Graph of pressure NI 9237 sensor error

I use my NI 9237 module with four pressure sensors that works very well as long as all the readings from all sensors in pressure four are on the same graph. However, what I need them because I would need each of pressure sensors to be on their own individual chart but when I try this I get an error that the device is already in use.

So for the moment I can't get a graph either showing the four pressure sensors or just a chart showing a pressure sensor, but I need four graphs showing their own pressure sensor. Any suggestions?

Thanks for any help

As you use the screw Express and dynamic data type, use the 'Split signal' function of the range of Manipulation of the Signal, the slide down so that it got 4 outputs and son each in a graph.

Tags: NI Software

Similar Questions

-

Tecra A9 - software for the fingerprint sensor error

My laptop is less than 3 weeks old and the fingerprint sensor has stopped working.

I just get an error message: can not find the fingerprint sensor device, 0xe7210005 error code.

can anyone help?Hello

you don't have many options. But I can try to give you some tips:

1. go into the Device Manager and search for the device of fingerprints, so if it s present, uninstall it and after a reboot it should reinstall itself.

2. go on Toshiba drivers download site and download the latest drivers for this device. Install the driver and check if it work s

3. If really nothing done then you should recover your machine with the media shipped (or HARD drive recovery)

4. the last resort, if all fails, is to contact the nearest [ASP | http://eu.computers.toshiba-europe.com/cgi-bin/ToshibaCSG/download_whitepaper.jsp?service=EU&WHITEPAPER_ID=0 000000871] in your country and ask them a hardware health check and repair.

Good luck

Greetings

-

ESX04i on HP DL385 G2 sensor error: System Board 2 ProcHot - limit exceeded

Hello everyone,

I installed a server esxi to a hp dl385g2 (8.50 firmware). After the first start, a sensor after the following error message:

System Board 2 ProcHot - limit exceeded? ?:|

can someone tell me what kind of error this is?

THX

Mike

Just download a previous HP firmware CD

-

I'm trying to set up a test bed to measure the linear moving of a hydraulic cylinder and it trace over time to a graph in labview. I was getting erroneous readings on the grapn (a point of tension for every ten samples). I have disconnected the wiring of the Terminal Board of my data acquisition card and the chart fills with 'noise '. If I remove the plate Terminal and move the wire that goes to the data acquisition card, the graph becomes fixed.

Any suggestions as to what can be causing this? All of the components are new, but would it be a bad block, the driver or data acquisition card?

Thank you

-

Relating to the creation of a graph, get an error with a statement "Union All".

Hello

I have some data in the table with the following fields;

Product, Jul-08 Aug-08, Sep - 08 etc. to Jan - 10.

The PRODUCT field is text showing many product names

The month of Jul-08 & others have numbers by product that must be aggregated for this month & plotted on the graph of the line.

My SQL to create the first point on the chart is as below;

Select the link null, label, SUM(JUL-08) "FFF".

of "SCHEMANAME." "' TABLENAME '.

WHERE PRODUCT = "FFF".

PRODUCT GROUP

ORDER BY PRODUCT

It works fine until I want to add the second point of this graphic line by using a "union all" join as follows:

Select the link null, label, SUM (JUL_08) "FFF".

of "SCHEMANAME." "' TABLENAME '.

WHERE PRODUCT = "FFF".

UNION ALL

Select the link null, label, SUM (AUG_08) "FFF".

of "SCHEMANAME." "' TABLENAME '.

WHERE PRODUCT = "FFF".

I can't work on how I can join the other months on the line graph of a series.

The error is as follows;

--------------------------------------

1 error has occurred

Failed to parse the SQL query:

Click link null, label, SUM (OCT_09) 'Non-communicable diseases - STD' of 'BI_A_DATA '. "" CDW_VS_NCDS_CALLS "WHERE PRODUCT ="MNT - STD' UNION ALL select link null, PRODUCT, SUM (NOV_09) "Non-communicable diseases - LOCAL" label of "BI_A_DATA". "" CDW_VS_NCDS_CALLS "WHERE PRODUCT ="MNT - LOCAL.

