reverse the engine problem!

Hello! ...

I have developed a program that has the algorith as follows:

1 x steps and Y steps determne table of pixel size I want.

2. for each Y increment the X scan by a fixed number of steps, then there

3 step 2 is repeated until there is reached its MAX State.

Problem:

After the scan X say 10 steps I want to reverse and go back to the original, and then again after Y increments X scan and return to original.

Its a RASTER scan basically.

I'm not able to understand why and how to add a part to get the engine back to its original position.

Please find the VI and tell me my mistakes.

Thank you

Hello

You have two nested while loops: one that moves in the direction y and one inside that moves in the x direction. There are two ways you can implement replacing the x-axis zero.

1. the stop direction x loop condition is once he traveled to the stop. You can add that a deal right behind what just loop said the engine back to zero.

2. in management's loop before the axis x running tell the x axis to return to zero. This would lead to zero each time before axis x begins his move.

Both ways will accomplish the same thing but got it back after the move and two the fact before.

Kind regards

Greg H.

Tags: NI Software

Similar Questions

-

reverse the direction of the engine

Hi, I need help with the following:

Detection time and the weft: sensor of the LDR (photocell) should be able to detect whether it is day and night (light or dark). During the day, if the Sun is so bright, special curtains should automatically shadow through the engine temperature sensors. During the night, curtains must be retrieved automatically. Note that the user has the ability to override decisions could make about deployment or recovering curtains.

I did a job on the vi program. However I don't know how to reverse the direction of the engine through labview. I'm controlling the speed of the motor using function (1 sample of Charron 1) freq counter DAQmx writing a command button. So I can't specify a negative cycle. Any suggestions?

My labview code is attached.

Thanks for the reply. I solved the problem by using a component electric H bridge and related lines Mydaq DO0 DO1

-

Powder dosing machine? Direct control of the engines?

Hello world

I hope it was not shown below, but I start my worki with nxt and labviev and a certain problem.

I want to build a dosing of powder, which consists of two conductors of powder (driven by motors) and the weight of lab controlled by RS232.

The goal is to be able to make precise mixtures in order to weigh the empty box of weight, tare, and then adds a charger of the weight of the powder (A) checks how much gave - if not enough adds some etc... etc... continued with 2 powder and mix to...

The problem is that I know that I can write the labview NXT program to run the NXT brick, but it would be very complicated to use - the best way would be to take direct control over the engine via NXT - therefore when I want the engine to move a few degrees it should not start the program in the nxt brick do the program level LAbview... IS this possible? Can I use brick NXT as a controller of engine itself?

Thank you

Marek

Marek,

This is possible in 2009 in Module NXT and NXT earlier toolkits. In 2009, just write your code NXT in a VI that is not the target of the NXT (e.g. it is targeted at the Instance of the Application My Computer/hand). The VI NXT know when they are targeted on the computer and automatically send direct orders to the NXT brick via USB or Bluetooth.

In previous versions of the tool NXT, you must use the Direct screw of NXT to accomplish the same task, which is not as transparent as the new method, but all works the same. Please let us know if you have any questions about how to apply this.

See you soon,.

-

Stopping the engine Service Variable OR in Windows 7 64 bit

Operating system: Windows 7 (64-bit)

Version 9 of Labivew.

I configured puts some Boolean and Out entries and an analog input (Double) for monitoring purposes. I use a server OPC Mitsubishi with Labview 2009. (It worked great for over a year)

When I delopy the Variable Libray it works very well for about 1 minutes, then NI Variable Engine Service STOPS. (As shown in the Attached files)

But if I remove the analog input, the Variable does not stop and works very well.

In the first attempt I stretched the Labview and 2nd attempt re-installed Labivew 2009 as well as Windows but still the same problem.

If his problem installing then why it works for Boolean types

Windows event monitor has additional information as to why the service stopped? If you create a new project with a library of double of accommodation and Boolean variables which also stops after a minute?

