DC motor control

I have a problem with the encoder signal pulses... I need to order a motor ensuring that it won't go above a certain threshold. It takes the pulse with a having a trigger to repeat. I got code for this on a more, but I don't know how to get this pulse signal... It sounds simple enough, but I ain't no where classes.

Hi Gotti_uncc

I just wanted to ask some clarifying questions about your application.

Are you counting the pulses of an encoder and read in a user input that will generate an impulse to change the speed of your engine?

What equipment do you use?

Tags: NI Software

Similar Questions

-

Hello

I have a cRIO-9014 with a NI9505 DC brushed servo drive module and I would like to program the FPGA to PWM and encoder, quadrature, interfacing using the functions of intellectual property intellectual property mentioned in "CompactRIO Motor Control Basics Tutorial":

DX of encoder quadrature method (FPGA, using SCTL) .vi

Pulse Width Modulation (FPGA, using SCTL) .vi

I did a search at ni.com/ipnet but I could not find them.

Where can I find free downloadable IP cores for the blocks of PWM and encoder to include them in my interface FPGA program?

Thanking you in advance,

Manual

Found by myself (google search!) to:

https://lumen.NI.com/nicif/us/codepowelecguide/content.XHTML

-

Help me build a stepper motor control in LV?

I need control a single linear axis slide that is driven by a motor nema 34. It will be very simple move, start, move at a constant speed, stop, return. I do not have the engine. I can use a controller and a software company that sells me the slide, but prefer to use Labview.

I currently have a PXI chassis with a 6713 or 6704 available, or a '2 M Gate FPGA and cRIO-9073' with a NI 9401 I'll take delivery of every day now. I don't know much about the system in real time, but I have to learn it soon in any case.

Can I use my existing hardware/software to create a stepper motor control, or at least can I use Labview to interface with a motor drive step by step if this is not possible. I am currently looking at a 34T 1 Vexta engine, but do not know much about the stepper motors and do not really want.

Edit: Should have mention that I LV 8.6, with no motion software.

Engines step by step to have two power circuits creating magnetic fields perpendicular to each other inside the engine (in mathematics a certain sense anyway) you can consider working like pistons on a crankshaft which are out of step 90 degrees. You can use LV to manipulate these two. Want to make their vector sum in different directions while moving. Imagine making a point on a chart around the origin orbit. You need to consider things like the speed at which you can start the dot in orbit. Engines step by step can't go very fast if you add the requirement that the application start and stop without having to build your own ramp.

But it would be a big enough work for all, but more simple movements. You will need to learn less about stepper motors if you buy a motor controller that supports ASCII strings on a line of serial port as its instructions. I did recently with good results. LV must compose strings and write to the serial port of the PC. Having the engine go to a post 2205 units requires composing a string like this:

d 2205

go

It works fine without another component or software purchases.

I did something a little more complicated and wish now I had started with a decision to use the material in motion control of OR, or at least look at more the issue. When things are more complicated, using a serial port as the bridge between the PC and whatever the microcontroller is located in the drive motor starts to introduce limits you can schedule around with a lot more trouble.

You have many options depending on your purpose what is and how much trouble, you have to take.

-

need suggestions on the way to a position on a motor control with current continuous

Hi, I'm a newbie with labview

I'm doing a position on current motor control continuous. I use a USB 6259 to generate an output voltage and acquire the angular position of a coder.

I enclose my system of proaction

How can I transform into a feedback system, with a given reference signal?

Thank you

The "cascade dc motor speed regulator" example uses the Control Design and Simulation Module, and it is thought to control a motor which is simulated. Since you have to acquire data from a real system the standard while loop is correct.

With respect to the operation of PID control, you can take a look at the following examples:

-

Hello

I use a system using a SMU with 2 Motors step by step NEMA34-6, driven by the readers of SMD-7621.

The system needs to be powered 24/24 7/7.

Most of the time, the engine didn't need to spend...

It seems that the engine still somehow braking mode 'active', and the player constantly dissipate heat, even if no movement is required.

I measured the temperature of the steady state of the reader, who is around 50 ° C, measured on the heat sink aluminum.

It is safe to have the drive constantly at this temperature, 24/24, 7/7?

Is it possible to move the reader into a kind of mode 'sleep', when no movement is required by the control? Would this mode, if it exists, decrease the temperature of the drive?

I control the system using Labview on an SMU using a surfboard OR 73xx, so this mode should be controlled via the code of Labivew, in which I could detect situations when I will not have to move the engine more...

Any help on this will be greatly appreciated.

J.F.

