Personalized with Multisim Labview instrument

Hello

I want to use an Instrument of Labview custom (Phasor_Diagram) with Multisim 13.0:

http://www.NI.com/example/30200/en/

I copied the Phasor_Diagram.llb and the Phaser to C:\Program NIUninstaller Instruments\Circuit Design Suite 13.0\lvinstruments folder, but

I can't find the Labview Instrument Phaser in my Multisim.

What's not? How to get this working?

What about Peter Stolz

Hi Peter,.

It seems that Phaser instrument was built using an old version of LabVIEW, I have rebuit in LabVIEW 2013.

Tags: NI Software

Similar Questions

-

extraction of your LabVIEW instrument

Hello

Does anyone know why your Extraction icon does not work in a Labview Instrument? When you try to use the Instrument of LV in Multisim, Multisim is quitting with an unknown error. If I take on the Extraction of tone icon and rerun Multisim without her, it works again...

Thank you

Ussr123

The problem is resolved. It is possible to use your snippet in a LV Instrument. The problem was something else, unrelated to the Subvi your snippet.

Ussr123

-

How to avoid the automatic launch of SignalExpress with a USB instrument?

When I plug in (or activate) a USB instrument (I have 2 USB power sensors and a signal RF N9310A Agilent generator) - SignalExpress 2009 will launch automatically. It is very annoying (and apparently by default) behavior. With 3 switched instruments, I get 3 instances of SignalExpress which must be closed. Anyone know how to disable this feature? Of course, I'm sure I could just uninstall SignalExpress altogether, but not this option, what is the solution? I'm running on Windows 7, with LV 2009 Professional.

After some research, I found the solution. As I said in the original post, it's Windows 7, so this may be a problem of Windows 7-specific.

To disable the autorun of SignalExpress property when you plug a USB T & M class in Windows 7:

1 run the configuration utility AutoPlay from the Windows Control Panel (Panel of-> hardware) and sound-> AutoPlay, or simply type AutoPlay in Windows Startup box.

2. scroll to the bottom of the list and you will see-> Test and measurement device. Change the selection to "Control Instrument using LabVIEW SignalExpress" to "not act."

3. Save and you're done.

I suggest you this info. added using SignalExpress for the next version.

-

Problem with 2 GPIB instruments

Hello everyone,

I work in a program with LabView 2015 this control 2 instruments, the Rohde & Schwarz Smiq02b signal generator and Analyzer of spectrum n9010a Agilent EXA. I use the cable Agilent - 82357 B USB/GPIB to connect my laptop with these two instruments (PC-> EXA-> Doganovic). I also installed the two drivers of instruments from their official websites.

The program worked correctly until I had to format my computer and reinstall LabView but something wrong now.

