Example: Front panel frozen L7780

My L7780 inkjet printer was working fine until today. Now, the façade has frozen - including the button ON / OFF.

I did twice a partial reset of its internal software (STOP - press and hold # and 6 while you insert the power cord) and it seemed to work until I went to Setup - network - wireless. It finds my network and partially printed a document from my PC. But then frozen again.

I tried, several times, powering down / turn on the power, including external power supply is disconnected. But nothing does not provide a permanent solution.

Is there anything else I should try or is the L7780 irreparably?

Try to reinstall the software/firmware told me that the L7780 is found on the network.

Well, after struggle with the L7780 for several hours (I've given up counting...) I decided to recycle and have bought a new printer!

You'll be happy to learn that it is another HP product. I hope this works as well as the L7780 did until it becomes terminal. HP has, I'm happy to say, to improve the quality of their software, which was a disaster when I had everything first to reinstall...

Tags: HP Printers

Similar Questions

-

Switch Soft Front Panel, active device classified

I have a with PXI chassis modules, two switches PXI-2350. Using the Soft Front Panel switch, it seems that the names assigned to the list of active device (both 2350's in this case) are backward, what to expect. Is there a way to reassociate those names to the 2350's physics?

Thank you

Confustus,

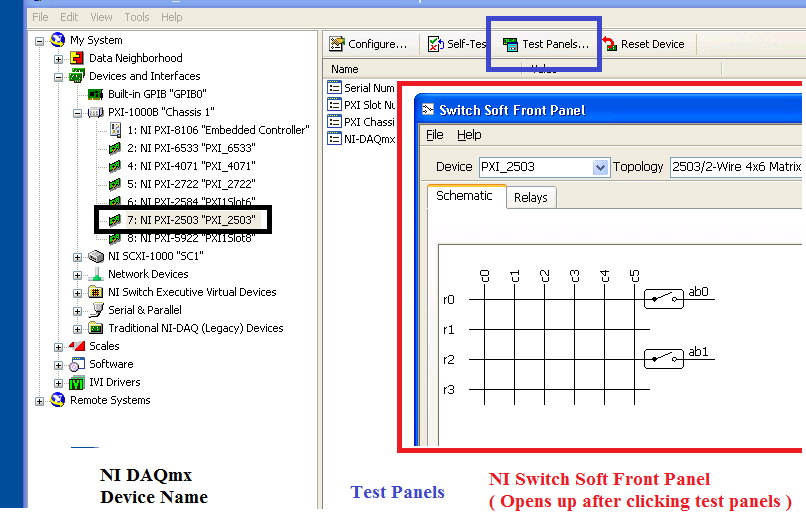

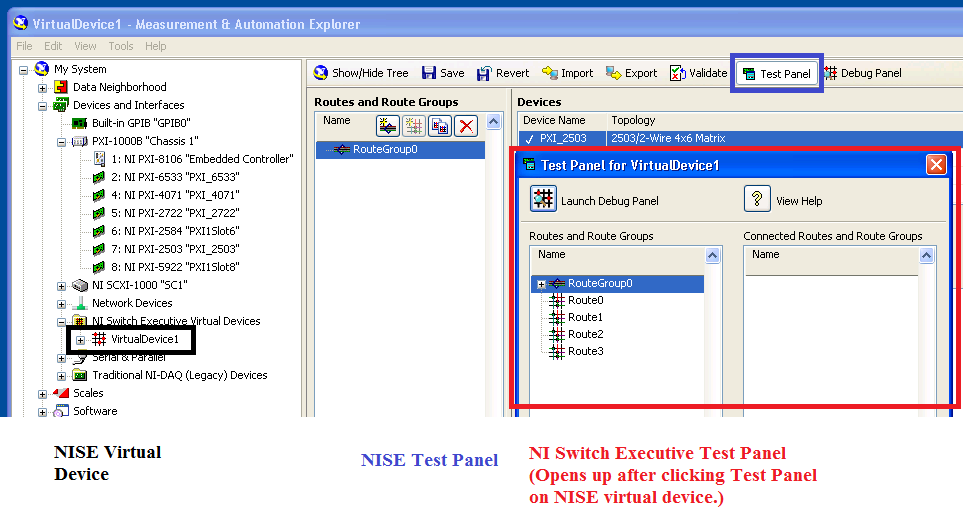

It's an interesting question that I've never seen before, your devices in a Soft Front Panel should be linked to features like labels in MAX. I was wondering, when you say "we can select using MAX, a road that connects the power supply to the digital multimeter using"Switch 1"(for example), and we can see the voltage reading show on the Soft Front Panel 4071 as planned", what you mean exactly? If you had to choose your hardware device, and then click test panels, the NI Soft Front Panel load switch. Are you saying that when you choose test panels and loading Switch Soft Front Panel of max works as expected, however the application outside opening MAX does not work?