Yes, this is the setting you should change. This player is actually a player movement applied Productss. I do not know how critical it is to keep your position. It is possible to lose the position a little bit if you go all the way up to 0%. For example, if you use microstepping, and you reduce the current to 0, the engine could jump to the next full step.

-

Stepper motor control while reading encoder

Hello

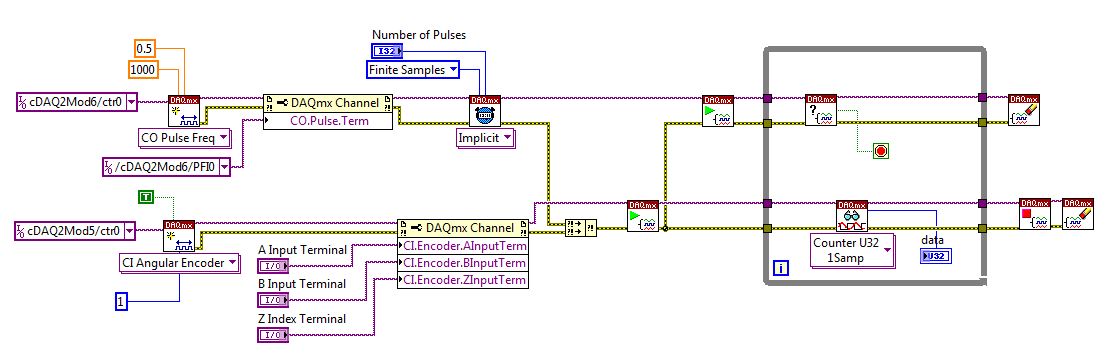

I'm looking to generater a pulse train to control a parallel reading and step by step motor in the impulses of the encoder of the motor. I was able to create two distinct VI who perform these taks individually, but when I put them into a single program (as shown below) is where I run on resource issues. I think I'll have problems affecting timers my properly and that's why I'm having these problems. I use a NI 9401 to generate impulses for the controller and a 9402 train OR read in the impulses of the encoder. If possible I would bring up just using the NI 9401 for the inputs and outputs if possible. The two are connected on a backplane cDAQ 9172 NU. Any help or suggestions would be greatly appreciated on what I'm doing wrong.

Thanks for the suggestion of Carmen, but I was able to understand what it was with a little help from NEITHER. The finite number of pulses of timing function requires 2 counters, so when I tried to read in the encoder data there where no meter more left on the backplane. Changing impulses continuously solved my problem. I'll take a background of most recent basket with 4 meters from the lab which should allow me to run the finite number of pulses and read data from encoder at the same time.

Thanks again,

Doug

-

DC motor control - axis of movement back

Hi all

I am currently (trying) to design a control of a servomotor system.

I use a cRIO 9082, NI 9514 C-module, a servo-drive Kollmorgen AKD and a Kollmorgen servo.

My main goal is to make the engine during continuous running + 15 deg to-15 degrees and with varying frequencies.

I checked my system using the 'straight axis' operation - example, that comes with LabVIEW.

How do I start making a model more sophisticated movement?

I modeled the DC motor in MatLAB using PID control. I can do something similar in LabVIEW?

See the image as an attachment to the model of behavior, that I want to accomplish.

Thanks in advance.

Best regards

JZaulich.

Hi JZaulich

You will need to use the NI Control Design and Simulation module to perform the simulation and model of different systems.

http://sine.NI.com/NIPs/CDs/view/p/lang/da/NID/209850

If you install this kit there are a good example called "DC speed control Cascade" engine that can show you how to model the motor and continuous control (both speed and current ". There are also examples of servo control.

Best regards

Anders Rohde

-

Maxon motor control with LabView

Hello everyone, I'm new here and I tried to find out how this process of work for some time and I ran out of options. LabView is very difficult to understand.

I'm about to order a controller epos Maxon motor 24/5. I have a vi that does what I do, but I need to find a way to make the process faster. Basically will control a wing that goes forward and backward at very high speeds. I'm not sure what I should do, I would also like to generalize the process by a power enter a function or a wave of the position of my choice. If any of you all can help me it will be greatly appreciated. Thanks in advance.

CarlosUT,

Without the subVIs Epos, it is difficult to say where downturns could be.

Take into account:

1. the mathscript node is probably much slower than native LabVIEW, special code for what looks like a logic very simple. Replace with the range of comparison functions. Also consider the feedback node initialization so that you know where it starts when the VI is called.

2. learn a few basics of data flow. Your delay (ms) and judgment is read only once at the beginning of the VI and these original values are passed to the loop. Any subsequent changes to these values will not see inside the loop. Move the terminals in the loop.

