PXI-6534 replacement by SMU-6537

I am currently ordering and receiving data from a device to measure with the PXI-6534, LabVIEW and DAQmx on Windows.

Can I replace the PXI-6534 by an SMU-6537 without having to change anything to my hardware (will be in other words, the cable connections and advice sheet be compatible)? If so, the code written to communicate to the PXI-6534 will be reusable with the SMU-6537?

Thank you comments or pointers.

X.

I'm really sorry, but I forgot to mention in my previous post that there is indeed an adapter that will allow you to use the same block that you used with the PXI-6534. You can find more info on this adapter cable on this link:

http://www.NI.com/PDF/manuals/374435a.PDF

Tags: NI Hardware

Similar Questions

-

Synchronization of two SMU 6537 in acquisition mode

Hello

I need to use two SMU 6537 in parallel for a digital acquisition, their examples of clock is synchronized and running at 50 MHz. In the manual, I can't know is possible to correctly route connections through PXI background:

-It seems that the path available only for export SAMPLING CLOCK in acquisition mode is 5 PFI, so no way to settle the two cards in a master-slave via the background.

-I don't see or can use the background 10 MHz REFERENCE for synchronization, because it seems impossible through the DAQmx driver to deliver this line as input for the time base and trigger (it is not even in the list of possible signal entries).

-The manual States that the maximum allowed value for an external time base is 50 MHz, whereas I need 50 MHz acquisition rate. I guess I should put in Sync synchronize databases internal time of the two councils through the background, but I can't figure out how.

Any suggestion on how to solve this problem?

Thank you, Piero.

Piero,

TO synchronize these cards, you must share the sample clock and a start trigger. You should be able to send the sample for PXI Trig 7 line clock and use it for each of them.

-Christina

-

Acquire more than 2047 samples with the PXI-4461 instaled in SMU-1073

Hi all, I would ask you for help with the buffer limit.

I intend to buy digitizer PXI-4461 and he instal in SMU-1073 chassis, namely control via MXI Express of Labview installed on a separate computer.

What I need:

-to acquire data of a single channel of AI, but at least a sequence of 20 kS by a acquire task, in some situations until 200kS by a task to acquire.

The question:

- I can gain more than 2047 samples in a single sequence, like 200kS, with the PXI-4461 installed in SMU-1073?

Internal buffer of the PXI-4461 is reserved to 2047 samples. So I'm not sure if Labview can download remotely via MXI Express the data in the buffer of the PXI-4461 via MXI Express fast enough without any affection of the sampling program.

-in the case, this PXI-4461 with SMU-1073 isn't the right combination, what chassis and a controller can do?

Thanks much for the reply

Jan

It will work for you.

The on-board buffer 2047-sample is used only as a backup if the flow of data to the PC host (via MXI Express in this case) is not fast enough... that it will be (explained below). DAQmx transfers data from the buffer of the device to the host PC as fast as he can and, in ideal conditions, should not save the buffer 2047 much at all.

Let's just say you get 110 MB/s (randomly from a MXI data sheet) flow on your MXI connection. The 4461 has 2 analog inputs, which will be at 24 bits, we just round 32-bit in case it transfers the data in this way.

4 bytes/sample (32 bit) x 200,000 s/s x 2 (channels) = 1.6 MB/s, which is well below the 110 MB/s, which will make the MXI link.

clear as mud?

Germano-

-

Problem with the PXI-6534 elimination change detection task

I ran into the following problem. I use a PXI-6534 and PXI-6602 with vb.net for detection with a timestamp of changes. My code works fine and I get data exactly as I want, the problem comes when I try to call the task.dispose function.

When I call him has, she throws an exception with error-200088 code, task does not exist. But the task is still stopped and I can run my code again and everything works fine. If I do not call the task.dispose, I get an error when I try to run my code again. The material seems to have left in an unknown state, and I have to restart my computer to get it back. (the MAX NOR even reset the 6602, he says only that the Council does not exist).

Interesting also is the exception thrown does not seem to be caught by the Try Catch method. The code traverses the Try Catch without any problem (step by step in the code anyway), but with the exception, the message box appears, either immediately or when coming out of the subroutine.

Also, I use TestStand 4.2 to call these functions, if that makes a difference.

Any help would be greatly appreciated! Its very frustrating that everything works and I get my data perfectly, but I can't run the code without exception popping up, and I can't seem to catch the exception.