Or are you talking about the Test panels you open in NI Switch Executive? The test for NI Switch Executive panels refer on behalf of virtual device NI Switch Executive, not the DAQmx device name. If you had named the name of the NI Switch Executive virtual device in the same way, that could be part of the confusion of the problems that you see. See the images below:

NEITHER DAQmx Test selection panel that leads upward.

Test NI Switch Executive Panel allows this. If these names are similar, I can see how that might be confusing.

-

OR-SCOPE Soft Front Panel errors

I can't capture a square wave 10 kHz using NOR-SCOPE FPS. The error that I get for the manual config and auto-setup is-200580 requested is not a valid Vertical offset.

Max test panel can capture the signal without errors.

My setup is PXI-5154 Slot3, chassis PXI-1031DC, Windows Vista, LabVIEW 2009, MAX 4.6.0f1. Entry test square wave 10 kHz, 4Vp - p connected to Ch0 BNC 5154.

Hi bmann,.

What is the descriptor of the resource able & Automation Explorer (MAX) for this device? Is it the same as other devices that were previously on your system?

The 5154 can't stand the vertical offset, but other devices (for example the 5152) support vertical offset. The NO-SCOPE Soft Front Panel (SFP) will use the resources descriptor to identify devices. If no configuration is not found for a device with a particular resource descriptor, then the FPS will run an automatic configuration on the device. However, if the FPS is a previous corresponding configuration with the same resource descriptor, it will attempt to use this same configuration. This is where I believe you can receive the error.

If you have a 5152, you can check the "vertical offset" parameter in the "Device setup" window - looks like this is the setting that attempts to commit to the 5154 the SFP and the NOR-SCOPE driver is throwing this error. For a 5152, this parameter should appear, but the 5154 this setting should not appear.

Could you try to re - appoint the device in your system for something unique?

Let me know if it helps. If not, it could be another question - let me know what version of the driver NOR-SCOPE you have installed if this is the case.

-Andrew

-

How to scroll through the front panel when running

Hello

I'm using LabVIEW 8.5. I want to scroll the front panel automatically according to the moving object. I enclose a vi for example, in which I move the image, but if it is out of range of screen I have to scroll manually horizontal scroll bar to see the position of the image, it is possible that it automatically scrolls according to my position of the object.

-Thanks in advance

Hi, Mary,

Well, now I see what you wanted. From my point of view using front panel scrolling for this animation is wrong way (if not I do not know your final objectives).

I would recommend that you use the image for this control. Here the work by hand a little more, but you will get better results and will not scroll to your façade.

For example, "quick and dirty" implemented:

Andrey.

-

VI front panel does not close when it is done executing, when this vi was called by reference.

