control valves to match a level in a supply tank (measured by differential pressure)

Hello world

I'm trying to regulate the level in a supply tank by opening or closing the tap of the tank of pure solvent above it.

To check the level, I have a differential pressure transmitter connected to the computer.

So when then the level is below a certain value, I would open the valve at the top with a pure solvent, and when the level exceeds this value, I want to turn off the tap (the level will go down because the system is running and do a permeate.

The valve and the DP transmitter are connected to the computer via USB. Valve: Omega-3-PSV, signal of 0... 20mA

I tried different ways, but it does not work.

I am a beginner with labview...

Thank you very much for your help

See you soon

Florian

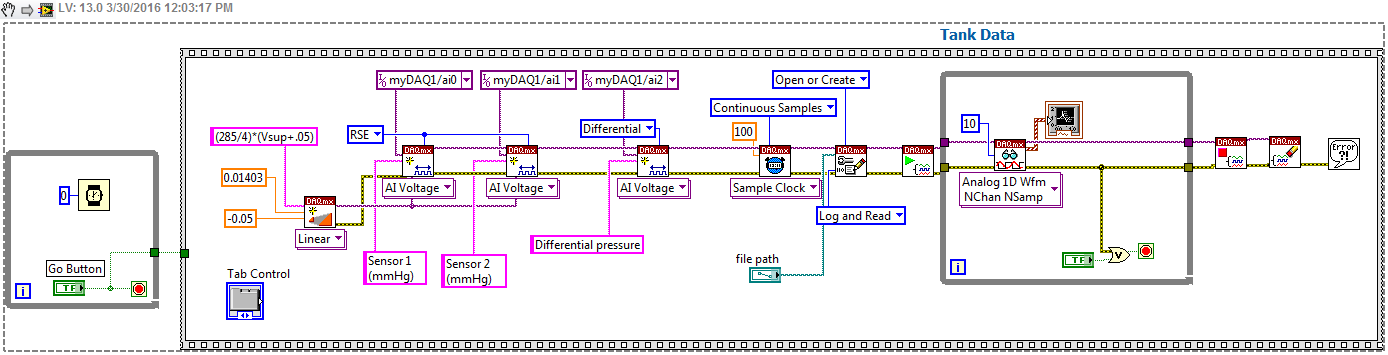

A screenshop, of the part of my program I was talking about!

I hope this will help other users!

Tags: NI Software

Similar Questions

-

How the repeating table inside a control valve?

Hello

Does anyone know how to make the repeating table inside a control valve in LabWindow CVI? I see that there is option for a Panel to scale content in resizing, but not available for a tab control. Any ideas?

Thank you very much!

Weiming

I don't know, I understand what you're trying to do, but you can set ATTR_SCALE_CONTENTS_ON_RESIZE on each tab panel.

GetPanelHandleFromTabPage (panelHandle, PANEL_TAB, 0, & tabPanel);

SetPanelAttribute (tabPanel, ATTR_SCALE_CONTENTS_ON_RESIZE, 1); -

NEITHER USB-6008 connect to thermocuples and pressure sensors, control valve

I am endevoring to build a gasification plant biomass for bench scale test process control plans. NEITHER USB-6008/6009 will be adapted for use as a data acquisition. I'll take RTDS, thermocouples and pressure sensors. I don't want to use industrial automation controllers. It is also possible to use the channel of analog output for sending signals to a control valve position (using sufficient current/voltage between the two drivers).

(1) OK. I just wanted to be sure that you were aware of the potential dangers.

(2) an RTD is a resistance that has small changes in resistance per degree of temperature change. To measure that you have need of a current source and a sufficient resolution in order to detect small changes. At 25 degrees C a typical RTD is 109,73 ohms and resistance ohms 0.38 per degree changes. If you had 1 my crossing this RTD voltage through it would be 109,7 mV and the voltage change of 0.38 mV by degree.

The resolution of the 6008 on the most sensitive range is 0.49 mV > 1 degree. The accuracy of the 6008 is 1.5 mV typical.

For a Type K thermocouple, voltage at 25 degrees is 1.407 mV and change by degree is 39 µV. Millivolt solving half of the 6008 translates into about 12 degrees.

If you need a source of excitement for RTD and a kind of amplification for thermocouples and RTD before she would make any sense to try to use USB-6008.

(3) I have not used anything except LabVIEW with DAQ devices and drivers. I think DAQmx can be used with MATLAB and other languages.

(4) the 6008 is the low range made by NOR. You will need to go to a more expensive camera or add signals conditioning circuits. Talk to your representative OR assistance in the choice of a suitable device.