Here is the code I use:

Public Sub StartChangeDetect_UUT1() If myCDrunningTaskA Is Nothing Then Try ' Create the task uut1ChangeDetectTask = New Task() '************************ Create the digital input virtual channel alias 'Assign ports to digital virtual channel uut1ChangeDetectTask.DIChannels.CreateChannel("Dev1/port0:3", "ChangeDetectUUT1", ChannelLineGrouping.OneChannelForAllLines) 'uut1ChangeDetectTask.DIChannels.All.DigitalFilterEnable = True 'uut1ChangeDetectTask.DIChannels.All.DigitalFilterMinimumPulseWidth = 0.000001 uut1ChangeDetectTask.DIChannels.All.InvertLines = True uut1ChangeDetectTask.DIChannels.All.DataTransferMechanism = DIDataTransferMechanism.Dma 'Assign ports to monitor for change detection, both rising and falling edges Dim rising As String Dim falling As String rising = "Dev1/port0:3" falling = "Dev1/port0:3" uut1ChangeDetectTask.Timing.ConfigureChangeDetection(rising, falling, SampleQuantityMode.ContinuousSamples, 4000000) 'export change detect event to PXI backplane so we can get timestamps from timer. uut1ChangeDetectTask.ExportSignals.ChangeDetectionEventOutputTerminal = "/Dev1/PXI_Trig0" uut1ChangeDetectTask.ExportSignals.ChangeDetectionEventPulsePolarity = ChangeDetectionEventPulsePolarity.ActiveHigh 'uut1ChangeDetectTask.Stream.Timeout = 20000 ' Verify the Task uut1ChangeDetectTask.Control(TaskAction.Verify) ' Set up the data table Initializeuut1DataTable() ' Create the readers for the DI and the CI uut1ChangeDetectReader = New DigitalSingleChannelReader(uut1ChangeDetectTask.Stream) uut1CDCallback = New AsyncCallback(AddressOf uut1ChangeDetectCallback) uut1ChangeDetectReader.SynchronizeCallbacks = False ' Set up our first callback uut1ChangeDetectReader.BeginReadMultiSamplePortUInt32(-1, uut1CDCallback, uut1ChangeDetectTask) myCDrunningTaskA = uut1ChangeDetectTask 'Set up Timer for time stamp uut1TimeStampTask = New Task() '****************set up PXI-6602 timer to get buffered change events. ie capture timer output on the PXI_Trig0 'we can then correlate this timer capture buffer to the change detect buffer to get the time stamps uut1TimeStampTask.CIChannels.CreatePeriodChannel("Dev5/ctr0", "TimeStamp1", 0.0000001, 0.02, CIPeriodStartingEdge.Rising _ , CIPeriodMeasurementMethod.LowFrequencyOneCounter, 4, 4, CIPeriodUnits.Seconds) uut1TimeStampTask.CIChannels.All.CounterTimebaseRate = 20000000.0 'Use exported change detect from 6534 board to take counter sample uut1TimeStampTask.Timing.ConfigureImplicit(SampleQuantityMode.ContinuousSamples) uut1TimeStampTask.CIChannels.All.PeriodTerminal = "/Dev5/PXI_trig0" 'uut1TimeStampTask.CIChannels.All.DuplicateCountPrevention = False uut1TimeStampTask.CIChannels.All.DataTransferMechanism = CIDataTransferMechanism.Dma ' Set timeout 'uut1TimeStampTask.Stream.Timeout = 20000 ' Verify the Task uut1TimeStampTask.Control(TaskAction.Verify) uut1TimeStampReader = New CounterReader(uut1TimeStampTask.Stream) uut1TSCallback = New AsyncCallback(AddressOf uut1TimeStampCallback) uut1TimeStampReader.SynchronizeCallbacks = False uut1TimeStampReader.BeginReadMultiSampleDouble(-1, uut1TSCallback, uut1TimeStampTask) myTSrunningTaskA = uut1TimeStampTask Catch exception As DaqException ' Display Errors MessageBox.Show(exception.Message) uut1StopChangeDetection("C:\PT3771\TestResults\") End Try End If End Sub Private Sub uut1ChangeDetectCallback(ByVal result As IAsyncResult) Try 'If runningTask Is ar.AsyncState Then If myCDrunningTaskA Is uut1ChangeDetectTask Then ' Read the available data from the channels Dim data As UInt32() = uut1ChangeDetectReader.EndReadMultiSamplePortUInt32(result) Dim b As UInt32 For Each b In data ' in TestData waveform Y axix is data, x axis is time uut1TestData.SetY(uut1ChangeDataIndex, b) uut1ChangeDataIndex += 1 Next b '' Set up a new callback uut1ChangeDetectReader.BeginReadMultiSamplePortUInt32(-1, uut1CDCallback, uut1ChangeDetectTask) End If Catch exception As DaqException ' Display Errors MessageBox.Show(exception.Message) uut1StopChangeDetection("C:\PT3771\TestResults\") End Try End Sub 'DigitalCallback Private Sub uut1TimeStampCallback(ByVal result As IAsyncResult) Try 'If runningTask Is ar.AsyncState Then If myTSrunningTaskA Is uut1TimeStampTask Then ' Read the available data from the channels Dim data2 As Double() = uut1TimeStampReader.EndReadMultiSampleDouble(result) ' in TestData waveform Y axix is data, x axis is time Dim b As Double For Each b In data2 uut1TimeSum = uut1TimeSum + b uut1TestData.SetX(uut1TimeStampIndex, uut1TimeSum) uut1TimeStampIndex += 1 Next b ' Set up a new callback uut1TimeStampReader.BeginReadMultiSampleDouble(-1, uut1TSCallback, uut1TimeStampReader) End If Catch exception As DaqException ' Display Errors MessageBox.Show(exception.Message) uut1StopChangeDetection("C:\PT3771\TestResults\") End Try End Sub 'CounterCallback Public Sub uut1StopChangeDetection(ByVal location As String) Try If Not (myTSrunningTaskA Is Nothing) Then uut1TimeStampTask.Dispose() myTSrunningTaskA = Nothing End If If Not (myCDrunningTaskA Is Nothing) Then uut1ChangeDetectTask.Dispose() myCDrunningTaskA = Nothing End If Catch ex As Exception MessageBox.Show(ex.Message) End Try uut1TestData.UpdatePointCount() uut1TestData.SaveToDisk("C:\PT3771\TestResults\uut1TestWaveFile.csv") uut1TestData.SaveToDiskBinary("C:\PT3771\TestResults\uut1TestWaveFile") End Sub 'StopTaskJoe,