3. double code: you have the same Subvi in each case in the structure of the case. Move the Subvi outside the structure of the case and simply use the box structure to choose which set of values will be used.

4. given that the minimum value of the delay (ms) is 150, the loop cannot run more than about 6 times per second. You don't specify what you mean by high speeds for the control of the wing, but this may be a factor.

Lynn

-

Need help with LabVIEW code for motor control.

Hello

My name is Sasi. I'm a grad student BME working on my thesis topic of assessment for back pain spine implants. To do this, I'm building a test machine that would apply pure moments of a specimen of the spinal column. I use LabVIEW 8.5 to implement the control of a brushless AC servo motor. My requirement is

Step 1: Initialize the engine.

Step 2: Start moving it to a uniform to the right PLAN (this value of RPM too user can enter).

Step 3: while doing step 2; at the same time read the couple cell data (acquisition of data using Asst.). DAQ o/p is 0 v to 10 V; 0 v is 10 Nm n

10 v is + 10 Nm

Step 4: What torque reached + 10 Nm, i.e. 10 V, the engine stops.

Step 5: from the position where the motor stopped (IE not need to return to the initial position) start moving in the opposite direction to the same

Uniform rpm as in step 2 at the reading of data in the cells of the couple.

Step 6: once more what torque reached-10 Nm, i.e. 0 V, the engine should stop.

Step 7: Repeat "Step 2" to the "step 6' 3 times.

Step 8: Reset engine position.So far, I managed to get the engine to move backward @ a desired vel, the accl, deceleration for 3 cycles before n n. I enclose my code. I have a problem inserting the code for reading DAQmx amidst all this. Can someone help me.

Thnks,

Sasi.

Hi Sonia,.

I took a quick glance to your problem and I think I have a solution for you. I certainly agree with the suggestion of the use of parallel loops Lynn. This will allow the portion DAQmx run uninhibited by the part of the motion, and vice versa. In addition, you need only perform an iteration of the loop of the movement whenever the voltage level exceeds a threshold. Thus, by performing an iteration on the code of movement in the same loop are you iterate over DAQmx code, you essentially waste processor.

I created a VI that should do what you are wanting. I tested it on me and it works very well. You have a tweak a few things to apply to your system (such as motion Council DAQmx and physical channel ID, etc.). I used two parallel loops and event programming. Basically, the loop of movement starts the engine turns at the specified speed. Once the engine is running, he expects the DAQmx loop to tell him that the voltage value has crossed the threshold. When the voltage value exceeds the maximum threshold (I put a value slightly less than 10 to jitter and saturation), the DAQmx loop indicates the loop of the motion that it may end its iteration. The motion loop stops the motion, causes a reversal and repeats the motion. Once the movement has begun, he expects the DAQmx loop once again to tell him that a threshold was held, but this time, it's looking for a minimum threshold. I used "Occurrences" to implement the event programming in LabVIEW.

I've commented the code pretty thoroughly, so I hope that comments will answer all remaining questions. The advantage of using programs that focus on the event for this is that you save time processor, and your movement is more closely synchronized with the DAQmx. Instead of one iteration of the loop of movement as fast as you can, updates every hour, you just put in pause and wait for the other loop to tell you when to start up again. Meanwhile, the processor doesn't have to worry about an iteration of this loop over and over again. In addition, when the accident occurs, you catch him immediately, instead of having to wait until the next iteration. Thus, you are more closely synchronized with the DAQmx code portion.

I hope this will help you. Please report if you have any questions about the code or its implementation. Good luck!

-

cRio Steper Motor Control NI9512 step by step

Hello

I have a project at the University, and I have to design a LabView VI to control a steper motor. Apparently, everything is installed correctly: cRio-9074 and NI 9512. The engine must be running to start. Problem is, I'm just new to Labview and I have no idea how to program such a VI. I just finished all the basic tutorials on the Labview works, but I need help on how to press control the engine through a VI.

Pls help me!

Thorsten Hey,.

There is already an open post regardin your subject. Continue the Discussion here:

Concerning

Romain Imhoff

National Instruments

-

Access platform Thorlabs APT with a joystick for motor control TDC001

Hi I am trying to use a joystick 3 axes for control TDC001 XYZ configuration engine controllers from Active-X and APT Thorlabs platform in Labview. I already follow this link: http://www.thorlabs.com/images/TabImages/GuideToLabVIEWandAPT.pdf

I'm able to control an axis in Labview platform APT now. Anyonw knows how can I access APT with my joystic 3 axes (either Labview or APT User Interface), so that I can use it to control the motors controllers? Thank you!

