stepper motor DAQ

Hey everybody,

I have a stepper motor wich work good with "control engine daq-stepper (constant speed).

My problem is the constant speed.

I need to change the speed during the motion, and I don't know how to do this.

Thanks for the help and sorry for my bad English!

Hello

With the example of a constant speed at all times generate you a PWM with a cycle of constant use.

To change the speed you'll have to play with the duty cycle.

To do this, you can take a llok at the following example:

How can I change the use on my continuous pulse Train?

Kind regards

Tags: NI Hardware

Similar Questions

-

Where can I find the tutorial or sample Vi to control the position and speed of the stepper motor?

Hi all

I use a driver on 3rd for a stepper motor and I use USB6356 as the controller to drive the motor. Could you recommend some VI sample or tutorial on the position and the speed control of stepper motor?

Thank you

The best

I think that what you are looking for is the LabVIEW SoftMotion Module:

http://sine.NI.com/NIPs/CDs/view/p/lang/en/NID/14234

Here is a good resource on stepper motor theory:

http://www.haydonkerk.com/resources/StepperMotorTheory/tabid/192/default.aspx

My recommendation would be to start from a counterexample of LabVIEW. These can be found in LabVIEW > help > examples > material input and output > DAQmx > input meter, output meter.

-

Stepper - motor count measures

Hello

I am a beginner in the LabVIEW.I need an advice. How to count the number of steps of the motor stepper motor control turn the potentiometer and its rotation is necessary to complete the 170 steps. The LabVIEW I did the manual control of a stepper motor. I used two case structures. First of all for the start and stop of rotation and the second to change the direction of rotation.

When the motor turns to the left, the "number of steps" is incremented, and when it turns clockwise, the number in the decrements of the indicator to zero, but I need to decrement the numbers, which are recorded during a turn to the left (for example) 56 instead of 0, -1, -2, 57, 58, 59...)

Can it be somehow put implement into my program or is there another solution for counting steps?

Thank you

Instead of 2 nodes (one in each case) feedback, you need 1. But to make life even simpler, use the shift register that you already have. Most of the logic inside case structures is not necessary. Just incrementing or decrementing based on orientation. Put this value in the registry to offset. That will keep track of your number of the step. Now for the boolean array to use index, just use the function Quotient & rest on your number from step 4. The output remains will tell you exactly which line of your array of Boolean to use.

-

B6560 & 28BYJ-48 stepper motors controller!

Hi all, a Hello,.

Finally, I got my B6560 stepper motor driver controller.

I am now looking at little cost of motor control to do my first tests.

I got this reference: 28BYJ-48, but I don't get any information on the current, he pushes and he needs.

http://www.poli.br/~Marcilio/Arduino/motor%20de%20Passo.PDF

is there anyone who has already used the B6560 with labview?

and how about the 28BYJ-48 engine any help? experience to share?

Thanks advance.

amayas

The plug-volatge is 5V, phase resistance is 50 ohms. 5V/50ohms = 0.1Amp.

-AK2DM

-

Help me build a stepper motor control in LV?

I need control a single linear axis slide that is driven by a motor nema 34. It will be very simple move, start, move at a constant speed, stop, return. I do not have the engine. I can use a controller and a software company that sells me the slide, but prefer to use Labview.

I currently have a PXI chassis with a 6713 or 6704 available, or a '2 M Gate FPGA and cRIO-9073' with a NI 9401 I'll take delivery of every day now. I don't know much about the system in real time, but I have to learn it soon in any case.

Can I use my existing hardware/software to create a stepper motor control, or at least can I use Labview to interface with a motor drive step by step if this is not possible. I am currently looking at a 34T 1 Vexta engine, but do not know much about the stepper motors and do not really want.

Edit: Should have mention that I LV 8.6, with no motion software.

Engines step by step to have two power circuits creating magnetic fields perpendicular to each other inside the engine (in mathematics a certain sense anyway) you can consider working like pistons on a crankshaft which are out of step 90 degrees. You can use LV to manipulate these two. Want to make their vector sum in different directions while moving. Imagine making a point on a chart around the origin orbit. You need to consider things like the speed at which you can start the dot in orbit. Engines step by step can't go very fast if you add the requirement that the application start and stop without having to build your own ramp.

But it would be a big enough work for all, but more simple movements. You will need to learn less about stepper motors if you buy a motor controller that supports ASCII strings on a line of serial port as its instructions. I did recently with good results. LV must compose strings and write to the serial port of the PC. Having the engine go to a post 2205 units requires composing a string like this:

d 2205

go

It works fine without another component or software purchases.