Last updated. It seems that when the task.dispose is run, recalls seem to have called one last time. I took the call to the stopUUT1ChangeDetect in the two recalls (so eliminate it would not enforce a second time), and no exception was thrown.

Thanks for your help! Although if you'd still answer my question on the PXI-6534 Digital input filtering, I'd appreciate it.

Thanks again.

Thad

-

Control PCLK when using the PXI-6534 in e/s mode

I use ports 0 & 1 on the PXI-6534 in e/s model mode and also use output control in the mode of e/s to unstrobed for simple. Users manual says in the mode of e/s model the PCLK control is not used, but the mode of e/s model seems to put down (or maybe he defines as an entry). This a problem for me because I expect to PCLK to stay a high return which I set earlier. Does anyone know how to set up the PXI-6534 in e/s model mode so that this does not affect PCLK... He's going to stay high?

Thank you.

Jim

Hi Jim,.

According to page 2 and 3 of the PXI-6534 user manual, if you configure a group to perform i/o, associated for this group synchronization control lines are not available in the form of additional data lines. The knowledge base, here, explains this limitation for the PXI-6534. In summary, port 4 is reserved once you are in e/s handshaking mode or a model and cannot be used as data lines additional unstrobed.

-

In the help file for the SMU-6537, there is an illustration of "Front Panel and connector pinout" and a table.

The illustration shows pin GND 8.

However, the table below shows pin 8 as a RESERVED pin, * not * a GND.

I design a Board to interface with the 6537. I massage pin 8, or let it float?

Hey Tom,

PIN 8 in the illustration should tell RESERVED and not mass, and therefore you must not connect. We will update the image in the next revision of the help file. So to answer your direct question, leave floating 8 pin (do not connect to it). Let us know if you have any questions or concerns. Thank you and have a nice day.

Kind regards

DJ L.

