Sample rate Max in ConfigureSampleClock on a PICe-6323

Hello

I use c# in Visual Studio to program a PCIe-6323. I was wondering what is the maximum sampling rate, which is the 2nd parameter in ConfigureSampleClock(), that the map can handel?

The maximum sampling frequency for an analog input is 250000 samples per second. I don't know where you see 5000 is the maximum.

Tags: NI Hardware

Similar Questions

-

Currently, I am trying to log readings of DC voltage with an AA battery in an ASCII using LabVIEW 2009 of SingalExpress file and the USB-4065 digital multimeter (DMM). I have two stages:

(1) acquisition of Signal > voltage DC using DMM

-resolution 4.5 with 3.333333E the value-5 sampling period

2) save in ASCII

-The value to add to the file, delete the file after each race

Faster reading, I can get is a data point written in the ASCII file every eighth of a second.

Furthermore, I am new and software OR LabVIEW, the LabVIEW SignalExpress software I have is only for evaluation as it was included in the CD of the driver for the USB 4065 DMM.

- Max (30 000 samples per second) sampling rate is only achievable by a LabVIEW VI?

- Don't I have the wrong settings for DMM step?

- Is it because I haven't activated SignalExpress and am only using the evaluation version?

Thanks in advance for any help!

Hello Lukos,

You are assuming that you need access to lower level functions in order to obtain the higher sampling rates. In order to get these speeds, we need to disable some settings that are not accessible via Signal Express. You can create a VI and then use a step VI call in Signal Express to stay in the same environment.

Kind regards

-Travis E

-

Hello

What is the sample rate max 5154 PCI for two channel inputs? The manual States the 2GS/s is for one channel only. So, am I not able to get a bandwidth of 1 GHz for the simultaneous measurement of two channels? Thank you!

Hi gbhaha,

First of all, TIS mode up to 20 GECH. / s using an ADC, while your real time sampling uses two converters a/n at the same time to a single channel. Take a look at these diagrams that I linked in my first post for more details on this architects.

About the difference in the bandwidth between the 5153 and 5154 - the 5153 has 500 MHz of bandwidth in its circuits, even when acquiring at faster sampling rates. The 5154 1 GHz of bandwidth, this is why it is more expensive.

Kind regards

-

On the NI PCI-6221 fast sampling rate question

Hi I was wondering if someone can answer a question of sampling rate on this card to PCI-6221 (http://sine.ni.com/nips/cds/view/p/lang/en/nid/14132).

Especially if I wanted to transmit simultaneously (analog output) and data acquisition (analog input), what is the sample rate max I could use. Kind regards.

Since the 6221 is multiplexing the analog input, your question for I / simultaneous ao is possible for one channel of the only. If your "simlutaneously" can include delays (e.g., 100us), you may be able to work with several AI channels as well...

HAVE the multiplexes, workable sample rate given that the total sample (250 kHz) frequency divided by the number of channels that you use. AO is faster than HAVE it, so it does not reduce this number.

hope this helps,

Norbert

-

How to get the rate max one sampling NOR 9263 and other cards?

Hello!

I'm using a NI 9263 map and a chassis cDAQ-9172 proyect and im he 8.0 whit CVI programming. IM generating a sine and square waves to do some tests on a radio.

I want my program to be functional for all cards of this type, and we know that most of the cards have different specifications, for example sampling max tariff, in this case the Pentecost of work NI 9263 100 kech. / s as the maximum. IM generating waves based on the sampling frequency.

If my program must be compatible with most of the cards, my need to program to acquire max sampling rate using a specific function of NIDAQmx.h.

Do you know if theres a function or attribute that can return this value?

I tried this function with different attributes, with no results:

DAQmxGetTimingAttribute (taskHandle, DAQmx_SampQuant_SampPerChan, & MaxSamp);

DAQmxGetTimingAttribute (taskHandle, DAQmx_SampClk_Rate, & MaxSamp);

DAQmxGetTimingAttribute (taskHandle, DAQmx_SampQuant_SampPerChan, & MaxSamp);

DAQmxGetTimingAttribute (taskHandle, DAQmx_SampClk_TimebaseDiv, & MaxSamp);

DAQmxGetTimingAttribute (taskHandle, DAQmx_SampClk_Timebase_Rate, & MaxSamp);The three first atribbutes gives me the rate real samp which is 1Ks/s (according to me, is the rate of samp set to the default value for all cards you before be initialized for the user), but do not give me samp (100Ks/s) max flow.