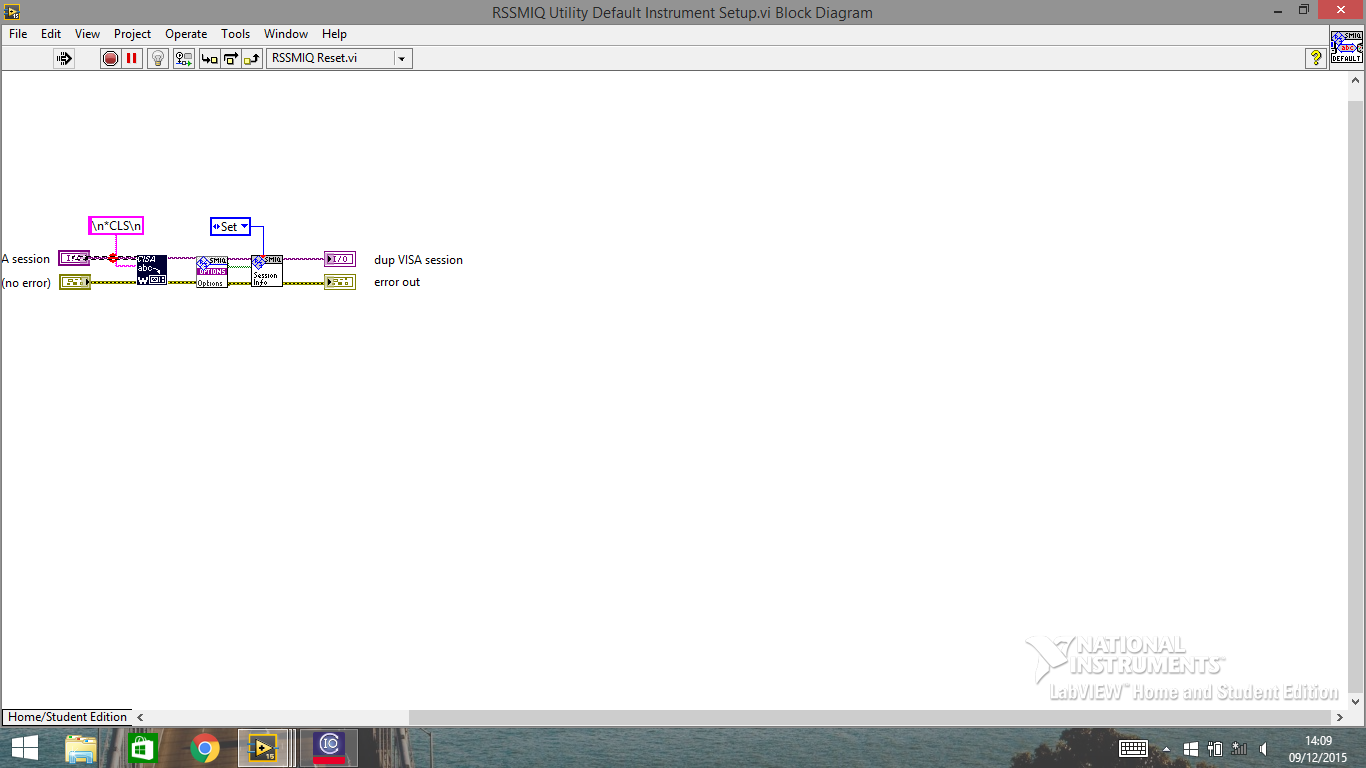

The problem comes when I run the program, is unable to initialize the SMIQ02b, the program stops and opens a new window of block diagram. This block diagram belongs to a block driver the instruments within this scheme, there is a VISA write flashing block.

This only happens when I'm initializing two instruments in the same program, if I create a new VI and use the Doganovic only, I have no problem.

I don't know what is happening, it is very strange that it worked well before, and now this happens.

That's what I installed in my laptop:

-2015 LabView

-NI Device Drivers (included NI-VISA 14.0 and NOR-488. 2 14.0)-Agilent IO libraries Suite (configured as secondary VISA) 17.1

-Passport OR VISA for tulip IT

I'll be very grateful if someone could help me with this.

Thank you!

You set a breakpoint, it's what's causing the break.

-

How can I control external devices using a stand-alone touchscreen with a LabVIEW app

For my senior project my group design and created a vehicle for extended range hybrid with 90 Li + battery which is charged by a 15 kW generator and/or who is also charged by a 5 kW fuel cell. Currently, our system is able to measure the tension on batteries and display them on a laptop via LabVIEW. To process these data, we use a cRIO FPGA. What we would like to do now, is having a touch screen for the pilot to choose which loads of source of battery power so that monitor a pressure reading from the fuel tank.

What kind of touch screens to LabVIEW to be downloaded on and used for controls?

A cRIO has the necessary capacity to supply such a screen and handle the transfer of the data from the sensor fuel and relay (for turning on and off will deepen)?

Do I need an additional license to create stand-alone applications and how I would go about creating a stand-alone application?

Sorry for the question as much. Any help with the answer. Thank you!

This looks like a very interesting project. If you are interested, National Instruments organizes an contest of Design student where you can win cash or a trip to Austin for NIWeek.

steve215 wrote:

What kind of touch screens to LabVIEW to be downloaded on and used for controls?

NEITHER sells computers touch screen that can be used to control LabVIEW applications. You can find more information here: HMIS and industrial touch panels and here: LabVIEW Real-time and Touch Panel Deployment and replication resources. Our computers 6-inch touchscreen , run Windows CE, programming on them is a little different from the programming on a full Windows operating system. You can find useful getting started with LabVIEW Touch Panel Module .

You can use third-party with the LabVIEW Touch Panel Module devices, although it takes a deployment license for it. More information can be found in the getting started guide.

If you were able to send the information of cRIO on a network (which according to your description, seems unlikely), you can use a smartphone to control your application. More information on our community of Smartphone group.

steve215 wrote:

A cRIO has the necessary capacity to supply such a screen and handle the transfer of the data from the sensor fuel and relay (for turning on and off will deepen)?