Also can you us more info on the double in question. Is this a normal SV or is it bound to an OPC tag? If unbind you it the EVS will remain after a minute?

-

Error-201314 whenever the engine killed

Hi guys,.

I'll build a test bed that takes a few smaller engine size measures. I use the 9188 cDAQ platform and a module in the series C 9401 to get the signal of an encoder that is mounted on the engine. Whenever I kill the engine I get code error-201314 saying the following:

DAQmx error: sampling Multiple clock pulses have been detected within a period of the

input signal. Use a sample clock rate that is slower than the input signal. If

you use an external sample clock, make sure this clock signal is within the j

Itter and voltage level specifications and seedless.The way I have the configuration of the task, it's pulse tachometer to act as an external sample clock and charges against the edges of 20 MHz clock, so I can hardly believe I'm getting any type of engine accelerates faster than the clock of 20 MHz. Anyone has an idea what this message means? So, I wonder if I need to be more careful about the way my reasons are connected.

Thanks for the help,

Ryan

Hi Ryan,

Small defects on the edge rising or falling of your tachometer signal could be picked up as additional edges. I suspect that the Act of powering the motor is presenting the noise on the line, whose meter is picking up as the edges in double during transitions.

The 9188 she supported for digital filtering on the meter inputs - introduced feature in DAQmx 9.4 for the 9188. You can use the digital filtering to reject any pulses below a certain duration. From your description, it seems this would be a likely solution to the problem.

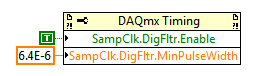

In LabVIEW, you can define a digital filtering of the sample with a property node DAQmx Timing clock signal:

If you use a different API and ill have to find the equivalent property do not forget to let me know. Remember that if you use a version of DAQmx before 9.4 you will need to update your driver to have the feature available for your 9188.

Best regards

-

Hi all

I use a CRIO-9075 with a NI9205 and Ni9263 to control the movement of a hydraulic jack. Activation and position/force signals are analog. I use the library softmotion to create an axis and take advantage of the generator of the trajectory and the control loop to execute in the FPGA.

I'm running the CRIO using FPGA and like softmotion for independent axis I synchronize RT and FPGA, for which I've read the engine periodically at 100 Hz.

The problem is that the analytical engine gets in a few seconds in fault mode. To return to the active mode, the only way is to reset electrically the CRIO.

I have attached an image of a minimal example in which to read the scan engine mode and read two panel controls before FPGA. The analytical engine returns 3 (default mode), but the variables read from the front panel are correct.

Have the engine of analysis in fault mode I cannot synchronize the RT and FPGA as in the example softmotion.

Why is my engine entering mode fault with the wrong 66341?

Thanks in advance

This is a bug described in the following link with a workaround that works

http://digital.NI.com/public.nsf/allkb/E2F4F2E4F3A91F6E86257BB9006589D1

-

Stop the engine when detects digital impulses of the reflective light sensor

Hello

I am doing my school project and I managed to make the deepening of the engine via digital port of the USB-6008 by setting the Boolean value of output in a while loop with use cases, but now I faced a problem because I have to use it with a reflective sensor and stop the engine when he feels a digital pulse. The sensor is configured as a counter using PFI0 on the USB-6008 with a circuit that will send in a digital pulse for data acquisition.

How to stop the engine when the detector reflecting is blocked, and then start the deepening again when it is not blocked

Thank you

The top spot is always implemented as a counter. You must change the DAQmx create channel as a digital input and the DAQmx interpreted as a Boolean variable digital 1 channel 1 sample.

-

How to implement Canopen on FPGA to run the engine using NOR-9881?

Dear,

Your support will be highly appreciated,

There is only one available for NOR-9881 example.

