Simultaneous to the AO and HAVE with the acquisition of data NOR USB 6001/MATLAB Toolbox

I am very new to data acquisition and bought a NI USB 6001 to start to learn. Because I can get free MATLAB through my University, I use Matlab data acquisition Toolkit as the data acquisition software.

My problem is that I get the following error message when I try to generate an AO (an LED voltage) signal and measure a signal I (voltage of a battery of 9V) simultaneously.

ATTENTION: This change is caused in the dump output data queue. Use queueOutputData for the queue data before the start of the object.

Hardware does not support the specified connection. Check the user manual of the device for the valid device routes and pinout.

However to measure IA or by generating the AO each by themselves works perfectly well.

My Matlab script looks like this:

daq.getDevices;

s = DAQ.createSession ('or');

s.Rate = 1000;

s.DurationInSeconds = 10;

addAnalogInputChannel (s, 'Dev1', 'ai0', 'Voltage');

addAnalogOutputChannel (s, 'Dev1', 'ao0', 'Voltage');

aoVoltage = 1.8 + 0.1 * sin (linspace (0, 2 * pi, 10000))';

queueOutputData (s, aoVoltage);

s

startBackground (s);

Note that adding the channels HAVE and AO at the session also works, however I get the error mentioned at the start of the session. This is a limitation of my data acquisition hardware (I don't see something like that mentioned in the manual) or do I have to modify the script?

The pins connected for the LED are AO0 (+) and AO GND (-).

The pins connected to the battery are AI0 (+) and (-) AI4. (The problem is still there if I use the reference to the ground for AI)

6001 cannot make simultaneous tasks. Very standard limitation of the low-end hardware... just don't have on board computing resources to handle such things. Even the 621 x boards have only limited multitasking abilities.

Can intensify to a high range data acquisition ($$$) or buy a 2nd a low end and synchronize tasks in software (not as precise calendar). I've done two approaches, one is "best" really depends on demand... If low-cost or high-performance is a priority.

Tags: NI Hardware

Similar Questions

-

Hello

Currently, we have two signals which are physically and logically linked together on the same line of data acquisition. The first, 'I' and the second signal, 'Q', are both related to "Ai6" (PIN 23) and "Ai GND" (Earth). However, when we probe the two lines coming our function "signal split", I drove Q by about 0.5ms. My question is, if these two lines are actually bound together physically and logically, then why are they phase shifted if they are both the same channel? They should be exact matches. I thought that the phase delay inter-channel occurs only in what concerns channels being read from data acquisition. I have attached a few screenshots as well.

Input signal is 20 kHz. Sampling rate is 40.5 kHz, number of samples/point is 1000.

Thank you.

Best,

Saami

System - Ultrawave Labs engineer

The board you are using is a multiplex. If you create several virtual channels, pointing to the same physical channel, we can enjoy this channel once for each channel. So what's happening essentially is that the physical channel was sampled once for channe 'I', then again for the channel 'Q' with a delay of a few milliseconds in between.

-

I have a PCI 6519 data acquisition card. I want to install it on the PC and use it outputs to control a robot. I have problems with the connections to the terminal block which is attached to the cable.

What type of connections I do for the acquisition of data PCI 619 card pins? What I have to give it to the ground and the CCV on the pins of the connector myself? What should be the value of the SCR I need to give to the PIN?

-

I created a custom and registered with a specific name date format. However, when I open a new worksheet, my saved format does not appear in the menu drop-down? Am hoping that I don't need to create the same format for each new sheet?

You must save the spreadsheet containing the new date as a model format and use this custom template for each new spreadsheet where you want that this date format personalized at your disposal.

-

Here is my sensor

Pressure sensorHere's the DAQ data sheet:

Here are my issues:

First of all I don't know what is LO and HI exactly in the DAQ 9219 material.

Second, I don't know what pin code I should connect the DAQ sensor signal wire. PIN 4 or 5 pin? The sensor has three pins, and I guess I should connect the other two wires to the power supply.

Thirdly how to calibrate the sensor. In labview choose voltage in the wizard?I'm pretty new in this acquisition of data and I need your help.

