Retrigger encoder and acquisition of analog input on the spur of Z?

I have a card PCI-6232 and use THIS angular Encoder on the counter 1 to provide a base mean angle for Internet high speed (50-100 kHz) measures the analog voltage. I use a period of CI on counter 2 to measure the duration of the impulse of Z to determine the length of each measure. It kinda works, but the result is somewhat contradictory. I get about 1 in three cycles without encoder data. I need to find a way to trigger the acquisition to record data for each cycle trigger on the pulse of Z. If you know another way to do this I'd be open to that as well. Thank you, Steve

Hi Sara,.

Thanks for your reply. What I wanted to do was to trigger an analysis of the encoder and an entry at the same time triggering the pulse of z analog encoder. It took a lot of digging through similar samples and after a week of fighting, I thought about it tonight. I'll post this once I clean up the mess. Problem solved thanks to dozens of you ad info and samples!

Tags: NI Hardware

Similar Questions

-

read the multiple analog inputs at the same time

Hi all

I use USB-6001 and want to develop an application to multiple tasks in C++. I try to read several analog inputs at the same time, but got some errors. To put it simply, I copy one of the sample code to read in analog data in a channel, and then turn it into function. Then I call this function to thread with the names of different poles (for example Dev1/ai0, Dev1/ai1) and I come across this error:

"The specified source is reserved. The operation can not be specified such complete"code of State-50103

I have search the forums, this may be because I use the hardware timing in this function, and this material timing cannot be used simultaneously by multiple tasks. I may have to put all the lines, I want to read in a single task (such as Dev1 / ai0:1). This way I can read two lines at the same time. However, when I try this, I encounter another error:

Status code "buffer is too small to contain the data read" - 200299

So here is my question, what should I do if I don't want to read the multiple analog inputs at the same time? Is the thing that hard time cannot be used by several true task? If I have to read several lines to a single task, how to set the settings?

-

What is the analog input of the NI PCI-6229 impedance?

I am trying to determine the effect of a 12 K resistor that is in series with an analog input of an NI PCI-6229 data acquisition card. Resistance of 12K seems to be part of a RC filter. I have a 0-10 VDC source this supply circuit. What is the impedance of the analog input of the NI PCI-6229 data acquisition card? If it makes any difference, the analog input is connected in differential mode with a 180K resistor to Gnd AI.

Thank you

RWB

Hi, RWB,.

The input impedance is classified in the specifications 10 GOhm. So, the effect of your k 12 resistance should be relatively low. Take care!

-

How to write constantly to analog output and read from analog inputs

Hi all -

I had a question about writing continuously to analog output reading simultaneously an analog input.

It's my first time to post a message to the community, so please let me know if I made mistakes.

I use Labview 2011 with a NEITHER-DAQ USB 6215.

I'm looking to generate a waveform and write it continuously in an analog output. It is then connected to an entry on the acquisition of data, where I am trying to sample the analog signal. (I realize, there is a system of trivial, but I'm hoping to build on it once I have run).

The task of reading from the analog input works fine, as I tested it in several other cases. I have a problem writing to the analog output.

For this task, I tried to follow the "Gen Cont Wfm Clck Int' VI to generate the wave form and start the task. I then try to write to the output of the analog timed loop. However, it does not seem to transmit a signal and doesn't give me any errors.

