amplification of the strain by using the cDAQ

Hello

I am a newbie in the use of DAQ hardware and hope someone can help out me.

I recently bought a cDAQ with the NI 9237 to measure the strains. The strains that I try to measure are very small 1 series micro. A bit of research showed me that I need to amplify the signal to measure these small strains (correct me if I'm wrong). But I'm not able to find amplifiers for the cDAQ.So, the questions I have are-

1. is it possible to measure these small strains (1 strain micro) using the cDAQ? If so, do I need an amplifier?

2. If I need an amplifier, are there more specific for the cDAQ with the 9237? If this is not the case, how and where can I get one?

Thank you

SID

SID,

These results were very shocking for me also, so I looked into it further. It seems that the 9237 can do better. Assuming you're within 5 degrees of the calibration temperature (25 ° C), 9237. 05% of span of error and. 05% offset error. With the range of configuration and 25mV/V full-bridge, you can calculate the absolute accuracy of the 9237 with the following formula. (Sound of full-bridge = 0.9 microV/V)

absolute accuracy = (gain error * reading) + (error offset * range) + (noise)

Do the math, we get

25mV/V + / 25.9 microV/V

In a full-bridge configuration: V/Vex =-(Gauge Factor) * strain

With a typical GF of ~ 2.0, we can say that the accuracy of the strain will be

12.5 mm/m + / microm 12.95/m

It's a little more in the range that you hoped for. Sorry for the confusion.

If this does not work for you, we sell solutions PXI who will be able to measure more precisely. Similar math help and type of configuration of full-bridge with SMU 4330 plug, we get:

12.5 mm/m + / 3.48 microm/m

In my view, that it is card data acquisition based on a bridge more precise and accurate that we sell. It requires a controller/chasis PXI.

Please let me know if you have any other questions!

Sincerely,

Tags: NI Hardware

Similar Questions

-

Run an application of LabVIEW 8.6 in win 7 (using the cDAQ-9172, 9219, 9422)

Hello.

I did a LabVIEW application for a few years. At that time, I used windows XP and labview 8.6. The material used is the cDAQ-9172, with NEITHER-9219 (reading of four strain gage sensors) and a NOR-9422 (using only a single input frequency).

First of all, can I install my old version of labview 8.6 in my 64-bit computer to windows 7? I got an error message when I tried...

Second, how much should I install? My old computer was slower after you install labview with its pilots. Perhaps I installed too much? Do I have to install 1, 5 GB DAQmx drivers?

If I need a new version of labview for win 7, how much is an update?

Thank you!

Hello

First version of LabVIEW which is supported on Windows 7 is LabVIEW 2009 SP1.

Regarding the drivers, if you want to develop or run VI:s in LabVIEW with the DAQmx API, then you must install the full DAQmx driver.

If you only meet built executable in the LabVIEW environment to run, then you just DAQmx Base Runtime.

If you also want to be able to configure the data acquisition equipment (to the MAX) in a runtime environment, you should also Configuration DAQmx execution.

For upgrades of licenses if please contact the local office of National Instruments or follow this link:

http://ohm.NI.com/advisors/UA/pages/UA/intro.XHTML

Best regards

Klas Andersson

OR Sweden

-

Online use of relaxation on the cDAQ-9181 with a cRIO-9401 module

I'm trying to accomplish something very simple with the cDAQ-9181 and cRIO-9401 material: when a trigger occurs, wait 20 ms and then set some digital output lines. Reading the documentation for the cDAQ-9181 and cRIO-9401, I see that there is a trigger of PFI0; I do not see a physical entry for it, so I guess that it is implemented internally in a way. I tried to use a digital camera of entry as a trigger, but I get the error-200524 with my code. I looked if the examples, but I don't see how to do it with my gear. Help, please. Thank you. See attached png for the block diagram.

-

Module AO trigger using PFI on the cDAQ-9188

I use a cDAQ-9188 chassis with an AO (NOR-9264) module. Is it possible to configure a PFI (channel on the frame) as an input signal to synchronize an AO channel with the trigger? Here's what I'm trying to do. I need a channel on the AO module to switch voltages in sync with the trigger when the user "push a button". So once the button is pressed, the channel of the AO will not change until the next trigger pulse.

Thanks for your help

Ben

Hello Ben

I hope you are well. The consensus is that it is possible. Have you tried this yet? If so, can you tell me what you have tried and how you made a lot of progress? I recommend the following VI example: Cont Gen tension Wfm - Ext Clk.vi. Are you able to get all the functionality you are looking for this VI. It was recommended that I'm showing you this. We find this VI under help--> find examples and then material input output &--> DAQmx-->--> voltage analog generation.

