Fix error front panel

Hello

I've implemented an algorithm for counting and tagging of the components plugged into the binary images (LabVIEW 8.0). At the end of programming, I inserted a tab (replaced by indicator) control and copied images in its pages for later use. The VI worked well until I close it. When I try to open it again, I get the following messages: "Save/load error: unknown error" and "save/load error: wrong format. The VI can be inserted into another VI and the code runs, however I cannot access the front panel again.

Does anyone know how to access the façade and solve this problem? Thank you!

fact...

Tags: NI Software

Similar Questions

-

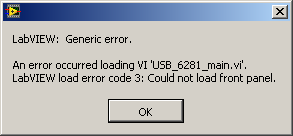

LabVIEW support 3 error code: could not load front panel

Hello

my colleague has a problem after the update to LV2011 (from 2010) and now get: LabVIEW support error code 3: could not load front panel

Even on my system (also tried a massive compilation)

He's afraid of losing some of his works.

Zipped file is attached

Hi Henrik,

It should work now.

Instructions to fix a corrupted in 2011 VI or more:

1. close LabVIEW

2. Add connPaneRecoveryMode = true to the file LabVIEW.ini (-the file LabVIEW.ini is located in the folder of National Instruments > LabVIEW 2011 > LabVIEW.ini)

3. open the VI corrupt.

4. press CTRL + A on the block diagram and the copy / paste to a new VI.

5. save the new VI.

6. close LabVIEW and remove the token of the ini (VERY IMPORTANT)

7 restart LabVIEW and load the new VI and check that it is correct. Save

Cheers, RMathews

-

OR-SCOPE Soft Front Panel errors

I can't capture a square wave 10 kHz using NOR-SCOPE FPS. The error that I get for the manual config and auto-setup is-200580 requested is not a valid Vertical offset.

Max test panel can capture the signal without errors.

My setup is PXI-5154 Slot3, chassis PXI-1031DC, Windows Vista, LabVIEW 2009, MAX 4.6.0f1. Entry test square wave 10 kHz, 4Vp - p connected to Ch0 BNC 5154.

Hi bmann,.

What is the descriptor of the resource able & Automation Explorer (MAX) for this device? Is it the same as other devices that were previously on your system?

The 5154 can't stand the vertical offset, but other devices (for example the 5152) support vertical offset. The NO-SCOPE Soft Front Panel (SFP) will use the resources descriptor to identify devices. If no configuration is not found for a device with a particular resource descriptor, then the FPS will run an automatic configuration on the device. However, if the FPS is a previous corresponding configuration with the same resource descriptor, it will attempt to use this same configuration. This is where I believe you can receive the error.

If you have a 5152, you can check the "vertical offset" parameter in the "Device setup" window - looks like this is the setting that attempts to commit to the 5154 the SFP and the NOR-SCOPE driver is throwing this error. For a 5152, this parameter should appear, but the 5154 this setting should not appear.

Could you try to re - appoint the device in your system for something unique?

Let me know if it helps. If not, it could be another question - let me know what version of the driver NOR-SCOPE you have installed if this is the case.

-Andrew

-

Sub - VI does not open (error 3 could open the front panel)

I work for the VI (the version of Labview 2011 trail), I created a Subvi. At the same time, I opened this Subvi to adjust terminals connection - what I've done before - and after saving the file and its closure, the Subvi is remained unadjusted. In fact, I am not able to open the Subvi more. And when I want to open the file in a VI (e.g. running VI in windows), I get "' load the error code 3: could not open the front panel." "

I can't also preform any task for example the recording of the main program for an older version, because this Subvi is present in the program.

Nevertheless, the VI still works as a Subvi in the mainprogram I wrote - in how it worked until I adjusted the connection terminals.

Is it possible to solve my problem without having to rewrite the entire Subvi? The Subvi about is attached in this post.

I thank in advance

PS. After the closure of Labview, it sends an internal report of the caveat.

Hi all

I added this issue to an existing bug report (what we call a request for Corrective Action); There was one reported with Labview 2010. I added this matter to him. The reference of this application is CAR #251753. With this reference, you can always ask the status of this bug report.

Best regards

-

display the error when editing on front panel

Hello

When I add another tab (notching amplifier) in the front panel, the program displays connection error. What should I do to get rid of these errors? I am attaching the file along the slot vi.

Kind regards.