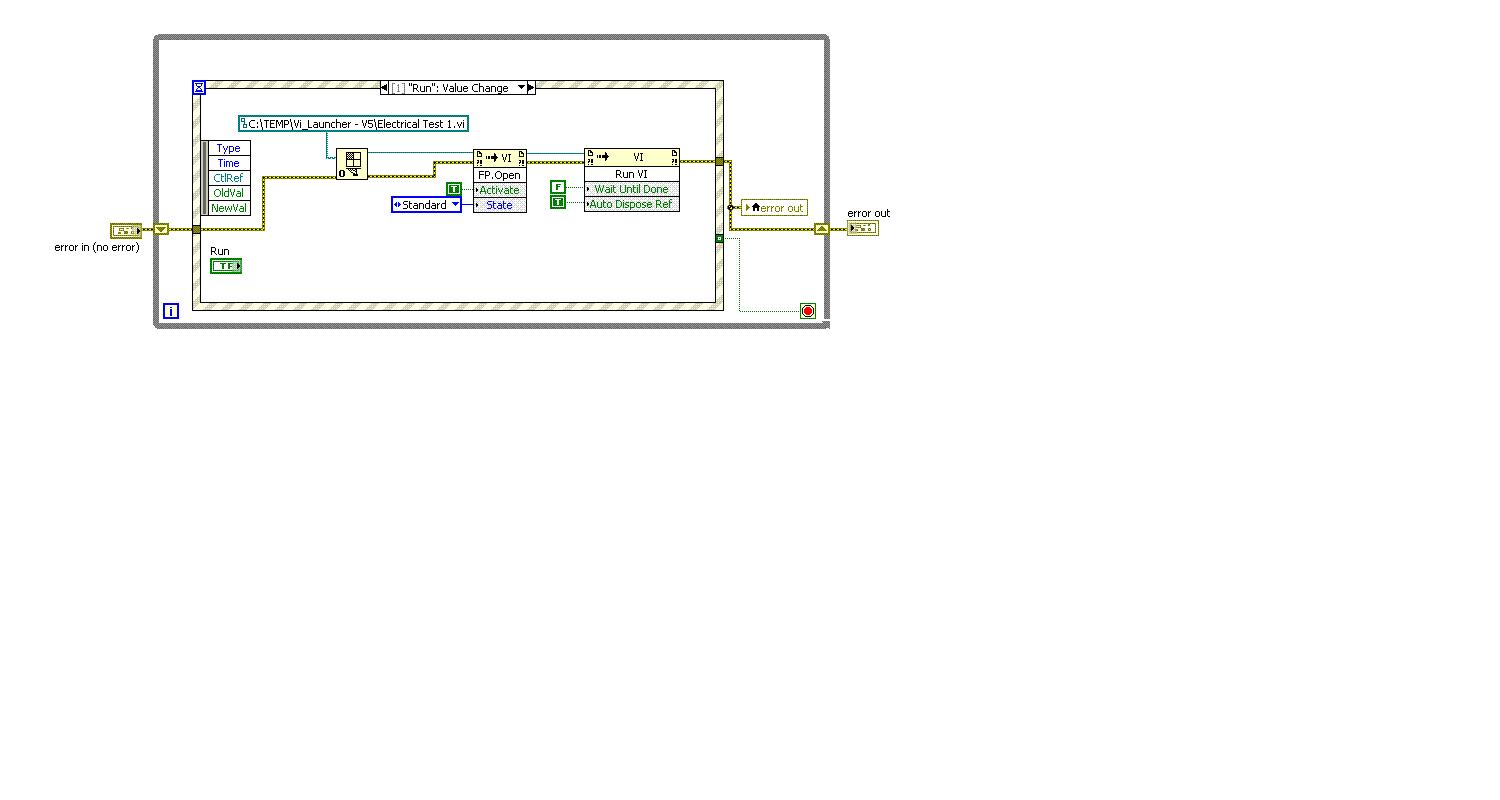

I created a simple vi set to indicate the problem I'm having. I run dynamically under vi to leave a main application. Simply the main application is my test exec and the Subvi I call dynamically is different tests. In the example I have write here the criterion vi is called Test electric 1(vi). I configured this electric Test 1 vi to see the front when it is called and close later while initially closed. Problem is that it doesn't close before.

Other things to keep in mind

- I want to be able to run the vi test and do not wait until it is done.

I'm using LabVIEW 2012 SP1.

Basically the fence after that call questions only if the VI is called as a Subvi (as if you open you a VI and run it, it does not close when it's done). Are two ways to work around this or have your app high lvl close the VI when it's done, it's explained here:

http://digital.NI.com/public.nsf/allkb/987B2026B41BD39786256CF800032E8C

or having your VI close when it's done. A reference of the VI and the front panel: Close call node.

I hope this helps.

-

Security on the front panel does not work

Hello

I have a problem and a question:

Problem: I created some controls on the front panel and some groups which they are responsible. Administrators can see and do everything, the operator cannot see some of them. If I build exe it works on development PC but if I copy them to another PC, it does not. It does not show these elements of façade. Areas are the same, SCADA, only the names of PC are different. The two computers are not in the same network. I create local domains and users on two computers through domain account manager. What could be the problem?

Question: How can I create an access control list (ACL) and assign them to the elements of façade programmaticaly? What is the syntax? I have found no examples of code.

