Analog output on and out bike

Tags: NI Software

Similar Questions

-

Hello

I have a power meter which provide the USB driver and a Labview program to get the data and NI USB-6221. The project I am currently working on the needs of:

1 acquire two signals (inputs of simple tension), pressure frequency KHz

2. acquire a flow signal, the output signal is 0 to 5V pulse, each pulse means 0.4 ml volume. So I use a voltage inflows to count impulses in certain period of time (in this case, 1 S) for water flow. ; KHz sampling frequency and the 1 Hz update rate

3. acquire a signal of engine speed. The output signal is pulse square wave whose frequency is related to the speed. I use a REIT port to measure the frequency. Sampling rate: Auto

4 give output voltage sine or square wave, I use AO do that.output rate: Auto

5 acquiring by VISA electricity meter data. Data update rate: every 50ms

Currently, all the 5 tasks work well separately. But when I put them together, some signals are beginning to hang, for example, pressure signals sometimes give nothing.

Another problem is the data record. I programmed the VI in such a way that whenever I press the button 'save start', he begins to record data and save them in a .cvs file. For some reason, I always get only the data in the first table. Coult someone help me? I download my code as follows

Hello

What I meant by open, write, close. For any type of file you are using.

Open the file, which produces a reference, then put the mention in a registry to offset.

Write data, using the function write (for this type of file) and the reference.

When you are finished, close the file reference.

Writing in the spreadsheet opens, written, close all at once. It is very good for this type of application.

***

The issue of the loop is more general. I would like to say first of all, I want to say that since each loop works on its own, it is own VI, and that this program has put all this into a single VI, which has a method to solve the problem is to disable all the loops and allow them one at a time to see if there is a culprit responsible for.

Using multiple loops executes the code at the same time, and some loops would be cycle faster than others, especially if some of them are loops just as they are.

Communication between the loops is a test to the address if necessary.

Running all these signals through different loops DAQ must also be examined. Don't know what questions are for read and write somewhat randomly in the channels.

-

Analog output of access on fly buffer

Hi all

I have a X Series DAQ and made many analog inputs and output tasks. My question is that can an analog output buffer be accessed or modified during execution of the task? I have a redeclenchables analog output task, and I want to replace the buffer after a trigger is done before the next coming. Is this possible? Or put it in general, how can access us the buffer without re - create the task?

Any comment is welcome. Thank you.

Hi Skuo1008,

Which development environment you use to write this code? You mentioned a textual DAQmx function above in this post. Using LabWindows/CVI or ANSI C?

Take a look at these examples:

Generation of analog waveform with update with DAQmx output buffer

http://www.NI.com/example/25039/en/I have also attached to this answer

-

How to write constantly to analog output and read from analog inputs

Hi all -

I had a question about writing continuously to analog output reading simultaneously an analog input.

It's my first time to post a message to the community, so please let me know if I made mistakes.

I use Labview 2011 with a NEITHER-DAQ USB 6215.

I'm looking to generate a waveform and write it continuously in an analog output. It is then connected to an entry on the acquisition of data, where I am trying to sample the analog signal. (I realize, there is a system of trivial, but I'm hoping to build on it once I have run).

The task of reading from the analog input works fine, as I tested it in several other cases. I have a problem writing to the analog output.

For this task, I tried to follow the "Gen Cont Wfm Clck Int' VI to generate the wave form and start the task. I then try to write to the output of the analog timed loop. However, it does not seem to transmit a signal and doesn't give me any errors.

I have attached the VI but also a screenshot.

Please let me know if anyone has any ideas. I would really appreciate the help!

Thank you

Peter Borgstrom

We will review your tasks one at a time. First of all, the task of generation/Analog output Waveform. Generate you a waveform (I'm unsure of your VI if it is a fixed waveform or not) and send it to a defined output function to produce a waveform continuously, using N-channel and samples of N (where you set not these previously). You should not put this inside has timed loop, as the DAQ hardware has its own clock - if you simply put it in a while loop (with a stop to break out of the loop), the loop will call the function for the first points of N, wait until all N have been taken out, then call it again to another N points (up to what you press Stop).

Now, suppose that you have the output connected to a load voltage (say a decent resistance). You can wire the input terminals of your A/D converter through the same load and set up a similar analog input loop, running in parallel (i.e. in its own independent of the OD loop, while loop). You pourriez start together (with, say, a merged error since the initialization code line loops HAVE and AO become lines of error in "loops of sampling" described above), but you might want to delay loop (a little) the AI so that the OD has a chance to set the voltage before the bed.