This happens because the data type of the tab control changes (you add another page). A tab control is essentially an enum and enum values are part of the data type. A reference to the tab control control is to be packaged and passed in several subVIs. Cluster of frontage on these subVIs control has the element 'Hand Control' value "Include the Data Type". Thus, what they expect to see (for example, a tab with 3 pages) is not what they get. That is why the thread cut. You must either:

- Uncheck "Include the Type of data" for the item "control of the hand. I don't know what other impact this will have, as I look at all the code.

- Update all the controls on the front panel with a new reference to the command.

Aside: who wrote this program needs a lesson on the typedefs.

-

Error when changing the language of the front panel in Japanese

Hello world...

I'm changing the front panel of the English language to Japanese. To do this, first I exported the strings through the Tools->Advanced-> export channels. After that I changed one of the label in Japanese and saved with Unicode encoding (as with normal ASCII coding Japanese texts will not be read). I imported the same file I recorded in a Unicode encoding format. But it shows that the error given below

"Error analysis during the import of channels

to test Main.vi

of D:\Riyas\Work\X 520\28-11-15\X520 RT-Host 20151127\Strings\Test Main_Import 1. txt

"Saturday, November 28, 2015 11:09:14.(See the attached screenshot of error)

So I tried to import the same file ASCII coding mmee, then it is successful. But the problem is that the modified label is not in Japanese that it shows a few points mark. I'm able to import the channel file saved in ASCII format code but the channel with coding ASCII file will not read Japanese texts. So please help me to solve this problem.

I need to import a channel file saved with a Unicode encoding or in any case format to enable Japanese texts as ASCII coded format.

I modified the configuration settings to activate the Unicode format as follows "UseUnicode = TRUE'." I'm using Labview 2014.

Thank you...

racahmd wrote:

My requirement is to change the language of the labels on the front. Is it possible to export the settings of the legend and label parameters separately? Currently, I am only able to export the two together. Also when I import the unicode file that does not contain unicode characters, it shows the same error.

Perhaps the requirement is statesd as such because the people who wrote the requirement had no idea, you can keep the labels even but change the subtitles only. Changing labels is a massive effort that could have profound ramifications to the code itself. Not the same with a legend.

-

pause button on the front panel

Hello.

I try to run synchronous, continuous analog conversion of 2 cards of PXI-6259, and capture the State of the several digital at the same time. I managed to get everything is configured and working properly, however I have a problem if the user presses the button "pause" on the front panel.

From what I can tell, acquisitions of data will continue to run in the background (I'm using a task DAQmx and stop was never called). For my analog inputs, this is not a problem. However, the digital inputs always generate a ' 200010 - on-board memory overflow error. Due to the limitations of system and/or the bandwidth of the bus, the driver could not read data the device enough fast to follow the flow of the unit. »

Is it possible to register for an event of user interface that is generated when the user presses the button "pause", so that I can stop the acquisitoin of data before the error occurs?

Thanks in advance,

-Rich

NormPgh wrote:

I thought to add my own button "pause" / control, but my users have become accustomed to hitting the pause on the front panel button, and it will be difficult to get them to change. I guess that the error would remind them :-)

Well, that's easy to fix - change the appearance of window properties if the toolbar is not visible, while the code runs, and there will be a pause button for your users to click.

Many of our applications have a function somewhat like this. My colleague implementation in a very simple way: he put the graphical indicator within a box structure. Connect a Boolean control "pause" to the structure of the case, and that's it. Data acquisition runs constantly but will only update the chart when the pause button is false. This approach might work for you?

-

OR DC Soft Front Panel, minorbug, small bug with the PXI-4110

Hello

The NI DC Soft Front Panel V14.0, with the PXI-4110, scrolling to negative tension, works as expected to-10V, but then returns to 0. If we change from - 1V procedure, it goes...-8-9,-10, -1, -2... instead of-8-9,-10, -11, -12...

Everything about her, a simple thing that I miss is a switch for all three voltages.

(Also, IMO, it would be logical for negative tensions with the arrow pointing down, not more).

My 2 c

Hello Janaf,

I completely agree with two of your statements, I tabled a report of corrective measures that you can monitor in the next versions of DCPower to see if this is fixed with the FPS. CAR number: 512257

I've added notes that only manual insertion of numbers - less than 10 works and that it was not logical to use arrow increment or upward arrow to reduce the output voltage.