If you use the 6-inch touchscreen panels, they need 18 to 32 VDC (the fuse becomes an open circuit if the input level exceeds 33 VDC). The transfer of data from the switching relay can be monitored and changed with the touch screen.

steve215 wrote:

Do I need an additional license to create stand-alone applications and how I would go about creating a stand-alone application?

If you have traveled the road of the touch panel, you need to purchase the LabVIEW Touch Panel Module and a touchscreen. Touchscreens OR have a touch panel deployment license. Guides step by step to create the stand-alone application are in the getting started with LabVIEW Touch Panel Module .

Kind regards

Elizabeth K.

National Instruments | Sales engineer | www.NI.com/support

-

suggestion for soil moisture sensors that compatible with NI Labview?

any suggestion for soil moisture sensors that compatible with NI Labview? Help me ~ ~!

Fauzan says:

any suggestion for soil moisture sensors that compatible with NI Labview? Help me ~ ~!

Let me address your concerns about "compatible with NI LabVIEW" by asking you a question. Which soil moisture sensors are compatible with C++? Visual Basic? Visual C? JAVA?

The sensors have a layer connection between himself and the computer. Sometimes, the sensor itself is directly connected to the computer via USB. Most of the time, there is a layer of connection which will interface to the computer - USB, RS-232, GPIB, PCI - and linking the layer is an acquisition of data, or simplified for your application, an analog input Module. It is up to you to set your software to interface with these devices.

Now, I don't want to insult your intelligence. I bet you already know such things. But your question reads as if you have the same false ideas about LabVIEW with many people. That, LabVIEW is somehow a direct interface with the hardware, and you just bought sensors and LabVIEW magically presents the data. No matter what some people well planned would have you believe, this is not the case.

OK, so take for example this soil moisture probe. It displays 0 to 3 volts and costs $30. So now we need a way to measure the voltage and send blood pressure data to a computer. We use USB. This thing right here will do the job and then some, for only $50, and is compatible with LabVIEW. My point is - LabVIEW is compatible with the device that ultimately connects to the computer - the sensor is simply a device of voltage output.

I am not affiliated with or endorse I receommend or two devices, I've linked to, they were simply the result of a 10 second google search.

-

Any camera regardless of the interface is available for use with the LabView interface.

Hello

I intend to go for some CMOS camera,

but I have a huge doubt before buying, the camera of menttioned above is not anywhere in this list. Nor can I see any type being supported USB device.

The question is

- is a camera regardless of the interface is available for use with the LabView interface?

- Can I build a VI to communicate with any device image and recording of camera and take the data?

Any kind of help or advice is greatly appreciated... I have to buy a CMOS camera and begin to run.

Thank you...

Hello Virginia,.

I am pleased that this information has been useful, one thing I wanted to mention is that USB 3.0 has its own standard USB 3.0 Vision which is currently not supported. If this camera is also Direct Show compatible then you will be able to acquire an image using IMAQdx and manipulate all the attributes that are published to the API Live Show.

I hope that USB 3.0 Vision will be supported in the near future, and we tentatively announced for this standard of communication for the August 2013 Vision Acquisition Softwareupdate.

See you soon,.

-Joel

-

Why do I get emails intended for person with completely different e-mail address?

Why do I get emails intended for person with completely different e-mail address? some of the Emails are addressed to names nowhere near the same spelling to my address and I always get them

You CAN receive email if your email is added to the BCC list [1].

Most spammers use this medium to spam others.

[1] http://en.wikipedia.org/wiki/Blind_carbon_copy

See you soon!

-

When I click with the left button of the mouse on the unique tool, open the window with the other instruments

Mohito Hi, this morning, I solved the problem by trying to support. I realized that the problem was in mice, because the click rate is at its highest level, and then click the instruments was like if he did 2. I will now set the minimum speed of the clicks.

Thank you

-

Fluke Hydra 2625 with NI LabVIEW drivers: can not read the output data

I work with a Fluke Hydra data logger 2625 have downloaded the drivers from NI LabVIEW, crossed the config., initialize and modes files and now trying to read data from a thermocouple.

Initially, I was getting an error message ("17" I think) but now, after correcting the port numbers, the recorder data and LabVIEW seem to communicate without error. I would like to know where I should look (in the panels before different drivers) for temperature data output.

Any advice would be appreciated at this point. Thank you.