Thank you

Hi SilasIII,

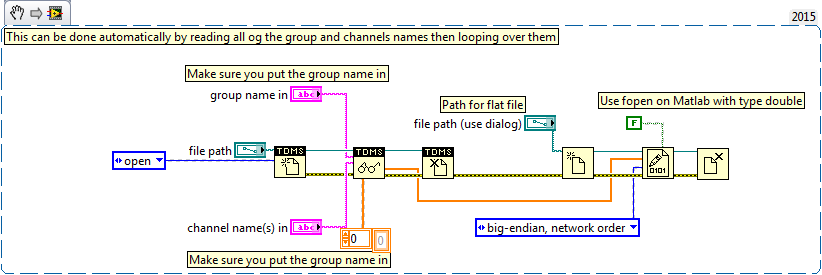

Hmm well 3 sons are probably on the ground, the power and the return signal. The datasheet for the sensor says:

First of all, you need to know which model you have (4-20mA, 0 - 5V or 0-10VDC). HI refers to the return signal, LO essentially means the land of the food that feeds the sensor. Then, you must get the 13-30 VDC supply. I don't think this should be too complicated and can be a simple wall DC power. You can learn how to create a custom in DAQmx scale. I hope that this is a starting point.

Kind regards

Eric

-

Read for the acquisition of data entries are overwritten

Hey there

I have a Daq reading input in a spreadsheet file

Data acquisition was told that one is supposed to have some time a loop around it and I cannot get it to run without one, so good

But my main problem is that it means that it replaces my written file each time that the loop repeats

He also asked me to choose the file to write in several times

How would I go about fixing this?

Thank you

Yes, you can convert digital to the chain, check the attached VI. I recommend you to go through the basic materials of LabVIEW and also play with example of NEITHER which comes with LabVIEW. Remember not to use the attached example and the acquisition of data, always use separate loops.

-

Use two assistants for the acquisition of data at the same time

Hello

I want to read multiple data channels of analog inputs on my DAQ hardware. However, when I try to create two separate data acquisition assistants for each entry, it gives an error saying "is reserved for the specified resource. The operation could not be performed as indicated "." Can't use two assistants for the acquisition of data at the same time?

I have to add different channels in the same assistant DAQ? I tried, but I couldn't separate the data in different graphs.

How does this work?

Kind regards

Allard

You can't have multiple tasks of the same type (in this case inputs analog) on the same device. Just so having 1 DAQ Assistant read all your channels and separate your channels for individual transformation.

-

We send 5v data acquisition using a voltage generator. Hook us it up to a voltmeter and see 5V. When connect us the generator voltage to a valve "normally open" parker, the voltmeter indicates .14V. It seems that when we connect the two sons of the valve for the voltage generator, the son act as pattern. We want to control the voltage flowing to tap through Labview. We checked the wires to the valve and they work very well, because if we send a constant 5V since the acquisition of data and put ashore, she, the voltmeter indicates 5V. Someone knows why the son act as pattern and low blood to .14V?

nsatpute wrote:

Our data acquisition is NI USB-6259. The valve requires only a 5V max and our DAQ provides up to 5V. However, after connecting the valve to the acquisition of data, the grave tension to almost 0. We start from the principle that the son somehow act as the reason, but we are not sure if this is the case.

The question here is not how much voltage the valve wants, it's the current needs of the valve. The 6259 can put only 5mA via an analog output. Your very likely tap needs much more than that. If you need to add in an amplifier circuit that can supply more current to operate your faucet.

-

Restarting a task for the acquisition of data inside a For loop

Hello

I need iterate through my acquisition of data. Currently, I'm doing this through the creation, implementation and tasks for the acquisition of data inside a loop For which is iterated according to the needs of compensation. Unfortunately, the creation of these DAQ tasks slow down my code.

I would like to be able to create the tasks outside the loop, pass them in and revive the tasks at the beginning of each iteration. Is there an easy way to do this?