Please let me know how you are progressing and if you have need of all aspects of this example explained. Thanks for choosing National instruments!

Sincerely,

Greg S.

-

The SD cards are recommended to be used with the cDAQ 9133?

Embedded controllers that are the recommended type and size recommended SD cards to be used with the cDAQ Win7 9132 and 9133?

Hardware specifications for two controllers, you will find that the SD and SDHC cards up to 32 GB are supported. There is no model or brand recommended, but there are 16 GB (783658 - 01) and 32 GB (783659-01) maps available for purchase through the OR. You can find those listed in the accessories section available hardware user manual. See the fees section of the controller product page for more details.

EDIT: Linked to the UNIFIED and product Messaging page

-

Why an amplification of the RAM does not change the index performnance of windows vista?

Why an amplification of the RAM does not change the index performnance of windows Vista?

Hello

I m not very well, but maybe you have more than 3 GB of RAM and Vista 32 bit.

Usually the 32 bit OS is capable to manage and send only 3.2 GB.

The more than 3.2 GB RAM will not operating system used and therefore would not increase the index

In addition the laptop will be not really faster after upgrading RAM. You will notice better performance using applications at the same time, but this does not affect the index of Vista.

But this is only my personal hypothesis.Welcome them

-

How many quadrature encoders may be read together with the cDAQ-9188 chassis?

We will record position periodically 8 engines (at the same time as we are to the corresponding samples entered analog). It seems that the 4 built-in counters limited chassis to 4 encoders. Is this correct? I am familiar with modules of counter PLC which manage high-speed counting, and then the CPU posts periodically to update the total values. This is how the NI 9401 card would work?

Hi jtrout,

You are right the 4 built-in counters than the cDAQ-9188 chassis 4 encoders. The following article deals with the use of the NI 9401 card for encoder measures: http://www.ni.com/tutorial/7109/en/.

-

I have 4 new cDAQ-9132 systems that go into the production thgis week. During the last two weeks that these systems are running, they break. Here's what's happening.

1. the system runs our application, or in some cases, just sitting there running Windows 7

2 the screen goes black, and there is no further response from the system. The power light on the controller is running.

Restart the monitor doesn't do anything, unplug and reinsert the VGA does nothing. No response from the keyboard at all.

3 press the RESET button or power cycle using the power button will restart the computer. Windows error logs have no information at all at the time of the accident, clean everything up to the new entries to the log at startup.

A strange thing about setting, is that there are very long VGA and USB cables. 16 feet. Two USB cables go 16 feet each two separate powered USB hubs. A hub has a touchscreen and keyboard, the other hub has a barcode scanner and a printer.

Four of these systems have all have the same symptoms. All four grids have a 9229 and a 9422 of each.

I set the bios on a USB overcurrent in the operating system report and stay OFF If there is a power failure. We used a stroke of luck using Min/Max to check the variability on power supply 24VDC used for controller, nothing was found. The controller has its own dedicated to food. Due to a quirk of the command, two system have a 24V supply type, the other two systems have a different provider supply. All the supplies are more than adequate for the controller.

You can provide any assistance is greatly appreciated!

Hello Palickar,

Is it possible to try to launch the cDAQs without long USB cables to exclude them as causes of accidents? If the chassis still crash without long cables USB, then maybe it might have something to do with the way in which power is supplied to the chassis.

Could you confirm that your installation complies with the section titled "electrical wiring for the cDAQ-9132 OR? :

-

Compile 32-bit programs on the cDAQ RT Linux

I have a (OR-9134) running Linux RT NI cDAQ

I am unable to get it compile 32-bit programs. The steps I've done were:

1 used "opkg" to install all the 'gcc', 'CPP', "gcc-symlinks", etc. - that I could see associated compilers.

2 export CFLAGS = "-m32' export CXXFLAGS ="m32", export LDFLAGS = 'm32'"

3 CFLAGS = "-m32". / configure

However only 64-bit binary are generated.

I'm unable to find through "opkg" all packages associated with 32-bit builds or anything related to 'multilib '. Could you get it someone please let me know how do NI Linux RT generate binary 32 bits?

Looks like you are saying that you need a 32-bit library to work with 32-bit LabVIEW. However, LabVIEW on your target cDAQ is 64-bit, as all software on our basic objectives of Linux RT Atom (the ARM-based targets are 32-bit). So, if you want your HDF5 library to run on the target of the cDAQ to 64-bit, you must use a 64-bit version of HDF5. This is true even if you connect/deployment to the target of a 32-bit version of LabVIEW.

