DAC (analog output through sreapder?) on Spartan 3 FPGA

Hello world

I searched on LabView training exercises for the 3rd Spartan Board, specifically the DAC.vi and the DAChost.vi in the exercise 8. The screws are in the solution folder, but there no real explanation for the DAC specifically in Scripture in the exercises section. I was also watching Xilinx in the Board Manual, but I can't seem to find the answer to my question.

My goal is to be out put an analog signal that is adjustable between 0 and 3.3V as a control to another system while the rest of my code is running. Of course, the premade DAC vi can be used to put analog voltages on the DAC pins, but I wonder is - it possible to the analog output of the signal through one of the connectors spreader (while the other digital connectors are also output)? It seems like it should be, but I don't know how to implement. If this is not possible, then well, I guess I have a big problem

Thank you

The only place where the DAC would release would be the pin of the DAC. I doubt that there is other options routing so that the PIN because you can't get an analog signal by an FPGA.

Kind regards

Matt M.

Tags: NI Software

Similar Questions

-

What is the minimum response of analog input, through DSP online, output analog time?

Hello experts!

I want to know if it is possible to get a very quick response latency (~ 1 ms) sound recording (analog input), through online registration (DSP online), the presentation of his (analog output) processing, by using the DAQmx programming codes. My system of NEITHER includes NOR SMU 8135, SMU 6358 DAQ Multifunction controller and SMU 5412 arbitrary signal generator. I also have access to the latest version of Labview (2015 Version) software.

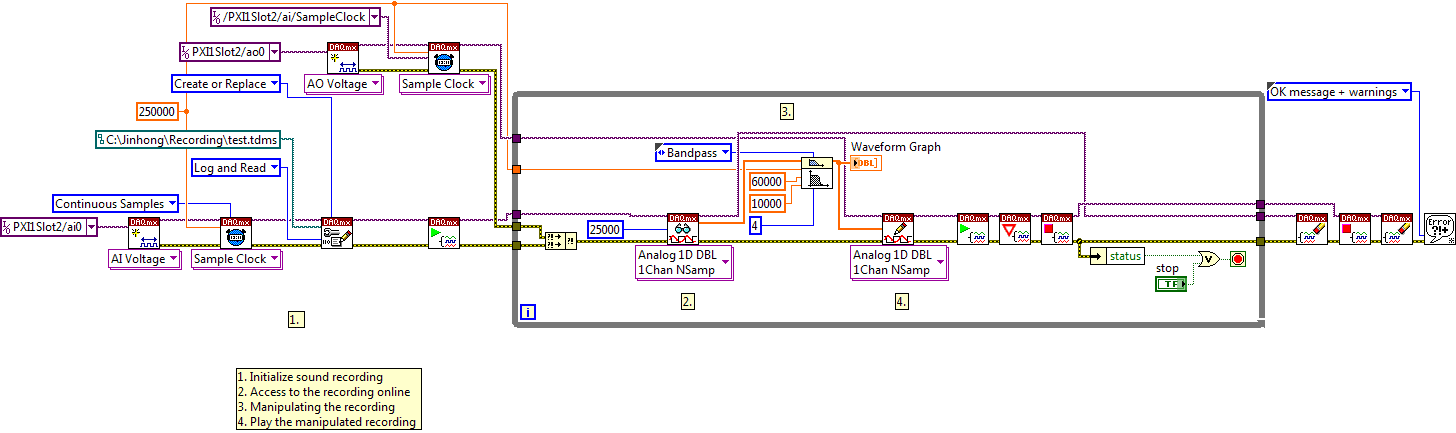

My project is on auditory disturbances, which inovles record vocalizations, manipulating the recorded vocalziations and then present the manipulated vocalizations. My current idea of how to achieve this fact triggered output voltage after reading the input using DAQmx Read samples. DAQmx Read output is filtered online and then passed as input for the DAQmx writing for analog output. For purposes of illustration, examples of code are presented below. Note for simplisity, codes for the trigger part are not presented here. It's something to work in the future.

My question here is If the idea above should be reaching ~ 1ms delay? Or I have to rely on a totally different programming module, the FPGA? I am very new to Labview so as to NEITHER. After reading some documentation on FPGA, I realized that my current hardware is unable to do so because I do not have the FPGA signals processing equipment. Am I wrong?

