2FIP % Ethernet NOR communication Allen Bradley

I want to communicate to the Allen Bradley plc cRIO (specifically ControlLogix L72, L73 or L725) via Ethernet/IP.

I am a beginner so I don't know exactly how to proceed. I downloaded the Ethernet/ip driver of OR. I just want to talk to one of the controller at the same time. Can someone give me some advice on where to start? Or give the code example.

Also it would be possible to simulate the cRio communication Allen Bradley plc using computer and cRIO?

Thank you

Hello

The NOR-Industrial Communications for EtherNet/IP includes several examples started getting. I suggest you take a look at EtherNetIP Adapter.lvproj in the finder of the example. "In LabVIEW, go to Help" find examples and search for EtherNet/IP. It should be the only option in there. There are some examples on the introduction to the communication of these devices. I suggest you take a look at the writing and reading Tag.vi for devices of Rockwell ControlLogix.

In addition, it is theoretically possible to simulate a PLC on the computer, but there is a bit of work to do. You can see this discussion here to get an idea of what is involved in the start-up of this.

Tags: NI Products

Similar Questions

-

Excel to Allen - Bradley CompactLogix .cvs file transfer

I am a new user of LabView and have not had the opportunity to go through training.

I have an urgent need to take an Excel spreadsheet (file = DX240_DB.csv) which has a range of 300 rows and 17 columns and send it to an array of Allen-Bradley CompactLogix L35E.

(Tagname = DX240_Data_Array, Data Type = 16-bit integer, Array Size = 300,17)

I'm going to a desktop computer (address = 10.10.10.179) via Ethernet to the programmable controller (10.10.10.180)

I was wondering if someone would have an example or a .vi which could be used to accomplish this transfer of data.

Hi J_Dogg,

You should be able to use DatSocket Read and insert the output of reading of the VI worksheet to the data of the old terminal. The two concerns here would be how to specify the source for the Read DataSocket connection and what kind of data goes in. In the first case, you can put the spreadsheet Excel on a URL and then specify this URL as the source. The kind of data that will is the variant, which means that Read DataSocket adapts to the nature of the data you feed. Please take a look at the example DS Reader.vi to understand how DataSocket Read is used. go to help > find examples and search for the above VI. I hope this helps!

Gregory C.

-

Driver for Allen Bradley Compatlogix or ControLogix

Before the project I'm looking for a Lookout driver who could work with CompactLogix or ControLogix Allen Bradley PLCs, Ethernet/IP protocol. There are 5 pilots AB Lookout, I will need a driver that works fully with these robots.

Please, no server OPC of AB, no serial...

Any recommendation?

Thanks to everyone who sent me their ideas and work around. I was looking for a direct driver in Lookout here talk CompactLogix AB and ControLogix PLC with Ethernet/IP protocol. But it is not to direct the driver to him, seems to me that the only way is using OPC Client/server like you guys, so I'll check the box as a response (or response) and close this topic.

I thought that the OPC of Lookout server will be good just to talk with other computers of Lookout, but I tried with Lookout 6.02. I had to put DCOM, and it worked! All the variables of abnd tags server-side appears in the client side!

Lookout is in itself a big OPC server, if you know how to use it.

Thank you all.

NOTE: The client mutual FUND of Lookout is real, all there need is a GOOD OPC SERVER, that's all.

Rudy Lopez.

-

RT webservice on allen-bradley panelview HMI?

Hello

anywhere I can find the requirement for the browser that will be used to display the a RT target wedsites?

I did a simple VI, just a few controls and indicators and I can easily see IE (even with silverlight disabled) - but the HMI shows only the title, then an empty picturebox where VI was supposed to be.

In fact just, I want to show an image on the Web page, nothing more - of ideas?

Henrik

Hi Henrik.

You must also install the enginer LabVIEW Run-Time in order to get the remote panel before working. After this installation, you should be able to use Internet Explorer. I also tried to use Firefox, and that seems to work perfectly.

How can I view a remote façade on my host computer?

I do not know the HMI that Allen-bradley is done, but according to this link

http://www.AB.com/en/ePub/catalogs/12762/2181376/1239781/1670480/10791114/12293528/introduction.html

Seems like they are run on Windows CE 6.0 with limited functionality.

