Traditional speed DAQ vs DAQmx comparison

I currently use four 4 boards of 16th-1 MIO PCI National in the HP running Windows XP workstation test simultaneously four 4 medical devices at a time. We currently use traditional DAQ and LabVIEW 8.2 to test our products to the main line. Our test software is strictly controlled and requires reesources important for validation when changes are made. We bought the LabVEIW 2010 and it supports more traditional DAQ. We know that somewhere in the future we will make the transition to DAQmx and LabVIEW 2010.

I need to perform a cost compared to the benefits of the conversion of the test of LabVIEW 8.2 and traditional DAQmx and LabVIEW 2010 DAQ system. If the profit is high enough I was able to hire a consultant to expedite this process.

I know there are many variables that factor in speed, and I know that I have not provided details, but can anyone provide rough estimates. Is this 2%, 10%, 20%? What is your best guess/estimate?

Thanks in advance

Hi Int_man,

Traditional DAQ 7.4.4 does support LabVIEW 2010, but to install traditional DAQ to a version of LabVIEW at once more, you have to follow a procedure described in the readme file. Traditional DAQ does not support newer operating systems such as Vista or Windows 7, and it does not support new hardware such as M or X series. Given your validation needs it sounds like you might not be upgrading your operating system or hardware in the near future, but if you ever decide to do, you would need to spend to DAQmx.

Performance is a little tricky... You could see a perforamnce increases with an upgrade to DAQmx, but this depends entirely on your application. I wouldn't feel uncomfortable providing any kind of estimate of the increase in performance without any information on the application itself. For example, DAQmx provides thread that can often be used to increase the performance of the application at the same time, but if your application writes past most of the time of digital static call in order, you may see a performance decrease slightly because of the overhead of a cheque that has been implemented in DAQmx in order to avoid the double-driving lines. Overall, most of the functionality has improved in speed, but it is not possible to say outright that "move to DAQmx will give X % increase in performance" in all cases.

That said, if you have to go through a validation anyway it might be timely to review the whole of the system as a whole (including the DAQ equipment used). Unless you are implementing your comments or need to input user scope, the speed of the software driver calls could be made essentially irrelevant if you are able to use the material that allows buffering and trigger your necessary inputs and outputs. As someone who has been loaded to optimize the suboptimal systems (if necessary), I strongly encourage you to review the entire application as a whole and where the greatest improvement.

Best regards

Tags: NI Hardware

Similar Questions

-

Traditional DAQ and DAQmx data representation

Hello

I use a card PCI-6013-NOR and used DAQ_Op and DAQ_Start to acquire the data of the device (with game 1 win), who have a CCD camera to acquire data.

I migrated the DAQmx application, it works fine, but the intensity of the curve drawn using data is lower than expected.

During the migration of the old code, I replaced the logic below DAQ_Op

/*------------------------------------------------------------------------------------------------*/

TaskHandle ulTaskHandle = 0;

DAQmxCreateTask ("", & ulTaskHandle);

Double dMaxVolt = 5.0;

Double dMinVolt = - 5.0;DAQmxCreateAIVoltageChan (ulTaskHandle, "Dev1/ai0", "", DAQmx_Val_Cfg_Default, dMinVolt, dMaxVolt, DAQmx_Val_Volts, NULL);

/ * This function handles various combinations to select the signal.

* - Select_Signal (1, ND_PFI_2, ND_IN_CONVERT, ND_HIGH_TO_LOW)

* - Select_Signal (1, ND_SCANCLK_LINE, ND_SCANCLK, ND_LOW_TO_HIGH)*/

RouteSignal();

DAQmxCfgSampClkTiming (ulTaskHandle, NULL, dSampleRate, DAQmx_Val_Rising, DAQmx_Val_FiniteSamps, ul64SamplePerChan);

DAQmxStartTask (ulTaskHandle);

/ * Allocation of memory for data acquisition. */

Double * pDataBuf = new double [ulCount + 1];long lSamplesToRead = (long) ulCount;

long lSampsPerChanRead = 0;DAQmxReadAnalogF64 (ulTaskHandle, DAQmx_Val_Auto, DAQmx_Val_WaitInfinitely, DAQmx_Val_GroupByChannel, pDataBuf, lSamplesToRead, & lSampsPerChanRead, NULL);

If (ulCount! = (unsigned long) lSampsPerChanRead)

{

}

on the other

{

for (unsigned long ulIdx = 0; ulIdx)< ulcount;="">

{/ * psBuffer is a short table.