I hope this helps.

BS

-

To input analog shutdown when the analog output is completed and synchronization

Hello

I'm trying to get my LabVIEW program to send analog output to a computer and read acceleration using the cDAQ-9184. Chassis output that I use is the NI 9263 and the chassis of entry is the NI 9234. I generate a signal of white noise using LabVIEW Express signal generator.

The first problem I have is the synchronization. I had an old VI that has begun to measure the acceleration just about a second after the entry has been given to the machine. I used the LabVIEW tutorial on how to sync the analog input and output, only to discover that it does not work with two different hunts. Then I found another tutorial that shows how to synchronize different frames between them.

The second problem is the cessation of the LabVIEW program. What I want to do is to generate the signal and then simultaneously send and read the input and output analog, respectively. It is because I don't want a phase difference or any shorter signal for a direct comparison. But as soon as the signal is sent to the machine, I want the entry to stop analog playback and then then the LabVIEW program must stop. I want to be able to choose any length of signal to be generated and stop as soon as the entire duration of the signal has been sent to the machine.

I tried 'DAQmx stop', "DAQmx Timer" and 'DAQmx's task made?' and none of them have worked for me. It is also my first time on a forum posting, so I hope I gave enough information. I enclose my VI as well. The VI shows I read an entry for the analog input voltage, but I am only using this to try to get to the work programme.

I'd appreciate any help I could get.

Thanks in advance

Peter

Hi Peter,.

I have some recommendations for you that I think you will get closer to your solution. First of all, I assumed you meant that you had 1 chassis (cDAQ-9184) who had two modules in it (NOR-9263 and NOR-9234). My next steps are based on this assumption, so if it's wrong, please let me know.

For your first question about the synchronization, the code you provided is very close to what you need. You need to do, however, implement architecture master/slave for startup tasks DAQmx functions. To do this, you can add another frame to the flat sequence structure and put the master start task (input voltage) after the start slave (output voltage) task.

To manage your second question and that the program ends at the point where you, the first step is to get rid of all the logic that you use with the local variable of length of time. Rather than use this logic, just wire the node "task performed?" of "is task performed?" operate to stop the loop. This will cause your loop to stop as soon as the signal is sent to the machine.

I have some other recommendations for you that will increase the performance of your program:

(1) rather than writing on file inside the last loop, you can use the DAQmx Configure Logging (PDM) .vi. You will place this VI between DAQmx Timing.vi and DAQmx Start Task.vi to the task of the analog input voltage.

(2) after the last while loop, you want to stop the task and analog outputs as well with another DAQmx stop Task.vi.

(3) rather than using a local variable for the entrance of displacement and wiring it in the DAQmx Write.vi, you can wire directly from the output waveform of the wave to build function node.

That should help you get started in the synchronization of these tasks.

-Alex C.

Technical sales engineer

National Instruments

-

How can I pause and resume the analog output using DAQmx?

I use a DAQ hardware to produce an analog waveform. I would like simply to break the output of the wave and then resume where it left off. I use DAQmx and LabVIEW 2011.

I've seen examples that use a digital or analog break trigger, but I would take a break in the software only. How can I do this?

-Joe

Hi Joe!

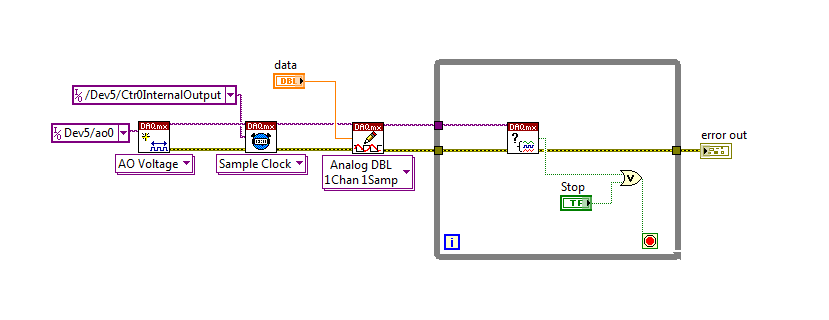

I spent some time thinking about it and I realized that you can technically use a fundamental mission of the analog output, as you previously wrote that runs continuously. However, the generated output samples are controlled by the sample clock pulses, and can be manipulated to fit our needs "suspension."