-

HP Z620: Front panel connector pinout

Kindly help me on what is the pinout of front panel to motherboard HP Z60 connectors? Nothing is indicated on the map.

Here is the motherboard front pinouts. This is a view of the motherboard. PIN 6 is the key, a missing brooch, which helps determine the orientation of the connector.

The Z420, Z620, Z820 and all have the same front panel connector pinout.

-Terminals 2 and 4 are for the power light. HP systems have back to back LED connected between these pins. A white LED lights up in red and a normal functioning (and flashes error codes) when there are errors.

-Connect a switch momentary between pins 7 and 8 will turn on the computer and off.

-The sensor pins are for a thermal sensor in cable from the front panel. If it's sensor is not installed, the system fans will probably ramp at full speed and very noisy.

-Speaker Out is the internal speaker.

-

Update of Acquisition of tension over on front panel

I have this simple motor driver program that communicates with a stepper motor controller. I now have to combine this vi with person who acquires a finite number of data points of tension. I found an example of tension over who works with my daq (usb-6009). I was thinking about another stacked in a loop sequence for works to save the voltages, motor training, save several tensions, etc. a desired amount of time.

I wish I could see the tension on the front panel, because I'm their record. Is there a simple way to do this when requiring a finite number of tensions? I use finish because I need only say 10 seconds of data in each engine position and fixing the number of samples whose rate is a simple way to adjust the ignition.

The examples I've seen update tension using a while loop. If I do this then the while loop keeps going until the user stops it.

Thank you very much. 2 vi, I work with is attached.

BTW, I'm a graduate of mechanical engineering student.

Hello

See this link on the waveform data type.

http://digital.NI.com/public.nsf/allkb/B965F316364DE17B862572DF00363B10

Writing custom file Express VI will be likely to work as a note for a long time the sample and, therefore, the loop rate is not too high. It's because the writing on a file of measures, although practical, contains a bit of overhead. If you want to display multiple channels, you can merge the signals and display them on a single diagram, or use several. It will be you.

The best indicator to use will depend on what data you want to display. The waveform table is going to be the most complete, but as you have found the samples back in the form of an array of double type, you can indicators table, or remove points on the table and use digital indicators as well.

-

The front panel indicator background color manually

Hi I'm trying to color of the lights on the front panel depending on whether a test was successful or not. I created a Subvi to do the job, but I can't choose the right to the property to be set depending on what type of indicator is in color (ie. digital or string) then I used a case statement and try to detect what type of reference is passed in so I can set the right to property. I used a number of existing posts about it to this day.

I seem to be unable to determine the type of reference correctly, I get errors about not being able to cast to the specified type, trying a color string indicator.

I tried to add a screencapture but the system hung while I attached the VI, any ideas would be appreciated.

Thank you

When you compare references, the result tells you whether or not they refer to the same object, it does not tell you if they are of the same type.

See VI changed to a technique to use.

-

Delay in resizing of front panel

Hello

I develop GUI which needs to look nice and the user will have the option to resize. Since the ladder under the window property fails, I wanted to use the resize Panel event.

But there is delay - controll is resized some time after I resize the front panel and that seems bad. When I look at the list of window or error of project it will resize instantly.

Why I can't get this result in Labview?

I could always sign size leash read say every 10ms and calculate the size of ontrolls on this basis, but is there best option by using this resize event Panel?

It should be more or less obvious that this parameter means when used. If you set a control to fit the pane and then resize this component, it does not wait for the mouse to start resizing it it will resize for each pixel the mouse movement.

-

Update the controls on the front panel producer consumer

Hello

I wanted to ask you a few tips.

Usually, when I implemented a consumer producer I use producer to create items from queue whose state of the enum and pack all the necessary data in the process of the event in a Variant.

Then the consumer does all the work.

There are two areas where I feel that I could not be using the best approaches...

(1) when I need to update a control on front panel I Pack a reference to this control on front panel in the variant in order to access the property nodes in the consumer and to update.

I have attached photos with an example. It's simplified code where the user must perform a task of data acquisition in the analysis of certain parameters. The code increases the setting of a fixed amount to each race to help the user in its sweep.

Is there a best way to do this?

(2) when events require the same control to be plugged into the variant for the handling of the loop of consumer I create local variables or references to this control to other events. Would it be better to have a registry change that crosses the loop producer which gets updated values of façade at each time the loop iteration?