* Here, I'm trying to convert and copy the new buffer (double value)

* to the old buffer (short values)

*

* I guess that old values will be in the millivolts range.

* To convert the values of v of the buffer in millivolt I am multiplying by 1000

*

* I don't know if it is true.

*(psBuffer+ulIdx) = static_cast

((*(pDataBuf+ulIdx) * 1000));

}

}I'm not sure whether the conversion I did new buffer for old buffer is true. I need to create a DAQmx_Val_FromCustomScale to get the same value DAQ_Op returned?

Could you find something wrong with the logic? How can I get the same DAQ_Op value returned by the double buffer returned by DAQmxReadAnalogF64() is there any best mechanism available?

concerning

Praveen.DA

The reason for your bug is that you apparently did not understand what does the DAQ_Op function. In help for this, it is clearly stated that the data returned is I16. Your choice of data F64 was an obvious conflict with how you have porgrammed traditional in DAQ board. The Council resolution doesn't really matter. The big difference is set to scale and without scales.

-

Why do my pci-6052e configured as traditional daq and daqmx in MAX?

I have an old computer of three year with 1 GB of RAM and a 3.00 GHz running Windows Server 2003. It has already been used for experiments of movement control and has a 7333 motion control card and a PCI-6052E. Now all I want to do is sample data of a pressure sensor and a flow meter using the PCI-6052E, but for some reason, this card is configured in MAX as a DAQmx device and a traditional DAQ (Leagcy) deivce. Unfortunately, when I write the LabVIEW 8.2 VI, the only available data acquisition tools are DAQmx and Max my two instruments are installed in traditional DAQ.

If there is only one card PCI-6052E in the computer, why MAX card PCI-6052E called dev3 DAQmx and a card PCI-6052E dev1 in traditional DAQ? How can I fix?

Cpesko,

I am happy here, you have a few things working under Windows Server 2003. We do not however have any software under this OS except what is listed here.

DAQmx and TDAQ are 2 different drivers and this is the behavior expected that devices that support both would be present in the title of each driver.

-

Traditional DAQ against DAQmx Counter

I'm trying to convert an existing legacy application written in LabVIEW LabVIEW 2012 6. I have a problem with a traditional Daq counter. Specicically the VI "event or time meter Config.vi. In the attached VI, you can see that 1 meter is configured to count the cycles of an internal signal, not a PIN counter SOURCE signal. This configuration generates an integer for each cycle of the internal signal: every 10 microseconds in this case. I can't find a way to replicate this feature in DAQmx. I use a DAQCard-6062E (PCMCIA Slot) card in a Dell D620 Laptop. I tried to attach a fully functional VI, but get the error 'the content of the attachment does not match the type of file.' to fix this I had to fix a JPG image. I've included comments in VI to clarify things. Any help appreciated. Thank you.

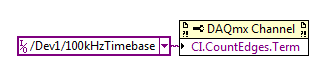

In DAQmx you can achieve the same result by setting the terminal entrance for a task of edge to the time base County internal 100 kHz:

The 100 kHz Timebase is considered to be a "Advanced terminal" (don't get started me on the topic) so see in the dropdown menu, you must right-click on the control / constant and select the appropriate name of I/O filtering option.

Best regards

-

problem by creating a virtual traditional NI-DAQ channel

Hello friends,

in fact I change computer daq to a machine, but for now I have problems when I try to create a virtual channel.