ORA-00937: not a single group group function

Some queries can be run when you run your application, if your query is syntactically correct, you can save your query without validation (see options below the source of the query).

----------------------------------------

If anyone can help?

I want a continuous linear graph showing monthly July 2008, Aug-08 Sep - 08 etc. to Jan - 10 for the same product.

I will then add other series for other products, thanksOK a graphic line will only allow you to draw 1 variable (in this case period). Given that it is only for a single product, so here should be the final sql:

SELECT null link, PERIOD label, SUM(ABC) FROM (SELECT 'JUL_08' PERIOD,SUM(JUL_08)ABC FROM BI_A_DATA.APEX_TEST WHERE PRODUCT = 'ABC' UNION ALL SELECT 'AUG_08' PERIOD,SUM(AUG_08)ABC FROM BI_A_DATA.APEX_TEST WHERE PRODUCT = 'ABC' UNION ALL SELECT 'SEP_08' PERIOD,SUM(SEP_08)ABC FROM BI_A_DATA.APEX_TEST WHERE PRODUCT = 'ABC') GROUP BY PERIOD -

4SNS/1/40000000 error code: VDOR - 18.678 & 18.679

MBP early 2011: I just ran the AHT twice, the first round gave me an error code of 4SNS/1/40000000: VDOR - 18.678, second inning gave the code 4SNS/1/40000000: VDOR - 18.679. Does anyone know what are these error codes? My best guess is probably the RAM, I have (2) modules of 8 GB 1600 Mhz DDR3 OR wireless networking equipment installed. I've noticed recently while multitasking, the wifi connection seems to cling and web pages will not load/downloads will pick up. But the way in which applications will be blocked for 60 seconds makes me think of a bad situation of RAM I have had in the past. Any help would be greatly appreciated since the nearest bar genius lies in 2 1/2 hour. Thank you!

No RAM - 4SNS is a sensor error.

-

Satellite Pro 6100 freezes and get error CMOS - need new motherboard

The machine hangs and restarts, you get a CMOS sensor

error.I need to find a new motherboard. If anyone can help?

Hello

Usually, if the CMOS error pops up that you need to replace the RTC battery.

This could help solve question and you worry t new motherboard which is much more expensive than a RTC battery. -

Test equipment 4SNS/1/40000000 error code: TA0P - 38.875

Someone who knows: Hardware Test 4SNS/1/40000000 error Code: TA0P - 38.875?

This means you need to take in service, Apple does not publish its error codes, but a quick search on Google seems to indicate that it is a sensor error.

-

Apple Hardware test error code: 4SNS/1/40000000: TB3T - 128,000

I ran, the Apple hardware test and received the error code 4SNS/1/40000000: TB3T - 128,000. I can't find anywhere what means this error code. What should I do to repair or correct?

Thank you for your time and consideration on this issue!

Warm greetings,

Paul

Paul, you should make an appointment and take your Macbook service, either to the nearest Apple store or FSAA. The error code appears to indicate a battery temperature sensor error.

-

Chart WPF with visual host RenderMode.Hardware error

graph rendermode = RenderMode.Hardware

debug error:

System.Windows.Threading.Dispatcher.Run ();

The calling thread could not access this object because another thread has the object.

I was able to reproduce the problem and track it to internal access not sent to the main window of the application and have created a task to solve this problem.

We do realize that this access once, so as a workaround, you can force this initilaization arrive early (before starting the graphic on the background thread) by adding the call to the constructor of the main window:

public MainWindow( ) {

new NationalInstruments.Controls.Primitives.Tables.RenderTargetBitmapWrapper( 1.0, 1.0 );InitializeComponent( );

} -

BindingExpression path error: 'Orientation' not found 'object' property "ColorScale'

Hi all

A data binding error is thrown by the Debug Output window just after setting the DataSource property to certain data :