I would recommend a newer operating system, like WES7 which are supported by OR.

http://sine.NI.com/NIPs/CDs/view/p/lang/da/NID/209369

Another idea is to use the dashboard of data. With this, you can publish data on LAN and connect an iPad that they are able to display the data and even give new data in your LabVIEW application.

-

I'm having a problem with the driver Allen Bradley. The help file says it "allows serial comm via a KE, KF or KF2 module. I'm using a KF2 device. I can check everything with RSLinx, see my program, RS that shows everything, but when I try lookout I still get the error "error STS 10 read xxx illegal command or format. Any help would be appreciated, thanks.

There are technicians OR out there who may know something about this? Anyone?

-

I have not so far had the chance to create a pilot for a PLC. I know few things about the PLC architecture, but what I read on the web. First of all, I would like to know is the similar to the 488 protocol driver interface. Can I simply write "string labels" in IP over Ethernet. Or do I need another tool to add to my labview to provide shortcuts to be able to write a driver for the PLC Allen of 5370 barley in LV2011.

I wrote a lot of drivers before by series and 488 but, it's my first PLC. I'm sure that once I had the chance to start on the interface, it will make sense, but now I'm unsure how to start. If the instrument I/O is string commands it seems straight forward. However I would need your experience and input for the best way to proceed to write the pilot and to monitor and predict.

Considers that Dwight Duncan

I have not personally developed a pilot for a PLC in LabVIEW from scratch, but I am familiar with interfacing with PLC via LabVIEW. If you looking to develop a code in LabVIEW that communicates with PLC of 5370 AB then I highly recommend exploring the EtherNet/IP toolkit for LabVIEW. It provides both implicit than explicit e-mail to send and receive data from a PLC. It also comes with several examples of starter to illustrate how to implement the functions correctly. I hope it's a little helpful!

-

Using the EtherNet/IP for industrial Communication driver

I downloaded this driver EtherNet/IP for industrial work with Allen Bradley PLC Communication. It works fine except one thing. I don't see a way to approach a long data type. Does anyone do this? I tried a lot of different things and had no luck. I added a comment on the bottem of the page to download as well.

http://decibel.NI.com/content/docs/doc-4065

Since it is a NI Labs product, you should probably post the question on the Support page of the industrial EtherNet/IP protocol. Developers and users of the pilot are looking at this page for support purposes.

-

I'm evaluate Labview now to see if that's what my company wishes to use. I try to test a CompactLogix AB Ethernet/IP communication and get an ICU error.

I can't get an idea clearer picture of what really means the error.

I've attached a screenshot of the error window. Any ideas?

See here

http://forums.NI.com/NI/board/message?board.ID=nilabs&message.ID=217&query.ID=1419258#M217

-

Has anyone connected a system Labview 7.1 worm with an Allen - Bradley Ethernet Contrologix PLC?

Have you tried a Search?

You may be able to use these. It does not say what version of LabVIEW, they are written. Given the date, I would say it is a recent version of LabVIEW. If you need them for saving on the back you can post request in the thread Downconvert queries .