-

Installation of RT for PXI 6534

I'll put up the PXI-6534 in RT and when I run in the test Panel, I get an error like this:

Error-50352 occurred at the test Panel

Possible reasons:

The requested memory could not be allocated.

Does anyone know how to fix this?

Hey j,

Some basics to cover, is something else using the card now as a VI or application? You have reset your card? Have you tried to reinstalled DAQ on your controller?

-

PXI-5154 making fried SMU-1075

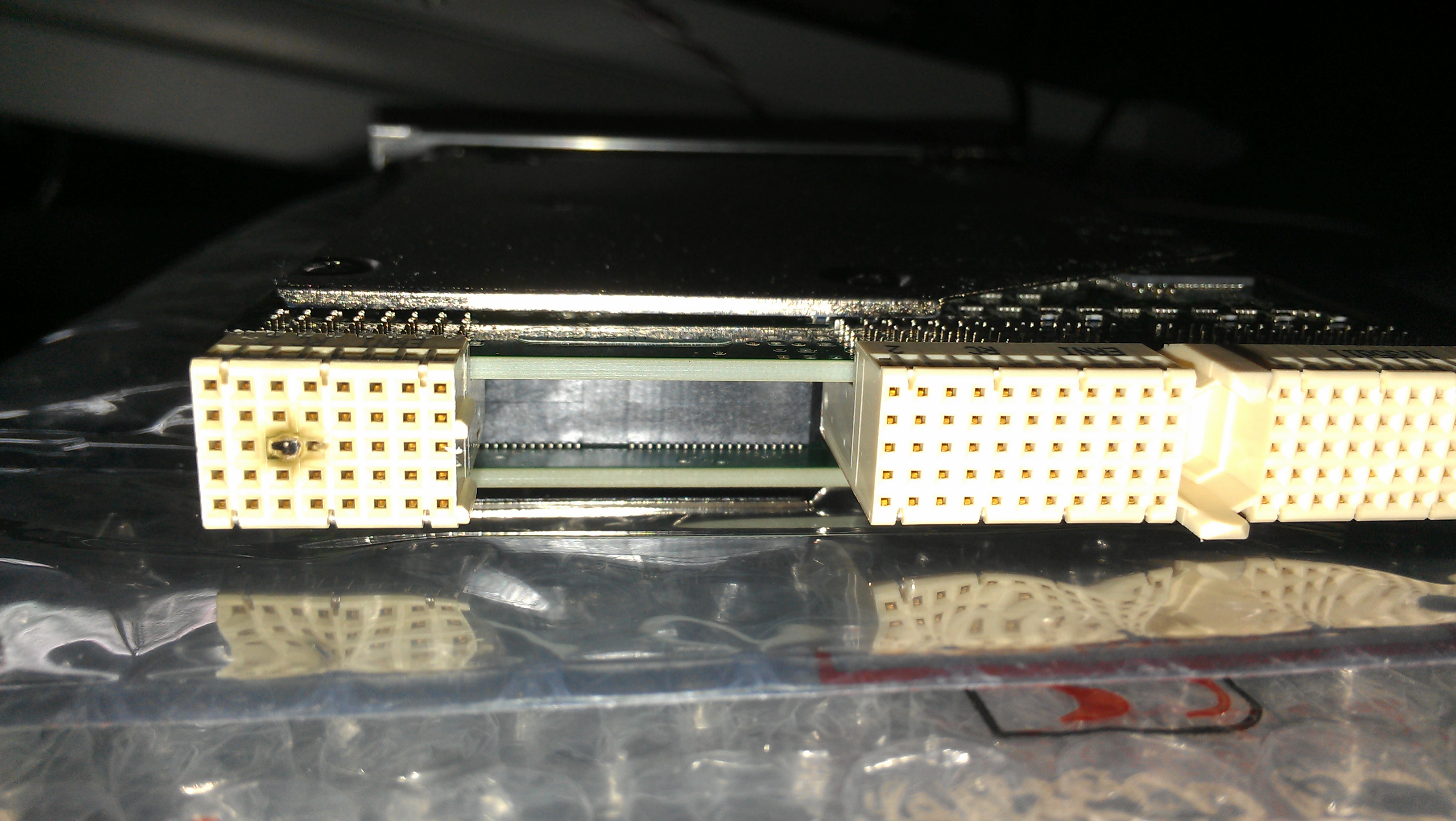

So, I just tried to install a PXI-5154 in SMU-1075 chassis. I followed the instructions that came with the card, but after turning on the chassis, there is no wizard detection of material, and no LED light came. I was going to try it in a different location, but when I slipped the card out of the chassis, I saw that looked burnt decision-making (see attached image). I'm not sure that I was wrong, and now I'm worried I might have damaged some of the other cards that have been installed in the chassis. So my question is double: 1) an idea of what went wrong here? 2.) nothing to say if the chassis itself is somewhat damaged? (3.) if the damage has not been caused by some error on my part of the user, is there an any warranty / replacement of the card?