System.Windows.Data error: 40: BindingExpression path error: 'Orientation' not found 'object' property "ColorScale '(HashCode = 50862316)'. BindingExpression

ath = direction; DataItem = "ColorScale' (HashCode = 50862316); Target element is 'DependencyPropertyListener' (HashCode = 6239444); target property is 'Target' (type 'Object')

ath = direction; DataItem = "ColorScale' (HashCode = 50862316); Target element is 'DependencyPropertyListener' (HashCode = 6239444); target property is 'Target' (type 'Object')I did the following:

Graph graphic = new Graph();

Graph Plots.Add (new Plot());

Graph plots [0]. Renderer = new IntensityPlotRenderer();

(Graph (IntensityPlotRenderer). Parcels [0]. Rendering engine). ColorScale = new ColorScale();

Graph DataSource = new list(); The error message is raised right after the execution of the assignment of a new list of the data source. The error seems harmless but it would be nice to understand what is causing this problem.

Thank you.

Hi, gabe0

It seems that this error occurs because the chart control is to look at his collection of scales to determine if scale orientation changes took place, but the ColorScale does not have a direction property. While you can't do anything to your program to work around this error, you can safely ignore it. I filed a bug for this behavior report.

Thanks for the comments!

-

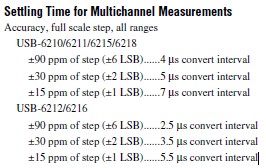

Error due to the small size of settling in OR-6211

Hello, I have the following question on NI6211.

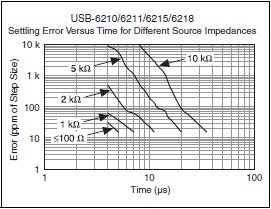

I use multi-channel system and signals to different channels differ greatly. For example, 10 mV to ch 1 and a few volts to 2 ml. The sampling rate is big (100 ksps / s), so there is no crosstalk between channels due to little break-in. Sources have large output impedance - 10 kOhm. The question is how can I calculate the amplitude or crosstalk (in dB) for the conditions of this measure. Accuracy to convert different intervals contained in the specification in paragraph "settling for multi-channel temporal." But I do not understand these data - why 90 ppm of step size is + - 6 of the LSB. I have thoght that step size is equal to LSB. And what source impedance are account bound to this data? And performance graph time receive values much more error (10 000 ppm).

Thank you for your attention.

Specification for NOR-6211: http://www.ni.com/pdf/manuals/371932f.pdf

If you view the chart from the top on the right side of this page, we show the chart for several source impdences.

In the paragraph you are referring to:

You will notice at the top we no it's for a "full scale step. Means the passage of the input range maximum to minimum range between channels (for example on the range of ±10V, reading 10V on ch. 0-10V on ch. 1). That's what 'step' made reference to, not LSB on the ADC but rather the extent of the difference between the readings.

The chart you will need is the graph on the right marked "settling error Versus time for Source of different impedances.

If you are sampling 100kS/s total on two channels, you have a time to convert 10uS. Source 10kOhms impedance, this means that you'll see an error about 4000ppm of the size of your stage. If you go from 10mV to 2V, this amounts to an error in subject 8mV on readings.

As your first signal is so small, you would probably better served by adding a Buffer of Gain unity between your source and your channels to reduce source impedance, which will give you much better set on-time performance.

-

6008 NI DAQ issues of reading pressure transducer

Hello everyone, I am a new user of labeled and not one expert on electronics, so please bear with me.

I'm trying to read a signal 4-20 my by a pressure transducer using a NI DAQ 6008 and Labview version 8.6. I am running Windows XP Professional. I'm the transducer, (http://www.omega.com/Pressure/pdf/PX01-I.pdf) providing a voltage of 10 v I have a 235 external resistance ohms between the terminals positive and negative data acquisition (although I am not sure that it is correct). At the start of my VI, I am able to measure a voltage of environ.9 data acquisition (verified by a voltmeter/ammeter) V and a current of environ.39 my.

My problem is the fact that when I have a supply pressure of my sensor, I have not received any signal whatsoever by the transducer, despite the fact that it is important that the pressure should give me a signal. Is this a problem with my installation, connections, data acquisition (which has been reset in MAX number of times and pass the self-test) or the sensor itself?