Thank you.

I found the solution. Maybe someone also needs:

You must copy the folder C:\Program Files (x 86) \National Instruments\Shared\Domain development pc to other PC, in which you want to have the same field and same users. It does not have to generate the new domain with exactly the same name on another pc and generate new users. You must copy the whole directory of your pc to the other pc. It works now.

-

Front panel FPGA Boolean mechanical action is important to control the actions of a host RT?

When a host RT controls an FPGA VI shipped through Boolean values on the face before of the FPGA VI, no matter what setting the mechanical action is used by the Boolean front panels? For example, they all just act as "Switch When you press on" or the law "lock when you press on" as one-shots?

Okay, it looks like I have a little bit of clarification to make.

First of all, the patterns of waveform above are correct. As soon as the handshaking signal Host_Write if high, the data is written to the next clock cycle. At this point, "Lock" options are equivalent to eachother, and all the options of 'Switch' are equivalent to the eachother. Each takes 150ns to receive the signal of Host_Write.

The only thing in my post above that is misleading is when I said that transitions occur at the same time. This is not true, as the writing must be serialy, 150ns apart.

In case anyone is interested, I enclose the test and the test bench project. On your host machine, simply generate the files for the simulation construction-spec, then replace the tb_NiFPGASimulationModel.vhd generated by the one I've attached (this is the test bench). This should be at "C:\NIFPGA\simulation\FPGA_Boolean_Mechanical_Action\FPGA_Target\MechanicalActionTest\user". Given that forums don't add .vhd files, please rename the .txt in .vhd.

-

front panel size between decoration

Hi all

Does anyone know if there is a way to size, a façade based on a decoration.

for example, I have a front apnel GUI with a flat frame decoration.

I spent some time tweaking the front panel to show what is inside the flat frame decoration. I go back and change some stuf and repeat these optimizations.

It would be cool if I could just put highlight the object of decoration and tell the VI to resize based on the decoration.

I tried this VI-> Panel-> Decos []-> Index [2]-> MasterRect to set the FP. PanelBounds.

It is assigned the same size as decoration, but not really where the decoration, see VI attached.

Any ideas?

-Sean

You must set the origin of the part of the façade as well.

But as Ian said, it is probably best to design your front and your decoration so that its located at 0,0 and place in upper-left corner of the window.

-

Any LabVIEW 2009 Front Panel Gage displayed as circle deg continues 360?

Any LabVIEW 2009 Front Panel Gage displayed as circle deg continues 360? I want to display a position of motor on the Panel before LabVIEW as a circle of 360 degrees. Is there a way to make the pledge appears as a circle of deg continues 360?

dbaechtel wrote:

Gauges and dials, buttons, none of them seem to be designed for continuous operation of 360 degrees. Of course I can set the scale of 0 to 360, but I can't get rid of the gap between 0 and 360.

How to set up a pledge to show a continuous 360 degrees without a gap between 0 and 360?

To change the gap, take the line high marker and move it to the desired location (in another origin, enter the low marker).

Also, don't forget to wrap the raw in 0.360 rank if it falls outside. Here's a quick example (LabVIEW 8.0).

-

Update of Acquisition of tension over on front panel

I have this simple motor driver program that communicates with a stepper motor controller. I now have to combine this vi with person who acquires a finite number of data points of tension. I found an example of tension over who works with my daq (usb-6009). I was thinking about another stacked in a loop sequence for works to save the voltages, motor training, save several tensions, etc. a desired amount of time.

I wish I could see the tension on the front panel, because I'm their record. Is there a simple way to do this when requiring a finite number of tensions? I use finish because I need only say 10 seconds of data in each engine position and fixing the number of samples whose rate is a simple way to adjust the ignition.

The examples I've seen update tension using a while loop. If I do this then the while loop keeps going until the user stops it.

Thank you very much. 2 vi, I work with is attached.

BTW, I'm a graduate of mechanical engineering student.

Hello

See this link on the waveform data type.

http://digital.NI.com/public.nsf/allkb/B965F316364DE17B862572DF00363B10

Writing custom file Express VI will be likely to work as a note for a long time the sample and, therefore, the loop rate is not too high. It's because the writing on a file of measures, although practical, contains a bit of overhead. If you want to display multiple channels, you can merge the signals and display them on a single diagram, or use several. It will be you.