Thank you

Well, turns out the instructions that came with the card were bad... the instructions say plug the card into a slot chassis marked with a number of cicrled, turns out I needed to plug the card into a slot with a number of cirled with a small 'H' beside him. Everything seems to be working fine now, thanks zeus

-

Dear community,

I am trying to implement a background basket (software) PXI trigger on a chassis NI SMU-1082 with LabView 2015 (32-bit) running on an SMU-8135:

HS-DIO (SMU-6544) in slot 2,

-Acquisition of data (SMU-6363) into the Groove 4,

-Flex RIO (SMU-7962R + OR-6583) in the Groove 3.

The trigger schema is explained in the attached file ' LV-PXItrig-HSDIO-DAQ - overview.jpg ".

Scenario 1: written DAQ analog signal and sends signals trigger HS-DIO (software) through bottom of basket, after East of waveform of the complete signals to DAQ for acquisition.

Scenario 2: logical impulse on an external port HS-DIO triggers signals HS-DIO, after HS-DIO waveform is complete DAQ triggered for the acquisition of the ADC by the backplane.

In principle this breaks down to send a trigger of module A to B by PXI backplane. The SMU-1082 chassis has a bus trip with 8 lines (PXI_trigX, X = 0,..., 7) more a trigger in Star controlled the slot 2.

I've linked to implement a software trigger, but I can't access the refreshing resource and execution, see the attachment. Other ways of implementation including the DAQmx Terminal / routine disconnect Terminal have not worked for me either. I am aware about the connection of trigger using the node property VISA but I can't make a trigger.

Tips, comments or solutions are appreciated. Thank you!

For scenario 1, you want to trigger the HSDIO acquisition to begin as soon as the analog output DAQ starts? You can use

DAQmx Export Signalto send the trigger for the start of one of the lines from the Trig PXI backplane. Then, you need to configure your HSDIO acquisition to use a trigger digital beginning on the same line of trigger. Take a look at the example of the "Dynamic hardware generation start trigger" in the Finder of the example (help > find examples)For scenario 2, looks like you do a dynamic unit HSDIO generation when a digital trigger arrives on one of the PFI lines. Once the build is complete, you want to send a trigger for the DAQ hardware to begin sampling. If this is the case, you again use a trigger to start material in your task of NOR-HSDIO, as you did for scenario 1, but use external trig line as the source, rather than the bottom of basket. There is no case of material when the build is finished, but you can use a marker in script mode event instead. The example of the Generation with dynamic event marker' in the example Finder gives a good starting point for this type of operation. You'll want to set the output terminal for the event to be a line of backplane trig, and then tap the DAQmx to start on the same line trig trigger.

-

The cheapest way to produce a TTL pulse using a chassis SMU-1062 q

I have recently updated an installation of a PXI-6534 surfboard in a to a Council SMU-6537 PXI chassis in a chassis SMU-1062 q.

One of the things that I forgot I needed is a way to output a TTL for some devices that I control of LabVIEW even software that I use... I counsel 6052E in my PXI chassis, that I used with CA-1000 enclosure for this TTL, but I always use this card in my PXI chassis, so this isn't an option.

What is the easiest way to get a TTL pulse out of my system SMU (cheaper?)? I can't use the SMU-6537 jury as it is used for other tasks (fast) (I mean the connector is directly linked to a device to communicate with).

Thank you

X.

Howdy X!

The cheapest way I can think of to generate a TTL pulse would be to use the USB-6501. Note that it only supports only avoiding so the length of the pulse is not exact, but if this fits within the limits for you request it's the cheap solution. Otherwise, I would recommend a card PXI DAQ as the PXI-6220.

Concerning

-

Hello.

I have a 1071-SMU-PXI chassis with controller SMU-8101 (Windows XP) and SMU-4496 module. Also, I NI DAQmx installed on the controller operating system and on another computer in the same network.