To do this, we will need another counter task that generates a pulse train (see our examples of shipping under material input and output > DAQmx > generating digital pulses > generate dig Pulse Train - Continuous.vi) that stops and starts the user to choose. This can be in another quite VI or controlled by software. We will use this as the task of our output sample clock.

Then, the task of the AO, wire a constant to the sample clock source and select ' DevX/CtrXInternalOutput"based on the counter that you specified in the task of counter. You will need to choose "I/o name of filtration" and check the box that says "include advanced terminals' and right-click of the constant. See picture attached as a reference. In this way, the task of the AO is constantly running, but it generates only actually all data when the meter running task.

Let me know if you have any questions!

Have a great day!

-

6009 outputs digital and analog input synchronization

Hello

I work in a program NI 6009. I want to leds by car with outputs digital NI 6009. For example, leads first will be on until what 200 micro seconds then second led will be on up to 200 micro seconds, and then first of all led will be on up to 200 micro seconds. I'll take led with photodedector signals and connect analog output photodedector input NI 6009. I want to synchronize the outputs digital and analog input and separate the first and second led signals the analog input for NI 6009 channel. How can you do with NI 6009? Please ADV

You can not do with the USB-6009 case. Its outputs digital are software with a maximum speed of slightly more than 100 samples per second. The outputs can produce 200 microsecond pulses and cannot be synchronized with the analog input.

You need a device with outputs digital hardware timed or counters that can produce a pulse outputs.

You can synchronize a bit digital output and analog input recording signal on an additional channel to HAVE. Will allow you to see the photodetector and LED the drive with the same schedule and such resolution as described by the sampling rate I. The maximum sampling frequency of AI on the USB-6009 case is 48 kHz that is shared by all channels. If you have two lights to led and photodetector two signals maximum sampling rate would be 48 kHz/4 = 6 kHz which is barely fast enough for your 200 US signals. For more than 4 channels, it won't be fast enough.

I suggest a simple oscillator circuit building and use it to clock a flip flop. This will give you alternating signals to drive the LEDs. You can use a line to reset the flip flop to give you control without the need for high speed.

Lynn

-

Switch between outputs, digital and analog input

Forgive me, I'm sure that there is a simple answer to my problem, but being relatively new to LabView, I do not know how to proceed.

With the help of producer/consumer achitecture I am trying to accomplish the following:

Producer

- Relay nearby

- Read the voltage

Consumer

- Compare the voltage to the expected value and append the true/false value in a table.

It will be run 8 times then wait for input from the user through the dialog box run then 8 times.

My question/problem is how I set up so that the digital analog in and out are timed correctly and get a sample of AI after each relay is closed?

Material used is the cDAQ, (2) NI9481 & NI9221 (1)

Attached, is the vi that I came with this day and a diagram to illustrate the intended application.

Any help is greatly appreciated.

-

Using of FPGA VHDL IP and analog output

I use a system with Labview 2014 PXI. I've got Labview FPGA to program and run the card PXI-7854R.

I have the VHDL Code I want to use to control an analog output of the card. I use the IP integration node for this now but I also tried it making the process CLIP and still have not been successful. The problem that arises is that the IP integration node must be in a timed loop, while the analog output indicates that it cannot be put in a timed loop. Is there a way to provide an output of VHDL analog outputs of the card?

I tried to embed a loop timed within a while loop, but it still does not work.

I can't download the VI due to the policy of the company, but suppose I'm generating a sine wave in my VHDL code which must lead to the analog output of the card (the actual wave is company owner information but it is generated by a glance to the top of the table as a sine wave VHDL would be).

In an attempt to work the problem I retried import CLIP of the HDL code in a new project in Labview and VI. I'm still not sure about why it did not work with each other when I tried it.

For anyone who seeks to solve this problem:

I basically used this tutorial for the process CLIP: http://www.ni.com/tutorial/7444/en/

It also explains the differences between the CLAMP and the IP integration node.

-

How do I get the analog input signal and send it to output analog (real time)

Hello world

I do a simple task in Visual C++ and I use PCI-6221(37 pin).

Basically, I want to send the same signal of "analog input" to the "analog output".

at the same time (or almost), to make real-time application.

Can someone provide me with sample program please.

I would be grateful if you could provide me with the great tutorial that explains

step by step everything about NOR-DAQmx for C/C++ programming.