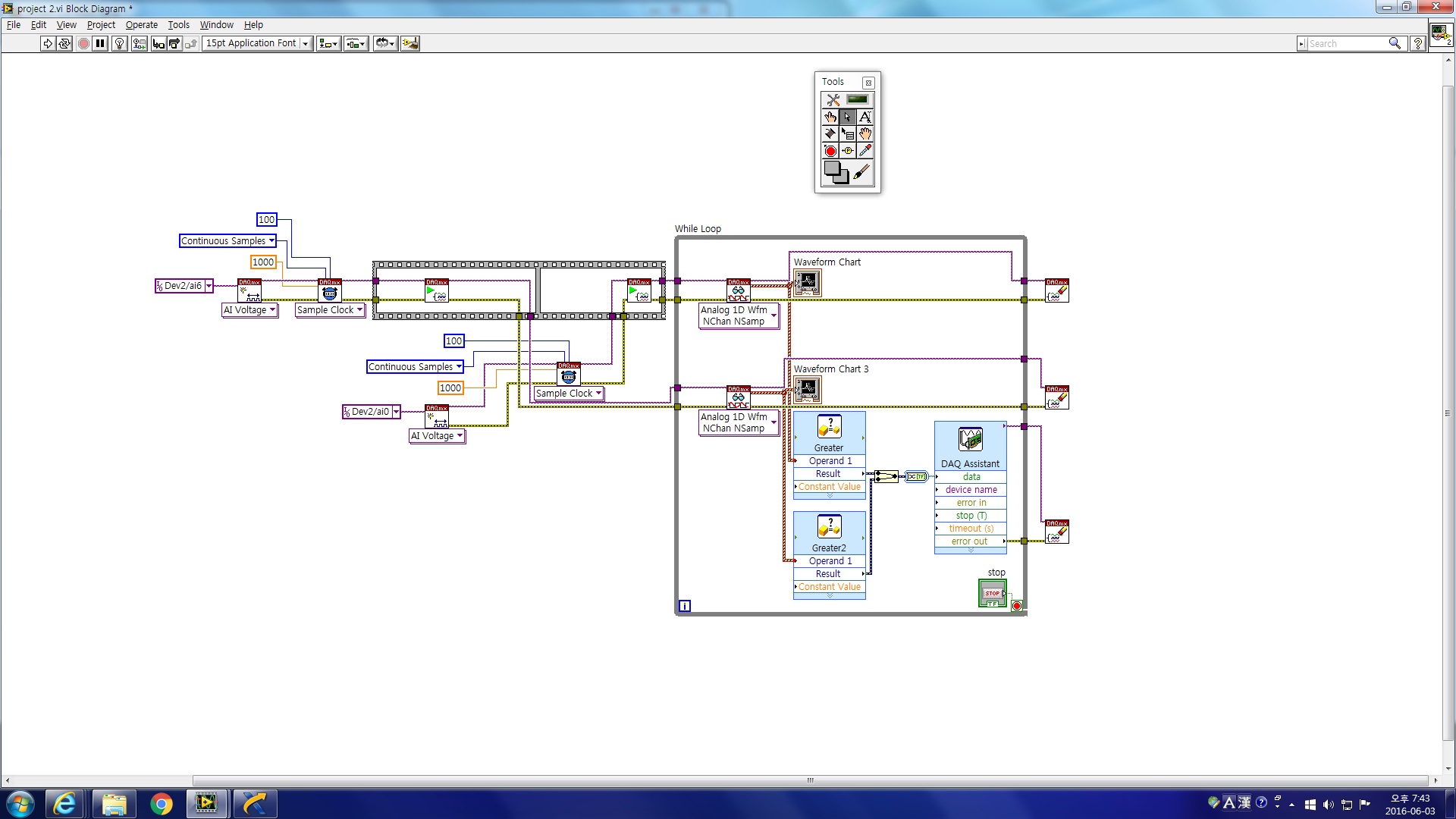

I have attached the VI but also a screenshot.

Please let me know if anyone has any ideas. I would really appreciate the help!

Thank you

Peter Borgstrom

We will review your tasks one at a time. First of all, the task of generation/Analog output Waveform. Generate you a waveform (I'm unsure of your VI if it is a fixed waveform or not) and send it to a defined output function to produce a waveform continuously, using N-channel and samples of N (where you set not these previously). You should not put this inside has timed loop, as the DAQ hardware has its own clock - if you simply put it in a while loop (with a stop to break out of the loop), the loop will call the function for the first points of N, wait until all N have been taken out, then call it again to another N points (up to what you press Stop).

Now, suppose that you have the output connected to a load voltage (say a decent resistance). You can wire the input terminals of your A/D converter through the same load and set up a similar analog input loop, running in parallel (i.e. in its own independent of the OD loop, while loop). You pourriez start together (with, say, a merged error since the initialization code line loops HAVE and AO become lines of error in "loops of sampling" described above), but you might want to delay loop (a little) the AI so that the OD has a chance to set the voltage before the bed.

I hope this helps.

BS

-

Generation and acquisition of analog signals simultaneously on USB-6212

Hello, I am novice programmer DAQ trying to create (what I think is) something very simple.

