Mach3 CNC

Hello

I'm Siya. I'm using a map of derivation mach3 CNC to control a 3-axis gantry system. triggering is done by engines step by step with the readers of gecko. I want to take readings of an LVDT Sensor via a DAQ (NI-MyDAQ) card at the beginning of each series. Does anyone know how mach3 can communicate with the DAQ card of NEITHER?

Hi Siya,

To connect a digital signal to myDAQ you can use one of the 8 digital I/O terminals on the device. Refer to the Manual myDAQ usage for more information. You will need to wire a digital output of a cnc, mach3 Board to one of the digital inputs on myDAQ. Once the wiring is complete, you can read your digital signal in LabVIEW. To learn to read digital signals in LabVIEW, refer to the following links:

Introduction to LabVIEW with myDAQ: entered digital

myDAQ tutorial: NI ELVISmx digital player (DigIn)

Tags: NI Hardware

Similar Questions

-

Hello Experts,

I'm in trouble with a call of ActiveX. Given an application called: Mach3 CNC program. Link: http://www.machsupport.com/downloads.php R3.043.066 Mach3

I want to it to interface with LabVIEW via ActiveX. I found a similar topic in the forum EITHER but the questioner is using LabWindows/CVI. Link: http://forums.ni.com/t5/LabWindows-CVI/ActiveX-controller-methods-import-as-callbacks/td-p/1038846

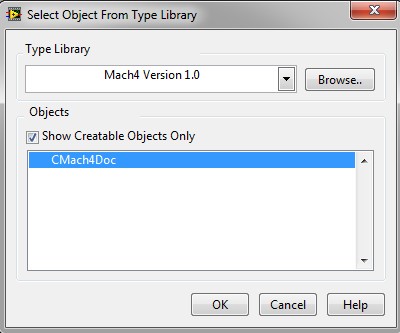

After you have installed the Mach3 on Windows XP 32-Bit, I found the tlb file that can be used for ActiveX calls under the following path: C:\Mach3\Mach4.tlb.

When I check: ' don't show Creatable object that "I can't see the full list of the ActiveX calls and the function returns an error:

Class is not registered.

I saved the file Mach4.tlb with regtlb.exe under Windows\.NET\Framework without success.

You select IMyScriptObject to open, the ActiveX calls appeared but I always had an error message: specified object is not that can be created in...

Could you give me a help how? Impatient you kind reply!

Hello!

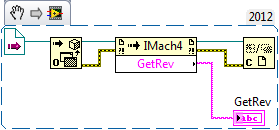

I downloaded the current version of Mach3. What worked for me was:

1 restart the computer after the installation of Mach3.

1. ensure that Mach3 runs in the background, without this, the class objects we is not available.

2 create an open Automation, with a constant as input.

4. search for the object class, select:

5. There are a handful of methods available for that particular category. This code checks the revision nr. :

That's what I've been able to achieve through ActiveX LV.

I hope this helps.

With regard to:

Andrew Valko

NOR Hungary

-

I have a model #1363 cnc:09 wireless mouse - 6802. IAM trying to find out if can replace the part (transister) you insert into the usb connector. mine was broken days after purchase. This is my 3rd purchased this year. the cost is going to add up, but I love the product if I can't get a new game that I'll have to try another brand

Hello

If you are talking about the Microsoft Mouse, please see the article mentioned below.

How to replace Microsoft software or hardware, order service packs and replace manuals:

http://support.Microsoft.com/kb/326246If it is a third-party material, contact the hardware vendor for replacement.

-

I am copying my files on my book reader cnc program. The problem is that the reader does not recognize the extension. PGM that I use on my cnc machines. I would change all the extensions at once to. TXT as there are that many of them. I can change one at a time, but it would take a very long time. Is it possible to do this?

Use the command prompt:

REN *.pgm *.txt

-

Combining vectors for use with a CNC machine

I work with a machine that creates its paths through vector illustrations of the CNC wood sculpture. Most of the time I create drawings in the CNC related software. I've been trying to learn more of AI to try to move more of my design in this program work. I'll do the best I can to describe what I'm trying to achieve with the final vector design.

I just got a client work to cut a plate. The PDF file opens fine in artificial intelligence as a design neat layers. What I am trying to accomplish for an easy translation for the CNC is to create a single layer vector with all vector hidden sections were scrapped. In addition, I wanted to see if I could create a vector image of all visible parts in describing all of the black lines or full black areas.