There is a driver not supported here. I have the instrument and you have not used one in quite a few years, but if using the example, the function can be set to temperature temperature with the 751 RTD or thermocouple. The results indicators min/max/last.

The pilot could really benefit from a full rewrite, but it seems that most of the basic functions are there.

-

Appeal of c# classes for LabVIEW instruments

The c# programmers here in my company have developed a great c# class that contains all of the interfaces of instrument for our various test stations. Instead of re - write all this LabVIEW code that would cause a maintainability nightmare, I want to use the class that they have created (and as an asset, tested and verified).

I can get to all different methods, etc. so, using the .NET / LabVIEW connectivity is not a problem. In addition, it's a matter of how exactly should I create the interop so that it is usable for our effective use of LabVIEW programmers.

A quick description of the structure of language c#, using the Switch class for example:

Upper level of the class has all the features of base common to all switches, and then as is normal, specific instruments have common methods in their breast and a few additional methods specific to this model.

They use the Ifactory model for all this.

Now I can be reading too far into this, or perhaps not far enough.

I know that when we create classes in BT we can do a general change of class, and then have children of this class of specific instruments. In my case, I duplicated their structure and I all methods of higher level in a class of 'Switch', then a folder of children of switch has classes for each of the classes of children. I then put in place so that the child class inherits from the parent for each child. All this with the intention of using dynamic dispatching.

My first question is: who don't already be managed in c# code? By calling the method of the parent class, wouldn't not on the c# code to take the correct child? Or is it since I was using just the class, but not all of the air capacity of c# (I'm NOT an expert in c# if it isn't obvious now) I'm having to manage the dynamic send in LabVIEW?

How exactly should I do after I have integrated LV class and configuration in pallets for future programmers? It's their programming, they know that they need a function from a specific switch, so they put that and by plugging in this interface of method, the class switch, it automatically performs the dynamic send call in the class (in fact, I typed, it made sense). What I was wondering, is that we are so concerned about the adaptability / changability; We have a proverb which says that if Exchange you an equivalent switch in, it should work without having to re - write the code. So of course, I am writing for this purpose. Again, as I write this, I find to say to me, 'If you must use a particular method to pass type, because it is what is needed, then would still have an equivalent switch, with this same ability of method.

I know I have rambled on this, but these are the roadblocks which my mind throw out there that I have create the method interfaces.

Did anyone done something like this before? Is there an example that you could send me or tell me? I can't believe I'm the first to try to take advantage of c# code that has already been written. I believe that I understand the nuances of make it right.

Thanks for reading and potentially for helping me through this. It's very appreciated.

Dan

You could still do the objects accessible .NET via pallets is to put them in a merger of VI - one that its content when it falls from a palette on the block diagram. You probably wouldn't want to do it for every single method, but if make you at least the major top-level classes or the available constructors in this way (or property or call node for a static class), you're going to do the hard part (finding the right assembly and class) easy.

-

How to display an object mesh continually update with the Labview 3D photo object