Something might be important to mention, I'm tasting with network (approximately 16 microphones) microphones at very high sampling rate (250 kHz), which is technically very high speed. Natually, these records must be saved on hard drive. Here again, a single microphone is shown.

I have two concerns that my current approach could achieve my goal.

First, for the DAQmx Read function in step 2, I put the samples to be read as 1/10 of the sampling frequency. It's recommended by Labview and so necessary to avoid buffer overflow when a smaller number is used. However, my concern here associated with the latency of the answer is that it might already cause a delay of 100 ms response, i.e. the time to collect these samples before reading. Is this true?

Secondly, every interaction while the loop takes at least a few tens of milliseconds (~ 30 ms). He is originally a State 30 late?

Hey, I've never used or familiar with the hardware you have. So I can't help you there.

On the side of RT, again once I don't know about your hardware, but I used NOR myRIO 1900, where he has a personality of high specific speed for the RT where I can acquire the kHz Audio @44 and process data. Based image processing is ultimately do the treatment on a wide range of audio data you have gathered through high sampling frequency and number number of samples as permitted by latency, please check this .

I lost about 2 weeks to understand host-side does not work and another 2 weeks to understand the even side of RT does not work for online processing (real time). Then, finally now I'm working on FPGA, where the sampling rate is 250 kHz (of course shared by multiple channels).

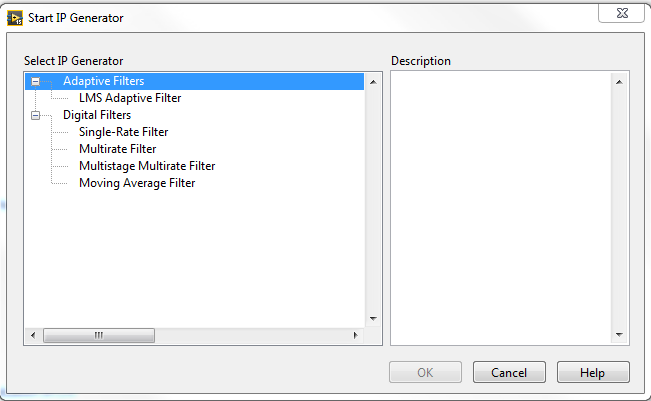

The complex thing with FPGA is coding, please check if the filter you want is given below as labview automatically generates some codes of some filters.

Most of them will work in 1 SCTL IE if your target has 40 MHz clock algorithm will run in 25 ns. That's what I was looking for, I hope you

See you soon... !

-

Problem of generation of the analog output on PCI-7342

I use for the control of servo motor with encoder Axis 1 of my PCI-7342 feedback

and trying to out of the velocity of the encoder on the analog output of the axis-2 which is currently not used.

For testing purposes, I pulled out a constant 16383 (half of 32767) to the analog output

through load DAC.flx permanently, but there is no voltage on the map of the motion.

I read

http://digital.NI.com/public.nsf/WebSearch/102BE3EEED8A8B0DC1256EDA0059EC47?OpenDocument

and configure my 2 axis to be a stepper motor. I also tried to disable axis - 2. None of them works for me.

Also, I tried to read the value of CAD using reading DAC.flx right after that load DAC.flx is called.

Correctly, the value was shown on the screen. (See the attached figure)

I'm really bad now. Please, please, please help!

Any possible solution is fully appreciated!

Ron Liou

-

read the output of a path of analog output current voltage

In DAQmx if you are unsure of the status of a digital output port, you can take a reading on this subject. When I try this on an analog output, I get an error. Is it possible to query the status of the output of an analog output? I realize that I could follow the State with a variable, but a direct reading would be really handy.

Hello, GIS.

There is no way to read the output in the AO modules without wiring physically the signal to a module to HAVE. You are able to use a variable to read the current value of the output, as you mentioned earlier.

Channels AO multifunction boards, however, can be read through tasks of entry by rounting in-house channel to read ao vs aoground.

Lisa

-

poor performance analog output (error 200018)

Hello. I have a 6124 SMU Board with controller real time SMU-8102. the Council is speced to MECH 4 analog outputs. / s (one lane), but I have problems to operate at anything beyond about 500 kech. / s. I enclose my example below program. If I put the rate at 500 k, it works. If I put 1 m, it does not work and I get the error 200018 (DAC conversion attempted before Conversion data were available). I use the DMA transfer.