To make it easy to imagine, if I needed to cut a black circle, I don't mean that only 1 line machine to carve out on, but would like 2 circles, 1 on the outer edge of the line thickness and 1 inside the thickness of line that the machine could cut in the meantime. If that circle more doubled with a square, where all the lines overlap, I would need the area cutting smooth the transition in the circle and the square where they intersect.

In the end, I would need all the lines and areas full to move freely in the other without any line of vector hiding behind or over lapping each other.

I hope that all makes sense. If you need more clarity, please let me know and I'll try to give a better example.

Thank you!

Louis

Expand all appearances

Convert all the traits shaped

Select all and use the 'Merge' pathfinder (from the Pathfinder palette).

Select all white objects (either with the magic wand by using Select > same > fill) and delete.

Check in outline view, if there is something else that needs correction.

-

Hello

I have a digital control and I put data entry etbasse and selected force. He behaves very well using the increment/decrement and when I type in.

I want to be able to load a predefined value read from a text file into the control. The problem is only with the help of a local variable, or node property to set the value, that limits seem to be ignored.

Is there a way to update the control so it checks the limits or a better way to load a preset value (the value will be different according to the informtaion in the text file).

Thank you

Use 'line and force"before the application of this value programmatically and manage exceptions as needed.".

-

Hello LV users,.

I have a VI that is used to initialize some experimental equiptment. She spends on a cluster of ten digital control whole DBL as parameters. Everytime I open the program the values are reset to zero and I have to enter the return values in. Is it possible to set default values for controls, so I don't have to change them every time I open the program.

Thank you

Enter the number that you like in the control. Then right-click on the control and choose 'Make default value '.

Mathan

-

arrow to increment or decrement clicked on CNC?

is there a way to tell which arrow has been clicked by the user?

Thank you

Only indirectly:

(1) read the value of the control

(2) if the EVENT_VAL_CHANGED event has occurred, read the value of the control

(3) the new value must be old_value + / increment_value; Since this change, it is possible to deduce the sign of the increment, which is positive or negative; This you can translate to up or down

HTH,

Wolfgang

-

c and d includes Acrobat Reader v8.1.0, I have an older laptop satellite Toshiba,.

Thank you for any input, either with you blessing!

So I try to play c & d in my computer that is assigned from

College, the course is a fast 40hrs a week with 3-4 hours a day homework.

So time is a premium.

Check with the people who you the project as to what its hardware specifications are assigned. You can try to watch a DVD in a CD player, or it may be a disk waiting for AutoPlay is enabled, but is not, and so on.

-

Resize the height of a CNC is not possible

Hello

Because I use a touch screen for my application buttons increment/decrement of the digital control becomes very low. Is it possible to resize the button increment/decrement is somehow?

Best regards

Friedrich Vollink

Pop - up and choose Customize.

Switch to edit mode and then resize the buttons.

Ben

-

CNC - text and background color changes when you use the inc/dec

Hello

I develop an application that has a sign with a black background and green or red numbers. I have added digital controls and set the text color and text background color attributes accordinglingy. I put the control digital hot or validate command mode and display the arrows of inc/dec, because I want to incr/Decr numbers.

The problem is that when I run the app and I hit arrows inc/dec, then the colors inside the scope of digital control become reversed: black background becomes white and cyan green number. I created an assosicated callback with digital control and tried to force the text color and the background, in the EVENT_VAL_CHANGED section, by using the SetCtrlAttrribute() function, but nothing helped. Also added ProcessDrawEvents did not help.

When I mouse click again outside the digital command, then it returns to its original colours (green, black text background).

Suggestions as to how can I fix?

I want it keeps its original colors at all times, even when I am clicking on the arrows incr/Decr...

Kind regards

pgriep

Hello Roberto,

I thought it would be another way to fix it. Just hoped that I could fix it in setting or by disabling an attribute.

Thanks for the effort!

See you soon,.

pgriep

-

I try both notepad and wordpad. I'm in Winows XP 2003. I want just a bunch of random numbers (about 120 of them) from the list, select "all" and reorganize in order digital computer. I can't understand how I've done it before. Google says select the balls feature, but all that is put a point in front of a certain number. There is no arrow down to select. No A - Z. No 1,2,3. what Miss me? is the Notepad or wordpad not the place to do that?