I see the jury on the devices and interfaces but when I fill in the parameters of the analog track exactly in step giving the ports, and the channel of material not appear anything and when I finished the configuration in the virtual channel properties appears invalid configuration and there I can't select anything in the hardware channels.

I don't know what is happening?

I installed labview 2009 Windows 7 with MAX 5.0 and NI DAQ 9.4

Please help me or ideas on the...

Thank you...

You change os or change at DAQmx. Traditional DAQ has been made obsolete when DAQmx was introduced with LabVIEW 7. If your card is one of the old cards that didn't is not supported by DAQmx, then Yes, you would also have to replace one if you stayed with windows 7.

-

Windows 7 is compatible wit DAQ or DAQmx?

HELLP? My CEO has a question on the XP of Windows 7 mode. He wondered if we can install NIDAQ driver of Windows 7 XP mode. But I think that it won't work and you guys OR not want to do, your timeless efforts on NIDAQmx

If you have already tested, let me know the result.

Kind regards

Hello anarkie,

In anticipation of the release of Windows 7, we have tested OR DAQmx on Windows 7 for a while. NOR-DAQmx 9.0 works well on Windows 7, both 32 - and 64-bit. It is not officially supported yet, but our internal testing shows excellent results. Official support should be available soon.

NOR-traditional DAQ won't work on Windows 7 and there are no plans to develop a version that works on Windows 7. XP compatibility mode helps with the functionality of the user mode only. NOR-DAQmx and NOR-traditional DAQ use calls to extended kernel-mode which will not affect using the XP compatibility mode in Windows 7.

Hope this helps,

-

Communication problem 6210 hardware DAQ with DAQmx 9.2.3 (Err 88302)

I would use NEITHER-USB-6210 with DIAdem 11.1 under Win 7 Home Premium. DAQmx software and supplied drivers are version 8.6, but does not support this DIAdem 11.1 (DAC-NOR-DAQ interface did not show any existing signal). So I decided to update software DAQmx on latest version 9.2.3 which should solve this problem. After installation, all previous configuration items, MAX moved well and DIAdem DAC block indicated all signals with success but start of acquisition and measurement is impossible since. After firmwareloader establishes the material connection seems to be running, but any attempt to transfer data or start any function Max raises failurie event-88302 "an internal error has occurred." Anyone help me please?

Dear Mr. Varga,

After that the PC was clean from previous installed everywhere DAQ and new installation repeated once more, problem has been resolved and now the system is fully capable to work with DIAdem, as well as with the Net. request.

Kind regards

Milos Riha

-

Difference between DAQ and DAQmx for acquisition of data PCI 6534

Hello

I use the PCI DAQ 6534 card for my digital I/o transfer. I am beginner in the labview.

I want to store the data coming in memory and the reading of the data at the level of the trigger.

I have seen the examples in the labview. Some have used DAQmx and DAQmx read write that screws and some have used the confg DIO port and all...

So I want to know the difference between these two. For my application that I use?

Hey Bo,

First of all, I would recommend that you discover the NI 6533/6534 for NOR-DAQmx help. You may be able to find some of your answers in this help document. Now for what you try to do in your application, it looks like you are only buying data. If this is the case, with the 6534, the device acquires data in memory shipped as soon as the DAQmx series start task VI, as long as you don't start hardware triggers have in place. If you have a trigger of starting material, then will make the purchase of the aircraft after the DAQmx start task VI and only after you receive this material trigger. If you call not the DAQmx Read VI, then the data will be stored in the memory board for you, as the driver manages this data in the on-board memory storage, until reading DAQmx VI is called, which at that time, data is transferred to the Board of Directors in the memory of the computer. Once you get it in the computer's memory, you can do whatever you want with these data, as this graph or treat. If you look at the sample programs (which have been mentioned on how to find those in a previous post), you can find an example that little shows you how it works. One of the examples that you can check is called reading Dig Port-Ext Clk.VI. In this example, it sets up to read a finite number of samples and then starts the task. If you set a breakpoint on the line of the error after the VI begin, the data will be acquired in the amount of on-board memory. Then when you cancel the break of the VI, data will be extracted from the amount memory embedded in the memory system with the reading VI DAQmx. Again, the pilot takes care to put the data in the memory board for you once you start the task.