I use a box NI USB-6212 and LabVIEW 8.5 is trying to generate a pulse train analog while recording a simultaneous analog input.

My first question is, is it possible?

Since I'm new to this, I use the DAQ assistant in LabVIEW. I can acquire a signal, I can also generate the desired signal, but I can't seem to operate simultaneously.

I have been successful in obtaining my program to work with both USB-6212, but I have to be able to do this with a single.

I have attached the block diagram and vi, I hope that's easy to answer the question, even if my research so far has left me empty handed.

Any help would be greatly appreciated!

Jon L

Hi Jon,

Well, first of all welcome to the DAQ programming! I took a peek at your code and published it with a device simulation very well, so I ran with the PCI 6251 card in my computer and he did not also get errors. Could you post the error code you get?

If I could figure out what is your error, I would say you encounter errors of buffer because it is too much overhead in the DAQ to wizards in the face of data rates. My suggestion would be to use the example called "Multi-Function Synch AI - AO.vi. This program can be found in the Finder for example of NOR (see Help"find examples in LabVIEW). "" It appears in the input and output material"DAQmx ' synchronization ' Multi-Function.

Can you give that a try and let me know how it goes? Thank you!

-

How to measure multiple analog input at the same time.

I tried to do a VI that controls a motor with two buttons. If I press the buttons, the VI took the analog signal from the buttons and the engine is running. Each button covers the different direction - to the left and to the right.

I need to enter the two report in the VI at the same time, but I can't. If I run the VI, VI takes only a random signal. I want to know what are the problems and how to solve them. Please help me.

You must use a single task for both channels. See if that helps.

-

How to reach an average of three analog inputs of the analog Arduino pins

Hi, I'm using Interface Labview for Arduino. I correctly interfaced Arduino with Labview and acquired of entry using the analog potentiometer. But now I want to take three signals at once and want to average there. If someone knows how to do it please change below program and fix it.

I just have three readings in a loop FOR. Create a table to store the channels to read and leave the auto loop on the channel and autoindex value index. This will create a picture of your reading. Then just use Mean.vi to get the average.

-

How can I display an analog input for the PXI-5105 on LabVIEW?

Hi all

I am very very new to LabVIEW and I started to tinker with it. I use the version of LabVIEW 2010 SP1 on Windows 7 OS. I also have the chassis NI SMU-1073 with SMU-6361 and PXI-5105 modules and the chassis is connected to my PC via PCI. I became familiar with the devices and trying to see some analog signals to one of the channels on the PXI-5105 module in a graph in LabVIEW.

I would appreciate your help.

Hello Henokview!

I would like to read through these tutorials to understand the steps of programming of the NOR-SCOPE, NOR-DAQmx. After reading these links below, you will be able to understand how to connect the output of a readfunction to a chart or table.

DAQmx

http://www.NI.com/white-paper/5434/en

OR-SCOPE

http://www.NI.com/white-paper/3382/en

Best regards

Jonas

-

How do I get the analog input signal and send it to output analog (real time)

Hello world

I do a simple task in Visual C++ and I use PCI-6221(37 pin).

Basically, I want to send the same signal of "analog input" to the "analog output".

at the same time (or almost), to make real-time application.

Can someone provide me with sample program please.

I would be grateful if you could provide me with the great tutorial that explains

step by step everything about NOR-DAQmx for C/C++ programming.

Best regards

Khassan

This is my code in C++, you can optimize it if that seems too messy. This code reads the analog input signals and exports it through the analog outputs.

To make this code additional work of the directories include and library directories must be added to OR.

I hope it helps someone.

#include

#include

#include "NIDAQmx.h".