Use Excel.

-

Attempt of outgoing connection of MALWARE-CNC Win.Trojan.Pmabot etc...

From time to time I get alerts such as the one above, there are others. These Holy typiically on a guest Wifi network I run.

In my ACP (Position 3), I have an input allowing the application of DNS of my DMZ (area Wifi comments) outside my ASA. Other rules below match policy HTTP/HTTPS, etc. The default rule (last position) in countries ACP is a IPS active file policy, defined on allow traffic.

I activated the config of the global block list in the settings of the CPA under the tab Security Intelligence & I changed DNS setting to include a blacklist of sites DNS that Taos record as a suspect.

To block the DNS entries that precedes, it is just a case of removing the request for DNS entry (Position 3) in ACP countries and change my default rule (last place) permit on refuse to ensure that DNS traffic is blocked suspected sites. Or by doing this, I am in danger of blocking other types of traffic.

I just want to allow HTTP, this HTTPS and DNS traffic, but with the latter to the destinations of confidence. During the research that trigger alerts above and others, I want to drop these if the DNS is blocked.

Concerning

Darren

Hello team,

First of all, make sure that you are in the latest version of the SRU in the device.

By chance you run PHPMyAdmin in the device? Also check what are the variables for the HOME_NET and EXTERNAL_NET variables?

If you think about it as a false positive alert, then provide as a result of the TACs in order to check if it is a false positive or an alert valid due to a problem.

1 package corresponding to the rule:

-Connect to the Web from DC interface

-Go to "Analysis" > "Intrusions" > "Events" > Change Workflow for 'Table View of Events' > select the corresponding alert > click on 'download package '.

-You should get a ZIP file that contains a capture of packets in PCAP format.

-Send the ZIP file to TAC team and request an analysis.

Note If the post will help you

Concerning

Jetsy

-

Model change DreamWeaver does not update of child Web pages?

Hello group,

Sorry for my question from newbie here.I loaded a HTML Web page and try it in a DreamWeaver template file.

I then created Web pages from the template file ((fichier-nouveau-Page à partir dele de modèle-Site-modèle) and made sure the checkbox "Update Page when changes were made to the model" was selected/checked.)

Then, I created several children Web pages and saved as .html files.

I decided to change the system of navigation - part of the region of uneditiabel in the model - bar by opening the template file and edit-ing this file and then saving them in the same DreamWeaver template file.

However, Web pages were not updated to reflect changes to the navigation bar in the French model?!

Can someone tell me what I am doing wrong?

I think it's something I'm doing wrong with DreamWeaver...

If anyone is interested, here is the HTML code.

-----------------------------------------------------------------------------------

<! DOCTYPE html PUBLIC "-//W3C//DTD XHTML 1.0 Transitional / / IN".

"http://www.w3.org/TR/xhtml1/DTD/xhtml1-transitional.dtd" > ""

"< html xmlns ="http://www.w3.org/1999/xhtml">".< head >

<!-TemplateBeginEditable name = "DocTitle"-->

< Title > CNC Joe workshop - Home Page < /title >

<! - TemplateEndEditable - >

< meta http-equiv = "Content-Type" content = text/html"; Charset = UTF-8 "/ >"

"" < link href = "... / style.css" rel = "stylesheet" type = "text/css" media = "screen" / >

<! - keep the http-equiv for IE8 meta tag - >

< meta http-equiv = "X-UA-Compatible" content = "IE = 8" / >

<! - link CSS file here - >

"" < link rel = "stylesheet" type = "text/css" media = "screen, projection" href = "... / style.css" / >< / head >

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ -->

< body >

< div id = 'wrapper' >

< a name = "top" > < / a >

< a href = "index.html" target = "_self" title = "Home Page of CNC - Joe" > "

"" < img src = "... / joesworkshoplogo.gif" width = "770px" height = "300px" alt = "Shop CNC Joe - Home Page" / >

< /a >

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~~~~~~~~~~~~~ -->

<!-BEGIN OF MENU DROPDOWN->

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~~~~~~~~~~~~~ -->< div class = "mainmenu" >

< ul >

< class li = "li_nc" > < a href = "index.html" target = "_self" > home < /a > < /li > "