I hope this helps. Please let us know if you have any questions or concerns about this issue. Also, certainly, discover and try to run all the programs related to the 6534 examples so that you can learn how the equipment works and how to use features to do what you want your program to do. Also, be sure to read through the help on the 6534, as well as the help of VI documentation to learn what makes each function. Thank you and have a nice day.

Kind regards

DJ L.

-

How to set up wizard DAQ or DAQmx tasks using an external text such as a CSV file?

I work in an environment were we have a lot of users VI. I develop the VI and technical personnel using the GUI (cover Page) to collect the data. In order to control the input parameters used on multiple hardware platforms, I'd like to develop a generic VI which will import or read a text file I created, and configures the DAQmx tasks to perform data acquisition. In fact, I have the generic VI full and need to understand how to make configurations DAQmx more transparent for the end user as long as the end user has the text file to import. For example, to generate the wizard DAQ DAQmx tasks based on information from text file?

I don't have time to do more than just a small example. The VI below contains a table with table fixed index functions. This would have changed to get automatically the correct rows and columns, but I hope that you have an idea. I does not have any code to define the type of temperature measurement or to set the correct configuration of Terminal. All of this plus all other possible options will be treated similarly to the definition of the type of channel and min/max which is located in the example.

Edit-attach VI

-

Name of the traditional model DAQ and SCXI-1530

Hi all

I'm using Labview 6.1 and 7.1 of DAQ traditional. I'm working on a system with a data acquisition card (PCI-6052E) and several SCXI (1520, 1530) cards. The SCXI cards are installed correctly because MAX can detect all.

I want to do a program with traditional DAQ that allows to detect all SCXI cards and Show names of model on the front panel.

I found in Tradtional DAQ, there is a VI entitled "Get SCXI information", which returns the types of models of SCXI cards, something like, 50, 51...

I found in the help file on 'Get SCXI Information' VI there are some kind of configuration file saying 51 stands for SCXI-1520. What does the acronym for 50? Where can I find the full configuration file or can somehow I change it? As 51 means something else...

Any ideas are much appreciated... Thanks to you all!

This is a duplicate of the last post in this thread: http://forums.ni.com/ni/board/message?board.id=250&thread.id=53087

-

Is there a DAQmx function to duplicate the traditional DAQ "Index.vi channel".

I've been converting an old app using traditional DAQ to DAQmx. It's a complicated piece of code and makes installation of all available channel group config, then the user selects the specific ways to acquire data on. It uses the "Index.vi channel" to achieve this. Is it possible to replicate this feature in DAQmx, or will I have to rewrite the whole mess? Thank you.

Thank you aNltaB. I was able to implement a task with the necessary channels for each thing that I did and circumvent the need to configure all channels and then indexing them. I didn't know how it was all rooted in the program, but make the separate tasks seems to work well. As far as I am concerned, this issue is resolved.

-

Conversion of a VI that uses OR-DAQ traditional to NOR-DAQmx

Hello

I'm trying to convert a VI that uses OR-DAQ traditional to NOR-DAQmx. I'm almost there, but when I run my new rear version number 'read' and 'scan' are not the same.

In the original version the "number read" always came back as 1 and "scan" backlog is always returned as 0.

In the new version, "number readings" and "rear scan" could come back with any value. It's sure to shake my recording of measures and VI the interaction with the rest of the program.

I have attached a light version of the VI for the old OR-DAQ traditional and new OR-DAQmx that illustrate this problem. The two VI is written in LabVIEW 2011 SP1. I would be willing to upgrade to SP1 2013 LabVIEW if it would help solve the problem.

I would be grateful for any guidance.

Thank you in advance.