I did something a little more complicated and wish now I had started with a decision to use the material in motion control of OR, or at least look at more the issue. When things are more complicated, using a serial port as the bridge between the PC and whatever the microcontroller is located in the drive motor starts to introduce limits you can schedule around with a lot more trouble.

You have many options depending on your purpose what is and how much trouble, you have to take.

-

Problems when you try to move the 3 stepper motors

Hello

I have problems when I Isaiah to compile a 3 stepper motors control program.

I have 3 steepest motors and controller (3 SMCP33 + SMCP33-EVA) nanotec.com, they also provide an example of Vi to control a motor that works successfully, but problems happen when I try to adapt the program to try to start the 3 Motors. The final application for this is going to be a Cartesian robot XYZ so finally I need to program coordinates to move the 3 Motors.

I am new to LabVIEW, so what I do is try to adapt the nanotec example to order 3 engine as follows.

-J' I assign each engine a different address, doing so that I can run each engine separately. But when I try to run 3 programs at the same time, they work but all moving them the engine (the first that has been run).

-If I try to make a sort of sub - VI is the same thing, only one motor is driven.

-Moreover, I get a warning when I try this, I have attached a screenshot of this.

I have attached the Vi and texture it to improve my description.

I woul be grateful if someona can help aport.

Kind regards.

Thanks for posting the original. By comparing the two screws immediately gives an indication of what might happen.

In the picture you posted you circled two places where you changed the address of the reader. In the Example.vi - Nanotec address of the player is connected to about 14 seats. So when you try to run the other engines in your modified program, the 12 places, you have not changed the address of the player are always preset to motor 1.

What you need to do is to divide the example VI in at least three parts. The first part initialization. The next part moves the engine. The last part ensures that the engine is stopped and made any required another stop. Each party becomse a separate Subvi. Each Subvi has the address of the reader as input. The initialization and shutdown parts are placed before and after a while loop. The movement parts are inside the loop. You can use three of each sub - VI for the three engines or a Subvi combined with subVIs move three to manage all three engines.

I can't say what approach might be better without knowing more about how you plan to order the engines - one at a time or all three at the same time, what kind of feedback is used, how management mistakes and other topics.

Lynn

-

Stepper motor and LabVIEW - loop

Hi guys,.

I'm trying to control a motor step by step using a 6008 OR. I did a little research and I know that there are some problems using the 6008 with a stepper motor, but for my project, it should work perfectly.

What I need:

A VI that will control a stepper motor and rotate the engine until the angle typed. The engine has a 7.5-degree increase. I build a VI that will continue to run the engine at the desired angle whenever I press the button 'GO '. But it only works for the first time that I press 'GO '.

The problem:

After the first iteration, if I press "GO" once again, it does not apply tension on the next pin, because it restarts the loop. And that makes the engine to become crazy.

The solution: (I don't know how to implement)

Make the engine go back to the initial position when I press the button "RESET". In the case, whenever I want to change the angle, I just push 'Reset' and then 'GO' and the engine would go to the desired position. Or even better: when I press the 'GO' button, the engine would automatically return to its initial position and then move to the desired position.

BTW: I would like to return to the initial position without having to do a 360 loop. I know how to do this.

The VI that I created is attached to this message.

Help, please.

Thank you.

Hi, Gear,

I tried to drive the stepper motor by a table of pre-defined and rotation of each step.

Hope that helps.

-

OR sell stepper motors or continuous or not?

Sorry if this is a silly question but I have conflicting information on this topic... Clearly, I see engine illustrated with prices but a rep OR was told that they don't sell the engines so they'd put me in contact with the 3rd party sellers? What sells not just dimmers NC status, but both engines? Thank you...

Hey, paris,.

Not ridiculous at all in question. We dinfinitely sell stepper motors. Initially, we didn't, but we saw that the demand was there for a "single window".

You can find a variety of them here

I hope this helps you.

-

USB-6501 as Stepper Motor Driver

Hello

I've been away from LabVIEW for awhile (6 years or more) and I have a small task to achieve and am really struggling to start.

I have a USB-6501 DIO and Labview version 8.6. I need to drive a motor not not that requires 4 input (in my case 2 Port (0 to 3)) and depending on the phase of these 4 signals with respect to the other (its a circuit of H-bridge) the engine to drive forward or backward.

I started with DAQ assistant and I seem to be communicating correctly with the OID and the engine, but I'm not at the stage of being able to produce my 4 signals. I know that the USB-6501 must be controlled with a timing (as opposed to the generation of a train of function for example). However I am stuck at start-up my possible solutions seem very long breath that I was wondering if there was a quick and easy solution to produce my 4 signals? I don't know I'm missing something.