Please note that the following materials were properly connected:

cRIO-9024, cRIO-9113, OR-9881 and motor Nanotec (SMCI36 against L2818L0604-T5X5), the following

sites Web shows the engine Nanotec in details:

http://us.Nanotec.com/products/660-L28-linear-actuators-with-trapezoid-spindle/

http://us.Nanotec.com/products/1041-SMCI36-stepper-motor-and-BLDC-motor-position ing-control /

The main problem is how to configure the inputs and outputs, where, in most examples, the entry and exit have been automatically

configured.

the following three examples and I wonder how to start:1 - example Nanotec: dependent VISA controls for data transfer

http://us.Nanotec.com/support/application-notes/LabVIEW-example/

2 - reference example CANopen for series C OR - 9853 Module CAN:

the NOR-9853 has default Can0 which was used in the codehttp://zone.NI.com/DevZone/CDA/EPD/p/ID/6093

3 - from finder labView example: search for 9881 then choose

NOR - CANopen_cRIO.lvproj, which depended on SDO orders for transfer orders

The attached picture shows that NEITHER-9881 can be seen, after compilation and

loading the bitfile FPGA.

Please, please advice me:

1. how to start?

2. how to create variables of entry for NI9881?

3. how to implement CANopen mode FPGA? where there is no CANopen palette.Thanks in advance and

Hello!

From my understanding, the 9881 can be treated from the FPGA, but only from the application of the RT. I think that the point 3 of your post examples of the use of the module fine.

Kind regards

Georg

-

I can't build a distribution kit, because the Builder seems to have saved a path to the NI Variable engine that is not valid. I seem to have the Variable engine OR installed. There is NEITHER Variable engine 2.5.0 fichiers.xml loaded on my computer (see the attachment for the list of loaded drivers). I don't seem to be able to break the bond of the CVI at my recent installers for drivers. I tried to create a new installer, but had the same problem.

I'm running a 64 bit computer laptop with Windows 7, a 32-bit application, CVI generation 2010 running.

The default path is the path to any distribution installed OR engine Variable on your machine. For example, if it has been installed from a driver disc, the path would probably be D:\. However, since the images you posted, I see that you were being asked to provide the path to one of your previous ATAHM distributions. It has been home to this path:

c:\Users\chill\Documents\Development\AATAS\ATAHM\distributions_ATAHM\ATAHM Oct 24 BitDefender 2011\

Do you still have this distribution? If you can point to this distribuiton, you should be good.

Now back to the error you saw... Your version of this manifest .NET file matches (except for the version number) review from the Base of knowledge, so you should try to replace it with Revision B (rename it to .xml NI .NET Framework 2.0 Language Pack x 86 Installer {F8ECD2D6-659C-49EB-8454-5F8F7B526FCF}). Make sure that you restart CVI after the file-swapping. I think that in order to solve your problem. If it isn't, you need to let me know what is the new number, or if you somehow still see the same error message.

A. Mert

National Instruments

-

reversal feeling engine movement MyDAQ

Hi, I need help with the following:

Detection time and the weft: sensor of the LDR (photocell) should be able to detect whether it is day and night (light or dark). During the day, if the Sun is so bright, special curtains should automatically shadow through the engine temperature sensors. During the night, curtains must be retrieved automatically. Note that the user has the ability to override decisions could make about deployment or recovering curtains.

I did a job on the vi program. However I don't know how to reverse the direction of the engine through labview. I'm controlling the speed of the motor using function (1 sample of Charron 1) freq counter DAQmx writing a command button. So I can't specify a negative cycle. Any suggestions?

My labview code is attached.

Use a relay of two bipolar directions connected to your daq dig out and the pilot and reverse the connection via the relay...

a real on the dig out will reverse the polarity

Note: realized that I had connected Daq GND to motor and... DO NOT CONNECT because of the reflex of induction coil of the motor, LSN has built in "flyback diode" for induction of relay coil.

-

Installation of the application with the engine running and system Config API kills many services OR

If I have an empty Windows 10 computer and install LabVIEW 2015 SP1f5 Run-time-Engine, then System Configuration 15.3.