Of course, if you want to run HDF5 on a 32-bit system, as a target of LabVIEW RT with ARM 32-bit processor, or LabVIEW RT older targets that use VxWorks or Phar Lap instead of Linux, or a 32-bit desktop machine running Windows or any other OS, you will need a 32-bit version of HDF5. But I would not recommend trying to build HDF5 for these environments of your cDAQ. I recommend compiling natively on the cDAQ, if you at all (*), for the code, you intend to run on the cDAQ.

(*) You should be aware of this already, but you can cross - compile your HDF5 library using Eclipse, i.e. http://www.ni.com/download/labview-real-time-module-2014/4846/en/ - some people prefer this to the compilation on the target, which is a little limited resources.

-

The transition of the cDAQ to cDAQ ENET USB

Hello community,

For some reason, I'd probably change some of the cDAQ USB chassis that I use for the Ethernet frame cDAQ base. I already have some applications developed on the platform of the USB and I was wondering how painful (or even at all) migration from USB to Ethernet. I guess also assign an IP address to the chassis and set it up in MAX, it should be relatively easy.

It would be nice to know about problems I can cope.

Thank you.

As far as I saw, just that everything is set up in MAX, and then it is homogeneous in all of your applications. You may need to remove all instances of your USB cDAQ located in MAX in order to reuse the virtual name.

-

buffer size and sync with the cDAQ 9188 problems and Visual Basic

Hi all, I have a cDAQ-9188 with 9235 for quarter bridge straing caliber acquisition module.

I would appreciate help to understand how synchronization and buffer.

I do not use LabView: I'm developing in Visual Basic, Visual Studio 2010.

I developed my app of the NI AcqStrainSample example. What I found in the order is:

-CreateStrainGageChannel

-ConfigureSampleClock

-create an AnalogMultiChannelReader

and

-Start the task

There is a timer in the VB application, once the task begun, that triggers the playback feature. This function uses:

-AnalogMultiChannelReader.ReadWaveform (- 1).

I have no problem with CreateStrainGageChannel, I put 8 channels and other settings.

Regarding the ConfigureSampleClock, I have some doubts. I want a continuous acquisition, then I put the internal rate, signal source 1000, continuous sample mode, I set the size buffer using the parameter "sampled by channel.

What I wonder is:

(1) can I put any kind of buffer size? That the limited hardware of the module (9235) or DAQ (9188)?

(2) can I read the buffer, let's say, once per second and read all samples stored in it?

(3) do I have to implement my own buffer for playback of data acquisition, or it is not necessary?

(4) because I don't want to lose packets: y at - it a timestamp index or a package, I can use to check for this?

Thank you very much for the help

Hi Roberto-

I will address each of your questions:

(1) can I put any kind of buffer size? That the limited hardware of the module (9235) or DAQ (9188)?

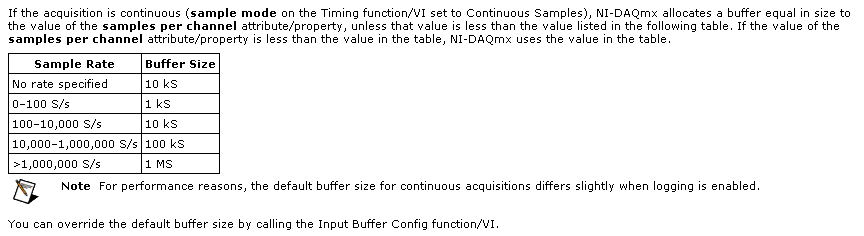

The samplesPerChannel parameter has different features according to the synchronization mode, you choose. If you choose finished samples the parameter samplesPerChannel determines how many sample clocks to generate and also determines the exact size to use. But if you use streaming samples, the samplesPerChannel and speed settings are used together to determine the size of the buffer, according to this excerpt from the reference help C DAQmx:

Note that this buffer is a buffer software host-side. There can be no impact on the material available on the cDAQ-9188 or NI 9235 buffers. These devices each have relatively small equipment pads and their firmware and the Driver NOR-DAQmx driver software transfer data device to automatically host and the most effective way possible. The buffer on the host side then holds the data until you call DAQmx Read or otherwise the input stream of service.

(2) can I read the buffer, let's say, once per second and read all samples stored in it?