Is it possible to acquire measurement data of this ADC on network computer using remote access? Or this feature is available only if you use real-time controllers?

Thank you.

When you perform a MXI installation like this, you essentially replace the embedded controller that installs in slot 1 with your laptop / desktop. You will need to install the driver daqmx for laptop/desktop computer computer which is connected to the chassis via MXI cable.

-

NI PXI - 8108 RT with real-time compatibility 2009 and PXI-1050

Hello

The PXI-8108 should work just fine with the PXI-1050 chassis. The only requirement is a chassis PXI uses a PXI controller and a SMU chassis uses a controller SMU. Since the 8108 both 1050 use the PXI standard, they should work very well together.

Eric

-

PCIe-6537 County in ANSI C sample clock

I want to get the precise times of the edges on 32 digital lines using a card PCIe-6537. The card should have a sample of 50 MHz clock (minimum and 200 MHz/N N is 4). So if I can get a count of the sample clock when the any lines going from low to high, I know the time at a resolution of 20ns. Each line should have a transition from bass up per second. They should all be synchronized, it is possible that more than one line will have an advantage in the same sample clock signal.

I'm programming in Visual C++ with the DAQmx ANSI C API.

What I've tried so far, I think I need to put in place two DAQmx tasks: one to count the sample clock and one to detect transitions on the i/o 32 lines. The next problem after that is the task of transition to trigger a capture of a county on the first task.

But I can't even set up a counter stain. I think I need to call DAQmxCreateCICountEdgesChan() to create a channel for the sample clock. The example code I found (Mult_Counters_Count_Dig_Start_Trig_TIO.c) sets the name of the channel to counter with a constant:

#define COUNTER_SOURCE1 "Dev2/ctr0.

My camera is 'Dev1 '. If I try to use ' Dev1/ctr0', I get:

Measurements: Physical channel specified does not exist on this machine.

Refer to the documentation for the channels available on this device.

Device: Dev1

Name of the physical channel: ctr0Task name: Dev1CtrTask

Status code :-200170

I tried to call DAQmxGetDevCIPhysicalChans() to get the name of the channel, and I return an empty string. So I tried ' Dev1 / ' and got a similar error, unless of course

The physical channel name: empty string

Is it possible to count the sample with the 6537 clock? Or is there a better way to get the values of accurate time for transitions on the i/o lines?

Frank

As for performance, I can personally attest that I have listened 12 SMU-6537 at the maximum rate (50 MHz) with 32 lines on the disc. It seems there a configuration delivers in this case

OK, well, I don't have not sorted. She is still ongoing at only 40 MHz. But we decided to resolution 25ns is close enough for now (ran out of time for development

). It's another problem of implementation of the task, so I asked a question separate from the maximum of PCIe 6537 ANSI C sample clock

). It's another problem of implementation of the task, so I asked a question separate from the maximum of PCIe 6537 ANSI C sample clockSince then, with the help of the forum I got my running program, I would like to summarize the thread and the solution to my problem, in case anyone else is the rising later.

- The problem is exactly the timestamp rising edges on a set of 32 digital inputs. I expect only a couple of edges per second per channel, but I need to know when they occur (in fact the interval between the edges on different lines) as accurately as possible.

- I thought that the card could detect changes on inputs and pass a count of the sample clock pulses during an edge has occurred.

- The 6537 has no channel counter, so it will not be a feasible way

- Definition of the card to read all 32 lines on the forehead amount of sample clock allows me to write a reminder that allows you to see the status of each line on each sample clock. Because I know that the period of the sample clock, I know that the time of each sample. The reminder I have used a few loops on the pad looking for changes.

- Surprisingly, this set only 30% a single processor and 40% on the other CPU on a 2-core 2.2 GHz PC. Well, that surprised me. I don't think that the PC could handle shoveling bits that fast autour. SCP got fast enough since the last time I built a. Sample clock was 40 MHz.

- The callback uses DAQmxReadRaw (taskHandle, DAQmx_Val_Auto, 0, SampleArray, SampleArraySize, unread, & numBytesPerSamp, NULL). The documentation for it says unread will be set to the number of bytes read; It should indicate the number of samples. And I should have used DAQmxReadDigitalU32() instead in any case.

