Hz noise, I want to sample at least 120 Hz).

Thank you!

Thank you very much for your answers.

I had to settle for ' high resolution ' on the NI9213s and its rejection of 60db 60 Hz with some 'best practices' noise when the wiring of the AC power lines and thermocouples. However, the noise is not completely filtered. Looking around for other data acquisition devices (no OR in particular) I found modules thermocouple with at least 120db 60 Hz noise rejection. I personally use another provider of data acquisition with a thermocouple module that filters the noise of 60 Hz as a charm. I wonder why limited filtering on the NI9213.

Tags: NI Hardware

Similar Questions

-

With the help of several NI USB-TC01 Thermocouple measuring devices

I am currently set up with 1 NI USB-TC01 (http://sine.ni.com/nips/cds/view/p/lang/en/nid/208177), and everything works fine. My question is, can Labview control multiple TC01s simultaneously or I have to buy the NI USB-9211 has (http://sine.ni.com/nips/cds/view/p/lang/en/nid/201881#) to manage multiple thermocouple measures at the same time?

Thank you

Ben

Ben,

I didn't know we even had this device but I think that all of the information you want are in the link below.

http://digital.NI.com/public.nsf/allkb/7A9DAE5554C9D503862576FC005A3908

If you use the built in program, it is four devices, if you are using LabVIEW, you are limited to 127 devices. I don't know if several windows built-in software should be used if you use a LabVIEW.

-

6033 PCI analog measurement noise

This post is also in the forum of Labview, I think it belongs here.I want to assure you that I do everything I can to get the best measurement possible

IM using a SCB-100; I use a card PCI 6033.

I have connected my analog son

Looking at a picture labeled e/s to 64 channel connector E series devices...

I see to reason a choice AI GND, SENSE of HAVE it, HAVE SENSE 2, EXT REF, AO GND, D GND.

I used the GND. HAVE

My measure is close but there are a few milliamperes noise 4.30 should I get 4.80 on some units

the extent of automation and I set up for single ref has ended and a 09:50 vdc extent

I connected a wire to the GND AI for my units I measure power supply ground wire is short less than 10 inches, 16 gauge.

I use the correct ground?.

Thanks-Kurt

Kurt,

Yes, it's good ground for a measurement of CSR. Is your source of signal floating or grounded? If it is connected to the Earth, I would recommend using differential or NRSE instead of CSR. Here is a document that is an excellent reference for wiring and noise considerations.

-Christina

-

With differential measurement noise problems

Hey everybody.

I use an NI USB-6211, LABView 2011 and Win7.

I'm trying to measure a voltage through a resistor using differential mode. But unfortunately im getting a lot of noise (on + - 25%).

The voltage source I use is variable and can go up to 600V. With my diet I am essentially heat a metal plate.

A parallel voltage divider is used to reduce the voltage by one hundredth (1 MOhm and 10 kOhm).

Two wires attached to the lower resistance then go directly into analog input 0 + 8 of data acquisition.

So if I'm trained 600V to the plate, data acquisition should get about 6V... and that's what I measure with my voltmeter attached to the acquisition of data input pins.

I also tried these resistances of POLARIZATION and connected the + and - leads to the analogous to the ground like a resistance I used 10 k, 100 k and 1 MOhm and 2 MOhm and

continue to receive a bad signal.

Two sketches of the wire as a signal (100V, supposed to measure 1V, no CORRECTION) are attached to the post.

Concerning

EDIT: I forgot to write that I even tried an another NI DAQ and still get this noise problem.

Also, I measured the voltage source signal using an oscilloscope and I see that noise. But the differential mode isn't supposed to

reduce noise to a minimum?

Hey everybody,

come to understand that the voltage divider resistors are medium to high and they were the main reason for the noise

problem.

Before I used 1 MOhm and 10 kOhm, now I use 100 ohm and 100 kOhm and with a median filter in this regard, it works very well!

But still, if I use the resistance of these BIASES they do not change.

Concerning

-

NEITHER 9211 / CRIO 9013 thermocouples measure?

Hi, I'm a beginner with thermocouple, but I try to read the values of the two thermocouples (type S and K) on my module 9211.

I thought that module analog 9211 send me the voltage and use a VI to convert it to a temperature.

But I'm wrong module give me the temperature on the A0 A1 channels!

So I try to use the example (C:\Program NIUninstaller Instruments\LabVIEW 2009\examples\CompactRIO\Module Specific\NI 9211) labview VI but I can't use it because I do not have the license th FPGA have so I don't have access to the track and the cjc chanel!