The rest of the attributes only gives me the value of the clk, which is 20 MHz and the divisor of the clk (20000). Also I tried with a card 9264 (max samp rate is 25 ksps / s) and the function returns the same results.

Any idea?

Thank you!!

Hey Areg22,

I think I've found the service you're looking for:

http://zone.NI.com/reference/en-XX/help/370471W-01/mxcprop/func22c8/

This link gives just the syntax for the function, but the following gives you more information about the function:

http://zone.NI.com/reference/en-XX/help/370471W-01/mxcprop/attr22c8/

When I used the property of this function node output was 100,000 for the NI 9263. Which is consistent with the plug. I would like to know if it works for you.

Thank you

-KP

-

With the NI 9205 module Max sampling rate - problems

Dear friends,

I develop a project of lv, which makes and control system of engine dyno. The material is CRio-9022 with other cards and also 9205 for AI. There is an encoder for angle attached to the motor shaft with 3600 chatted by Tower as well as an index to indicate the end of a revolution. the output of the encoder is measured by card 9411. The speed of the motor is 1500 rpm. I measure pressure data and couple when I receive a 'tick' of the wheel. This means my sampling rate for pressure and torque each is 90KO/s.

but I was not successful to lead it. The program is great and I can show them, but I believe that there is a problem in the choice of material for the task. With the data of pressure and torque of the 9205, I also measure other channels for the controller output mass flow and temperatures. So in all I use 8 channels of the 32 available. But only the pressure and torque are acquired at the wheel-driven sampling rate. the rest are acquired about 5 times per second.

Since the 9025 is a multiplexing ADC, 250K sampling frequency is divided by the number of channels accessed = 250 K/8 = 31 K samples/channel. With this in mind, I decided to acquire data of pressure and torque with each beat 3rd rotary encoder, essentially on 30K samples/s sampling. However, I see a large amount of noise.

So I decide to average more than 1 second cycles (so the engine runs at about 25 cycles/sec, I averaged over this issue). The resulting pressure and torque graphics do not match with those measured by an oscilloscope in terms of amplitude but the frequency and shape is correct.

I noticed an interesting feature in the charts. When I pass interpolation between the points, I see several curves made by points instead of a continuous locus of points. Accordingly, I find that the acquisition is slower than necessary, and so there are less number of points sampled as required. These points are not synchronized 25 cycles I have on average and therefore the separate "curves". It is because of the possibility that some points receive a higher number of 'contributions' several times (when you add), the neighbouring points.

so I conculde that the 9205 is not fast enough to do the job. also noise, perhaps due to crosstalk or gosting when the mux changes channels. the impdences output pressure and the couple are of the order of 10 K ohms.

the Labview code outline: well, there is a vi FPGA, which takes the rotary encoder ticks and sends a signal to the case of each 3rd tick. The signal contains a 16-bit integer, indicating the number of ticks. This signal is sent to a 1 element FIFO. This fifo is read in a parallel while loop, where it remains awaiting a new element. The while loop bed fifo, where data are available, takes a measure of pressure channel. A node memory of the method is called to provide data according to contained in the index number equal to the number of ticks to signal fifo. Then he adds the current pressure reading to the reading of the memory and stores the sum in the same memory location. Thus, an array of elements of 1200 is formed, where each elemnt is a sum of the values taken of more than 25 cycles. This memory is transferd to a dma fifo and reading side host. is done similarly to involved couple. host-side the fifo is read and divided by 25 to get the average. This average is displayed on a waveform graph.

Please check the attached file to get an idea of the problem. Sorry for the long post.

Please suggest if you understand the problem and suggesstions or solutions.