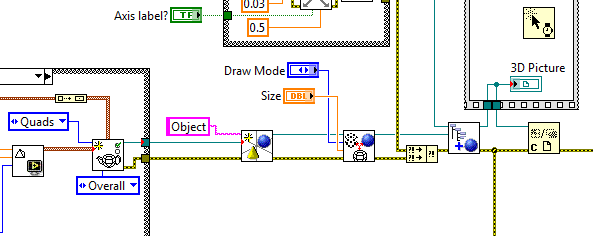

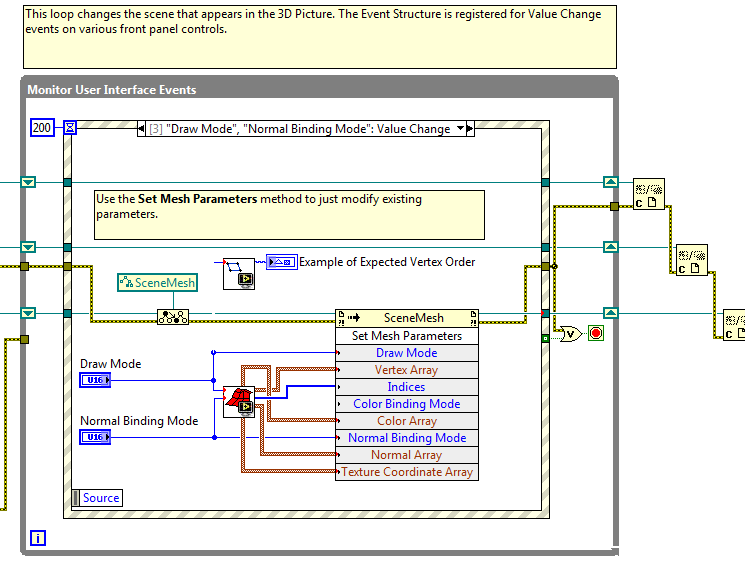

I have a stream of update permanently of 3D images that can be represented in a mesh (a film in 3D if you want). I want to display in the 3D image object so that whenever I acquire a new 3D image that it is displayed. Examples are rare, and I couldn't find anything that dealt with this particular issue.

Currently (in a FOR/loop WHILE) for each iteration I create an object of the scene, set the geometry as an object mesh newly created, set the texture and it wire eventually to the 3D image. This implementation seems a memory leak (Task Manager shows permanently increases the used memory and processing speed will eventually drop). I guess that's because I recreate the object for each iteration. Problem is, I can't find something that would let me release/delete the object once I'm done with the framework. All the examples I found only deal with the creation of the 3D object once and manipulating.

What is the appropriate way to code this?

You just need to use the "narrow" VI on reference photo 3D like this code below. It runs inside the loop.

Now, if you're dealing with the mesh, then you should use the set the mesh to change the points inside the loop and then just close the reference after the code is done. Look at this code below. The trick is to recover the object using Typecast (to more specific reference VI) reference.

Also, look at examples of shipping to:

C:\nivs_dev\2013\InstallTo\ProgramFiles\National Instruments\LabVIEW\examples\picture\3D Picture Control

and especially the with Meshes.vi.

-

No communication with a gpib instrument

How can I send CR and LF at the end of writing with the instrument control.

Instead of/r/n, use \r and \n.

You can also configure the GPIB controller to add these characters if I remember correctly (I know you can do it with LabVIEW). I don't have a GPIB interface installed and do not exactly remember the procedure, but there is an option somewhere to change what is sent with the EOI.

-

External DMM communicates only with the LabVIEW executables

Hello

I currently have a system of power supplies connected with GPIB and an Agilent E34405A DMM connected via USB. The system works fine when I use the complete Labview program, but when I make an executable and installler and put it on another machine, that I can not get the DMM communicate the work of supplies of power very well and done my other equipment. Any thoughts?

If your program LabVIEW use NI-VISA, you need to charge NI-VISA run-time on the target computer.

-

Hi all

I'm using LabVIEW 8.5.1 and TestStand 4.1. I did a sequence TestStand with a VI in this document, which uses items Report Generation Toolkit. On my machine I use LabVIEW and TestStand development system license. On another machine I use TestStand with basic deployment license and I chose the LabVIEW 8.5 run-time engine in the Configuration of the adapter. Everything works well except this VI with elements of Report Generation Toolkit. The error message shows that the VI is not executable. It works well only after I installed with a trial license and selected LabVIEW LabVIEW 8.5 development system in the Configuration of the adapter.

I found other posts and a document in the knowledge base with a similar problem: http://digital.ni.com/public.nsf/allkb/8A0E6274D9BD7B1986256F62006AD402?OpenDocument but I am not no EXE files in my sequence, so I do not know how to fix mine. Someone has an idea?

Maybe you are looking for

-

battery or solar powered iphone 6?

I have an iPhone 6 and would like to know if I can safely power favorite free this device using a powered solar panel or an external battery such as those like below. I'm having a bit of time figure this out on my own and do not want to try it unless

-

iPads not working only not with the cache server

Hello! We have implemented a Server Cache El Capitan... And the strange thing is that it works with macs and iPhones but not with iPads! Has anyone of you ever heard of something similar? Thanks in advance! Carl

-

Satellite C650D - left click on the touchpad does not work

Hello The left-click on my touchpad has stopped working. It works * very * sometimes, but mostly it's not. It also freezes the screen if I try to click on it too often (in a bout of mood usually ;))) A USB mouse works fine, who of fine when I work on

-

Password BIOS for hp mini model # 110-1030? fatal error code is [redacted]

Got the computer to the garage sale and I can't wait to use it once I can get into it!

-

I have Windows XP and the computer must remember my passwords

original title: passwords Hi, I am very new to computers and any qualified. I have Windows XP and you want the computer remember my password so that I don't need to tell or to type them every time, but don't know if I can do it? Penelope