I think I did. Use-1 to erase everything in the buffer when the program is waiting for the countdown to the end and then just ask for 1000 measurements when the countdown reaches 0. Do not need the Scan back or number reading. Also don't need to add the measure in table 1 at a time because I get them all at once.

I enclose a copy of my solution for all those who might need to do something similar in the future.

Gary

-

Need help to convert DAQ traditional subvis DAQmx configuration

I need to convert these screws (of NOR-traditional DAQ) to be used with a new data acquisition card that supports only NI-DAQmx.

Please help me in this...

Can I use the same traditional NI DAQ VIs with the NI PCI-6221? If so, how? This device can be configured for NI DAQ traditional?

NOR has several resources to help move tradtional DAQ DAQmx. A good place to start is the getting started page. There is a tutorial on how to transition. There is also the compatibility screws which replace certain traditional DAQ functions with wrappers around functions DAQmx. The DAQ example you posted is pretty trivial and really shouldn't take a lot of time to convert once you get a basic understanding of the DAQmx.

-

DAQ traditional Windows 7 (x 64)

I changed to Windows 7 (x 64) of Windows XP, with a new PC (need more memory). I am programming for a PXI with LabVIEW Real - Time 2009 SP1 system. There is a map of temperature traditional DAQ running inside the PXI chassis. I read somewhere that traditional DAQ is not longer supported by NEITHER. In fact, the installer to update driver 7.5 Beta displays an error message on Windows 7 (x 64).

I don't want to run Trad. Acquisition of data under Windows but on LabVIEW 2009 real-time. I have it takes rather to programming on my Windows host. Is there no alternative to the use of Windows XP?

I think that it is not possible to use an in general for a NI 4351 DAQmx driver.

For example, in the file Readme of NOR-DAQmx 8.0.1, I found the following information:

Devices limited to NOR-DAQ traditional (old)

NOR-DAQmx does not support the following devices. The following devices are supported only in NOR-DAQ traditional (old):

....

Dataloggers for NI 4350/4351

-

Synchronize two E-card with traditional DAQ series

Hello

I have a PCI-6052E and a PCI-6071E and I have a Matlab program that interacts with traditional hardware DAQ driver cards.

It is possible to synchronize the two cards use RTSI or something? If so, what should I do in matlab to achieve?

I'm a bit confused, because I don't know if this is only possible using DAQmx.

Thank you!

Hi zlyhere,

Using DAQmx would definitely be the best choice.

In terms of using C vs the Data Acquisition Toolbox for The MathWorks Inc. Matlab® Software, I would recommend the Toolbox for ease of use. The MathWorks develops the Toolbox, so they must have documents on how the maps can be synchronized.

If you find that you need more features, you can fall back to C. Documentation is available at

"" "" Start menu"all programs" National Instruments "NOR-DAQ" support textual Code ' using NOR-DAQmx C reference

MATLAB® is a registered trademark of The MathWorks, Inc.

See you soon!

Maybe you are looking for

-

iOS 9.3.2 My iPhone and iPad wake connected to cellular data so that I have a home network and expect things to happen on my network home. It costs me in the case of the background activity while I'm SLEEPING on my cell the att network connection. Ho

-

HP Pavilion 15-au074sa: HP Pavilion 15-au074sa RAM Max upgrade

Hi guys,. I am looking to buy a HP Pavilion au074sa 15, its currently on sale in PC world UK, he says, it comes with 8 GB of RAM PC WORLD LINK - http://www.pcworld.co.uk/gbuk/computing/laptops/laptops/hp-pavilion-15-au074sa-15-6-laptop-silver-10... I

-

Trackpad and keyboard are not working windows 7

I just installed windows 7 and I do the first set upward but my trackpad and keyboard do not work, I tried to use a keyboard usb and bot mouse still the same, any help?

-

Quite often my G20 does not close down properly... help!

-

Want x 360 M6 keyboard doesn't pop up in tablet mode

I just got a renewed desire x 360 and the keyboard won't pop up in tablet mode, but the regular computer keyboard laptop mode works very well. Is there a button I'm missing?