-

DMM (NI 4070), how to correctly set AC Freq (bandwidth) by the sampling rate

using a NI4070 multimeter and I see the max connection is 300 kHz by respect it. But I don't understand how to set the min and max, acFrequency according to the sampling frequency or speed reading.

6 1/2 digits resolution, the speed can vary from 0.25 s/s to 100 s/s and this range corresponds to a lower end on the connection (minimum acFreq) from 1 Hz to 400 Hz.

(Q1a) - is the playback speed, controlled by the minimum setting of IviDmm_ConfigureACBandwidth? or vice versa?

Otherwise, I do not see how to control the rate of reading or the sampling frequency. IviDmm_ConfigureMeasurement only allows you to control the range and resolution.

(Q1b) - is there a way to directly control the sample rate (digitizer) or playback speed (dmm)?

(T2) - the upper limit of the bandwidth of AC always seems to be at 300 kHz... is there still a reason to reduce this maximum value?

(T3) - Finally, unlike the traditional niDmm function, the resolution via the IVI configuration should be passed as absolute value; does directly when number of digits and the beach? For example if I want to 6 1/2 digit to 300V range, I guess that by the specifications that the resolution should be set at 0.001 V... followign, if I want 5 1/2 digits to 1V range, the resolution should be set to 0.00001 V?

Hi Rjohnson,

I'll try to answer your questions as best as I can:

Q1A. The ConfigurACBandwidth function is used by the driver OR DMM to calculate the good aperautre for the measure. So yes, by adjusting your minimum frequency, you will affect your reading speed.

Q1B. Your reading rate will depend largely on your measuring cycle. To get a fast measuring cycle, there are a few things that you can adjust. You can programmatically control your time aperature, as well as your time to settle.

Q2. I can't find a reason to change. This parameter is only used for error-checking and verifies that the value of

This setting is less than the maximum frequency of the device.Q2B. I think what you say is right, but I'll need to check on that - I'll let know you as soon as.

Hope that helps. "" "I would recommend checking the explanation of the Cycle of the DMM measurement in DMM help' devices ' NI 4070" DMM Measuments "DMM measurement Cycle.

Take care!!

-

Meter in a loop and read reduced sampling rate

Chassis: 9188

AI: 9219

CI: 9401

As pictured, without reading of CI, I can adjust the sampling rate of metered software. But reading of CI, the maximum rate is around 5 Hz. I already changed 9219 high-resolution property to high speed. What is the problem?

Hi, Carlos, thanks for your response. I acutally has solved this problem by using the connection series I and CI (i.e. connect error off HAVE error in the CI) but not parallel as the pic shows.

-

6255 sampling rate causes the dc offset

I see a dc offset in the measures of analog input I select different sampling frequencies.

I have USB-6255 (mass termination) multifunction data acquisition and I use measurement and Automation Explorer to put in place my entries.

My raw analog input is-0, 6250 volts dc, I have set up a task that uses 4 differential channels with no custom scale.

I have defined the scope of the input signal to +/-0 .8v for you sure I get good resolution.

Acquisition mode is continuous, samples of read is 1 k and I play with the order of 10kS/s rates 50kS/s.

While this task runs in the MAX, I can put my cursor in the rate field and use the top and down arrow keys to change the sampling frequency. As I do, I can see the light changes reported as much as 150 MV rate from one to the other.

It is a significant change when the total time of entry is lower to +/-1v.

The direction of movement is independent of the increase or decrease of the sampling frequency.

For example,.

23kS/s, the declared value is - 0.540v,

24kS/s, she moves to-0.620v.

25kS/s, she moves to-0.690v.

26kS/s, she moves back to-0665v.

27kS/s, she moves back to-0.625v.

and 28kS/s, she moves to - 0.535v.

At first, I thought that the sampling change made a change of the input impedance and change the load on my source, however, all the time, my dc signal source remained at the - 0.625v (as measured with a multimeter fluke at the connection point to data acquisition).

Why this is happening and what can I do about it? I want to give my users the ability to choose their desired sampling frequency.

My guess is that I need to add an amplifier to fixed gain with a gain of 5 to 10 to make the input signal to use the maximum of the analog input level (+ / 10v).