Any help/comments would be greatly appreciated, as I'm very rusty and I have no time my solution.

See you soon,.

Karen

I solved my problem...

-

Different starting point of a stepper motor when vi is stop and run again

Hello

I have a vi that will drive and move through the digital output of the DAQ hardware, but now I am facing a problem with it because whenever I have stop the vi and run the starting position is the vi again, what he does not to her but just run again the vi of the last position He is arrested.

Is there a way to resume from when it is stop and start walking again? The vi I used please advice is attached.

Thank you

the reading and by saving it to a file, which is then read to say where the engine was when collapsed would completely stop the program and restart it. Of course, he will have no way of knowing if the position of the motor has been physically changed. Do this to an absolute position encoder, as a previous poster mentioned. Otherwise, to have a "home position" that you can always stop back as a switch of position of origin, or physics.

-

Hello. I have a problem with a prototype of movement control, and I am at a loss to know where to look next.

I run a computer running Windows XP with LabVIEW 8.6.1. The computer contains an NI PCI-7332 motion controller nine connected to a card NI UMI-7772 control a P70360 stepper drive. I'm trying to run a command of CTP 11 ELF 11 Danaher engine with little success.

All the lights on the boards are the appropriate color. I followed the implementation of the steps in "Getting started: P7000 series Stepper Drives. I have the correct indicators in the interface of MAX, and I can not even the motor to hum a little when I press 'Start', but the axle does not turn. I check the wiring of the driver of the engine and both Multimeters and diagram agree that, at worst, to run it back. This is before any programming LabVIEW. I'm just trying to make the engine start with MAX.

Any help would be greatly appreciated as this is my first time setting such a system.

Ben

Hi Ben,

Looks like your engine, and if your player are not compatible. 11 ELF 11 CTP is supported by the P70530 and not by the P70360 (see table 5 in the P7000 manual start-up). The P70360 (320 V) bus voltage is too high for this type of engine. Please contact your local branch OR for redemption for the right hardware options (you will need to swap the drive or motor).

In addition, I highly recommend using the software tools P7000 in combination with a cable (P/N 780099-01) series to set up the reader. It gives much more flexibility to use switches dip and you can optimize the performance of the drive and motor by adjusting the inductance of the individual motor drive.

Kind regards

Jochen Klier

National Instruments

-

Stepper motor control while reading encoder

Hello

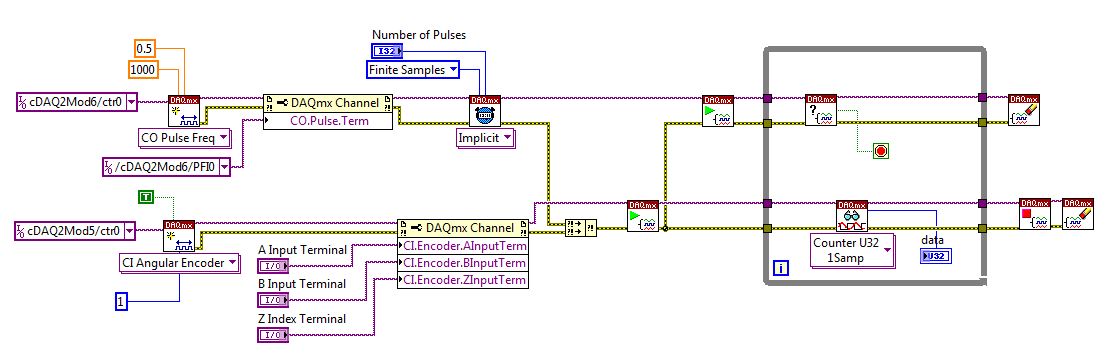

I'm looking to generater a pulse train to control a parallel reading and step by step motor in the impulses of the encoder of the motor. I was able to create two distinct VI who perform these taks individually, but when I put them into a single program (as shown below) is where I run on resource issues. I think I'll have problems affecting timers my properly and that's why I'm having these problems. I use a NI 9401 to generate impulses for the controller and a 9402 train OR read in the impulses of the encoder. If possible I would bring up just using the NI 9401 for the inputs and outputs if possible. The two are connected on a backplane cDAQ 9172 NU. Any help or suggestions would be greatly appreciated on what I'm doing wrong.

Thanks for the suggestion of Carmen, but I was able to understand what it was with a little help from NEITHER. The finite number of pulses of timing function requires 2 counters, so when I tried to read in the encoder data there where no meter more left on the backplane. Changing impulses continuously solved my problem. I'll take a background of most recent basket with 4 meters from the lab which should allow me to run the finite number of pulses and read data from encoder at the same time.