Thank you.

Because you use a loop of events such as the producer, I would use user events to update your controls. This way you are not circulate references just to set/update a control. You can make a user event and handle this event with the structure of your event. Your client sends just the event with all the necessary data. I found this configuration really useful since it retains all the GUI code centralized in a single loop.

-

Best way to reset all controls on the front panel except one?

Hello world

I have an interesting problem, whereby I need to run successive tests using a test station which has several indicators on the front panel. At the end of each test, I need to reset all to default values, with the exception of a control (Test ID) who needs to keep his information - its value is used in an initialization status for test to ask for information from a database, so it can not be reset with the rest controls.

I post all orders at a time using a reference ThisVI and VI Default Vals.Reinit All method, but this will obviously reset my control values (Test ID) as well. Any suggestions on how to keep properly or may store this information control while resetting all others. I can reset individually others but there is a little and more can be added as this system is developed.

I don't really know what is the right way to proceed, and Labview has maybe one trick in his bag that I know to work around this problem.

Thanks in advance for your suggestions,

Alex

Flank the node invoke with two nodes in the value property of the control to maintain the value. To the left we read as well as a right and the wires together. Connect three nodes with a thread of error to establish the order of execution.

First reading place value on the wire, which is then written after the values have been reset to the default value.

-

cRIO, Webservice (REST) and front panel

Hello

I created a few simple webservice screws for greater application that runs on a cRIO. The webservice screws can be used to send simple commands to the application and give your feedback. So far, I used a LV frontpanel for interaction with the system, but for several reasons, I am looking for another way to do it.

It worked well in the development environment. After deployment webservice screw they have communicated with the application according to the needs and I am able to control the system using simple URL typed in the browser's address bar. Later, I will add static content, but for debugging, it is fine.

The thing is that now I have compiled and deployed the application, and now when I try to open the front panel I get this error message:

"VI requested is broken and cannot be read or controlled."Previously I did not use the Web OR Application Server, so I installed to use the web services. Are there conflicts between a Web application server and remote server Panel? Any suggestions on how to proceed?

I use LV 2012 and NI RIO 12.0

Best regards

Simo

Hi Simo,

If I understand correctly, you have the following configuration:

cRIO with a Web Service of LabVIEW and several Web Service screw

Some ways to debug deployed screws of LabVIEW Web Service are:

You can have the Service of the Web of LabVIEW deployed in debug and debug remote Web Service of LabVIEW desktop.

You can use a tool like factor to make it easier to apply and test your Web Service screw (similar to go to the url in the browser).

You can create LabVIEW screws of office using the Palette of HTTP Client to test the Web Service.

You mentioned the following"I have compiled and deployed the application, and now when I try to open the front panel... "

I'm a bit confused as this front panel you open. For example, do you mean that a LabVIEW project has been opened on the desktop, the Web Service of LabVIEW in the project has been deployed to the target of RT cRIO, and now, when you open the Web Service screw on the desk to look at the front panel, you get an error message?

Maybe you are looking for

-

I saw this question on other laptops, but not this one. I have a g4-1215dx and I was wondering if I could install a backlit keyboard. Size and which in fact adapt is not my concern, but is rather everything that he in my laptop to connect a backlit k

-

Z510 - performance graphics card

I have Lenovo Z510 and supported with NVIDIA GEFORCE 740 m and intel HD 4600 (2 GB total), 6 GB of RAM and 1 TB of HARD drive. When I play a HD game on battery performance of the demotion of the card and the game move slowly so that when I run it on

-

Create a data streaming from C++ stream and read it in LabView

Hi all. I'm working on a project that is to connect to a tracker of movement and reading data of position and orientation of this in real time. The code to get the data is in c ++, so I decided that the best way to do it would be to create a c++ DLL

-

How can I get my camera PTZ (Cisco WVC210) to send files to detect movement directly on the installed on the router (same LAN) USB flash drive? I am getting bombarded with email alerts. The router is an ASUS RT - N16 with on-board USB capabilities.

-

AVG scan returns broken digital signature

Original title: scanned any computer with AVG 2011 first time and had 13 results. Here is one of them. What it means? ;" C:\Windows \Installer \14475d.msi «;» The file is signed with a digital signature that is broken, published by: AVG Technologies.