How can set the NI 9211 to give me the right temperature with the thermocouple model? or how can I convert the sending real time the odule byx in the right a (type S or K)?

Thanks for your help

Auto answer:

Simple (too simple maybe

) to configure thermocouple I need to press on the property of the module (not on the channel, I tried just this one)

) to configure thermocouple I need to press on the property of the module (not on the channel, I tried just this one)and you can configure the type / unit and for the result!

Hates me...

-

I need to a portable data acquisition that can measure up to 15 thermocouples which is usb

Hello, a friend of mine who has no experience with labview wonder on what daq can he buy in order to have a portable thermocouple, measuring system. It must be usb so he can take it with him and his laptop computer and can connect up to 15 thermocouples. I've seen some usb based systems which are specifically for thermocuple measure but have only 4 entries. It is all daq usb that I could use for this application and that I also have to cancel any unwanted noise via programming?

Take a look at Measurement Computing which is a part of National Instruments. The USB-TC has 8 channels, so 2 of those who would do the job.

-

Reading of Thermocouple Type K with myRIO

I have a myRIO (room only) and I need to read for an internal PID K type thermocouple measures. I am able to do this directly in the room? Or I need an adapter?

Be as specific as possible.

Thank you.

The above listed connector is the connector for the card myRIO only.

In addition, the thermocouple type k has a + and - sign. If the + needs to go to one of the analog inputs and - needs to go ALWAYS, analog ground. See page 5 of the below myRIO 1950 manual for the pinout of the connector.

-

Measurement time 4132 SMU is too high

Hello

I use PXI - 4132 DC EMS to perform some DC measurements at high speed. I just took a 1 K Ohms resistance, forced 1mA and measure 1V. I have this done configuration and code completed. I get the correct measurements. But my problem is with the measurement time. The total duration is about 45ms to complete installation and measurement, with the exception of the 'initialize and close '.

I checked the time at every step and I noticed that the maximum duration is taken during the "voltage reading. Out of the total 45ms, it takes about 34ms just for a measure. It's just a VI "Ukraine power measure" takes about 34ms, which is ridiculous compared to the Kiethleys. I tried to vary the time of "openness" and turn off the 'Auto Zero'. But the measurement time is still high. Can someone help me and let me know what is the best time of the measurement obtained with 413 x series SME?

Thank you!

Hey Phx_tech,

The amount you reduce your delay source depends very much your HAD and how regular you have to your level of tension until you start taking your measurements. If your Instrument is reactive, you can see discount gas and unintentional ringing during the transition from your output level and therefore would allow enough break-in before taking your measurement. The best thing to do is to experiment with different delays of source and see how much delay need you to get a consistent and reproducible measure. If you have a scope that is available, it will also show you the step response of the SMU with your Instrument. If your first reading is higher than your other readings, that this could very well be a problem with not enough time settling. What kind of DUT Testez_ you?

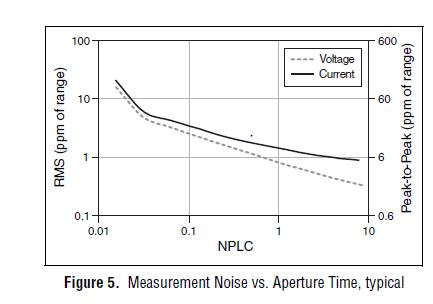

From page 4 of the specification, you can see that 1 PLC, we can expect about 1 ppm RMS noise of the range to 1 PLC. This means in the range 10 au our measurement noise would be 10 pA RMS or 60 pA pk - pk. However, your DUT + cables will pick up the extra noise and you should consider using wires of twisted shield pair to reduce noise picked up in your system. The shield can be terminated at the mass of the chassis on the side EMS of the cable to help reduce noise appearing in your measurement.

Let us know what you find after experimenting with you HAD.

Thank you!

Brandon G

-

All, I am new to this, make an old system of will vary from data upgraded. I've been through basic training 1.

I have a problem.

I use one OR momo-9178 with NI9211 and NI9205. The NI9205 is a simulated flow signal removes a conditioner of frequency. I use the DAQ Assistant to acquire signals. I am currently plotting flow vs temp just to get an understanding of the XY plots. My problem is this... when I write temp and flow values to a file TDMS I noticed that my thermocouple measurements are as follows (see below). Don't know what I'm doing wrong, can anyone help, see attachment.

78.52764246 78.52764246 78.52764246 78.45823079 78.45823079 78.45823079 78.45823079 78.5143133 78.5143133 78.5143133 78.44951917 78.44951917 78.44951917 78.44951917 78.45512712 78.45512712 78.45512712 Hi rfireton,

Is the concern that there are 3-4 copies of the same data?