Thanks again,

Doug

-

Control of Stepper Motor with case NI USB-6009

Hi all

I am currently creating a movement control system with a double movement actuator

and two bipolar chopper drives (see table), which should power the motor. We already have a NI USB 6009 in our lab, so I was wondering if I could use it to send signals to the two pilots to control the speed and direction of each axis on the engine?

Enclosed driver's manual indicates that input signals should be 0-5 V DC (TTL logic). I have been informed by the engine distributor that the 0-5 V DC TTL drivers required, the signals are analog. The NI USB-6009 manual reading, there are two 0-5 V analog outputs on the acquisition of data usb so I could provide two signals?

There are often posted however similar problems, it is usually a digital signal NI6009/6009 sends the driver. Looking at the driver's manual, can someone tell if an analogue signals or required as I have said, I was misinformed or 0-5 v DC signal will be enough. I can get more in touch with the dealer if you have any questions you guys think I should ask him.

Thanks in advance for any help! It is much appreciated.

I looked in the manual and it doesn't seem to be very clear. I know that the USB-6009 case is capable of AO and DO, then you would be although it is. I could contact the Haydon Kerk support for more concrete details on the gap between what says the manual and what they told you.

-

Bipolar stepper motors (x 2) to follow a set of coordinates

Hello!

I want my bipolar Motors (2 x) to follow a set of coordinates, so I hope that someone could help me get started.

Motor control step by step vi receives an amount of markets, negative amount to take a step back.

As well; to calculate the amount of the steps needed to get to the next coordinate: number of steps = active coordinated - previous details

In the game/list/table I want to indicate if it is for motor 1 or 2 and if a specific, additional signal is on or not.

Example of

10231 engine 1 without additional signal on, moves to coordinate 231

11300 engine 1 accompanied by a signal on, moves to contact information 300

00231 2 engine, without additional signal on, moves to coordinate 231

01300 engine 2, accompanied of a signal on, moves to coordinate 300

When the first digit indicates the engine 1 or 2, the second digit if the additional signal is on or off and the 3 last is the desired coordinate.

The first 2 numbers must be split individual signals.

The amount of contact information will vary.

Regrads,

Thorstif

Place a cluster in a table, it unbundled by name.

-

I can't launch the stepper motor using NI 9501 with the example given.

I have a NOR cRIO-9025. I'm trying to run a motor drive with NI 9501 with the help of the given example (Veloity control (open loop) - NI 9501). The program is compiled on the FPGA, but the motor step does not move. The poster drive status always "disabled by software. What I am doing wrong? I'm under the RT and FPGA live

Hi Pranjal,

You will need to provide an external power supply to the module. If you look at the Manual 9501, you will see that the pins 7 and 8 are intended to power 8 - 30V. If you do not connect this offer, you will have a fault and the Red led should light up. The manual shows you different ways to connect your motor.

When you run the VI, you will want to run only the RT VI. The FPGA VI will run automatically when you start the RT VI.

You are right that there is no file "Items to Move. Instead, you want to spend the following things to your new target: speed control (open loop) - .vi NI 9501 (RT), speed control (open loop) - .vi OR 9501 (FPGA) and the target value. You want to make sure that you drag to the appropriate hierarchy. The RT VI must be less than the RT controller in the project and the FPGA VI and set FIFO must be below the target FPGA. Finally, you want to make sure that Mod1 is a 9501.

I would like to know if any of this helps.

Thank you

Maybe you are looking for

-

I can't do widows update updates, I get this error error number: 0x8024400A.

When I go to windows update I can't do updates I get this error error number: 0x8024400A. I can't use fixit until I can get the updates. When I download the net framework that I can get up to 2 sp 2 when you usually try 3 we net connect for 4 days no

-

Easy transfer does not recongize. MIG file

I replaced the drive in my Dell d830. I gathered my files on the external hard drive. When I run easy transfer on "new computer", it does not recognize the file in the box go. I can see it on the disk, but it does not load. Help?

-

HP 7510: Can I scan to an OCR?

I have a HP 7510 printer/Scanner. I would like to know if I can scan to OCR output. I get a pdf and jpg file when I press "Scan", but it is possible to obtain for scanning to OCR? Thanks in advance. Adam

-

VLC player and other applications won't record video correctly, only works for .mp4 videos.

Hi, I have a problem with the video recording of vlc player and their opening upward. Once save the .avi video it doesn't give me the audio. It does not with .mp4, however. Which cuts and works fine when I play the video. He just started doing last w

-

applications Adobe CC does not open

Help. My CC adobe apps will not be open. I get an error message 'bad image '. My power went out recently, but in the past, this has not been a no problem.How can I get my apps to open?Greg