I also tried to increase or decrease the number of samples written by loop (between 50 and 300) and using a loop timed in labview real-time. That essentially gives the same result (sometimes I get error 200016 instead, "exceeding accuracy onboard device memory").

Because the controller is a dual core controller that do literally anything else (what I showed is the whole program, nothing else running), I don't know that I have some setting wrong software. I can't believe that this controller is unable to deal with this card. Does anyone have any suggestions on what I might try?

Version of LabVIEW is 2010 and DAQmx version is fairly recent.

Ok. I thought about it. Here's an interesting fact. At the rate of 1 MECH. / s, tries to write to 4096 samples each microseconds 4096 works perfectly well. But any attempt to write to 4095 samples fails! 4095 course is 2 ^ 12-1. It seems that DMA was running only transfers of 4 k at a time, so when he got 4095 samples, he was waiting for a sample more start the transfer, but at the time where he got this sample, it was too late. I changed DataXferReqCond property for "almost complete." Now, I can write about 150 samples at a time instead of 4096. Greatly improved!

Moreover, it would be really good to put in the text of the error message for the error 200018 so that others live several days tearing their hair like I did...

Thanks for the help

Daniel

-

Hello

My question is about the analog output (0 - 10V) of the myDAQ unit.

On the card, you can read:

"Overdrive Protection +-16 V forever."

Lets imagine the worst case: 0 V output DQA, but outside a battery or anything else is connected with 15 V to the analog output.

Fact an "unlimited" current in data acquisition or protection 'Overdrive' works here and the material is safe to destroy?

The background: I want to OD are protected from transient voltages and toilet on a simple zener diodes clip or a tvs diode...

Thank you all, Markus

Markus,

To use a zener diode as protection, you must also have an impedance of current limiting in series with the source against which you are protecting. The manual for the device of maDAQ indicates that the lines of the AO are pushed by OPA1642 op amps. TI the MSDS for this unit shows the current limiting internal ~ 36 my short circuit with Earth and a thermal shutdown circuit that tries to protect against the terms of overpwer.

However, under your 15 V battery, 11 V zener and 0 V programmed DAQ exit, the situation may be different. The current from the battery through the zener will be limited by the impedance of cables or any type of resistance on the line. This has no direct effect on the myDAQ device, but it will probably destroy the zener unless resistance limits the current to a lower maximum current nominal zener. As long as the voltage at the output of the myDAQ is lower than the internal supply voltage (+/-15 V), on the OPA1642 current limitation should apply. With 11V applied to the output and the value set to zero the device would probably be to try to sink the maximum current for-15 V power supply. Which translates to a dissipation of power of more than 900 mW, which exceeds the rated capacity of the op amp. Themal protection should, in principle, reduce the current to a level that does not exceed the thermal limit under development.

This test can be a costly process. The unit may be destroyed. Given that the maximum current specified for an analog output channel is 2 my and the maximum voltage is 10 V, I would consider a series resistance of perhaps 1000 ohms and clamping schottky diodes at the + 15 V and - 15 V power supply. This will limit the current to 10-20 my in all conditions you have mentioned and would also provide protection to the case where the battery is connected the myDAQ device is turned off. He alsoe does not care about the polarity of the external source. It will drop the output voltage according to the load impedance. If this should be used in a student lab, the calcualtion of this decline is something they should be doing anyway, and would be a small price to pay for protection.

Lynn

-

Hello

I just started using an NI USB-6008 box. At this point, I don't need to fill all the specific tasks other than learning to use the device. I used a fair bit of LabVIEW but never with this kind of material, and I would like to help to understand it please.

In particular, I have attached a VI in which I try to get an analog signal through the USB-6008 and read again (also with the USB-6008 - I wired the pins together). However, I do not understand what is happening when I run this VI. I expect the output a sine signal of 10 Hz for 1 second, 0.1 seconds record and see 1 full cycle of the sine wave. In practice, I read about 10 cycles and constant tension then. Presummably, this means that either the reading continues for more than 0.1 second, otherwise the output signal is more than 10 Hz.

I also tried to use the related calendar DAQmx screws with the output pin to try to adjust the output rate (samples/s) but everything that I've tried return errors. I also tried to open some examples NOR, but these errors returned as well and I still just try things on mine.