The reason is that the 9211 is considered a module included in the slow sample (14 s/s in this case). A feature of these modules is that they allow you to define a sampling frequency more quickly what is technically possible on the module, but just repeats the data if necessary. This feature was a necessity for these modules included in the sample slow to operate in the same task in the form of modules faster as the 9205.

Indeed, the former cDAQ chassis (9172), he was required to put all the modules of analog inputs in the same spot. 9178 chassis more recent that you use it is no longer necessary (but it is still possible). 9178 a 3 engine synchronization of input analog, so you can actually run a separate task for your 9211 at a rate of support if you want to avoid receiving duplicate data.

Best regards

-

PCI-6120 noise performance is higher than in the data sheet.

I use the PCI-6120 card in warp mode, at 1 MHz. everything works, but there seems to be a discrepancy between the measured acoustic performance (with 50 ohm or short) and performance between quotes in the datasheet, 6120/6115. Here is my comparison.

City of range AI N + Q (uV) measured N (uVrms)

+/-42 V 550 1410

+/-20 V 220 600

+/-10 V 110 280

+/-5 V 69 140

+/-2 V 31 60

+/-1 V 18 30

+/-0.5 V 10 20

+/-0.2 V 5.1 15

It seems to me that N + Q data are shifted a range of analog input as numbers are good but not on the beaches of right. For example, the range V cited 42 N + Q agrees with the V 20 measured noise range. Everyone knows this?

So what you measured here is actually the system noise, who we spec on page 4 of the specification, uncertainty about the noise, which we spec on page 3. The noise of the system for the PCI-6120 is shown below. To calculate the noise from the system of these specs, you use the following formula:

(LSBrms system noise) * (Input Range) /(2^Resolution) = Vrms system noise

Thus, for the 42V range, noise specified in LSBrms is 1.2 LSBrms. The input range is 84 (±42V is total 84 volts). The resolution is 16 bit. So:

1.2* ((84) /(2^16)) = 0.001538 V = 1 538 uV

For each of the beaches, the sound of the system is:

Range LSBS Sound system (µV) 42 1.2 1538.09 20 1.2 732.42 10 1.2 366.21 5 1.5 228,88 2 1.7 103.76 1 2 61.04 0.5 2.2 33,57 0.2 2.8 17.09 Hope that answers your question.

-

Synchronization of data from different sample of data acquisition rate

I use a high RT 8135. I'm sampling of signals from analog pressure thermocouples to 20 ms and 10 ms. I use the stream network to transfer the data from the SMU on my host. I would like to be able to synchronize the timestamps of all data to the 1ms sampling note and record in a file.

Search in the file my sampling data 10ms end timestamp does not match the timestamp of 20ms, missing data... I know you have empty queues to get the rest data but is possible to interpolate any data to adapt a unique timestamp?

Thank you!

Hi aokada09,

Looks like you are facing problems resulting from parallel execution two loops you have. There is nothing necessarily bind the two loops together, so that each of them an iteration at the rates you specified, but are allowed to start each software (sort of random) dictates that they start.

To get a solid synchronization, share a sample between the two measures clock, but run the sample clock at 100 Hz for 50 Hz for thermocouple measurement and pressure measurement. You should be able to use shared inside the SMU chassis backplane clock. This will be as close as possible to synchronize without using a card of timing. The only real source of delay/tilt between readings at this point is the physical distance that must travel the clock signal. This will not lead to steep, but there will certainly be some (probably on the scale of the high-nanoseconds or microseconds bass). This article gives more information about the synchronization and the sample clock:

-

Number of channels of "scan list" to decode

Is it possible to decode the number of channels in a scan list? The example of NOR (niSwitch Thermocouple Measurements.vi) that I use, requires the entry of "scan list" and "number of channels.

Hello Ddemara,

If you're multiplexing through a bunch of thermocouple, the scan list will be not complex, then we could easily write code to determine the number of channels. Our code will have to do the following:

(1) start a counter with the value 0.

(2) Iterate through scan list user-defined and add 1 to the counter whenever you find a comma. The last element will not have a comma, so we will need to add 1 to the value at the end.

(3) find each instance of a colon (":"), then find the two numbers on each side of the colon, subtract these two numbers and then add them to the value of the counter. We don't need to add one to the value of end here because we have already included the first item in the series

(4) the value of the counter is at this point the number of channels in the scan list.