I use MAX version 5.0.0f1

Thanks for any help,

Tobin

Hi Tobin,

What do you use to generate the signal-. 625 volt? If you are using a switching power supply, you can experience aliasing where the power supply is turned on and stop.

In addition, are see you the same tensions at the same sampling rate? See you always - .540v to 23kS/s or vary over time?

Finally, you have a second 6255 you can try to replicate this on? It could be that the unit is defective.

N

-

fast sampling rate question...

Hello

I use USB-6009 and max sampling rate is about 48 K samples/s according to

the specification...

Question 1.

48 K samples/s means... only when you receive 1 analog input?

If I have 2 analog inputs then forge would be just half of the 48K?

Question 2.

using the daq assistant.

I would like to get about 50 samples between 10ms

If I do the math I get 5 K samples/s, which is enough for me

However, I played with samples to read and throughout the day, the sampling rate,

do not get this rate... (I'm outputing in file with LVM)

I searched on the sampling frequency, and people here said

samples read and sample rate do not havea correlation...

but I see clearly that they are relevant. When I change a setting

I get a different number of acquisition... I do N smaples.

Please help:)

Q1. Yes, except that the switching of channels takes awhile so the net price per channel is slightly less than half the rate of single channel. The USB-6009 specification document does not indicate what is the switching time. You should be able to get 5 kHz on both channels. 20 kHz might be close to the upper limit, but that's just a guess.

Q2. The DAQ Assistant is often not the best choice for maximum performance. I do not have the DAQ Assistant, so I can't be more specific. If you get the data as an array of DBL, rather than dynamic data type, it can be recorded directly, without conversion. The other thing that can make a big difference is a loop two architecture of producer/consumer. This allows the acquisition of data and save it to the file to run it at different speeds so that each can be optimized separately. If you are trying to acquire 50 ms of data at a time and then, he writes to the file, you write to the file twenty times per second. The first time, the operating system must reallocate some file space or do something else what delays write the file, your timing loop is disrupted.

Lynn

-

Hello

I'm looking at possible solutions for data acquisition. I use 4 or 5 entries analog and two digital inputs. During the analogue entered most of them will not need sampling extremely quick rate except for one who needs the least 100ks/s. I noticed solutions cost-effective have overalls sampling rate (eg. 250 ksps / s) which extends on all channels. For these products, such that the NOR-9205 compactRIO module, is possible to distribute unevenly sampling rate between channels (ie. could I give up 100ks/s for a single channel and spread the 150ks/s rest between the remaining channels in use)? Thanks in advance for any help,

Adam

Hello Adam,.

To answer your question on the sharing of the sampling rate, it is not possible to have a single module different sampling frequencies, as described in this KB: here (http://forums.ni.com/t5/Multifunction-DAQ/Aggregate-sampling-rate-and-Multichannel-Scanning-Rate/td-....)

In the case of the 9205 this module multiplexes between all channels (32 cases set up in single ended mode or 16 in differential) this means that the sampling rate of 250 kech. / s matches total on all channels.

If you are using the differential mode then the samples per second on each channel will be 250 kech. / s divided by 16, IE 15KS/sec. However if you only specify 4 channels max sampling frequency will be 250 kech. / s divided by 4, IE 62.5 kech. / s.

One way around this is to use 2 x 9205 in one of our new CompactDAQ chassis, which has 3 engines of timing to HAVE. This allows to set different timings in 3 different modules. What is described in this KB: here (http://digital.ni.com/public.nsf/allkb/E7036C1870F6605686257528007F7A72)

I'm sorry of this reply took so long, and I hope the above information helps.

Please do not hesitate to answer questions.

If you want I could get one of our technical sales engineers to give you a call to discuss further with you data acquisition system?

Kind regards

-

High sampling rate for 18 strings in a single task - DAQmx

Hello

My current experiences require the acquisition of 18 channels (6 HAVE custom voltage with excitement, voltage AI 12) data at a sampling frequency of 50 kHz. My question is if it is faesible using a single cDAQ-9172 chassis. Used modules are 2 x NI 9237 and 4 x NI 9215.

