loop control and simulation: sync settings

Hello

Is it possible to access times higher at 1 kHz source in synchronization settings, control and Simulation in a loop, without use of real-time targets? For example, using time cpu.

I use myDAQ OR data acquisition, and I need a 100 kHz synchronization source about.

Thank you very much.

Kind regards

Keshav

N ° when running on a PC of the class, you are working with a set of standard material (with its clock 1 kHz) and a non-deterministic BONE, and there is nothing you can do about it. That is why acquisition cards NOR are all smart devices with their own processors, memory, and clocks.

Mike...

Tags: NI Software

Similar Questions

-

How can I extract a part of a signal inside a loop control and simulation?

I would like to extract the part of my signal between 0 and 3 seconds. I tried to use the extract of Portion of Signal VI Express, but it does not work. I'm setting the length to the offset 0 and 3 seconds. However, nothing is displayed in the output. I used this before VI successfully, but it wasn't in a loop control and simulation. Is there something special I need to do to make this work properly in this case?

This forum shows how to measure the time between the Digital pulse http://forums.ni.com/t5/LabVIEW/Measuring-time-between-digital-pulses/td-p/1056881

In addition, it would be a good link https://decibel.ni.com/content/docs/DOC-12160

-

Synchronize loops control and Simulation

When simulate control with adjustment of the LV systems and Simulation loops, I often have several loops running at different speeds. For example, I have a loop PWM works at 20 kHz, a loop running at 100 kHz data acquisition and a control loop to running at 10 kHz. How can I synchronize all these loops so that they stay on the same time basis? Of course, the main time base must be at least as fast as the fastest simulation loop.

I tried to synchronize all the loops at 1 kHz clock (I'm on Windows), but each loop runs a period by beat of clock (for example my 20 kHz loop count progressive 50us by beat of clock, my number of loop 100 kHz up to 10 by beating of clock, etc.). I need all the loops to be synchronized in a main time base so the simulation time is identical in each loop, but each loop will be executed at a different pace.

Any thoughts?

Hello

A quick suggestion - why you cannot run three systems in a single simulation loop, but have different sampling frequencies for the blocks for each system?

Your system is fully digital, or a mixture of continuous and digital - we can simplify things if you can convert in discrete time.

Hope this helps,

Andy Clegg

-

Function of memory in the loop control and Simulation - problem of the ODE Solver

Hello

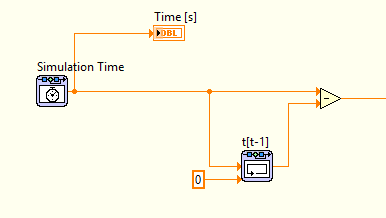

I'm correctly using the control loop & simulation to simulate the behavior of what is essentially a shock absorber-spring-mass system. In the process of change in time (dt) is used to integrate an arbitrary value. I use a rack depending on memory to store the time, to calculate the change of time (dt).

The simulation is quite complex, because of the precision required, not all the ODE solvers can all support. Currently I use the Adams-Moulton method, this works very well for the simulation. However, it cannot detect the change in time, the change is constantly zero. This problem has auto market by using an another ODE Solver, but then the simulation has been messed up instead (even when I listen to the step sizes and tolerances). So I'm pretty confident that Adams-Moulton is one of solver ODE best suited to the problem at hand.

Is there another way to store the previous hour and use it calculate lag, that the use of the memory function? Everyone knows about these problems before?

I did a lot of research of error using the probe, but I'm sure that there is a problem with the ODE Solver and memory function. See the image below, showing basic how is calculated the change in time.

I'm pretty new to LabVIEW, so if there is something else I missed I would be happy to hear it.

PS! I set the tolerance minimum step of size/relative and absolute for the Adams-Moulton to simulate the behavior of the system properly.

Problem solved!

It turns out that the ODE Solver has struggled because of two "table 2D find" used functions. This was created for the interpolation/extrapolation, which caused a problem constantly and the ODE Solver could not resolve correctly, so the functions of memory doesn't work does not correctly or the other.

By increasing the table manually, I could use closest method instead, with also good results as interpolation.

-

problem of loop control and simulation

Hi all

IM undergoing a project where I created a simplified model of a Powertrain engine. In the next paragraph, I'll go through briefly how I go about it, but I'm not sure if this will help solve you the problem that I have. To be honest, that it will probably be that I understand you're all busy people.

The basic principles behind it are that RPM is an initial feed an equation which describes the torque curve. An initial couple comes from it and then using the appropriate ratio, it is multiplified, the friction losses are very roughly taken into account (currently looking for a better way to implement the friction losses, but that is besides the point...). Drag is developed using the engine rpm, converted to car speed rpm and threrefore wheel. Wheel torque is multiplied by the radius of the wheel, to find the force to the front, the drag force is then subtracted from the force before finding the net force feel of the car. This is then divided by the mass of the car to find the acceleration. The acceleration is then integrated with a systems integrator linear continues to find the speed and it is then added to the original engine rotation speed (after the relevant conversions).

