Why my digital control flicker?

I have the simplest VI attached to illustrate this problem. Why my digital control flicker?

More importantly, how can I stop this annoying flicker?

Why the flag is set to "synchronous display? Turn that off!

This indicator origin, specifically, why it turns blue if I color the transparent background?

Have you tried selecting a specific font that is guaranteed to be available on all computers?

Tags: NI Software

Similar Questions

-

A digital control takes no account of the limits of data at entry entry is typed, why?

Limits of data located in the property entry seem to have no effect on data entry. A value written to a property node limit the contribution of the increment of buttons but not the data which are entered in the control. How to stop digital control to accept out of desired range values? In the attached example, why I can type in any number for control and data entry limit is ignored?

In the Properties window of data entry for the digital control, you have the "answer of value out of range" ignore the value. Change it to compel.

-

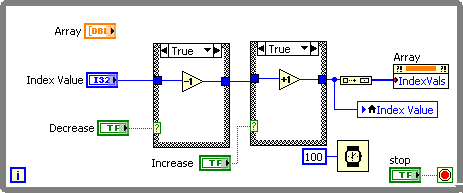

Can I use a digital control to change the illustrated index of an array?

Hey people,

This could be one of these questions, get feedback 'why would you do?', but I wonder if there is a fairly simple solution, I don't know everything...

I know that tables are not exactly gems when it comes to claims for benefits, but with my particular application, if I could get a digital control to define what the array index appears, it would be great. In addition, assuming that it is possible, then I think I could find a way to have two Boolean values which would increment/decrement the element indicated by updating the digital too...

Any ideas?

A popular entry!

THX

Is that what you wanted to achieve

-

Digital control system, using limits of entry of data with global variables

Hello!

I have a Subvi with several digital control sliders. These control framerate, the pixel clock and exposure of a camera and their change in max/min/increment whenever one of them is changed - they are interdependent and get their information from the camera continuously during execution.

I'm trying to remote control this VI, but during the passage of a value using global variables, it doesn't "stick".

Example:

The value for exposure is 237,48 Ms. different values are constrained to the nearest value. So if I pick 240,00 ms at the Subvi, he should know that this is not a valid value and change to Mrs. 237,48.

But it is not do and I don't know why. When I enter the values manually, it works fine.

Any suggestions?

The limits on the controls that apply when their control from the front and is not passing values via the connector pane.

You should use something like "line and force" within the VI to validate the values are within the range (maybe constrain data or return an error).

-

Some otherwise identical digital controls have white behind the numbers, other gray

On the attached screenshot, there are two Express Digital controls in the lower right corner. I did the replace operation to make sure that both are the same type of control, still it white behind the numbers and the other is grey behind the numbers.

I do not change the settings of these controls when I inserted the. I don't see anyway to change the background number without having to build a custom control.

The two controls appear in the same loop, are of type DBL, floating point with 2-digit precision.

Can someone tell me why these environments is different and if there is anything I can do about it?

You must choose the background color to change the background of the indicator. Note that there are two color boxes in the choice of colors. The upper left corner is for the text. Bottom right is for the background.

-

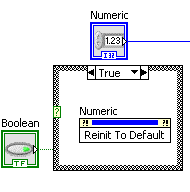

strange appearance of the digital control

Hello...

I met a strange appearance of a digital control, see the below two screen captures.

Reminder: on a tabpanel, two of several digital controls have been changed programmatically if I put an indicator with a checkbox that is located on another tab of the Panel:

-control mode is switched / battery hot

-precision went from 6 to 4 figures to compensate for the space of digital arrows

These changes are applied to three checks, but only the first (highest) behaves unexpectedly, while others are very well...

(A) if both attributes are changed, the two top controls look like this:

in other words, the left most of the characters of the control are somehow overlapping, giving the impression of a fat o material

(B) if only the command mode of the higher control is changed to hot, the following result is obtained:

This makes it more obvious that somehow the two zeros on the left of the control are pressed together.

Interesting, if I operate the higher control by clicking on the arrow/top down, the result displays (1.0000E - 3) is ok.

I was much afraid to post this mystery which could well be a stupid mine mistake, but unable to locate a problem in the code, I thought that it could possibly be linked to the issue tab panel reported here

Comments, suggestions?

Thanks, Wolfgang

Hi Wolfgang,.

I checked your project, and it looks like a bug. I created a CAR. The number is 282946.

I guess that at the moment, you have to live with it or place the box on the same tab.

See you soon,.

RMathews

-

Is it possible to have explicit '+' sign to digital controls?

Hello

I was looking for a possibility to show the sign of a numeric value to digital controls, i.e. the control should display "-1.2345" or "+ 6.789" because this value will be added or subtracted another parameter value. "". " Accordingly, no sign, i.e. "6.789' is not meaningful in this case."