#include#define DAQmxErrChk (functionCall) {if (DAQmxFailed (error = (functionCall))) {goto error ;}}

int main (int argc, char * argv [])

{

Int32 error = 0;

TaskHandle taskHandleRead = 0, taskHandleWrite = 0;

Read Int32 = 0;

float64 context [1000];

char errBuffRead [2048] = {'\0'};

char errBuffWrite [2048] = {'\0'};

bool32 done = 0;

Int32 wrote;DAQmxErrChk (DAQmxCreateTask("",&taskHandleRead));

DAQmxErrChk (DAQmxCreateAIVoltageChan(taskHandleRead,"Dev1/ai0","",DAQmx_Val_Cfg_Default,-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleRead,"",100.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,0));

DAQmxErrChk (DAQmxCreateTask("",&taskHandleWrite));

DAQmxErrChk (DAQmxCreateAOVoltageChan(taskHandleWrite,"Dev1/ao0","",-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleWrite,"ai/SampleClock",100.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000));DAQmxErrChk (DAQmxStartTask (taskHandleRead));

DAQmxErrChk (DAQmxStartTask (taskHandleWrite));While (! fact &! _kbhit())

{

DAQmxErrChk (DAQmxReadAnalogF64(taskHandleRead,1,10,DAQmx_Val_GroupByScanNumber,dataRead,1000,&read,));

DAQmxErrChk (DAQmxWriteAnalogF64(taskHandleWrite,read,0,10.0,DAQmx_Val_GroupByChannel,dataRead,&written,));

}

_getch();Error:

If (DAQmxFailed (error)){

DAQmxGetExtendedErrorInfo (errBuffRead, 2048);

DAQmxGetExtendedErrorInfo (errBuffWrite, 2048);

}

If (taskHandleRead! = 0){

DAQmxStopTask (taskHandleRead);

DAQmxClearTask (taskHandleRead);

}

If (taskHandleWrite! = 0){

DAQmxStopTask (taskHandleWrite);

DAQmxClearTask (taskHandleWrite);

}

If {(DAQmxFailed (error))

printf ("error DAQmx: %s\n",errBuffRead); ")

printf ("error DAQmx: %s\n",errBuffWrite); ")

}

printf ("end of the program, press the Enter key to quit\n");

GetChar ();

return 0;

} -

Input signal is set to +/-0 .5V when it is connected to an analog input

Hello

I have a difficulty connect an analog source to the analog inputs of my acquisition of data (USB-6215). The analog signal is output operational amplifier through a 10 k resistor. I wore the signal out of the amplifiers is 10V peak, I then move the probe across the 10 k (the analog input terminal) and the signal is clipped to +/-0 .5V. If I reduce the amplitude of the signals of source less than 0, 5V Ridge there is no clipping.

Maybe the analog input range the value +/-0 .5V which is causing this as a form of protection? I don't have a LabView to try to change the input range as I do just the wiring.

Analog source is connected to him HAVE 0 and the ground of the analog source is connected to the GND AI.

Thanks in advance.

J

Joel-

Have you tried to read the data through the data acquisition device? If that's what you try to do, I'm curious about what we read.

If you have measurement and Automation Explorer, go ahead and open a Panel to test for the unit and see what are your tensions.

Let us know how it goes.

-

USB-6211: analog input signal affecting another of the same map AI

Hello

I use the DAQ-nor-6211 map and DAQmx features to read a hammer and a signal of the accelerometer and then use other LabView functions to make the FFT of these analog input signals. However, it seems that the analog inputs where the hammer and the accelerometer are connected generate a kind of noise or influence in other entries of this data that is not connected to any other sensor acquisition board.

I've had different experiences in order to check if the problem is with reading the card: put the accelerometer and hit the dog in another table where the DAQ card table was located (to avoid the vibrations on the map and a possible noise), ai1 entry was logged on the differential mode on the dog and the ai4 of entry is connected to the output (z axis) of the accelerometer. The other 2 ai2 and ai3, entries that can also be read by my LabView program, are open (i. e., any other sensor is connected to the card). When the structure where the accelerometer is located is struck by the hammer, the signal of ai2 ("x axis" seen in the first attached document) has a curve (on the time domain) which initialize almost at the same time that the hammer and the a3 of entry has a weak signal, but with the swing as well as the signal of ai4. The document "hammer ai1 + z_axis connected_ _x_axis disconnected ai2 + y_axis ai3 ai4" images that I captured the chart created in LabView. On these graphs, it is possible to check on the FFT the ai3 signal and ai4 has the same behavior (with different intensities), and enlarged figure of time domain image, we can see that the signal of ai2 increase almost at the same time of the signal of the hammer (ai1). The signal picked up by the sensors are probably creating a sort of noise on open entries ai2 and ai3.