Did I miss something obvious here, but any help would be appreciated!

Edit: I had to update this post & attached VI I had made mistakes. The default values on the front panel show what I see after the execution of the VI.

Orbital Hi,

As far as I know, you will need to use the DAQmx Read and VIs write in loops and functions of synchronization to determine data rates you want.

I also did a quick search and found a white paper which you may find useful: http://www.ni.com/white-paper/9541/en/

Kind regards

-

Redeclenchables/continuous to a custom waveform analog output?

Hello

I try regular output an analog signal using the box USB-6211 and Labview2009. I looked at various examples of waveform, including the retriggerableAO.vi example, but I can't seem to understand how to send a 'waveform' custom stamp (terminology is perhaps the question). In all the examples (including waveformbuffer), I ran across the single waveform, the options are sine, square, etc. Previously, I posted on this forum looking for hardware suggestions (link here) and explained what I try to do and got the big help. To sum up, I would like to read a 'waveform' from a text file, send it to the usb-6211 buffer and then continue to an analog channel. At the same time, I'll use the beginning of the analog task to trigger a digital signal once per cycle as well.

I got in what concerns the establishment of the waveform, but am stuck to figure out how to get into the buffer and setting the frequency, etc.

Thank you

Gabe

Hi Gabe,

Dennis is correct that it will take some room to modify the existing screws to fit your need. As he says, the Con Gen tension Wfm - Int Regeneration.vi Clk - no example provided with LabVIEW. In the example, it can be shown that there is a custom VI used to explain the problems that arise when a waveform of a given frequency to a frequency of sampling and outputs analog specified.

With all that said, it seems you want to read from an existing waveform file that you created and this waveform to an AO output channel. There are a few things that will be needed to know before proceeding:

-What is the waveform as you try to output (5000 samples, 10 k, 100 k, etc.)?

-What pieces of the size of the wave you want output (100 samples at a time, etc.)?

-you want to again and again, or simply run through once the waveform looping?

Assuming that you already have the waveform and will only step by step, here's what I would like:

-break the large waveform into smaller pieces of waveform of standard size

-import the waveforms in LabVIEW and create an array of waveforms

-bring the waveform in the example Dennis mentioned previously with automatic indexing enabled on the tunnel

-Remove the generator of wave functions existing the while loop

-wire your indexed table of waveform for the data of the VI DAQmx of analog output terminal

It is possible that you will have to play with the settings of your waveform and timing of your VI, but this should be a good starting point. Please let me know if something is not clear or if I have misunderstood your original message. Have a beautiful reast of the day.

Best,

-

DAQmx: Analog input directly to the analog output at the hardware level

Hi all

I searched for a while, but I couldn't find any suitable implementation for what I'm trying to do. A person where I work introduced me to an interesting challenge. Is there a way to set up a DAQmx task (or set up otherwise an MIO Board) to route an entry directly to an output to the analog analog hardware level? You may be thinking, "why the hell would you do? To reduce the electrical complexity, a colleague would like to concurrently read an entry while 'reproduction' of its signal on analog analog output. I know that I can easily accomplish this while the buffering by the PC, but they are interested in ensuring that the output signal is also similar to the input at the level of KHz signal, by introducing a minimal difference in phase (shift buffering of the PC).

For the record, we have for most old maps of the E series here like the PCI-6070E (PCI-MIO-16-1). I was first asked if it could be done through SCXI, but I figured I would start by asking about the MIO tips.

This looks like a long shot, and I've never heard of someone at - he never did this, but I thought I'd ask to be sure!

Thank you

Jim

Hi Jim,.

With the help of our driver is not a means of generating data directly from the FIFO of AI, it must first pass through the software. You can try the following code to the output of one of THE duplicate on the AO line to see what kind of delay you can imagine. It is similar to your original with a few adjustments code:

Use delayed output Version of avian influenza in DAQmx AO

It seems you need to do, you might consider instead the search by using a voltage follower to isolate the Vout wine.

Best regards

John

-

Bad analog output help Every_N_Samples-NI-9263 cDAQ-9172 chassis (works with cDAQ-9178 chassis)

Hello

The NOR-9263 analog output voltage geberation works correctly with the cDAQ-9178 chassis but gives wrong result using the chassis NOR cDAQ-9172.