If you have any questions to set this up, after. Have a great day!

FYI: The number of lanes in the example you mentioned allows us to recover data from the DMM as the first element of the array is always the thermocouple. If the number of channels is wrong, extract indexing element 0 will cause plug wrong value to the CJC for thermocouple input scaling of vi.

-

How to sample multiple sensors in a vital task?

I need to a thermocouple sensor and voltage sensor in a vital task of the sample. My hardware configuration includes a cDAQ-9172 chassis with a NI9211 TC module and a NI9221 voltage input module.

I started with the example C code for thermocouple measurement found here:

Instruments\NI-national DAQ\Examples\DAQmx C\Analog In\Measure Temperature\Cont Thrmcpl samples-Int Clk\ContThrmcplSamps ANSI - IntClk.c

I then added a few lines of code for the measurement of additional tension.

The task runs for about 20 seconds, until the buffer overflow with the error 200279.

I can run task, thermocouple or voltage, indefinitely. It's only when I include them both in the same task as the buffer overflow.

I have tried many combinations of sampling rate, the size of the buffer and DAQmxRegisterEveryNSamplesEvent nSample size.

Below is the code I'm running. Changes to the original file are marked in bold. I've attached a screenshot of the output of command line.

Can anyone offer a C program example showing how to sample multpile sensors permanently in a task?

#include

#include #define DAQmxErrChk(functionCall) if( DAQmxFailed(error=(functionCall)) ) goto Error; else int32 CVICALLBACK EveryNCallback(TaskHandle taskHandle, int32 everyNsamplesEventType, uInt32 nSamples, void *callbackData); int32 CVICALLBACK DoneCallback(TaskHandle taskHandle, int32 status, void *callbackData); int main(void) { int32 error=0; TaskHandle taskHandle=0; char errBuff[2048]={'\0'}; /*********************************************/ // DAQmx Configure Code /*********************************************/ DAQmxErrChk (DAQmxCreateTask("",&taskHandle)); DAQmxErrChk (DAQmxCreateAIThrmcplChan(taskHandle,"cDAQ1Mod1/ai0","",0.0,100.0,DAQmx_Val_DegC,DAQmx_Val_K_Type_TC,DAQmx_Val_BuiltIn,25.0,"")); DAQmxErrChk (DAQmxCreateAIVoltageChan(taskHandle,"cDAQ1Mod4/ai0","",DAQmx_Val_Cfg_Default,-60.0,60.0,DAQmx_Val_Volts,NULL)); DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandle,"",1000.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000)); DAQmxErrChk (DAQmxRegisterEveryNSamplesEvent(taskHandle,DAQmx_Val_Acquired_Into_Buffer,1000,0,EveryNCallback,NULL)); DAQmxErrChk (DAQmxRegisterDoneEvent(taskHandle,0,DoneCallback,NULL)); /*********************************************/ // DAQmx Start Code /*********************************************/ DAQmxErrChk (DAQmxStartTask(taskHandle)); printf("Acquiring samples continuously. Press Enter to interrupt\n"); getchar(); Error: if( DAQmxFailed(error) ) DAQmxGetExtendedErrorInfo(errBuff,2048); if( taskHandle!=0 ) { /*********************************************/ // DAQmx Stop Code /*********************************************/ DAQmxStopTask(taskHandle); DAQmxClearTask(taskHandle); } if( DAQmxFailed(error) ) printf("DAQmx Error: %s\n",errBuff); printf("End of program, press Enter key to quit\n"); getchar(); return 0; } int32 CVICALLBACK EveryNCallback(TaskHandle taskHandle, int32 everyNsamplesEventType, uInt32 nSamples, void *callbackData) { int32 error=0; char errBuff[2048]={'\0'}; static int totalRead=0; int32 read=0; float64 data[1000]; uInt32 i; /*********************************************/ // DAQmx Read Code /*********************************************/ DAQmxErrChk (DAQmxReadAnalogF64(taskHandle,-1,10.0,DAQmx_Val_GroupByScanNumber,data,1000,&read,NULL)); if( read>0 ) { for (i = 0 ; i < 2*read ; i++ ) { printf("%.5f\n", data[i]); } printf("Acquired %d samples. Total %d\r",read,totalRead+=read); fflush(stdout); } Error: if( DAQmxFailed(error) ) { DAQmxGetExtendedErrorInfo(errBuff,2048); /*********************************************/ // DAQmx Stop Code /*********************************************/ DAQmxStopTask(taskHandle); DAQmxClearTask(taskHandle); printf("DAQmx Error: %s\n",errBuff); } return 0; } int32 CVICALLBACK DoneCallback(TaskHandle taskHandle, int32 status, void *callbackData) { int32 error=0; char errBuff[2048]={'\0'}; // Check to see if an error stopped the task. DAQmxErrChk (status); Error: if( DAQmxFailed(error) ) { DAQmxGetExtendedErrorInfo(errBuff,2048); DAQmxClearTask(taskHandle); printf("DAQmx Error: %s\n",errBuff); } return 0; } One more thing I've noticed is that the size of the data [] has not be increased to include additional channels. Wear in 2000 and also to increase arraySizeInSamps (parameter 5) and 2000 to the DAQmxReadAnalogF64 function call. Given that it was only the value 1000 samples, it will get only 500 samples per channel causing the overflow.