Yes. You would achieve this by choosing a DAQmx Read size equal to the inverse of the sampling frequency (during 1 second data) or a multiple of that of the other playback times.

(3) do I have to implement my own buffer for playback of data acquisition, or it is not necessary?

No, you should not need to implement your own stamp. The DAQmx buffer on the host side will contain the data until you call the DAQmx Read function. If you want to read from this buffer less frequently you should consider increasing its size to avoid the overflow of this buffer. Which brings me to your next question...

(4) because I don't want to lose packets: y at - it a timestamp index or a package, I can use to check for this?

DAQmx will meet you if all packets are lost. The default behavior is to stop the flow of data and present an error if the buffer of the side host DAQmx overflows (if, for example, your application does not pick up samples of this buffer at a rate equal or faster than they are acquired, on average).

If, for any reason, you want to let DAQmx to ignore the conditions of saturation (perhaps, for example, if you want to sample continuously at a high rate but want only interested in retrieving the most recent subset of samples), you can use the DAQmxSetReadOverWrite property and set it to DAQmx_Val_OverwriteUnreadSamps.

I hope this helps.

-

synchronize 2 cDAQ-9215 modules on the cDAQ-9174

Hello

We collect 8 channels of the AI of the comments about 32KS/s, but they must be synchronized with precision. We intend to use 2 CDAQ-9215 modules mounted on a CDAQ-9174 chassis. This system will do the job? And what kind of calendar and clock configuration should I use to improve the precision of the synchronization.

Thank you.

Hello

I'm sorry I didn't know not the 9215 was a simultaneous module. Instead of the S series card, you should be good to go with a 9174 and 2 9215 modules. If you use the same DAQmx task to run on all 8 channels acquisition they share all the same timing engine and snack at the same time.

-

Frequency control of NOR-9476 on the cDAQ-9188

I am using a cDAQ-9188 with a NI 9476 module, and I would like to control the frequency of the digital signals that the module was released. I tried to use the example of Pulse Train digital continuous with control of the frequency, but impossible to select the 9476 since there is no internal counter, and when I change the 'Digital output' task, the frequency control disappears. Is it possible to use the internal counter of frame to control the output frequency of the 9476? I need to get out a range of 0 to 1 kHz.

Most of my program would output a digital signal of a certain frequency every second in real time from a given table. For example, if I have an array of [10, 20, 15, 100,...], it generates a model of up/down of 10 cycles per second for a second, followed by 20 cycles (with a shorter period) for a second, then 15 cycles per second for a second, and 100 cycles per second for a second.

I tried to use avoiding to do, but it was very slow, with a delay of 63 ms between each cycle, when I wanted a 1 ms delay.

CDAQ-9188 has 4 counters built in, but you cannot access it by using the NI 9476-, but the NI 9401 module can access the built-in meters.

The good news is that you can always generate your pulse train, using counters, it generate on the PFI lines on the chassis itself and not through your module. If you need to generate more than a pulse train, or use all four counters, you will need the module NOR-9401/9402.

In order to get the speed, you will need to use the capabilities of hardware counters timing.

I hope this helps!

For more information:

-

Hi all

A complex project I have to implement an interface acquisition of material for a linear motion sensor using the output of the synchronous serial (SSI) commune in the control of the industrial movement. (I have a bit of experience in digital electronics, but I'm new to hardware synchronized timer e/s digital in LabVIEW).

To do this, I need to create a clock timed by the busted hardware signal pulse train TTL. Each burst consists of 25 down transitions, with a period of complete cycle of 2.67 microseconds (375kHz). The output is then held high until the next outbreak, that produce at 1ms intervals.