So my problem is that my program hits, the engine of 8500 rpm redline in what I can only assume is milliseconds. I fiddled about with the entry node settings, but I can't seem to make it work. Even though I know that the model is pretty gross I do think that his inaccurate THAT. I have attached the VI, please excuse the bad practices, I've used, it's the first time I used this programming language. Any help will be much appreciated.

Victor

NB: the default settings of the vehicle are based on a porsche 911.

I solved the problem by synchronizing my loop with a source of synchronization. I also did the period '1'.

-

Control and Simulation in a loop / while loop with TCP/IP reading / writing of synchronization

Hello, I have a problem with reading TCP/IP and written in two loops. The problem is NOT to get the two loops to read and write to and from the other. This has been accomplished. My problem is when I run control and the loop simulation on my laptop and the while on a RTOS remote on the controller on-Board of LabVIEW in a remote PXI chassis, the while loop the remote system running on four 4 times faster than the loop control and simulation on my laptop. In other words, for each iteration of the loop control and simulation on my laptop, there are 4 four iterations of the while loop on the remote system. I need to know how to get a degree of kinship (1:1) with these iterations of the loop. When I run a longer simulation in real time, say 10 seconds, the control and Simulation loop begins to slow, i.e. the simulation time slows down until it is no longer in real time and the "Late Finish"? Parameter is set to true and the LED lights and continues to stay lit. At this point, the system destabilizes due to what I believe is being well sampling rate too discreet and I have to end the simulation. How can I get a ratio of one to one between the loops and also to avoid slowing the loops causing destabilization?

To give an overview of my application, I implement a control system in a network, seen in "image2.png". This is achieved using my laptop as a subsystem 1. Reference signals are generated from the laptop and the error signal is produced. Control measures taken and the control signals are sent via TCP/IP to the remote system. Position feedback is returned, and the process repeats. My system has Core I7 Procs w / 3 GB of RAM, up to 1 GB/s speed via ethernet and LabVIEW 2011 installed with all necessary modules and networking tools. The attached VI Custom_Wireless_Controller works on my laptop. The remote system I'm working on that has the 7830 NI R Series with FPGA card. OTN runs on the PXI chassis with an enbedded controller that has networking capabilities of up to 100 MB/s via ethernet. I use the FPGA for the acquisition of data and apply control signals to my plant. The plant is the PCE twist connected to the FPGA through the cable of the ECP - RIO of NOR. Subsystem 2 is this side of the CNE. The FPGA collects position, he sends to the controller via the network, receives signals from the network drive and writes signals to the plant power amplifier that operates the plant. This process is repeated and the VI and is titled Custom_Wireless_Plant.

I appreciate the help really and look forward for her and for any question!

Well, the first step is to understand what you have set up right now. Your control and Simulation loop on the side of the controller is configured as 'Runga Kutta 4' and you have a loop timed on the other side. In addition, you have the primitives of TCP/IP on the control and the Simulation diagram and means he will perform (a message) on the size of each minor step, which in your case is 4.

So, you have two options:

1. replace the Solver side controller Runga Kutta 1 (this must synchronize loops)

2. hold RK 4, but create a Subvi around two primitives of TCP/IP and configure from the VI to run than the major (continuous) step-size. If you do it right, you should see a 'C' on the upper right part of the VI you have created.

Please let me know if what I said is not clear...

-

control and simulation Module spring mass

I'm using Labview 2010, and tasked the simulation module (just 15 days before the date of expiry. trying to see if the program will work before I spend $4 K) and try to calculate the dynamic response of a spring index.

I was able to complete the program in the simulation section (I think). I now need to feed a sign of acceleration in the module which I have already captured at a sampling rate of 100 k/s.

Test technician said I should add 500 ms from zero to the front of the track to make sure that the system is stable before the trace of acceteration of power is in the simulation module. I have alreay done reading and adding zeros to the chain.

I can't feed the trace in the module control and simulation.

The engineer said he was able to do the math in MatLab and simulink (I think), because I have not used this program and we do not have a copy I am doing it in LabView.

In addition, I would add that this forum is blocked by my firewall to work.

If you need more information, I'll have to return to work and get it.

-

Problem control and Simulation

I worked in the module of control and simulation of NI Labview 2013 and created a VI as indicated in the attached file, but I don't understand the output of VI.

I applied a progressive input signal to device to transfer function = 1 /(s+1) and the desired output (exp (-t)) appears in green color (drawn by me in MSPaint) but it displays the output as one shown in red color.