Another experiment was conducted to check if the signal from a single entry that may affect the signal read from each other near the entrances: the DAQmx task Create channel had a physical channel has changed: ai3 entry has been modified by ai7 (maintain the same connection mode: differential), and the results are visible on the second attached document. In the graphs obtained in this experiment, it seems that the entrance of the hammer (ai1) affects the signal of input ai2 and ai7, which are not connected. And the ai4 signal does not seem to influence the other inputs, because he has a different curve on the graph of the FFT.

The same experiment was conducted using the CSR connection (change threads and create the DAQmx Channel Configuration), but the results were the same as those found using differential connection.

Finally, if the output of the accelerometer is connected on the ai2, the signal of the other open entries ai4 and ai7 seem to be affected by the signal of the accelerometer on ai2 (last document attached).

Could you tell me if the problem I encounter is caused by the DAQ card with this information that I gave to you? And if the answer is Yes, do you know if there is a way to avoid this noise create in one entry on the other hand, it please?

Thank you

Maybe Ghosting or crosstalk? Just an idea.

-

Analog input voltage assistant DAQ

Does anyone know why theres error when you use two assistant DAQ (in a while loop at the same time) for reading of the analog input voltage?

There is not a problem if you use a wizard to data acquisition for analog input voltage reading simple.

If you get an error, wouldn't it useful that you have told us what it was, we may be able to explain it?

I'm guessing that you have error-50103, and if you look in the forums for '50103' (leave out the negative sign), it will give you the answer for this question has only requested thousands of times before.

-

Synchronization of two inputs frequency meter with several analog inputs

Hi all

I'm relatively new to LabVIEW and I'm trying to collect data from multiple sources with calendar sync on the acquisition, but I can't understand. My problem is that I have two inputs frequency meter, an optical tachometer reading one pulse per revolution and a max flow meter machines with a 12000 k coefficient. I can't find a way to synchronize the calendar with my multiple analog inputs. I tried to first get the speedometer to synchronize with the analog inputs following the example linked here. (https://decibel.ni.com/content/docs/DOC-10785) So far every time I run it I get an error on the DAQmx read timeout or an error "several sample clock pulses have been detected" (see image). It seems if I slow the way to down to say 10 hz and make sampling rate ensure that the tachometer signal is more than 800-1000 rpm (13-17 Hz) before starting the VI then the program will run without error until the ROTATION speed is below this threshold, then the "sample Multiple clock pulses" error occurs. The code is attached below.

Does anyone know of a better way to synchronize the entries of frequency of the counter with analog inputs? I would like to have a VI that can display 0 RPM (and possibly 0 flow as well, but I think I need to understand the timing of a meter before I have add another, because it seems that I can't have two counters to the same task). Any help on this would be greatly appreciated.

LabVIEW version 13.0

Chassis cDAQ-9178 with NI 9401 for both counter inputs and NI 9205 for the analog inputs.

Thank you!

Richard

I know the error requires to restart the task at least (this particular error puts the material in a State that cannot be recovered from during execution of the task - I've been down this road before) but I'm surprised that you would have to delete and re-create the task altogether. And then I had to do this to workaround other questions in the past. It is awkward and should be considered a bug, if this is indeed the behavior.

Honestly, regardless of this bug, the way the material dealing with the situation of several sample clock edges makes measures of sampling frequency clocked essentially unusable for purposes of synchronization (in my opinion anyway) If you encounter a more slow than your sample clock rate. You are supposed to be "synchronization" of the measure, but it really no longer applies if you have to restart the task over and over again (if you must delete it or not).

Workarounds can get kind of creation (which isn't really a good thing). For example, you can configure a measure of implicit frequency to keep a buffer of frequencies and use a leader board task (source is the frequency signal, sample clock is the sample clock HAVE) to establish a correlation between the index of your buffer of frequency for singing HAVE sample clock.

Best regards

-

Test the analog inputs in a PCI-6013

Hello. I m using a PCI-6013 OR DAQmx 9.1.1 with Labview 8.2 (sued) WinXP. The jury has undergone an immersion in water during a flood but was cleaned, recognized by WinXP and NIDAQmx.