-

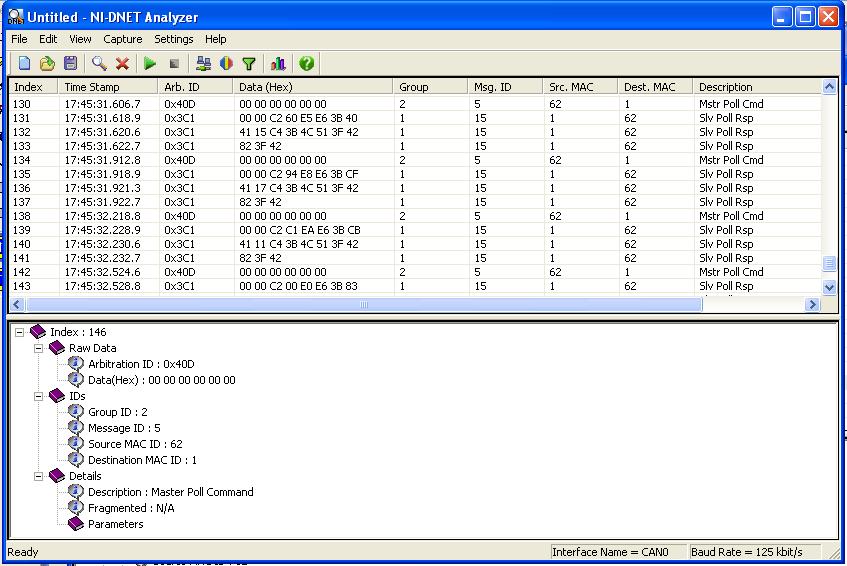

I use a card PCMCIA-CAN, series 1, first with NOR-DNET 1.6.2 and 1.6.3 now and I monitor traffic between an Allen Bradley SLC 5/04 with a scanner of DeviceNet 1747 - SDN. The scanner MACID is 62, and the unit is MACID 1. When I start it, I get normal Dest. Fields of MAC and the Description, as shown here:

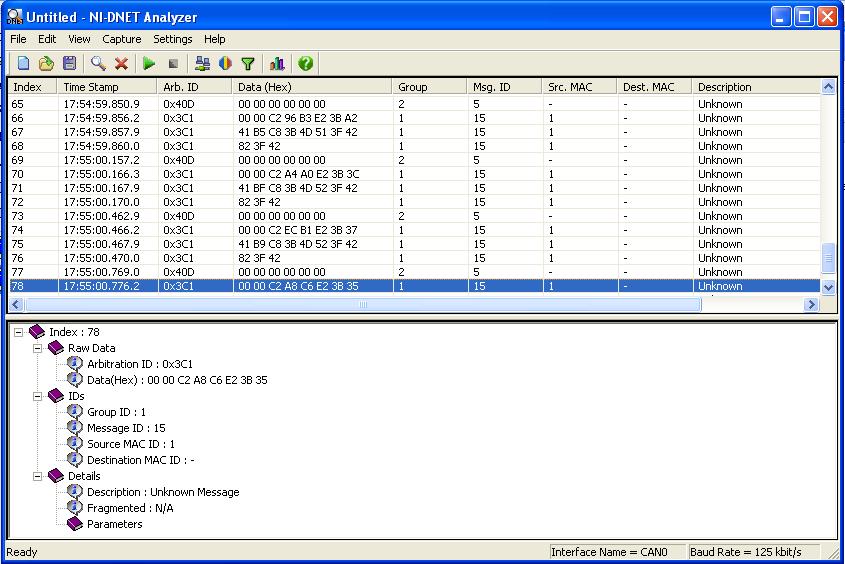

If I click on the Red Square button 'stop', and then the green "run" button, I get the following results, with dashes in the two fields MACID if the source is 62 and go always in the Dest. field. The description always says 'unknown '. The PLC device and e/s continue to communicate normally during this period.

To clear this point-, I unplug the cable DeviceNet controller and plug in again - this always clears the problem and it starts showing the right data again. Clues about what is happening?

This is an expected behavior in monitor OR DNET.

DeviceNet is a basic state machine Protocol. The parser need the message of setting up connection to know what a CAN ID is linked to a connection of IO.

Figure 1 works well because the parser also captures the message of establishment of connection and the following messages of e/s or EM. So, it can analyze a package type and detailed information.

Figure 2a of many "unknown" because the Analyzer only captures the following messages of e/s or EM without the connection message. (Notice: parser won't 'remember' the last message of setting up connection after a new 'start capture'.) It ensures that the state machine is supervised in a State of cleanliness).

The key to this question is always to capture the packets including the wiring diagram. The safest way so start to capture before your scanner DeviceNet starts to work.

NOR-DNET Analyzer supports the logging of large file. You can connect a large file and analyze the messages by filtration or research.

-

Windows Media Player makes calls of NOR-fast Motion (Revisited)

About 2 years ago, I posted a message on this forum about a condition where running Windows Media Player increased the rate that my Visual Basic 6 program has been able to contact a PCI-7344 Panel using calls OR-Motion (original post). To summarize the post, my VB program be called functions OR-Motion speed after that the computer is started and simply in the process of running Windows Media Player would allow my program make calls of NOR-faster Motion. I created a program demo, posted and was able to reproduce the situation constantly using several different computers & cards PCI-7344. However, no one at National Instruments could reproduce that; It seems that the calls function always ran fast for them and never ran slowly. I finally gave up and let the issue of dying and said reluctantly, our customers just start WMP to increase the speed of the machine.