In the attached code example, a single cycle of a sine wave is composed of 40000 samples and came out in the background using Every_N_Samples at a rate of production of 5000 samples per second.

The output buffer size is set to 10000 samples.

Prepare us the buffer writing 10000 samples 1, then write the remaining data in the background using the Every_N_Samples callback.

Bug: Using the cDAQ-9172 chassis, to the 5000 s/s sampling rate with the help of an external field (or through closure to another HAVE), we observed that 1 10000 samples came out twice, followed by the rest of the waveform. The last 10000 samples are never exits. If you are working properly, we would expect to see 1 full cycle of a sine wave.The bug does not occur with the chassis NOR cDAQ-9178. I use the driver NIDAQmx v9.2.1f0 on Windows XP

The bug does not happen with simulation devices, so you will need to use harwdare real to reproduce.Please find attached an example of code C based on the example program OR "ContGen - IntClk.c" to reproduce this bug.

Thank you

whemdan,

The MathWorks

Hi whemdan,

By default, DAQmx regenerate old samples if no new data is available. To give the correct behavior, you can:

Use DAQmxSetWriteRegenMode to disable the regeneration (DAQmx_Val_DoNotAllowRegen). In most cases, this is recommended if new data are written continuously in the buffer as the build is in progress.

If you just need to generate 40 k samples, you can write them just all at once, rather than in 10 pieces of k (the code you attached probably is just an example, so I'll assume that you have a reason to write the data into segments in your actual code).

I think the difference in behavior between 9172 and 9178 can if explained by the different way, buffering is set up on each product. The 9172 uses a buffer of 8 k (on the STC2) in all cases (source). The 9178 uses an 8 k of memory buffer (on the STC3) If you use regeneration shipped, but uses the 127 samples FIFO cartridge, if you use no on-board regeneration (source).

Then... on the 9172 8191 samples are immediately transferred to the FIFO. By default, the hardware is going to request new data when the FIFO is less to fill (this is configurable with DAQmxSetAODataXferReqCond). I'm not sure what the transfer data request size is in your case (you can set the maximum value with DAQmxSetAOUsbXferReqSize), but obviously it is bigger than the other 1809 samples that you have not yet sent to the Board of Directors of your first entry. At this point, the pilot will regenerate 10 existing k samples so that sufficient data will be available to meet the demand of data transfer.

The 9178 however use the FIFO of 127 smaller samples so you will not have the same behavior in your case.

In summary, the behavior is explainable by the difference of material. If you want to avoid to regenerate old samples, you should ban the regeneration using DAQmxSetWriteRegenMode.

Best regards

-

analog output digital start trigger the api c

Hi, I'm trying to start analogue output based on a digital trigger (either PFIO or a PXI line) I can make this easy in LabVIEW. However with the C API (through the Python wrappers), the problem is when I call DAQmxBaseWriteAnalogF64, writing will always be timeout that the acquisition was not triggered. However, I can't call it after the trigger occurs, because obviously, it will be too late.

I can't find any examples of C API where the analog output is triggered a digital triggering. I can find for the analog input, but is fundamentally different that you can CONV read anytime after the trigger occurs.

Python code as follows (functions are equivalent ot C API, even if you have no need of ot pass the task handle such that it maintained as part of the Task object)

# create analog output task analog_output = Task() analog_output.CreateAOVoltageChan("Dev1/ao0","",-10.0,10.0, DAQmx_Val_Volts, None) analog_output.CfgSampClkTiming("",outputRate, DAQmx_Val_Rising, DAQmx_Val_FiniteSamps, numSamples) analog_output.CfgDigEdgeStartTrig("/Dev1/PFI0", DAQmx_Val_Rising) analog_output.StartTask() analog_output.WriteAnalogF64(numSampsPerChan=numSamples, autoStart=False,timeout=1.0, dataLayout=DAQmx_Val_GroupByChannel, writeArray=data, reserved=None, sampsPerChanWritten=byref(samplesWritten))print("Analog output: Wrote %d samples" % samplesWritten.value)# create digital trigger dig_out = Task()dig_out.CreateDOChan("Dev1/port0", "", DAQmx_Val_ChanForAllLines) # create digital trigger function highSamples = 1000 numpts = 3 * highSamples doData = np.zeros((numpts,), dtype=np.uint32) doData[highSamples:2*highSamples] = 2**32 - 1 # send digital trigger doSamplesWritten = c_int32() dig_out.WriteDigitalU32(numSampsPerChan=numpts, autoStart=True, timeout=1.0, dataLayout=DAQmx_Val_GroupByChannel, writeArray=doData, reserved=None, sampsPerChanWritten=byref(doSamplesWritten)) print("Digital output: Wrote %d samples" % doSamplesWritten.value)Hi PatrickR,