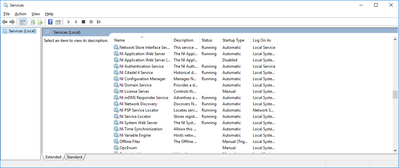

I see that several OR services are running OK on the machine subsequently:

However, if I can install a built (LabVIEW 2015SP1) app - using an installer which includes also the 2015 SP1f5 RTE and the configuration of the system API 15.3, five services will not start and cannot be started manually either (affecting all the services into recovery mode restart fails too). Error code when you try to manual start is 1068 that indicates they are missing a dependency, but * any * of them will start...

I suspect that is the reason that neither Max 15.3 ends with a timeout during the peripheral configuration warning - AND my use of RAD / system configuration set image function is a failure...

Why the hell the same software support (which should really be installed in all cases, the application itself must be installed) has this devastating beats me. The only way to obtain the services of backup and running is to uninstall everything, even to delete all files remaining and records... and then reinstall the original RTÉ and SysConfigs.

The problem seems to be a sort of obscure corruption both of my computers for development... I took the same source code and built the installer on a third computer with all the same IDE versions, and voila - everything works well.

It would be good to know exactly what the problem is, but for now at least, I have a solution... (hopefully fix my machines and/or before you wipe them clean and reinstall the IDE together on them will get back on track...) Without knowing what the cause was however makes me wonder if I might have the same problem again later).

-

You must stop your request before the engine may stop

I have an integrated application that uses LV DSC 6.0.2. The application starts and stops the engine tag programmatically. The application works fine, but on some machines, I'll get continuously the next dialog box when I try to stop the engine of the tag:

"You must stop your request before the engine may stop"

It's strange, because it only happens on some machines (it seems that it can occur on computers with ONLY of DSC Run-Time installed, not the full dev system. DSC LV).

The dialog seems to refer to the application of 'control' which tries to stop the engine... it isn't telling me that my devices servers need to be stopped.

This dialog box does not seem logical, I should be able

to build an application that can start and stop the engine... and why I get this dialog on some machines but not on others?John Paul,

There are two points that we should ask ourselves:

1: you can have different loops while in your application where you read/write to and from the engine of the tag with the read/write Tag.vi. These screws has a stop of production which must be wired first the while loop. If you have cases where you do not connect this output to your time stop loop you could access the engine while you want to stop the engine in another loop with the Shutdown.vi engine. -> Make sure you have all drivers of DSC to access loops has stopped before you turn off the engine.2nd: I guess he was once an issue of race with the DSC engine condition and how it access to shared memory with the read/write Tag.vi. But this condtion of race must be agreed with the version of LabVIEW DSC

6.1 or with other fixes for LabVIEW DSC 6.0.2. You can download patches (in this case, particularly the BVRTDatabase.dll) driver update page & of NOR: www.ni.com/support/ > Option 3, drivers and updates > Search drivers and updates > type 'LabVIEW DSC' > choose LabVIEW Datalogging and Supervisory Control 6.0.2 fixes.

You must apply the patches of this as well on your DSC 6.0.2 Run Time System!I hope that one of the help of two suggestions to solve your problem.

Concerning

RolandFTP://FTP.NI.com/support/LabVIEW/labviewdsc/fixes/6.0.2/

-

How to control the speed of the engine without tachometer

Hello world

Thanks for stopping by and have a look at my problem

I have a PCI7344, UMI7764, DC motor, encoder and drive motor. Everything works fine. Currently, this system allows me to control the motor through feedback from encoder (which means, first I set my target position, and the engine will run to some targets detected by the encoder position).

What I want to do now is to control the speed of the engine, however, I don't have a tachometer feedback, since my speedometer only allow me to display the number of LAPS. is anyway that I can do this (control and maintain the speed of the engine at a certain RPM value) with all the listed facilities I have. Can someone help me on this?

Thanks in advance for any suggestion and recommendation.

Using LabVIEW, engine behavior will not change. If you see massive oscillations, my first guess is that should change your settings of PID. Please refer to this document and the other pages that are linked.