Otherwise, is there a way to make the standard DAQmx digital startup trigger trigger several times (so that it starts each pulse data acquisition in a long pulse rather than just the first pulse train)?

Thank you!

-Evan

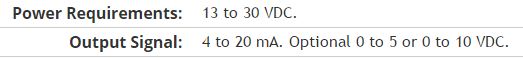

I whent before and created this example for you (and many others.)

-

Problem with the acquisition of data on XP Embedded

Hello

I'm using LabView 8.5, 8.7 DAQmx. My application is collection of data of NI USB-6009 14bits. I tried to create applications for tablet PC with installed Windows Xp Embedded. I created the installer on tablet with installed Windows 2000. I solved all the problems that occurs during installation. First version of the program have assistant DAQ in a main VI who collect and process the data. It worked properly on Xp Embedded. Second version was split into two of the Subvi. One is data collection and secondary processing. Each VI have own while loop. Both Subvi is placed in the large loop and they start at the same time. I am writing all the data to global variables. On PC with the windows application created 2000 worked properly. Error occurs when I moved it to Xp embedded. VI, which is the collection of data, the error see the 200361 code and text:

DAQmx reading (analog 1-d Wfm NChan NSamp) .vi:2

The task name: _unnamedTask<0>I know its something with the sampling and the clock, but I do not see where is the problem. In the main loop and two Subvi I 'wait until the next ms Multiple"block with a value of 200. DAQ Assistant were set as follows:

Price: 1000

Number of samples: 1000

Timeout (s): 10

Can you tell which can cause this error?

If you would like more information please write here.

Problem solved. There was connection between PC and USB-6009. Program works when I connect the USB-6009 housing directly to the PC. Previous connection was through usb hub.

Thanks anyway.

-

Combining the scalar output with the acquisition of data time vs RPM

I have no idea why my 9402 NOR does not work as it should, but I don't know he counts the pulses, and at that time I need data for my forthcoming report.

I came to a .vi that contains a very basic way of relating counties in time, however, I need to save the data to an excel sheet for I can analyze it. I have a motor which is connected to an assembly. My encoder measures the rotation of the shaft (no measure of direction availible) which is directly activated by the engine. As load us the assembly, I want to see what the speed of the motor through the encoder. So let's set the engine speed (anywhere from 1 to 100 rpm) and then load the assembly and see if the engine cannot maintain speed. Seems simple but my module is having a difficult time getting one any frequency of the encoder.

Anyway, the .vi I use counts the pulses and divide them by 100 ms once every 100ms. This generates a scalar value that I want to record with regard to the overall time, prefferably every 10th of a second (100ms). I know that I combine the values in a table (2 columns, an indefinite quantity of lines). How can I combine two elements ([time, RPM]) in a table every 100ms and having the table keep expansion of the lines until I hit stop?

Hello Evan

There you go!

Mart

-

Hi all... I learn LabVIEW since few days.i want to acquire a signal of pc6251 of acquisition of data and perform fft it can u people please help me? Thanks in advance

If you do only use LabVIEW for a few days, you should get familiar with it first by looking at some of the resources available here. After that, you can watch heredata acquisition.

After reviewing these documents, you can post back with any specific questions.

-

Writing data to extend the acquisition of data for the sampling rate high file

These are the tasks that I have to do to take noise measurements:

(1) take continuous data to USB 6281 Office, in a sample of 500 k (50 k samples at a time) rate.

(2) save data continuously for 3 to 6 hours in any file (any format is OK but I need to save in a series of files rather than the single file). I want to start writing again file after every 2 min.

I enclose my VI and pictures of my setup of the task. I can measure and write data to the file continuously for 15 minutes. After that, I see these errors:

(1) acquisition of equipment can't keep up with the software (something like that, also with a proposal to increase the size of the buffer...)

(2) memory is full.

Please help make my VI effective and correct. I suggest to remove him "write in the action file" loop of consumption because it takes a long time to open and close a file in a loop. You can suggest me to open the file outside the loop and write inside the loop. But I want to save my data in the new file, after every 2 min or some samples. If this can be done efficiently without using Scripture in the measurement file then please let me know.