As the inverse of 1 /(s+1) Laplace = exp (-t), the graph must be a value of 0.3678 at t = 1 and 0 to t--> infinite but the (red) output is exactly opposite.

Can someone explain please exit this is why it is like that?

Concerning

When you apply a step response, you must multiply your transfer function of 1/s to account for the progressive input signal before making the transformation from Laplace to get the correct result. In your case, the transformation gives: (1 - e ^ (-t))

There are many explanations of answers online, but here's onestep.

-

External template function (control and Simulation Module) on Linux using target

Hello

I am trying to run the 'EMI_Integrator.vi' for example on one OR cRIO-9024 (nor a myRIO).

I moved the file 'EMI_Integrator.so' to the ' / or-rt/system ' on the cRIO and the .so file added to the target in the LabVIEW project. I can not navigate to the .so file directly so I specified the .so path manually, but the VI is not able to run and an error of-2366 'reissue model '.

"You can find the original version of VI in the Finder for example OR", but I've included my modified version that has a LabVIEW project and targets already loading.

Thank you

Mitch

Hello Mitch,

If you want to use the external model on a 9024 node, you must copy the appropriate VxWorks library (.out) file to the/or-rt/system folder of the target. The .out file is located in LabVIEW\Examples\Control and Simulation\Simulation\External model Interface\EMI_Integrator\RT-Lib\vxworks.

In LabVIEW, have the external model node refer to the file of the library appropriate for your operating system. In my case, I use a .dll for Windows file located in the folder EMI_Integrator, above.

When I run the VI on the cRIO target, referring to the library on my host computer, it will automatically search the folder to/or-rt/system for a file with the same name with .out.

Kind regards

-

With the help of control and simulation module; e to get the time the MISO model Manager

Hello

Please can someone show me how to find the response time of the system below using the module control and simulation?

(y (k) - 1,7407 y (k-1) + 0.6236y (k-2) + 0.1782y (k-3)) =-0.0932 u(k-1) + e (k)

where there is out, u came and e is a white noise.

I tried to enter the CD construct MIMO model, then connect it to CD response time. * s vi.

But what I really need to enter the model coeffs every time? and I still don't see the answer!

Help, please...

Kind regards

ruser

Hello

you have the correct image... I used the Toolbox ID sys (Assistant)... to estimate the system model...

and I tried all week last get the model of my system in labview for use the control on this module.

Alhamdulillah...

I ended up doing... I saved the template to a file from the Toolbox id sys... (my model is in discrete form) then I loaded it in labview using load file pattern...

so now I in labview...

now for control parts...

..

..Thank you again...

ruser.

-

Control and simulation and data acquisition

Hello

I am applying to motor control in Labview. I'm sampling speed from DC engine in real time through an acquisition of data. (my sampling time is 1000 samples per second)

Then wrap speed as input to a Simulation (simulation and design of the order) and inside the loop simulation, I have a PID controller. The PID has the actual speed of the engine for the acquisition of data and the engine reference speed as input.

Reference engine speed comes from the generator of signals (control design and simulation-Simulation) and is a waveform.

My step in the engine size is 1000.

I am running this application real-time and drawing the reference signal and the motor real signals. I run into several problems with regard to the calendar.

1. when I change the size of the step of the simulation loop, the frequency of squares of reference also seems to change. For example. What step size = 1000, duration of pulse = 1 s. What step size = 100, pulse width = 0.1. (My pulse frequency is 1 Hz, Simulation clock - 10 kHz). How step size can affect the pulse width.

2. can you explain the relationship between the DAQ, the Simulation step size loop sampling time, Loop Simulation period.

3. If I want to collect different sets of data using sampling different hours, it's OK to change the sampling DAQ time without changing the size of the step of the simulation.

Would also like to emphasize that the DAQmx calendar under sample clock mode is placed in front of the simulation loop and the output is connected to the loop simulation.

Appreciate any help.

Hello

Maybe some screenshots of your code would help. Furthermore, what you have read your samples together with your DAQ screws?

(1) If you have a waveform, the output is specified as:

For example, if you change the size of the step of the simulation loop, you change the simulation time which are introduced into the signal generator and affecting the waveform that you see if you do not have a size quite small step to characterize the waveform that you generate.

(2) sampling DAQ rate is the speed at which samples are taken on the acquisition of card data itself. The size of the simulation step, help. "Specifies the interval between the time when the ODE Solver evaluates the model and updates the results of the model, in a few seconds." Simulation loop, still using, "Indicates the amount of time that elapses between two subsequent iterations of the loop of control & Simulation.". " "Step size determine the value of t that is introduced to the functions you use in the loop simulation while the loop simulation period controls simply to how fast you change the following t value. The sampling rate of DAQ hardware is a clock of completely separate hardware controlling the analogue-digital on the DAQ card converter so that you can get a deterministic dt between the samples being acquired.