You try to learn programming manual from the (not-so-bad, actually) LabVIEW, you reference in your message? If so, it would be wise to find a LabVIEW guru and get to teach you the basics of the LabVIEW programming, including the importance of data flows (and how to serialize your code using error line) and good programming Style LabVIEW ("Lesson #1 - all the diagrams should fit on a single screen of laptop , and if it's not then break down the task into sub - VI. ("" "" Lesson #2 - all sub - VI and VI is in need of an icon and a Description ').

You don't say what the problem is that you are experiencing. Could I guess that it involves the three-axis Joystick? There are Joystick support in LabVIEW, but it's a little dark and a little outside the usual way of handling equipment.

Give us a better idea of what questions you have.

BS

Tracyfu wrote:

Hi I am trying to use a joystick 3 axes for control TDC001 XYZ configuration engine controllers from Active-X and APT Thorlabs platform in Labview. I already follow this link: http://www.thorlabs.com/images/TabImages/GuideToLabVIEWandAPT.pdf

I'm able to control an axis in Labview platform APT now. Anyonw knows how can I access APT with my joystic 3 axes (either Labview or APT User Interface), so that I can use it to control the motors controllers? Thank you!

-

AKM21C using LABVIEW servo motor control

Hello

I'm controlling only 3 engine AKM21C using LABVIEW. I want a user to enter a certain length and width to move the motor in x-y-directions, and through the GUI LABVIEW on the façade. Two of the engines must evolve synchronously in the direction, while the third engine moves in. x I have a query UMI-7774 interface connected to the reader of the AKD engines.

Could someone please guide me on how to proceed with this?

Hello

Assuming you are using one of our motion controller cards, follow-up guide will be an excellent aid step by step to get you started: http://www.ni.com/pdf/manuals/375543c.pdf.

-

Best way to make this step motor control system

The goal of my project is to have real-time data collected by a controller of Sir 158u Dataq a stepper motor. I grappler planned on executing it with the basic stamp, but I realize that's not possible. I have a stepper motor and a L293DNE driver. I'll be permanently registration of data with the dataq, the form of volts and want these values to determine how the engine works. For example, if the voltage is 0-3 volts, I want it running clockwise, 3-5 volts not turns not, and 5-8 Volt turn clockwise.

I tried to understand this last week, searching through discussions with basic stamp, matlab and labview now.

Is there an easy way to do this? or easier way that I'm trying to understand?

Any help would be greatly appreciated!

Thanks in advance.

-Nick

Nick,

What I was describing, this is how you configure the motor controller to accept PWM of LabVIEW and mode locked anti-phase so you can control the direction of the motor. Much on the part of LabVIEW depends on the acquisition of data you use. For example the acquisition of your data doesn't have a counter which can generate a PWM? I did some checking everything on time and the acquisition of your data is not made by National Instruments and I couldn't locate the native LabVIEW drivers. I did however go to the MFG Dataq 158u site and found that they do not have drivers LabVIEW BUT their software (SW) should run in the background. Dataq 158u website also has a help forum, I suggest you start to understand the capacity of the 158u Dataq. Also it seems that you are not familiar with LabVIEW, until you can take on a project like this, you have to start with the LabVIEW Basics, learn how to manage the tables so you can store your results of EDA and records the use of loops and timing and movement. NOR has a basic training FREE as the intrudction 6hr to LabVIEW, I would like to start their. Oh, and in your OP (original post) you doubted the Basic Stamp could do that, I do this type of control using the Atmel microcontrollers all the time, I'm sure that the stamp eaisily could do. Download right on one of their forums for more information. Oh and to answer your question a UPS is an IC that reverses the input signal, which you would end upward with the direction of you pines motor controller is PWM on a spindle and 180Deg off phase PWM, on the other hand.

Alan

-

infrared 6008 or stepper motor control

HY! I want to try to control an engine with NI6008 and an infrared receiver TSOP3848. I want to start the engine with the "play button" on TV remote and stop the engine with the button 'stop' at a distance. The problem is that my infrared receiver 38 kHz frequency and the NI6008 can't receiver 10Ks/s... If anyone has an idea how to get the infrared signal with Ni6008 and how to start and stop the movement of the motor please help me!

Find out!

-

Not motor control steps (very basic)

Hello!

I want to build a Labview/application software that will directly control the motor step-by-step to a cnc one axis (right now).

first of all regarding the software my requirements are:

(1) I have read a CAD or any vectorial image.

(2) so I want to be

(a) generate code for g and control through reader (what is conventional)

(b) or direct control via usb (data lines). (I'm not sure about that, please help here)

I went through the tutorial provided by the labview for control of the movement of the motor, but is it possible to make my way?