Thank you in advance.

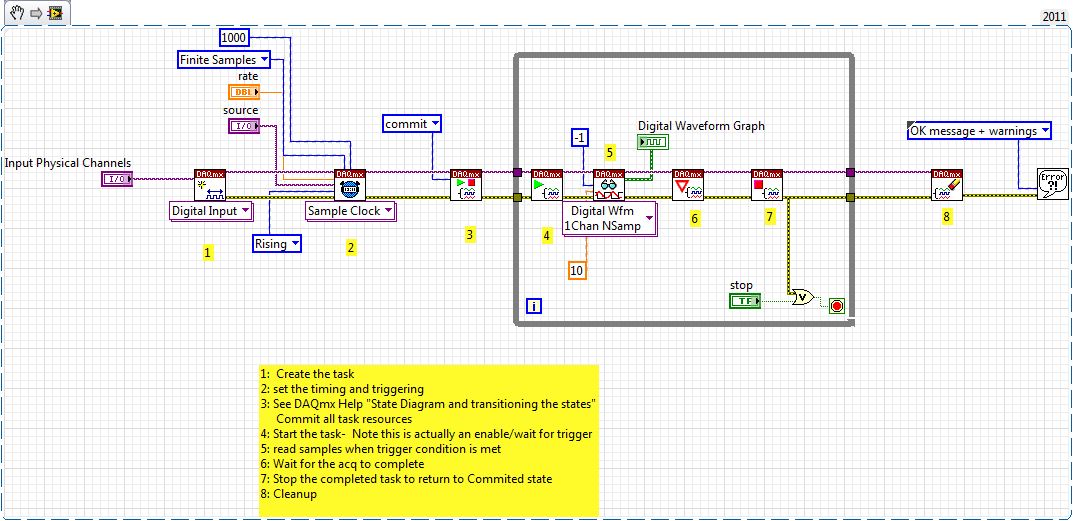

This example here is for a single file and a channel, you should be able to loop over that automatically. The background commentary should be the name of the channel, no group namede the name of the channel in the control.

-

Question about the Acquisition continues through NOR-DAQmx

I'm a bit new to NIDAQmx methodology and I was wondering if someone could could give me some advice on accelerating certain measures of tension that I do with a case of DAQ NI USB-6363.

I have a python script that controls and takes measurements with a few pieces of equipment of laboratory by GPIB and also takes measurements in the area of DAQ OR DAQmx via (I use a library wrapper called pylibdaqmx that interfaces with the libraries C native). As I do with the data acquisition unit is 32 k samples at 2 MHz with a differential pair to AI0. An example of code that performs this operation is:

from nidaqmx import AnalogInputTask # set up task & input channeltask = AnalogInputTask() task.create_voltage_channel(phys_channel='Dev1/ai0', terminal='diff', min_val=0., max_val=5.) task.configure_timing_sample_clock(rate=2e6, sample_mode='finite', samples_per_channel=32000) for i in range(number_of_loops): < ... set up/adjust instruments ... > task.start() # returns an array of 32k float64 samples # (same as DAQmxReadAnalogF64 in the C API) data = task.read(32000) task.stop() < ... process data ... > # clear task, release resourcestask.clear()del task< ... etc ... >The code works fine and I can all the 32 k spot samples, but if I want to repeat this step several times in a loop, I start and stop the job every time, which takes some time and is really slow down my overall measure.

I thought that maybe there is a way to speed up by configuring the task for continuous sample mode and just read from the channel when I want the data, but when I configure the sample for the continuous mode clock and you issue the command of reading, NOR-DAQmx gives me an error saying that the samples are no longer available , and I need to slow the rate of acquisition or increase the size of the buffer. (I'm guessing the API wants to shoot the first 32 k samples in the buffer zone, but they have already been replaced at the time wherever I can playback control).

What I wonder is: How can I configure the task to make the box DAQ acquire samples continuously, but give me only the last 32 samples buffer on demand k? Looks like I'm missing something basic here, maybe some kind of trigger that I need to put in place before reading? It doesn't seem like it should be hard to do, but as I said, I'm kinda a newbie to this.