You can review examples of code NI-DAQmx (ANSI C) text based on the production of an output using a trigger to start digital analog. If you included/checked support textual dusing your NI DAQmx driver installation, you can navigate to Windows start > all programs > National Instruments > NI DAQ > Teaxt-Based Code support > ANSI C examples > analog output > generate voltage > Mult Volt updates-Int Clk - Dig start. If you have questions/doubts about the material.

-

How to determine the number of highlight ' to write ' for DAQmx generate analog output?

On the configuration of the stage for DAQmx generate analog output, there is a field "value to write. I can't find any explanation for what it is, how it determines the value to enter, nor what he writes. I am trying to go through the tutorials and it cling.

Someone would give an explanation?

Hello

To write value specifies the value to write in the channels, lines or ports selected in string parameters. In other words, this value will be the value of your DC output (for example if you enter 5, your output will be 5V). To get information on different fields in SignalExpress, access help"context-sensitive help. A pane will appear in your work environment that displays the coordinates of the field when you place your pointer over them.

For new users of SignalExpress:

Generation of DC signals with NI DAQmx devices: step in the DAQmx build, select 1 sample (on request) in the generation Mode dropdown. You can select a programmatic input to generate, or you can remove the check mark from the check box use programmatic input and specify a value for generating in the field of value to write . NOR-DAQmx help also provides additional information about the data generation.

Best regards

M Ali

Technical sales engineer

National Instruments

-

Simple examples of analog output USB-6343

I've tried passing by 'find' examples and does not know how to find what I want.

I'm doing a simple analog output on a USB-6343. Examples of waveforms say they work with the USB-6343, but I really don't want a waveform, just analog of output does not exceed 10 Hz speed of renewal. Some of the more simple examples show that they work with the pcie-6343 but do not list USB-6343.

I worked with USB-6009 in the past, but when I try to use an analog output task that uses 1 sample on request, I get the error "not buffered operations clocked by the hardware are not supported for device and channel type.» Set the size of greater than 0 buffer, do not set up the timing of the sample clock or the value Type of sample On Demand time"

I tried samples N, 100 samples to write to 10 Hz - the same error. Samples of continuous - same error. 1-sample - timed HW - same error.

There is a series of examples of I/O for the X series? Is it possible to search the device examples rather than go through all the examples and by checking the list of devices individually?

Is 'size of the buffer' the 'writing samples"in MAX?

After contacting the support I was provided with the names of the more simple examples for analog i/o:

Analog output-Gen power Update.vi

Analog Input-Acq & chart voltage-Int Clk.vi

They are found in the getting started screen of

Click 'Find examples' near the lower right corner

Filter the results to material by clicking on the menu drop down for the material in the lower left corner and selecting USB-6343 (only connected equipment will be displayed)

Don't forget to check the box "limit results to material" below.

In the center pane, double-click 'Material Input and Output'

Double-click DAQmx

Path for the analog input - double-click Acq & chart analog measures - double click on tension - tension-Int Clk.vi

Double click on analog generation - double click on Power - Gen Update.vi of analog channel output voltage

The examples are for the single data point. Samples and exit multiples are produced by putting the writing or reading VI inside a loop. The beginning and the clear functions should be out of the loop.

Additional information, I need technical support was how material-filter results and identification of more simple examples which were not obvious from the examples of names.

-

Analog output of signal generation custom

Hello

I have a VI that generates a signal from the values in an excel worksheet. I'm trying this waveform through an acquisition of output data. I use a box NI USB-6211.

I copied the exit code for the acquisition of data from other VI that generates a sinusoidal signal coming from an excel worksheet. This program works very well. (attached for reference - Analog Output VI + sinusoidal waveform)

I have two problems at the moment. First of all, I get error-200560 about waiting until the function, attached.