Best regards

Khassan

This is my code in C++, you can optimize it if that seems too messy. This code reads the analog input signals and exports it through the analog outputs.

To make this code additional work of the directories include and library directories must be added to OR.

I hope it helps someone.

#include

#include

#include "NIDAQmx.h".

#include#define DAQmxErrChk (functionCall) {if (DAQmxFailed (error = (functionCall))) {goto error ;}}

int main (int argc, char * argv [])

{

Int32 error = 0;

TaskHandle taskHandleRead = 0, taskHandleWrite = 0;

Read Int32 = 0;

float64 context [1000];

char errBuffRead [2048] = {'\0'};

char errBuffWrite [2048] = {'\0'};

bool32 done = 0;

Int32 wrote;DAQmxErrChk (DAQmxCreateTask("",&taskHandleRead));

DAQmxErrChk (DAQmxCreateAIVoltageChan(taskHandleRead,"Dev1/ai0","",DAQmx_Val_Cfg_Default,-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleRead,"",100.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,0));

DAQmxErrChk (DAQmxCreateTask("",&taskHandleWrite));

DAQmxErrChk (DAQmxCreateAOVoltageChan(taskHandleWrite,"Dev1/ao0","",-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleWrite,"ai/SampleClock",100.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000));DAQmxErrChk (DAQmxStartTask (taskHandleRead));

DAQmxErrChk (DAQmxStartTask (taskHandleWrite));While (! fact &! _kbhit())

{

DAQmxErrChk (DAQmxReadAnalogF64(taskHandleRead,1,10,DAQmx_Val_GroupByScanNumber,dataRead,1000,&read,));

DAQmxErrChk (DAQmxWriteAnalogF64(taskHandleWrite,read,0,10.0,DAQmx_Val_GroupByChannel,dataRead,&written,));

}

_getch();Error:

If (DAQmxFailed (error)){

DAQmxGetExtendedErrorInfo (errBuffRead, 2048);

DAQmxGetExtendedErrorInfo (errBuffWrite, 2048);

}

If (taskHandleRead! = 0){

DAQmxStopTask (taskHandleRead);

DAQmxClearTask (taskHandleRead);

}

If (taskHandleWrite! = 0){

DAQmxStopTask (taskHandleWrite);

DAQmxClearTask (taskHandleWrite);

}

If {(DAQmxFailed (error))

printf ("error DAQmx: %s\n",errBuffRead); ")

printf ("error DAQmx: %s\n",errBuffWrite); ")

}

printf ("end of the program, press the Enter key to quit\n");

GetChar ();

return 0;

} -

connect the sensor (0-5V analog output and 9-28Vcc power) to NI 9219

I m chemical student here. And I'm not trying on the measurement of the pressure.

I have a pressure sensor with the specification of 0 to 5 Vdc analog outputs and power supply 9-28Vcc. And I intend to plug the connector which can be used for the NI 9219 (4 analog input). Therefore, there are 6 terminals and I have to choose the correct mode voltage (which is the terminal 1, 2, 4 and 5 which will be used), is?

So there are four wires for my sensor connector:

Red: power supply (+)

Black: Return supply (-)

White: Output 0 to 5V

Green: output

Therefore, how to connect these wires to the national instrument?

Looking forward to you guys.

Thank you.

Best regards

David

Hey David,

My previous suggestion is wrong, it's good.

Red (pressure sensor) = + power supply

Black (pressure sensor) = - power

Green (pressure sensor) = Hi, pin 4 (9219)

White (pressure sensor) = Lo, pin 5 (9219)

Sincerely,

Krisna

-

Strange problem with analog output PCI 6251 and BNC-2110

I'm controlling current source of third parties using the connectors of analog output on my card PCI 6251 and BNC-2110.

The current source needs an input signal of 0.1V. I tested it using a battery, the potentiometer and the voltmeter, and by manually adjusting the voltage of power current works - current output with control voltage scales according to the specifications and is relatively stable.

The data acquisition card works too - when I connect a voltmeter to the AO0 AO1, the measured voltage corresponds to the target with great precision value.

But when I connect the current source of third AO0 AO1 data acquisition card, the measured output voltage drops and fluctuates. This applies to both channels of the AO.

I wonder what is the problem here. I suspect it could be a matter of the grounding - the current analog control of the source is an entry with two floating terminals differential. I tried to return the switches FS/GS on the BNC-2110, but that makes no difference.