Unfortunately, I couldn't find any opportunity to do so (CVI8.5.1). I don't want to use a text control where this would be possible, because I have the up and down arrows to scroll upwards or downwards. I've missed something trivial - or is really not possible STD? Seems so simple and natural...

Thank you very much

Wolfgang

Hello Wolfgang,.

We will add this as a suggestion of product. In the meantime, have you tried to capture the top and bottom event keypress in the reminder of chain drive and increment/decrement the value yourself?

Moreover, you always expect to see a sign "+" when the control value is 0? Or no sign at all, in this case?

Luis

-

As in the title. I want to create a digital control (no current limitation on its type) with a range of 1 to 10 (and a step of 1). The only difficulty that I have, is that the user should only be able to increase or decrease 1 at any time. Code initiated by this change of value must have completed at least once before that the value can be changed again. This is because code of VI is mainly contained in a while loop and control are read once at each iteration and its last value should not differ more than 1.

Is this possible with LabVIEW 6.1 and if so, how?

One of the solutions that I came up with so far is to disable the control immediately after its reading, and to turn it on again immediately seized is read the next time (I have to assume that the user is unable to click twice before the control is disabled). It is an acceptable method, or is there a better way?

I also had an idea of partially disable a normal digital control, such that it could not be typed in - only arrows remained operational. However, I'm not sure how.

James

Hi James,

You can use the two buttons (by releasing latch) and a digital display that shows the current value. Button increased the value and the other decreases. Store the value in a shiftregister to work with her.

I don't know if your solution would work because use may directly enter the new value.

It will be useful.

Mike

-

Update of digital control with different values with array function

Hello

I have attached my code base. I want to execute the code for 2 sets of digital control with a gap between the two values, then pass it. Something like that

ABC

Initialize the P1 = 10; P2 = 20; P3 = 30; P4 = 40

Run the code

delay = 10ms

Update of P1 = 150; P2 = 200; P3 = 350; P4 = 500

Run the code

jump to abc

I am stuck how can I update the values of P1, P2, P3, P4? I thought about using a function table but couldn't go further.

Thanks for the help,

Ana

Hello Ana,

One way you might achieve what you are looking for is using property nodes. These property nodes will allow you to change the values of the block diagram control. You can set up a structure of case inside your loop that will change control through nodes of property value after a certain number of iterations. Here is a community sample that shows how to use the nodes property to change the Boolean controls:

https://decibel.NI.com/content/docs/doc-22669

-Erik S

-

Capture digital control last values

Hello

My front panel has several digital commands that I expect the user to enter data in before pressing a button that takes the values of the digital controls and

a power supply programs. What I discovered is that if a user types the digital control and does not support on enter or moves the cursor with the mouse to a new

control, the valleys of news are not captured when the button is pressed.

How to capture the most recent value in numerical order without waiting for the user to press ENTER after that that they typed in the value?

Two possible approaches to capture the value most recent inside a structure of the event:

(1) read the values of your digital controls in the case of events for the button. It is the simplest solution. If you need access to these numerical values in other cases of event, use the event to change value for these controls to update of the shift registers, or use a local variable.

(2) take advantage of the cause of the time-out period (if you are already using it you may need to do some creative re-use). Store the time-out value in register shift and set to default-1 so that he will not run. In your case of button, set the timeout to 0 shift register. Move your key event code in the case of timeout. LabVIEW will be re-read the values of your digital controls and the time-out event runs immediately.

-

Digital control over several orders of magnitude

Hi all,

I'm trying to get a digital control with a suitable addition to the order of magnitude.

For example, I have a front panel for an osziloscope, sometimes that samples on some ns, sometimes a few seconds, sometimes a few milivolts, sometimes a few volts, who knows, right

I was playing around with the digital control units, but it doesn't quite fit my needs. I can't change the prefix of a unit on the duration, for example of microseconds to seconds, but then I change the issue as well, because on change the prefix, the previous number is only multiplied by the factor according to, for example, 1000, so 5 became US 5th-6s. So change the record length of the default value of 500 ms to 100 ns would require two klicks type, and I can instead just type "100th-9', which is good too."However, I would like to have a digital control from 0 to 1000 combined with for example a button for prefix i.e. nano, micro, mili etc. and combine this values internally, i.e. of mulitplying accordingly. But I couldn't set the increment to "3 orders of magnitude" even with the option to log scale.

I know, I could use an enum with the names and values according to, but this is not very satisfactory.

So perhaps the question would be: is it possible to combine two digital controls or the value for the prefix, in a suitable and easy way? Or how do you manage the digital values over several orders of magnitude in a case like mine?

Thanks for your replies in advance.