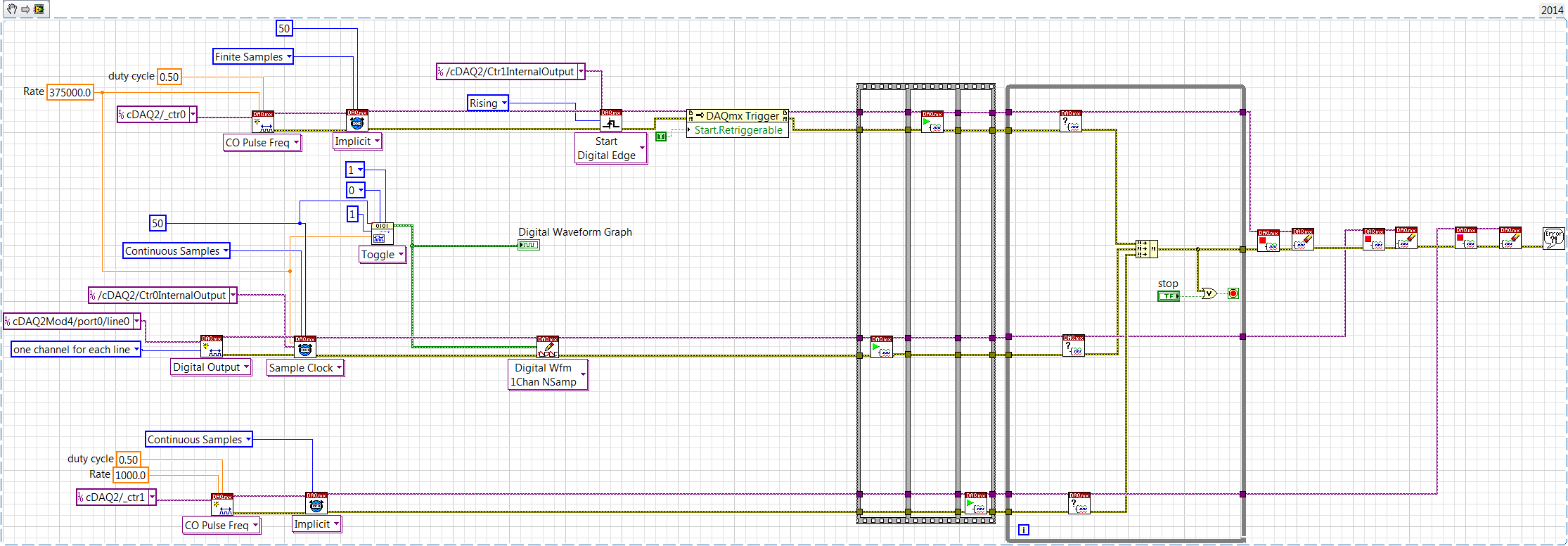

Using of cDAQ timers and a NI 9401 (based on the example http://www.ni.com/example/30256/en/), I was able to create the pulse train burst as described (see attached image VI). Then I need to configure another timer to set off this explosion to repeat at 1ms intervals.

Someone at - it guidance on how best to accomplish the hardware timing for the repetition of the pulse train?

Any suggestions of alternative strategies or observations about the way that my noobish code is stupid or ineffective are welcome as well!

Thank you!

Hello RyanBiggs,

You will need to perform the following operations based on the code that you have joined.

- Set up a second output continuous counter task which will give an impulse to 1000 Hz.

- Set up your first task of meter output to start according to the configuration in the first step using the vi DAQmx trigger.

- Configure the first task of the meter output to redeclenchables via the property node so that the output meter pulses when he sees a rising from the second task of meter output.

The implementation is shown below.

Kind regards

Izzy O.

Product Support Engineer

NI.com/support

-

The cDAQ-9134 USER1 play button

Hi all

My idea is to use the User1 on the cDAQ-9134 chassis to start recording.

How to read this button in my VI (Windows)?

Many thanks in advance,

Thomas

Hello tom1757

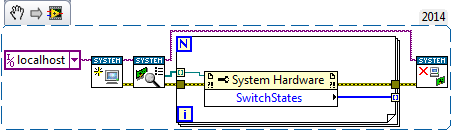

I don't have the material at the moment. You can change the seal snipped for only

read you the 9134 material switchstates.

I hope this helps

Maybe you are looking for

-

Can we see it? Are they able to answer? I think that the mo forum is broken, or is not yet open, it's just a test

-

Windows Explorer does not and sound problems

I'm running Vista (home edition) on a laptop and I'm having problems with my windows Explorer. The other day it was working fine and I have updated to service pack 2, after he installed my computer went crazy! My exporer windows keeps "not responding

-

Two months ago, I bought a 8 GB clip which I use it in Germany in European mode (in increments of 0.05 MHz in FM transmitter location). The clip found some shippers of FM. When I listen to one of them, after some time (5-10 minutes) is deteriorating

-

Error: BT Yahoo is not available due to a long-running script. How can I remove it?

Original title: a long-running script Why constantly to make the message-' BT Yahoo is not available due to a long-running script. How can I remove it?

-

XPS 13 9350 - USB DAC - severely distorted Audio

Hi all I'm playing a DAC USB files DXD (352.8 kHz FLAC) and I'm getting intermittent severe distortions which, to me, looks like a problem of USB transmission caused by the DPC latency. My configuration is: -Earn 10 Pro-jRiver MC21-Mojo chord connect