I have run the Measurement & Automation explore and use the test under option OR-6013 'Dev1' panels 'devices and Interfaces. Here, I can see that the digital and clock output work perfectly (I can change the State of the digital channels and duty cycle and frequency of the clock). The problem arises when you try to measure an analog voltage. I tried on several cases not all analog channels using NRSE and differential modes (switch accordingly connections).

The signal comes from a (4 Hz, squares and sines, 5Vpp) signal generator via a CB-68LPR connector.

I only see something comparable to the entrance of singal when you use differential inputs (signal connected by J57 and J23) AI7, but the signal I see comes with 100 mVpp instead of 5 Vpp (I can see changes in the shape, every time that I have spend of a sine, square, ramp...). I also tried connecting J23 AISENSE (J62) and AIGND (J67), to avoid the problems of floating source. The same thing happens when enter and set up the acquisition by the vicinity of data in the Explorer of Measurement & Automation. I m using the reach of the signal in the different ranges, tried with 04:55, -1 to + 1, 09:50... When you configure tasks NIDAQmx I choose to read different samples (100, 1000, 10000) rate (100 Hz, 1 kHz,...) and combinations. Anyway, the input signal is always 4 Hz. I checked the signal with an osciloscope and I see it perfectly.

Is it possible to have the broken while the digital and general-purpose analog input clock outputs are OK? Y at - it a tip for the connections I should know about? Thanks in advance for any guidance!

Thank you both, KateB and MarisolM for your answers.

I made several the tests con señales DC y con señales senoidales, instalando placa en back different computers, y no obtengo resultados positivos, is spite of what el self-test selling well. Seems that the Plaça realmente esta fallando.

I did several tests with DC signals and senoidal, installing the card in two different computers, without positive results, even if the self-test is OK. It seems that the Council really works hard.

Are concentration cotización por su reparación. Gracias!

-

Frequency measurement of analog input using DAQmx C APIs on SMU-6341 map

Hello

I use Linux DAQmx and attempt to measure the frequency of analog input using the map DAQ SMU-6341.

There is an ANSI-C frequency measurement example:

/ usr/local/natinst/nidaqmx/examples/ansi_c/Analog_In/Measure_Frequency/Cont_Freq-Int_Clk-SCXI1126

However, the call to DAQmxCreateAIFreqVoltageChan results in the following error:

DAQmx error: selected physical channel does not support the type of measure required by the virtual channel you create.

Create a channel to a type of measure that is supported by the physical channel, or select a physical channel that supports the type of measure.

Property: DAQmx_AI_MeasType

Required value: DAQmx_Val_Freq_Voltage

Possible values: DAQmx_Val_Current, DAQmx_Val_Resistance, DAQmx_Val_Strain_Gage, DAQmx_Val_Temp_BuiltInSensor, DAQmx_Val_Temp_RTD, DAQmx_Val_Temp_Thrmstr, DAQmx_Val_Temp_TC, DAQmx_Val_Voltage, DAQmx_Val_Voltage_CustomWithExcitationTask name: _unnamedTask<0>

State code:-200431

DAQmx does support the function of the frequency on the map 6341, or should we use examples of voltage and calculate the frequency manually?

Frequency of HAVE it is a type of channel that has been supported only on the SCXI module name of the example.

You will need to use a voltage input channel and calculate the frequency manually for your device.

Maybe you are looking for

-

Message: Shared spreadsheets cannot be changed when the number is offline now

I just updated to IOS10. I can open all other spreadsheets in numbers (shared and non-shared) bar one when I get the above message. Locations - iCloud drive

-

PC World Curry always ask my iCloud password...?

Hello world! So, recently, I sent my MacBook with world PC of Curry. I've bought from them and my MacBook has been to them before, but I have to ask... Why do need my iCloud password? So, I understand that they'd need if there is a technical problem,

-

HP2000-2d19WM: System disabled [63727402]

Unknown admin password.

-

I use Live Mail client and SSL, but I can't recover the messages in my subfolders in my Hotmail account, how can I do this? I can use a web browser to display, but Live Mail client only update the subfolders, only the Inbox.

-

How can I change the drive letter assigned to the partition of 'winretools' on a laptop Win 8?

I'm just going through the process to customize a new Inspiron 14z with Windows 8. The only thing that left me speechless are all provided partitions installed on drive, thanks to a combination of everything be different on Win8, Dell make their own