-

Help required to resolve the error-200022

Hi all

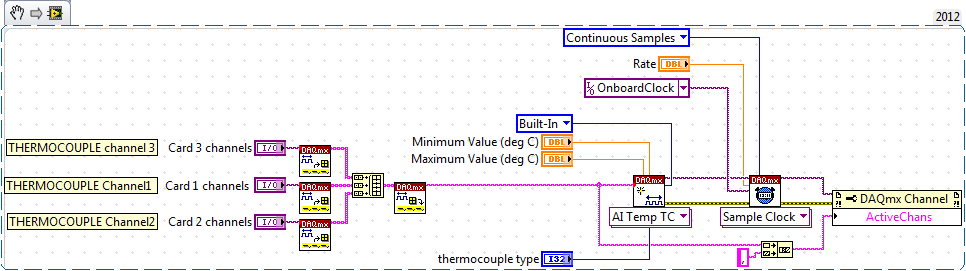

I have a VI that throws the error-200022 (after acquiring data mx). This has got 5 data acquisition channels off 2 of them (THERMOCOUPLE sensors channel 1 & pressure - channel 1 commented on the left within the program) are throwing this error and do not read whatever it is reasonable and the program stops. However the other channels are read good values. When I checked the individually, it works perfectly fine but when I put them together in the same program he throws the error above.

I looked into some of the suggested solutions, but nothing did. Can someone help me solve this error. I have attached the VI as well.

Thank you very much

Rivet

I have it..!

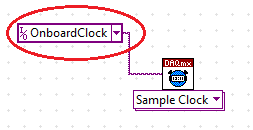

You use "embedded Clock' for all the three tasks (thermocouple measurement) and its causing conflict... !!If you see here, the main reason (as I already specified it) is "resource requested by this task has already been reserved by another task." "" ...

I suggest you club all three tasks into one...!

-

Noise thermocouple with PCI-6230

What level of noise should be expected for a K type thermocouple used with an acquisition of data PCI-6230 and a map derivation CB-37F-HVD? I read the data with LabVIEW and Daq Assist module on the setting of the thermocouple and the noise see of +/-1 ° C. For a type thermocouple K 41uV / ° C is 3 times the 6230 noise expected (13 uVrms) runs around 0.2 full scale. I think it should be more stable measures or is this a normal behavior?

http://sine.NI.com/DS/app/doc/p/ID/DS-31/lang/en

Thank you

Dan

This level of noise is expected. To improve, you can use a card with a noise filter. A dedicated thermocouple module would also work, but this includes a noise filter as well.

Maybe you are looking for

-

Satellite L655-11Z (PSK1JE) - how to position the external fan coolers?

Hello I buy laptop cooler and I would like to know how to position the fan for best results rigorous. I read manual from top to down, but only the bottom showing pic of this laptop is only for "this is batery. I would like to know, where (from the bo

-

Disk full error but USB drive has enough free space

I am trying to copy a file to a USB flash drive even if the drive is empty when I try to copy the file, I get an error message telling me that the disk is full. The file is 8GB and the drive is 32 GB, so there is plenty of room. How to fix this?

-

Update fails (32-bit) KB2596686 to install.

I want to install the updated KB2596686 for Outlook 2007. I don't have the update installed on my XP - x 64 pc. I tried several ways to install. Through the Security Center, I search for updates and install updates found. Through the ESET NOD32, whic

-

We have a Manager Communications Group to serve our PBX. We recently bought a new telepresence system and a 2nd CM cluster that is dedicated to the CTS. Telepresence SRND States to put the CTS codec in the VLAN voice. There is no mention of this VL

-

Hi, I installed windows 7 Home premium. at the back of the pc, the regesterd key worked not for authentic Windows that give me an error in server code. How can I solve it please help me