(3) you can change the schedule for the acquisition of data, but you will need to restart each time the changes take effect. If you change the calendar of data acquisition and want your values to correlate with your simulation, you will need to change your size of step as well.

-Zach

-Zach

-

Discreet Integrator (control and Simulation Module) - LabVIEW 2015

Hey everybody,

I'm trying to drag the discreet Integrator on a block in 2015 of LabVIEW diagram. All other vi in the "range of discrete linear systems are draggable, but not the"discreet"Integrator." I noticed the same thing for the continuous Linear Systems Integrator. Anyone explain how to solve this problem?

Sincerely,

Lex

Lexicondi,

Unfortunately, these functions cannot be moved out of the loop control & Simulation. We support only discrete transfer, of State spaces and ZPK models function.

So, if you want the "discreet Integrator" outside of the SIM card, you have the following options:

one) to use the "discreet transfer function" as T /(z-1) (or any other type of discretization available in discreet Design continuous monitoring);

(b) you can develop your functions inside the control and the Simulation loop and then create a subsystem of her. The subsystem can move outside the SIM card also. Here, you can use any SIM function you want;

I hope that this should be sufficient for your application.

-

Global variable control and simulation

Hello!

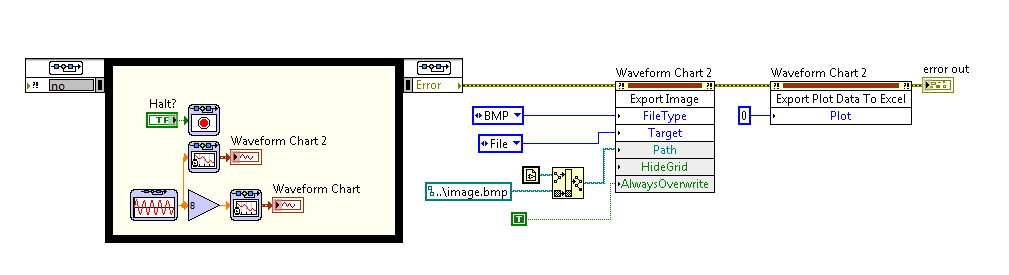

I have a probem with the export data of the Simulation loop in the graphic form.

I have created a global variable, but in the façade is not updated or exported the data necessary, but in the file as a global variable do?

I would like to gather (gathering) all the data after the simulation data file as Excel (trace the export data to Excel or save the spreadsheet file) as well as the image of terminal.

Please find attached my files - someone has an idea or a solution?

There must be some easy trick

Thank you!

Vasco

(1) why are you doing this problem much more complex it must be using a global variable and another loop like that?

(2) why you son of path of the VI in the picture? You try to crush the VI on disc with the image?

(3) be careful not to ignore the output error.

The code shown in the attached screenshot works very well. I'll take Bravo if it helped you.

-

How can I add another entry to a subsystem of control and simulation?

I tried to add manually by dragging the wire in the subsystem, but it does not connect. See attached photo for clarification of the situation.

Inputs and outputs of a subsystem work similarly to a Subvi.

You will need to open the subsystem, add a control to the front and connect this control to the connector pane.

The process for a Subvi is pretty well documented here.

-

design and simulation of control tools

Hi all

Does anyone know if indexing is possible in a loop control and Simulation in Labview? I need to save to a table of all simulation data.

Thank you

Ussr123.

Resolved: the required icon is called: collector.

Maybe you are looking for

-

HP Pavilion dv7: unable to connect to the Internet

I can't access the Internet via ethernet or wireless. It seemed to happen after an update of Windows 10. Other computer and android phone can access the wireless. When I click on the wireless icon, I see different networks, including mine. However, i

-

All the FSMO role transfer failed

After the disaster, I did transfer role to the additional domain controller in windows 2003.two roles successfully transferred1 - PDC role2-infrastructure owner but three roles are still pending and could not contact the fsmo owner,1-schema ownerThe

-

I have added an external hard drive to my XP but cannot access

I have added an external hard drive to my XP but can't access it because I have no letter in my computer. not very conscious of their hope if someone can give a sense computer question and help thanks

-

You sent me an e-mail about the renewal of MSN, but I can't get on the web site. I have the instructions and followed by a "t" and can't always get there

-

Reg: Installation of updates on Windows 7

My computer got off when I was checking updates on windows 10 and restart I did a windows 10 downgrade to windows 7, then my PC shows to reboot the computer, as the updates are being installed. I restarted many times but still the message is wrong. N