< class li = "li_hc" > < a href = "cad.html" target = "_self" > CAD < /a > < ul class = "ul_ch" > "

< class li = "li_nc" > < a href = "cad_intellicad.html" target = "_self" > IntelliCAD < /a > < /li > "

< class li = "li_nc" > < a href = "cad_draftsight.html" target = "_self" > DraftSight < /a > < /li > "

< class li = "li_nc" > < a href = "cad_progesoft.html" target = "_self" > Progesoft < /a > < /li > "

< /li > < /ul >

< class li = "li_hc" > < a href = "cam_html" target = "_self" > CAM < /a > < ul class = "ul_ch" >

< class li = "li_nc" > < a href = "cam_mach3.html" target = "_self" > Mach3 < /a > < /li > "

< class li = "li_nc" > < a href = "cam_vcarve.html" target = "_self" > V-Carve < /a > < /li > "

< class li = "li_nc" > < a href = "cam_cut3d.html" target = "_self" > Cut 3D < /a > < /li > "

< class li = "li_nc" > < a href = "cam_bobcadcam.html" target = "_self" > Bob-CFAO < /a > < /li > "

< class li = "li_nc" > < a href = "cam_meshcam.html" target = "_self" > lattice CAM < /a > < /li > "

< class li = "li_nc" > < a href = "cam_deskcnc.html" target = "_self" > desktop CNC < /a > < /li > "

< /li > < /ul >

< class li = "li_hc" > < a href = "projects.html' target ="_self"> project < /a > < ul class ="ul_ch">"

< class li = "li_nc" > < a href = "projects_zzeroplate.html" target = "_self" > Z zero plate < /a > < /li > "

< class li = "li_nc" > < a href = "projects_x0y0edgefinder.html" target = "_self" > X 0 - Y0 Edge Finder < /a > < /li > "

< class li = "li_nc" > < a href = "projects_digitizingtouchprobe.html" target = "_self" > touch scanning probe < /a > < /li > "

< class li = "li_nc" > < a href = "projects_millwebcam.html" target = "_self" > mill webcam < /a > < /li > "

< class li = "li_nc" > < a href = "projects_laseredgefinder.html" target = "_self" > Laser Pointer Edge Finder < /a > < /li > "

< class li = "li_nc" > < a href = "projects_davidlaserscanner.html" target = "_self" > David Laser Scanner < /a > < /li > "

< /li > < /ul >

< class li = "li_hc" > < a href = "reference.html" target = "_self" > reference < /a > < ul class = "ul_ch" > "

< class li = "li_nc" > < a href = "ref_gcodes.html" target = "_self" > G-codes < /a > < /li > "

< class li = "li_nc" > < a href = "ref_nema.html" target = "_self" > info motor NEMA < /a > < /li > "

< class li = "li_nc" > < a href = "ref_vbearings.html" target = "_self" > V-bearings < /a > < /li > "

< class li = "li_nc" > < a href = "ref_linearguides.html" target = "_self" > < /a > < /li > linear Guides "

< /li > < /ul >

< class li = "li_hc" > < a href = "offtopictopics.html" target = "_self" > off-topic topics < /a > < ul class = "ul_ch" > "

< class li = "li_nc" > < a href = "ott_backyardfoundry.html" target = "_self" > BackYard Foundry < /a > < /li > "

< class li = "li_nc" > < a href = "ott_blacksmithing.html" target = "_self" > forge < /a > < /li > "

< /li > < /ul >

< class li = "li_nc" > < a href = "links.html" target = "_self" > links < /a > < /li > "

< class li = "li_nc" > < a href = "contact.html" target = "_self" > Contact < /a > < /li > "

< /ul >

< / div ><!-END OF THE MENU drop-DOWN->

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~~~~~~~~~~~~~ -->

<!-END OF THE MENU drop-DOWN->

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~~~~~~~~~~~~~ -->

<!-TemplateBeginEditable name = 'content'->

< h2 > projects: scanning Touch Probe: < / h2 >

< ul >

< li > < /li >

< li > < /li >

< li > < /li >

< li > < /li >

< li > < /li >

< li > < /li >

< li > < /li >

< /ul ><!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~ -->

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~ -->

<!--end of the editable - the rest is boilerplate-->

<! - TemplateEndEditable - >

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~ -->

< br / >

< p > < a href = "#top" > top < /a > < /p >

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~ -->

<!-- Footer Region -->

<!-- ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ ~~~~~~~ -->

< div id = "footer" >

< hr / >

< p >

"< a href ="http://validator.w3.org/check?uri=referer">."