Now, I'm working on rewriting the software to the machine using VB.NET 2008 and Windows 7. My first hope was that the problem had gone with either the new VB, or Windows 7, but that doesn't seem to be the case. When I was with Windows XP, I could get recall for an improvement of the functions running WMP. With Windows 7, I can not get the increased rate even after the execution of WMP.

Today, I took two new computers identical and loaded Windows XP on Windows 7 and one on the other. I put a new PCI-7344 card in each computer. I then installed version 8.2 of NO-Motion on each. With the exception of Microsoft .NET 3.5, which is necessary for my test VB.NET program, no other software has been installed, do not even Visual Basic. I started on each PC, ran my test program to determine the calls/sec, start Windows Media Player and my test program is represented. Here are the results:

Test Windows XP & VB 6 program-128/s before launching WMP, 1024 Kbps after the execution of WMP

Test of Windows XP & VB.NET 2008-128/s before WMP program, 1024 Kbps after WMP

VB 6-256 calls/s before launching WMP, 256 Kbps calls after execution of WMP and Windows 7 test program

Windows 7 test program and VB.NET - 256 Kbps calls before you launch WMP, 256 Kbps calls after execution of WMP

As you can see, WMP has increased the rate of call of function OR-Motion on Windows XP, but has no effect in Windows 7. In addition, it did not matter which version of Visual Basic has been used.

My first question is: what determines the rate at which he called on a NOR-Motion function? It seems that the maximum is 1024/s, which is consistent with what I saw 2 years ago even on slower computers. I would have thought that would be a faster PC function calls could also be made faster, but appears not to be the case. And is there some significance at 128, 256, and 1024 rates?

My next question is: someone at - it else noticed faster or slower speeds using NOR-Motion after moving to Windows 7?

The software that I work on the controls, a machine used on a production floor where the cycle time is critical and even save a fraction of a second can be important. With Windows XP, we have reduced the cycle time of 5 or 6 seconds by running WMP. We would like to start using Windows 7, but we won't be able to if it means cycle slower times on our machines.

The source code for VB 6 and VB.NET 2008 for the demo program is attached. This is the computer that I used for the test today, but I was also able to reproduce this on computers Dell, LS, Xycom and Allen-Bradley. I also used several different versions of NOR-Motion and WMP with the same results.

-

Hi all

I am very new to connect via Ethernet/IP and I got the mission to integrate a SMC EX600 Ethernet/IP fieldbus module into a labview system. Currently, the EX600 is attached to 10 solenoid SMC and SMC 8 SOP 2 digital input modules.

I did some research on here, and it seems that I got myself a bit confused on the ability of a Communication and the Communication Scanner adapter. What I read, the EIP Toolbox is an adapter, so it cannot start I/O communications between other adapters. It turns out the SMC EX600 is also one adapter per pg 29 of the data sheet (http://www.smcworld.com/upfiles/manual/e/EXxx-OMN0032.pdf), bad luck. So I have reason to assume that implicit messaging is out of the question?

This might be fine with me, as I don't need a constant flow of e/s and I would rather contact the EX600 on a point-to-point basis. In reading some posts, I found that explicit messaging is supported (http://forums.ni.com/t5/Industrial-Communications/SMC-Valve-Ethernet-IP-Communication/td-p/2979621). This means that I can always get the status of a digital input port or set the position of a solenoid, correct?

Define States of solenoid valve using messaging explicit or by reading the data sheet, I'm at an impasse on how I actually read entered digital. Could someone clear this up for me? Thank you.

Quick update,

After a careful reading, I was able to communicate with the MSC EX600. Using the example of Assembly (Explicit) .vi access Instance data I could read the State of the digital input modules, as well as to define the State of the digital output module and operate solenoids on valve battery module.

On page 60 of the manual (http://www.smcpneumatics.ie/media/EX600-SEN1_2-Ethernet.pdf), it describes which instance of the assembly to use when specifying inputs or outputs. Using these values, I get a decimal number response corresponding to the State of each module. Convert this number in binary retrieves the value of bit for each individual digital line. Digital outputs are processed similarly except that you write the digital number.