Jochen

-

Hello. First of all, thank you for taking the time to read this message. I'll try and add all the valuable information that I can. However, if you would like more information to help solve the problem, please let me know. So a few weeks ago, I noticed that my audio was very distorted (as you know that your laptop does when you work it, the sound the sound). I downloaded the driver HD audio Realtek, made sure it was updated to help with the distortion. Well, then the volume become too low. I continued install audio drivers Realtek HP, remove all devices from realtek (under sound, video, game in Device Manager controller), passing through updates on internet, etc., but nothing works. In addition, I have gone from reading devices (under the volume in the taskbar icon), by selecting My speakers, go to the properties and selecting improvements and selecting "Loudness Equalizer." So far, which helped a bit. My volume is now 100% and it looks like he did when he was 20% (when there is no problems).

Unfortunately, I do not know how long this problem has persisted, and I don't think that there is a restore point before that time to try to reverse the effects. Is it possible that I can find the original driver delivered with this laptop? Currently, I went to Device Manager > Sound, Video, game controller, Realtek HD Audio, update > Browse > let me pick > choose the driver earlier.

Any advice would really be welcome

Hi @kendrat0,

Welcome to the Forums of HP's Support. It's a good place to find the help you need, other users, HP experts and other support staff. Thank you for sharing the details of the problem. I want to help you.

If I understand correctly the audio quality is lower than expected and need a solution.

(Correct me if I'm wrong, and I thank you for the details)

Could you please provide me with the product number of the PC? If you don't know how to find this information, please click here for more information.

I have a few steps, you can perform to resolve the issue: remove audio drivers & reinstall the original drivers update Audio drivers on the official website of HP for windows 10 (click on the changes on the top to switch between the BONES).

Increase the volume on the playback device settings after you set your speaker as the default device. For more steps, follow a similar post on the HP Forums: click here

Perform a hard reset

* Reset the BIOS default

* Run the test Audio of Diagnostics of material for the PC HP (UEFI)

* Update the BIOS

* Reset your computer

Perform a recovery of the HP system

I would like to know if these measures worked for you. If they did, it's great! Give us some reinforcements by clicking on the solution and laurels, buttons that help and others see that we have the answers!

If you are unable to reach a resolution, please click on accept the Solution to help others with similar issues.

If you like my assistance, please click on the thumbs up icon.

The two icons are below this post.Kind regards

-

How to make the engine shut down on FSX before playing?

Hello

In flight simulator x, I would get the engine power off before playing the game. Whenever I start a new free flight, the engines are always lit. I have turned off. Please tell me how. My flight ends also in the middle of the flight and then a window appears and says, "this is a problem in FSX. Please understand that I have to do. Thank you.-Maryse

Maybe you are looking for

-

Make the change in functionality modules if I put everything: the default configuration values?

I was wondering if I could clean up my old FF of database/values. Can I set all settings by default in: config without any problems with my Add-ons?How can I fix: default config?Do you have other tips to make my cool FF as new without exporting all m

-

Hi all. Just a curious thought, without agenda. Apple Announces the end 2013 6,1 MacPro for Intel Xeons with Turbo Boost when needed. In my case, the 4 core 3.7 ghz will be TB to 3.9 ghz. I recently downloaded app Gadget power of Intel, and here it i

-

HP p2-1334: do not install drivers

I installed Win 7 Pro 64-bit on the desktop HP-P2-1334 which had win 8 above. I downloaded the network and video drivers to win the 8 initially provided with the computer The two pilots installs drivers but nothing happens. At the beginning when I in

-

Utility RAID does not work after upgrade to Vista

Hello I have a Qosmio G30 with 2 HD 120 GB each. After that I've upgraded to Windows Vista Windows XP, Toshiba RAID Utility no longer works. In Windows XP Home Edition, it worked OK, but in Vista, there is no way I can reflect the HD. In other words,

-

Split view activity monitor and Console?

On my iMac I'm able to run the Console and monitor activity together in split-screen mode, I find that gives me a good workspace for diagnosis. However, on my new 12 '' MacBook, I am unable to do so. Both applications are enabled for the split screen