Thanks to all those who helped with my lights

Frank

-

SMU 8262 streaming performance with HDD-8264 on an SMU 1062 q chassis

Hello

I have a SMU 1062 q chassis, Win XP, running with a 8262 connected to a HD8264 and two SMU 6537 installed, all three pension being on the express slots (3, 4 and 5). The application of benchmark to test the speed of streaming (Win32FileIO) I get something like 100 Mbit/s with data of pieces about 4 MB and about 140 MB/s with 64 piece Mr. Comment can improve these results to the limit off the coast of 600 MB / s? Y at - it a software/driver tip to apply?

And, in case, which is the best way to exploit the 8262 written c++ from the code (using the libraries OR)? Is there something similar to the Win32FileIO library? I tried to use the RAID system in program c ++ test, and performance seems very poor, whereas I would need, if not the 600 MB/s rate, at least something around 200 MB/s of diffusion continues.

Thanks in advance,

Piero.

Hi Neil,

I actually have a 8130 controller, and in fact, this was not the problem: I found the problem was the file interpreted by Windows file system caching. If you use standard fstream calls of C source code you can not get around, but using Windows native call (CreateFile (...), WriteFile (...) API) and definition of the indicator for no data cache or buffering inside the call, I managed to get the full bandwidth of 600 MB/s.

In any case thanks for the quick response!

Piero

I guess you have a controller that only supports PCI Express 1 x. The SMU-8130 is our highest bandwidth controller, with links to four x 4 goes on the chassis. In the case of the 1062, each of the locations, 3, 4 and 5 get a dedicated link to the controller. x 1 links on about 200 MB/s max and x 4 maximum at 800 MB/s.

So your first step is to use an embedded controller or MXI-Express x 4 instead of x 1 back to a host computer. The SMU-8130 is the best for data transfers broadband, the SMU-8106 should also suffice your needs.

If you want data streams on an SMU-6537 drive, it is already integrated into DAQmx. You simply specify a file name and the data are intended to drive. If you want to stream * of * disc, you will need to do it yourself. Here is an example of C/CVI for broadcast disk using a C API scanners and Windows file IO functions.

Neil

Senior Engineer

National Instruments

-

problems in real-time with 6534

Hello

in our application, we use a PXI-6534 card to acquire datas. With 20 MHz, we acquired 32 bit data. We have several applications that work without problems. But now on the current project we have problem and we don't know why.

When we create test signals and read them in the 6534 we have several failures, which means bits that are not read correctly. Because we have 3.3 volt signals and the 6534 is a 5V card, it was expected that the problem is there. But now we think that it may also be that we broke the real time.

Parameters:

-Data entry

-20 MHz clock frequency

-32-bit

Does anyone know if the 6534 is able to acquire datas really up to 20 MHz?

Thanks in advance

Oliver

Hi Marco,.

During this time, we did an independent test.

We have created an independent generator that sent a test signal 3, 5V and 20, 8 MHz and 32-bit to thePXI6534 and checked if the data are complete. We discovered, that there is absolutely no data loss.

For us, this means that our problem is before the 6534 somewhere inside our electronics.

In general, this means that the 6534 can handle 3, 3V signals to 20 MHz.

Thanks for your help

Oliver

Maybe you are looking for

-

Satellite A350-212 on the fence the leds on my laptop

Hello There are seven symbols that are related to windows media player on my laptop near the power button... I could close with touch first conducted before, but recently it does not work, I could not close all of the led or rather the power button c

-

Lenovo G40 ~ 70 ram upgrade problem

I bought a lenovo G40 ~ 70 cell and I wanted to update my ram. It contains 4 GB of ram and I wanted it go to 8 GB. What kind of ram card should I buy and after upgrading my computer will have problems? Thank you.

-

No number of model everywhere!

Hello. First off thank you for taking the time to consider my problem. Recently, I was struck by a really bad virus that had to be removed through a fresh install of XP pro. Problem now is that I can't find a model number on this PC to get the dri

-

With a variable number of input ports on a Subvi

How can I have a Subvi with a variable number of input ports that can be changed in the other VI that uses the Subvi?

-

The best Format Possible Rip for Audio quality

I am running Windows XP Professional with Media Player 11. I don't care about the size of the files because I have lots of storage and I don't like using my music on a laptop or device drive. I'm only looking for to get the best possible audio qualit