Valves after your output in table modules and are managed by groups of 4, because there might be 2 solenoids by valve on some configurations. 0 disables the block of 4 and 255 turns on the block of 4. The correct binary value convert decimal to obtain the desired combination.

I hope this post can help someone who has the same problem on the road.

PS: Don't forget to put your EX600 have a static IP address before you do all this. The utility BootP rockwell has not worked for me, but this one did http://www.anybus.com/support/support.asp?PID=509&ProductType=Support%20Tools

-

ERRORDSNF on all the resources NOR-FBUS 3.1.1 blocks.

Does anyone have experience with the ERRORDSNF on all blocks of resources on a network?

I'm trying to connect a new device to an existing network, but it won't let me download

I'm new to Fieldbus Foundation and we have NEITHER-FBUS 3.1.1 with devices of liaison 1788-CN2FF Allen - Bradley.

The values in the PLC program are changing, so I know that communicate the devices on the network.

Hi GCobb,

Edit:

Please refer to the post herefirst.

And try these newer files in the attachment to this post.

--------------------------------

Only the new device you connected on the network has this issue, or all devices have this issue when the new device is connected? I mean if you can refine the device which has caused this problem and separate and then check what was wrong with the device, or PLC programming or whatever it is.

Regarding the diagnosis, the diagnosis to a tab helps block.

Regarding the error message, the fcs.pdf that comes along OR FBUS installation has a chapter entitled: Messages of error and warnings that explains OR-FBUS Configurator error messages.

Thank you.

-

File reading EDS for EtherNet IP

Hi friends,

I need to check the file EDS for EtherNet IP communication. I want to read the EDS file, check the details of the seller and the parameters which are written in the EDS file in order to check.

Is it possible to read the file EDS for EtherNet IP?

Kind regards

Ganesha Moorthy

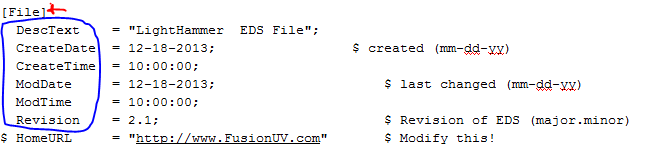

Hi gnshmrthy,

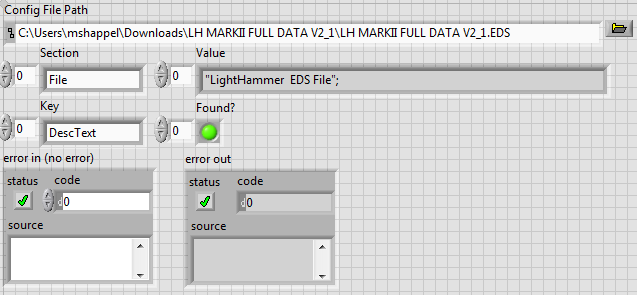

The example displayed KB should work with your EDS file. I was able to use it successfully with the default values for the section (device) and the key (VendName). I think that you run into questions because you are using an invalid value for the key. In this image, I use a red arrow points to the section and I'm circling the different keys that are valid.

As a result, you should see results like this:

Let me know if it works!

-

I am communicating with a PLC using ethernet IP. Currently I use poling in time event to read PLC labels but wants to set up an event to automatically respond to a change in a tag value. Does anyone know how to do this?

Unfortunately, keep voting PLC, since the library is not for you. What I recommend is to use another loop for Ethernet/IP communications and send a user event when a value changes to inform your main loop.

Maybe you are looking for

-

backup impossible ipod classic 160 GB in itunes

backup impossible ipod classic 160 GB in itunes

-

Hello, im thinking about buying the y2p and upgrading the RAM 4 GB version later. Is this possible?

-

Most of my desktop icon reflects works such as the program to open the files. I get a pane that says that Windows cannot open this file and select the program from a list. Choose which program for all the icons open and be able to reset the default

-

How to remove the virus Vista Home Security 2011?

Vista Home Security 2011 has blocked internet activity from my computer. It is unregistered and I can't understand how deleted.I did a full scan with McAfee and it blocked three viruses. I see the path of the program, but cannot locate. C:User/Joe/A

-

BlackBerry Skype on BlackBerry Smartphones?

Is it possible I can get Skype on BlackBerry smartphone?