"< img class ="logo"src ="http://www.w3.org/Icons/valid-xhtml10"alt ="Valid XHTML 1.0"Transitional height ="31"width ="88"/ > < / a >""< a href ="http://jigsaw.w3.org/css-validator/check/referer">."

< img style = "border: 0;" width: 88px; "height: 31px;

"Class ="logo"src ="http://jigsaw.w3.org/css-validator/images/vcss"

ALT = "Valid CSS!" / >

< /a >

< /p >

< h5 > < strong > < i >

This site is only for educational purposes. Any resemblance to any person, alive or dead - is purely coincidental

< /i > < / strong > < / h5 >

< / div >

< / div > <!--end Div Wrapper - >

< / body >

< / html >OK - I thought about it!

When I edited the .dwt model - I used 'SAVE AS' to save the file - it's FAKE!

I should have used just on 'SAVE', and DreamWeaver then asks if I want to update the files created with the template.

Further Questions:

-Whence the DreamWeaver store information about which pages were created with what model?

-

MAC G4 - starting from different OS

Hi I need help. I'm completely new to Mac. I have two Power MAC G4, an assembled in Ireland = Y and the other Singapore = Z, but inside, the components are different. I have two HDD, drive HARD-A = OS X 10.3.1 (7 C 107) and the other a HDD - B = BONE Z1 - 9.2.2. The two hard drive HDD - A / B boots in computing Y but only drive HDD - B actually starts in computer Z. When I placed the HARD-B disc in computer Z, says MAC OS ROM 10.2.1.

I would be grateful if someone could explain to me how do the boots with HDD - A computer, which are that I really need. HDD - Is a software that control a CNC machine.

PowerMac G4s internal hard drives are usually the parallel ATA IDE drives, with a particular rider (a tooth two pins plastic that snaps on the two pins next to the port of the interface in the diagram shown on the sticker from the outside of the hard drive. If these hard drives are hard drives internal to these two PowerMac G4, you must verify that the two PowerMac G4s are in fact identical in terms of vintage before starting one with the other. Target disk mode is a tool that allows a PowerMac G4 except the first model to turn into a very expensive external hard drive Firewire with internal drive basically designed to start any installed Mac OS on it.

Say if you want to have a car that can boot Mac B, but were not sure that he could start A Mac, you can always insert into the slot of the internal drive A Mac as a master drive and it is not visible in target disk Mode. Target disk mode is described here:

How to use and troubleshoot disk mode target FireWire - Apple Support

This trick allows to identify your Mac:

http://discussions.Apple.com/docs/doc-6413

This trick lets you know which operating system provided with your Mac and more recent operating systems of the Mac retail can start:

Mac OS: Versions, versions included with the Mac PowerPC (since 1998) - Apple Support

In General, no Mac cannot start an older Mac OS X or more old Mac OS 9 that shipped with it.

Editions of the later retail sales are identified further on this tip of the label on the CD:

And they can't say update, dropin or OEM.

Maybe you are looking for

-

How to perform a soft reset rule soas can I open without download?

the default value of the system is gone - and now the rule seems to be: download all email or system db attachments when clicked on...but i would like to have the option to open attachment /view without downloading/saving file. I would like to reset

-

Address bar is no longer enabled when opening blank tab

Since today, when I open a new tab (be it with ctrl + T or by clicking on the Green over a symbol), the address bar is no longer enabled, which means that I have to click it before you start typing. When I have about: newtab (the one with the tiles a

-

Hi allI'm getting ads on all the sites that I opened. And this page is still my home page no matter what I do to change it.I tried to disable all the add ons and extensions. Moreover, it happened without me adding an extension or an add on. in the pi

-

Hi, I have a Lexmark X 5495 All In One Printer. I have had it for 3 years & hanging on this same computer. 5 days ago, I printed a shipping of my computer label. Now, I get a message about "spooler" when I try to print & when I go into Control Panel,

-

printer HP PSC 1310 series problem

I can make copies and I can scan, but it does not connect to my PC more.