Thank you for your time and consideration

Hi prenerk,

You are right that resistance must be connected to the terminals positive and negative a way to HAVE to create a measured voltage to current. Here are two troubleshooting steps you can try:

1. check with an ammeter so you are detecting a change in the current when you apply pressure to the transducer.

2. open the Explorer Measurement & Automation and use a Test Panel to measure the voltage of the device. This will ensure that there is a mistake in your LabVIEW code. Also check the MAX pinout diagram to see if your sons are correctly plugged into the channel of GOT it.

If you have not discovered a problem with the above steps, we will have to learn more about your sensor pressure and how you connect it to the 6008. We will need the information on the sons of the Omega instrument and how they are connected to the excitation voltage source and 6008. Let us know how it goes!

Brian

-

Graph XY no lines, just Points?

Hi all

I want to build a graph of pressure relative to the temperature. It must be a standard XY graph, but I just want to see the scatter point without lines connecting the points. Is it possible to eliminate the lines between points (or make them invisible)?

Thank you!

You can do this in the properties of the graph. Right-click on the chart and select Properties. Go to the locations tab. Select an icon for the point (something other than

) in the third column of icons. Then select the top of the list in the fourth column. It is the symbol with the track of the points, but no lines. This will give you what you want. -

S371 signature Update error code

I am trying to update my sensor to S371 and receive the following errors. I upgrade to a Director of virtual machines on a unit 4240. I was able to update S370 successfully. Any help is appreciated.

I enclose the test in a file in the case of word wrap calendering.

ERROR MESSAGE FROM THE DIRECTOR OF VIRTUAL MACHINES:

My-sensor: Signature Update process

Exception in the place of the sensor: the sensor is rebooted with 8,0000 E3S370 version

instead of the version expected 5.1 (8) E3S371, but no errors were reported during the

Update.

Errors encountered during the update of sensor, this sensor update are abandoned.

Errors encountered during the update of sensor, this sensor update are abandoned.

===================================================================================

THE SENSOR ERROR MESSAGE CONSOLE:

The message of [email protected] / * /-sensor

(somewhere) at 18:26.

Update IPS-GIS-S371-req-E3

The message of [email protected] / * /-sensor

(somewhere) at 18:26.

Error when sending the sensorApp control operation. The restoration of old signatures.

The message of [email protected] / * /-sensor

(somewhere) at 18:26.

Full update

The message of [email protected] / * /-sensor

(somewhere) at 18:26.

UN-installing IPS-GIS-S371-req-E3.

The message of [email protected] / * /-sensor

(somewhere) at 18:27.

Uninstall complete.

Yes, it's a bad package, not just a problem on your side.

Withdrawing now.

I am unsure of your Setup, but the package of sensor s371 from here:

http://www.Cisco.com/cgi-bin/tablebuild.pl/ips6-sigup

can be used to update your sensor (s). This however leaves you with a version of the sensor out of sync to the version number for the CSM sensor.

Maybe you are looking for

-

I have an older iMac that has a Firewire 800 port and no USB 3.0. I would like to use the Firewire 800 port and convert it into a USB 3.0 with some sort of connection. This way I can take advantage of the most recent items USB 3.0... Is this possible

-

Can I see a conversation by CAT on iPhone from last week?

I did a cat in my iphone last week, I know this conversation again? I need badly. Thank you

-

How can I correct the mistakes of PMSpeed.exe

As my computer starts up, I get an error that says "PMSpeed failed to load. It is also said that something about INSO Library failed to load. Is PMSpeed a type of file that is needed by XP to run right? If not, can I find the file and delete? I ran t

-

"office impossible to load or run C:\Users\Ray\AppData\Local\Temp\ccrss.exe' specified in the registry." Make sure that the file exists on your computer or remove the reference to the registry. » Never had this message before. Sought a "registry". no

-

Warranty end date Dell monitor

Hello I work for a company who directs Dell products in bulk (several hundreds). Asked me to know the dates of end of warranty for all monitors. I have no way to make at the present time, because the monitors have no service tags, serial numbers only