The best indicator to use will depend on what data you want to display. The waveform table is going to be the most complete, but as you have found the samples back in the form of an array of double type, you can indicators table, or remove points on the table and use digital indicators as well.

-

LabVIEW version of the source code of the NOR-DCPower Soft Front Panel

I work with an SMU NI PXI-4130. There is a front panel soft exe called the "NOR-DCPower Soft Front Panel" that can be used to control the instrument. I was wondering if there is a version of LabVIEW source code for this driver?

Jim,

as much as I know there is no LV source code provided for the Soft Front Panel. But there are a few examples of LV, which will be close to the characteristics of the SFP. So I suggest to you to dig in the examples you find in the Finder of the example.

Input and output hardware > Modular Instruments > NI-DCPower.

hope this helps,

Norbert

-

Requirements Gateway - objects on the front panel

Hello

I'm about to start using the gateway requirements and I have a few questions to help me go...

1. If I create a vi on a machine without RG installed and then move it to a machine with the Receiver General installed, will be always recognized tags?

2 - RG recognize the syntax [covers XX] if it's on a façade and not the block diagram?

Thanks for your help.

Darren.

I know a little RG.

1. Yes.

2 RG will scan the three areas of a VI for references: VI Description, control/indicator Description and diagram commentary (free labels). That's why he won't see a reference on the front panel (for example data text or text of the label or a caption).

-

Open the front panel Excel file

I tried to open an existing to open the front panel button... excel file but looking in the forum I found two examples... attached... done with the document word and another notebook... However I am unable to do it with excel...

In the second example that uses Sysexec.vi... I tried to enter the path of excel file... but it does not open... but same file opens when I write it on 'Run' in windows vista...

Advisor...

I found the solution... using sysexec.vi and the command line...

Thank you...

-

Hey!

How can I include the "impedance" and "Probe atténuation" options at the front view of NOR-SCOPE?

Now, this option run "Edit-online Device Configuration"!

Thank you

Patrick

Hi Patrick,

the soft front panels are demo applications for our various modular instrument drivers. We do not distribute their code, nor can you change their GUI.

If you are programming with LabVIEW I would recommend that you build your own version of a scope to start with an example of our example search tool (help-> find examples). A good starting point would be the Acquisition of niScope configured EX example which also gives you a good overview of how to use the scope pilot.

If you have more specific questions do not hesitate to ask!

Best regards

Peter

-

Can I link an LED on front panel for a specific element in an array of Booleans?

In LabVIEW 2010, I have a string of LED. I and array of boolean values that contain the values that the LEDs have to indicate.

What is the best way to connect the LEDs to elements in the array of Booleans?

Can I link an LED on front panel for a specific element in an array of Booleans?

How this is done?

Can someone show the code example?

Maybe you are looking for

-

Need driver of basic system / SD controller Driver for A30

Hello I just picked up this A30 - I had to use a recovery disc different that we had lost the original The laptop is running all the other drivers instyalled - I can't find the sysrtem SD or Base driver anywhere on the net Can anyone help? Thank you

-

External hard drive: cannot empty trash, because certain elements are in use

Hello! MacBook Pro 13 "2014 retina El Capitan 10.11.2 I have a 1 TB external hard drive. It is to Transcend. I found a useless file and I wanted to remove it. OK, all the files are removed but some records are not. There are 8 or 10 empty folders, an

-

frequency sweep performance in the profile of stimulus Editor

Hi all I am trying to understand what is the best way to do this. I have an output signal. I want to start with a 5V signal, so I want to do it in a sine wave of amplitude of 0.05v starting at 1 Hz and gradually increase the Frequency, squirt up to 5

-

How can I delete the invalid entries in the "Change AutoPlay settings?

Hello I deleted some programs on my computer (an OEM of PowerDVD and Nero 7 Ultra version). .... How the hell can I get deleted in the "Change AutoPlay settings" entries in Windows Vista? The programs are still listed, but the icons for the program

-

My laptop stops due to the malfunction of the fan and gives me a message about it.

Please tell me how to solve the problem with a laptop. I have HP Pavilion g6-2320er (A6) and on the Windows 8 operating system. For a year this laptop works well (from the date of purchase spent more than a year). Warranty expired in August 2014. (At