Best,

bastlwastl

Display format is SI units

It helps in these situations

-

How to separate the 'down' key panel and digital control

Hi all

I have a key to proecess vi events for Panel and a digital control in this Panel. the app will do:

1. when the Panel is focused, allows the user 'up' and 'down' to the driver of some hardware.

2. when the digital control is activated, 'up' and 'down' change its value as usual.

somehow the other did not, because the round table 'touch down' was trigger as well when I use «to the top "'down' key aminata CNC.»

Then, I used "Key down?" digital control to block the "up/down" key But the first time, when I run the Vi, the Panel always got triggered only once.

any suggestions on this? test code attached to this post too.

Thank you

It works for me in 2014. In short, you just need to check to see if your digital has the focus. If it isn't, then you treat the value of the key. No need of any other event here except the stop button.

-

Flashing LEDS with digital control

Hello

I want to do a simple program that goes like this. I have 2 digital controls and 2 comparisons. 1 digital will compare if the number if there is less than 50. Second comparison if it is longer than 50. If less than 50, according to this number LED is blink your eyes upward and will stay on. If the second number is greater than 50 the LED belonging to this number is then blinking and will remain lit. NOW...

If one OR both of these lights light up, a THIRD light should BLINK automatically. If the two first two traffic lights are off, then the third should stay off.

I tried using shift registers and a deadline for the delay, but I'm stuck.

Any help would be great. Thank you!

Thuba25

First, you must modify your code for an interactive real state machine. Your code is inside-out.

Currently, the controls are read once at the beginning of the program and then never.

- Do not use internal loops. Use a single outside WHILE loop that encompasses all of the code.

- Get rid of the stacked sequence, she is useless and obscures just the code.

- The case structure belongs inside the loop and not vice versa.

- Read the commands with each iteration and decide depending on their value.

- ...

See how far you get... Good luck.

-

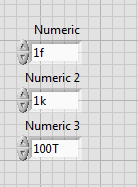

Digital controls by default Reint?

I am VERY new to LabVIEW and were loaded to think beyond my skill level. I'm sure it's an easy fix, but I am at a loss.

I have a digital control that changes of the user. The value of the digital control is then added with a reading of a strain gauge. I need to find a way to return the digital order to its default value. I read something on the forums on the use of a node to invoke, but I don't have a clue how to set up.

Thank you so much, in advance.

Thank you so much, I spent hours trying to use the loops and conditions. I didn't know where to put it in my program. One of the loops has finished the program to the point where the display was 5 seconds behind the data behind.

You guys are life savers!

Here is a selection of the node implimented. I used a button to "lock when you press on.

-

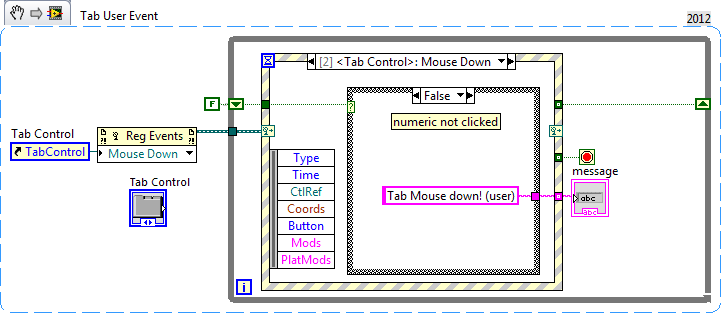

Hi all

I have a digital control in a tab control. Both of them have their own events 'mouse-down' in a while loop. But when I click on the digital command, instead of raising the event of digital control only, both of these two events fired.

Maybe I can check if the mouse is in the range of digital technology to filter events, but if the window is resized, I have to recalculate the range once again.

Is there another way to do it?

I pasted the test code too.

Thank you!

Excerpts of work

Side note: I really don't like the controls on the tab and use them very rarely. And the few times I use them, it is for tabs to which I often use to select among the screws to put in a secondary school.

Maybe you are looking for

-

Update CPU on HP Compaq nx7300

Hello What type of CPU can I put in my HP Compaq nx7300 instead of /FSB Celeron M 440 1.86/533? Thank you.

-

Programs you have problems with - very slow connection with all pages Error messages - on the profile of my son is unable to connect at all with the error message Recent changes made to your computer - windows 7 but added meeting the problem before t

-

has stopped working on my tv too

-

Try to catch as the exception handling in Pl/Sql

In a procedure, I want to do 1 logical unit, is not serious if it fails, execute the logic unit 2This seems to be a typical scenario of try-catch. But how can I do it in pl/sql?create or replacePACKAGE BUILD_PKGASPROCEDURE reset_seq_and_truncate_tbl(

-

Lightroom 6 supports 10-bit color depth?

I am a user of Lightroom 5.7.I know version 6 introduced the gpu acceleration, but the 10-bit color depth has been introduced through openCL?