Anyone knows similar behavior? Does anyone have any suggestions?

-

Incorrect value for analog output USB-6008. Cannot not out more than 3V

I use USB-6008 analog IO, but the analog output (AO0 or AO1) can go up to 3 - 3.5V. The output can follow accurately the value of 0 to 2, 5V, but then he start the values adjusted trolling and not can not spend you 3.5V exponentially.

The only strange thing the entire circuit is that I connected all patterns (analog source and I/O 5V) between them, but I don't see what affect the output.

Kind regards

ISSOKO

Thanks for the quick reply Ana.

It is not the Council NOR, nor the Council of motorization. Apparently, the interface for motor control (motor spirit C: solutions - cubed.com), load the analog output. A tension following actually isolated op amp output USB-6008 and solved the problem.

Best regards, ISSOKO

-

LabVIEW 7.1 Analog Output is incorrect, computer crashes and often generating output resignations

Try to put in place an old pc with Labview 7.1 NT with an AT-MIO-16 x card... everything is loaded, I can load OR-DAQ 6.1 examples and Configuration DAQ ESPECIALLY utility works correctly.

In the config utility, I can put all the settings are correct, but I get the dreaded "the device does not respond to the first IRQ setting" for all the IRQ numbers acceptable that I choose 7,9,10,11 as 5, or 15. Others are simply not available, and all those who are to generate the same message. However I can run the test panels and get an analog output, for example, fine, tested with an LED.

So I moved upward to load an example VI, the function generator... Sort of works, it breaks easily, or stops, generating a total, if I hit the stop button and restart, and its output looks nothing like one of the square, etc. in sawtooth, sinusoid, shapes, watching on a scope, it is just hard hitting high then low, sometimes spitting a gust of sinusoid for half a second or so.

I suspect this is related to the issuance of the IRQ, I searched all knowledge bases, come up with nothing that solves this problem. Thought maybe someone could lend an idea. LabVIEW is really more stable than this right?

Well I've tried a bunch of things and success. Looks like my MIO Board is kaputt. Good thing I have 3 of the guys. The other set up fine in config and short decent for the torque screw daq example I tried.

Continuation and thank you very much for answering.

-

Decent analog output of my Qosmio F20-154

I use my Qosmio as a Microsoft Media Center with my TV connected via VGA output. It gives me a pretty good image.

However, my TV does not support most of the modes of zoom for VGA; or it does for DVI or HDMI.

So I tried the image output via S-Video - which produces a shitty and unacceptable photo.

Unfortunately, Qosmio has no TV output, so I can't try it.

So, does anyone know of a piece of hardware that can be used to make the Qosmio to produce a decent analog output, such as TV-Out (antenna) or Composite?

Thanks in advance,

BrianAs far as I know you have only two options to send the video signal.

Qosmio F20 supports viga video and s-video ports.

So either you will use the video VGA (15-pin) port or output video super TV (S-Video) 4pol mini to connect the TV to the laptop...I have connected my laptop to the TV also using the s-video port and the photo quality is OK.

Please check you s-video cable and if possible test another in addition, I would recommend check some settings on the TV and s-video option

Maybe you are looking for

-

Why FireFox fails recently block pop-ups?

Recently the pop-ups began to appear. The content parameter is to block pop-ups. I used CCleaner to "clean" the hard drive and do a full scan with Microsoft Security Essentials to try to get rid of the problem. But today, I always get a pop up tellin

-

Satellite Pro U400 - C14 - I'm looking for a replacement of the battery

HelloI am looking for a replacement battery for this laptop.Could you please tell me if the piles of: Satellite U400-108, Satellite U400-10I, Satellite U400-10J,Satellite U400 - 10L, Satellite U400 - 10 M, Satellite U400-10N,Satellite U400-10O, Satel

-

Tecra A2 - keyboard replacement

Hello Looking to replace a keyboard on an A2 and would like to know the part number to make sure that I get the right pair. Also A2 all models use the same keyboard Thank you very much

-

Pavilion 15-bc004nt (X0L73E): HP Pavilion 15 - bc004nt (X0L73EA) have Double-Fan?

Please help me... HP Pavilion 15-bc004nt (X0L73EA) has he fan, Double or Single?

-

LabVIEW database problem: create a database of the user-defined fields

I am trying to create a new table in Access database opened by an ODBC connection from information between a table stored in the database, but whenever I try to create the table, the toolkit of connectivity of database of Labview VI to create a table