I understand the implementation of python that I use is not something that is supported by NEITHER, but if someone could give me some examples of how to perform a measure like this in LabView or C (or any other ideas you have to accelerate such action), I can test in these environments and to implement on my own with python.

Thanks in advance!

Toki

This is something I do a bit, but I can only describe how I would do it in LabVIEW - I'm no help on the details of the C function prototypes or the python wrapper.

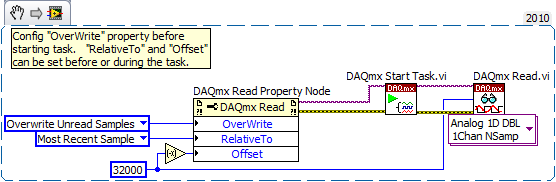

In LabVIEW, there are accessed via the 'DAQmx Read property node' properties that help to implement. One is the Mode "crush" which I'm sure must be set before performing the operation. The other pair is known as "RelativeTo" and "Offset" and they allow you to specify what part of the CQI data buffer to read data from. If you the config to "RelativeTo" = 'most recent sample' and 'Offset' =-32000, then whenever you read 32000 samples, they are the very latest 32000 which are already available in the buffer of data acq. Between the readings, the task is free to overwrite the old data indefinitely.

Note that you will need to do this continuous sampling mode and that you can explicitly set a buffer size smaller than the default which will choose DAQmx based on your fast sampling rate.

An excerpt from LV 2010:

-Kevin P

-

Components for the Acquisition of data for a Sub miniature sensor

Hello

I'm looking to acquire the data of two simulatneously cells (T4 - 100 L Measurement Specialties ELFS) load Sub miniature. The FS it out 100 lbs to 2.83mv / lb. I already have LabVIEW 8.2 and have acquired data using an analog I / 0 but my signal was weak compared to the noise in the system. I am a high speed data capture because the application that I use has an impact.

My question is: what the amplifier signal conditioner and the DAQ combination would be the best for this aplpication?

Thank you

Scott Kramer

Hi Scott,.

Welcome to the forums EITHER! Looks like you might be interested by the 9237 bridge and strain measurement Module. The 9237 comes in a USB, Ethernet, or Wireless channel, or as a stand-alone module for use with a cDAQ chassis. The 9237 offer a 50ks/s/ch sample rate, up to 10V of internal excitement which should reduce the noise from your system. Based on what you mentioned, it's the product I would recommend - you can find the manuals on the links above to verify that it meets all your needs. There are additional specifications that you need?

-John

Maybe you are looking for

-

HP LaserJet 1536dnf print, pirouette

Hello Expert, At our office, we have a printer model HP laserJet 1536dnf that link as a local printer so that the laptop has the following specifications: Windows 7 x 64, 8G OF RAM Graphic AM 1 G 1 TB hard drive This has recently sturdiness with the

-

iCloud calendar and contacts unavailable for Outlook

I use Outlook on a PC (Windows 10) 2013, and I keep my calendar and contacts on iCloud, so you can get them on my iPhone. Today, I restarted the PC for other reasons and concluded that Outlook can no longer access my iCloud calendar or contacts. When

-

WSN-3202 sensor supply voltage

I want to know the amount of voltage that provides power to the sensor of WSN-3202. In the datasheet, it is written that it provides 12.6V. But if I operate the WSN-3202 battery, then to the maximum node, it can get 6 v battery of four. then, how it

-

HP EliteBook 2760p: security for the Client software HP will not install on Windows 10 Version 1511

I got the HP Client Security software installed and running under microsoft Windows 10. It will install is no longer under Windows Version 1511 10. - Or nearby - 17 November Microsoft has released an update to Windows 10 Version 1511.The Windows Upda

-

Use of the virtual machine / machine is safe?

I have windows 8.1 pro I want to use operating systems diferrent/test I use virtual box to install the OS on my laptop, it will be useful for me to install os without data lost, but I noticed that when I run the VM my system's struggle can I use the