MY GOAL IS TO CONTROL THE MOTOR DIRECTLY AND IT THERE WILL BE ONLY TWO COMPONENTS - MY LAPTOP AND THE ENGINE STEP BY STEP CONNECTED TO MY LAPPIE.

Please help me,

I plan to do my college project.

-

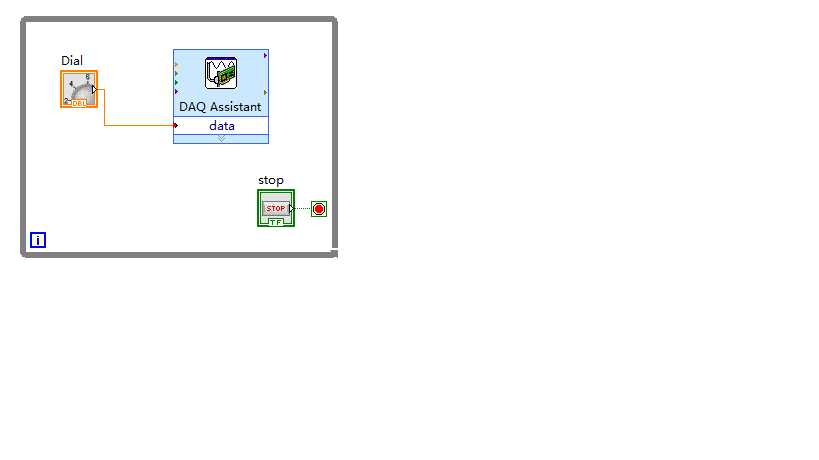

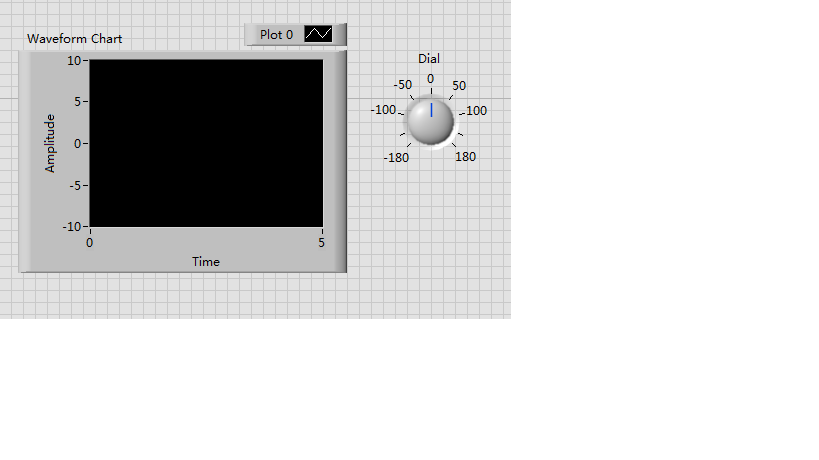

direction of the motor controlled by the adjustment wheel

How to control the direction of the engine using the adjustment wheel, for example, if the pointer locates the negative area, the engine was reversed. Usually the engine management is determined by AIN2 and AIN1 values in the microchip, if the value of AIN1 is larger than AIN2, the engine would turn in a certain direction, otherwise, the engine was reversed. However, I would use only Dial control to control direction. What should I do?

Use the feature comparison > 0.

Maybe you are looking for

-

With Chrome, I can rt.click and print or save pages or pages. in format PDF. How in Firefox?

for example. If a document has 6 pages I print or save to PDF format, some or all pages.I use a 6560 probook, Professional 64 bit, windows so I PDF without using PDF Complete, which is the only choice for PDF in the print file.

-

Satellite U300 - strange problem with volume control wheel

I bought a U300 last week and I find that the volume control wheel doesn't move very easily. It seems that you have to push it slightly to adjust the volume, and when you release your finger, the volume goes in the direction you moved to slowly. Ever

-

Power tips for beginner Manager

Hello First, forgive my English. It is not my first language. I am new to this forum and new in the world of Thinkpad. I went from Apple, and while I am fully satisfied with my Thinkpad L430, I'm a little overwhelmed by all these settings I can shape

-

CM1415fn: all-in-one printer HP CM1415fn clining after each numbered page process

I have all-in-one printer CM1415fn. After each page same printer starts cleaning process, then the even pages printed again. For example, I print or copy 4 pages. First are the pages 1 and 2, and then the process begins, then clean again page 2, then

-

Delete/rename a file in use by another program

How to find which program accesses a folder? I'm going to erase an and he said: I can not because it uses another program. I was last send photos to this folder can be disconnected from the camera while I rebooted this program and it has closed