The previous researcher on this project used 2 different Renault to do this, but I was hoping that I could reduce it to a single DAQ to simplify the synchronization of all channels.

I wrote a *.vi (attached) to do this and write to a TDMS file using a structure of producer-consumer; However, when I run the * .vi, I can run for minutes, but the number of samples recorded for the PDM is rarely more than 100 k. Subsequently a buffer size error (attempted to read from the samples that have been overwritten) with less than 200 k samples ever record. I checked the max sampling rate (using a property timing node) with the configured task as in the * .vi and it shows a maximum of 235kHz.

I can't say if I make just the structure of the producer consumer incorrectly or if I ask too much of the cDAQ-9172 unique?

Any help would be much appreciated.

See you soon

Bart

Hi bart.s,

TiTou speaks sampling aggregate not simultaneous, so sampling rate 50kS/s is the same for all channels.

I see the problem in the loop of the producer. If your sampling frequency is 50kS/s/ch and you read that a single sample/ch you will lose data because the producer loop cannot run so fast. You should read more than one sample. I recommend you also to move your tracing to the consumption loop code and work with larger amounts of data.

The second problem may be with the error handling in your loop of consumer. Merge the mistakes of loop of consumer and producer and also add a few general for two loops off if the error occurs (for example, using local variable).

Best regards

CaravagGIO

-

Hello.

I have problem with maximum sampling on USB - 6259 of NOR. I measure the hearts of rabbits EKG and I need to know, what maximum frequency can I sample this signal. I use 10 channels and I don't know if the maximum sampling frequency is for each channel or one. I know, I use the sampling rate 1 MECH. / s, but I don't know if MECH. / s means MHz I do need knowledge rate (frequency) Hz sampling. I know that USB - 6259 OR maximum sampling rate 1 ms/s, and 16 bits of resolution. This means 2 MB/s, but it is for each channel, but only one? Can I sample my signal with sampling rate 1 MHz theorist?

Thak much for your answers.

Since you have only a clock unique convert and the channels are multiplexed, by channel sampling frequency is the rate divided by the number of channels max. In your case, you would be sampling each 100kS/dry.

-

So maybe this is a stupid question, but I need to know because I train for a specific sound. Is there a way [to logic] to shoot/change of a certain frequency sampling rates. I can imitate the sound I'm looking for with a low pass filter, reverb and a distortion. But I don't want to 'emulate', this sound, I want to create. Then I can put my own effects and play with it like I want to. If I have to use a bunch of effects to make it sound like I want that also the addition of said effects remove the sound and sound horrible. as to where pulling the sampling frequency of the high frequency and no downs will make me THE noise that I need and always allow to add nice effects to make MY sound instead of someone else. I hope you know what I mean. Let me to you specific real once more. I want to pull or carry a certain frequency sampling rates for a sound under water. I don't want to use filters to make the sound. So can you please help me. I invited everyone locally on how to do it and nothing works. Also if this is not possible in the logic of tell me if there are third party plug ins or maybe even a different DAW that could do like komplete Kontrol or audacity.

See if this thread is helpful at all...