Second output amounts only to about 5.5 v instead of 9V specified in the data.

My VI generate several types of waveform according to selected tests, but I'm trying to get an output DAQ working with the first test, named "disconnection of the battery" work first before implementing it in the other tests so please ignore others for now. To run this battery select VI disconnect under tests select then direct to the attached excel (BD values under 10V) file.

I hope that I myself have pretty much explained, otherwise please ask for more! I'm new to LabVIEW so your help would be very appreciated.

Thank you very much

Parker

aeParker wrote:

I've made a few improvements to the VI but I always feel the DAQ 5 Cap output, 5V.

Dear Parker,

I guess that this statement is based on the values in the chart show, AO 0. However, this is not (necessarily) the voltage produced by AO 0, but rather the tension being sampled by AI0. If you look at the DAQmx create channel for the AI voltage channel, you will see that you have left entries Maximum and Minimum Value unwired, which means that they take their values default to + 5v and - 5v. This may explain the behavior of cutting that you observe. Try the + 10 and -10 wiring and see if that solves this problem.

Bob Schor

-

How to write constantly to analog output and read from analog inputs

Hi all -

I had a question about writing continuously to analog output reading simultaneously an analog input.

It's my first time to post a message to the community, so please let me know if I made mistakes.

I use Labview 2011 with a NEITHER-DAQ USB 6215.

I'm looking to generate a waveform and write it continuously in an analog output. It is then connected to an entry on the acquisition of data, where I am trying to sample the analog signal. (I realize, there is a system of trivial, but I'm hoping to build on it once I have run).

The task of reading from the analog input works fine, as I tested it in several other cases. I have a problem writing to the analog output.

For this task, I tried to follow the "Gen Cont Wfm Clck Int' VI to generate the wave form and start the task. I then try to write to the output of the analog timed loop. However, it does not seem to transmit a signal and doesn't give me any errors.

I have attached the VI but also a screenshot.

Please let me know if anyone has any ideas. I would really appreciate the help!

Thank you

Peter Borgstrom

We will review your tasks one at a time. First of all, the task of generation/Analog output Waveform. Generate you a waveform (I'm unsure of your VI if it is a fixed waveform or not) and send it to a defined output function to produce a waveform continuously, using N-channel and samples of N (where you set not these previously). You should not put this inside has timed loop, as the DAQ hardware has its own clock - if you simply put it in a while loop (with a stop to break out of the loop), the loop will call the function for the first points of N, wait until all N have been taken out, then call it again to another N points (up to what you press Stop).

Now, suppose that you have the output connected to a load voltage (say a decent resistance). You can wire the input terminals of your A/D converter through the same load and set up a similar analog input loop, running in parallel (i.e. in its own independent of the OD loop, while loop). You pourriez start together (with, say, a merged error since the initialization code line loops HAVE and AO become lines of error in "loops of sampling" described above), but you might want to delay loop (a little) the AI so that the OD has a chance to set the voltage before the bed.

I hope this helps.

BS

Maybe you are looking for

-

How to read the status of User1 DIP-switch with a cRIO FPGA chassis?

How to read the State of the DIP switches on a FPGA cRio chassis? I work with a cRIO 9022... My idea is to put the system in "service" mode with USER1 switch to IT and communicate with the FPGA via the FPGA - GUI (VI) on the host computer instead via

-

How the strange names and addresses appearing on my address list?

I just noticed 6 different names and addresses of electronic mail on my address book that I did not put there. It is relative, and I would like to know how they got there and how to remove.

-

Lost my offices of broadband (DSL) for Intel Dial-up modem. Microsft or Dell?

Installed Samsung laptop computer to my service (DSL) wired according to the instructions it uses Intel. My two Dell computers use modems to broadband in the CP. They went to Intel and lost my broadband. Went through the ISP (At & t) and IP (aol).

-

1st problem: yesterday I started getting a popp window with the text following formulation - "there is no disk in the drive. Please insert a disk into drive \Device\Harddisk1\DR1' I have no idea what this introduced him or how stop it. Any suggestio

-

Recovery of password on the new computer

I just got a new 10 "laptop Toshiba and was tired when I typed in privacy. I have the idea and know what the password should be... but he won't let me little matter what I do. I tried caps, I tried to upper and lower case... tried almost everything