-

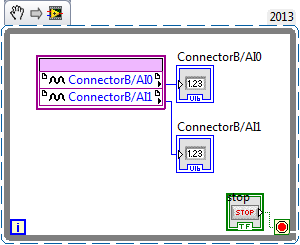

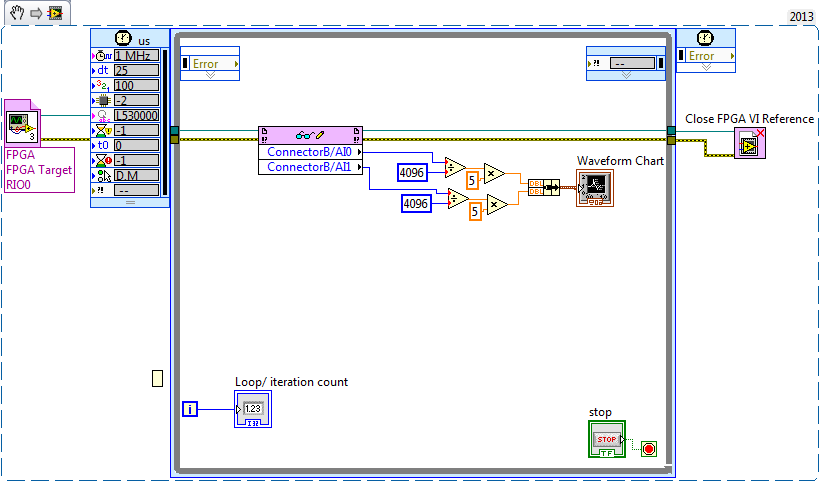

I'm new to myRIO and use it to measure sine wave (0V to 5V) of up to 10 Hz 20 KHz. I also quickly transformed of Fourier (FFT) of the signal measured in real time.

Sideways FPGA of things, I try to keep things pretty simple, just read 2 channels of AI (connector B: AI0 and AI1), therefore potentially able to read each HAVE 250 kech. / s (as the unit has a capacity of 500kS/s). Does that mean this program gets a two analog inputs data exactly every 4 microsecond? If this is not the case, how can I make sure that the data is acquired through a fixed sampling rate?

I realized that we can add to the FFT in FPGA function, but I wanted to manipulte the acquired data of analog inputs before it is sent to the FFT, which I don't know how to do now. Can someone explain me how do the arithmetic data (muliplication, division and so) on the acquired data and analog inputs to reducde the 12-bit resolution 10-bit to program FPGAS.

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

If I read in the forum for help, I couldn't have the full answer to my doubts

Discussions at the Forum I did reference:

A lot of good questions here, I will try to answer as much as I can so as to offer a bit of advice.

First of all, if you are looking to acquire data at a very specific rate on the FPGA, you'll want to use the Timer VI. You are also going to use a FIFO of DMA to transfer data of FPGA in real time. A node read-write using as you do now means you'll run out of samples, or read the sample even several times. The link below is a very good tutorial on how to do what I described above.

http://www.NI.com/Tutorial/4534/en/

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

In general, you should not run a timed loop much faster than 1 kHz. Using timed inside loop knots, you can monitor the real rate of loop during execution to see if f you meet your needs of the moment.

The portion of your myRIO RT is slower than an FPGA in the sense where it cannot manage the rates of lines 40 MHz (he makes up for it by being able to work with much better pictures) and it is important to remember that it is just a computer. The advantage of a real-time operating system, is that you have more control on the Scheduler, not that he is faster (less jitter, not faster code). There is more good reading below.

http://www.NI.com/white-paper/3938/en/

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

I would say that it is generally advisable to treat your FFT on the side FPGA as long as you have the resources available, but for many applications probably little matter ultimately.

Maybe you are looking for

-

How to turn on the light on the keyboard?

I have a new computer ENVY how to turn on the light on my keyboard?

-

How to make the current façade, as values of standard values (in an exe file)?

There are a few posts about this, but I couldn't find a satisfactory solution to this. Just an example of what I'm looking for a solution: the fronpanel includes a digital input element. I start the VI, change the value of the element of digital inpu

-

Lying VDI Desktop on Mac remote access

original title: Remote Desktop VDI on Mac I just installed on my Mac OSX Lion of mountain and can no longer access the Remote Desktop VDI. Apple customer service told me to check with Microsoft, if they have an update for OSX Mountain Lion.

-

Windows 2000 is the network via an ethernet connection does not work.

Windows 2000... CHANGED DIAL UPWARD... FOR ETHERNET I just installed a Lan card so I can connect an Ethernet cable to the router, as I had the OLD DIAL-UP CONNECTION to A TELEPHONE LINE...but I am unable to connect to the Internet... I checked my dev

-

"Windows Media Player cannot burn the files to CD" error while burning a CD

My Windows Media Player says "Windows Media Player cannot burn the files to the CD. Check that the disc is clean and not damaged. If necessary, select a slower recording speed or try a different brand of blank discs. I have burned several CD from Wi