Lynn

-

Control valve tank with plots and twists of the water

Hello everyone!

This is my frist real project. And I am in love with this program so far!

I have a little problem. Here it goes:The project of the University which has been given to us is to simulate a (entrance OPEN/CLOSED valve) water tank filling and emptying (output range of 0 to 100% valve), but with a few twists. It is done by the command to the movement by the following formula: flow rate [%] = position of the valve [%] * current water height [%]. (The output valve takes values in percentage from 0 to 100% giving the voltage digital output of 0 volt to closed(0%) or 5 volumes for open(100%), the strange part, is that the digital output can have a value of 0 or 1, so the position of the valve is "simulated".) And the supply valve (valve entrance) water can be open or closed (if 0 or 5 volts)

-Sequences cannot be used (only one for initialization and cleanup can be used)

-When the water level reaches 10% of the max height, LED lights, the output valve closes and the input valve opens. The LED is on until the button is pressed. The output valve cannot be opened until the water height is greater than 50%.

-When the water level reaches 90% of the max height, LED lights, the entrance valve opens. The LED is on until the button is pressed. The output valve cannot be opened until water height is less than 50%.

-There are two mode selectios:

Control by hand: the person sets the position of the valve in percent and the flow is calculated by the formula and displays on the screen.

Automated: Every 2 seconds the program assigns the place valve so that the current is constant, it is the value by the person.

-(N'ont pas gottern ici encore) ESD (Emergency shutdown switch) the when is pressed both the entry and exit valves are closed. The entrance valve cannot be oppened up to the RESET_IN key. If the program is 'Control in manual mode' output valve cannot be opened until the RESET_OUT touches. In which case the output valve is in "Auto" mode, it does not start work until the RESET_OUT touches.

My main problem here is the fact, I cannot use sequences and nested, then the loops do not work. The aqusition of data stops until the inner circle loop ends and I need both work. Especially for the 50% rule.

I've been hitting my head for a few days and still couldn't come up with a solution.

I have attached the VI.

Tips are welcome!

For the time being the outputs inputs/digital analogue are a simulation (when the time comes the USB-6008 material is used).

There is some things that confuse me (as if the valves are percentage, from 0 to 100%, or digital, 0 or 1), but regardless, it's a detail.

Review the task and consider what you want to do and that the "States" the system may be in. [This with a pencil and paper, do not open LabVIEW yet...]. The description of your problem learn you something about the transition from one State to another. Here is a thought exercise:

Suppose you are in a "State". Let the system to "do its thing" for a second, which could involve the water flow. At the end of the second re - evaluate your state - it changed? Continue to do this...

This model of 'something' is called a State Machine and LabVIEW has some very good examples and tutorials on the creation and use. The important things to do before you make your coding is (with the pencil and paper) decide on your statements, decide on the transition rules, and then you are ready to code.

There are different ways to build a State Machine in LabVIEW, but the basic idea is quite awhile (to keep things moving along, a shift register which includes the current state, usually represented as an enumerated, Type whose values are simply the names of your States (made for a very mnemonic routine) and a Case statement whose power is the State of the shift register that contains the code to achieve this) particular State of loop, including the implementation of transitional rules (which can cause a new State on the registry to lag when it comes out of the investigation of the case).

A great exercise. Strive to keep your block diagram on a single computer screen by making use of the screw subgroup chore (as the management of changes in the water level based on the current water level and "States" (which here means 'values') two valves). Once you understand the 'Idea' State Machine, you should be able to write the code for this problem quite easily.

Bob Schor

-

Control valve, choose which module?

Hello world!

I need to create an application with Labview with HMI etc... and I also need to control 3 solenoid valves.

I have the choice for the type, and I was thinking about using those:SMC VT307 with 24Vdc power consumption 5W

To fight them, I've identified:

cRIO-9481 with USB-9162Is this a good choice? Because I wonder if this USB device can give enough power to control the valves that I see no external power to the USB device?

If you think of a better choice, your proposal will be welcome.

Thanks in advance for all.

Everything he needs more, it is a 24V power supply.

You must choose valves with a built in shock absorber circuit or free diode to protect the Tower relays running spark that you get to turn off an inductive load voltage.

This protection will increase turn it off of time (a few ms) valve (just in case it matters

)

) -

Control of CSOS for HP4194A LEVEL?

Hi all

I work with HP4194A and try to set the LEVEL of the CSO, but I can't find any VI in intrusment pilot can control the output. Any idea can help. Thank youI do not use the drivers for this instrument, but I just send the orders. You can do a write GPIB with the command "OSC =?". Replace the? with desired level and do not use the quotes.

-

How to control the display of the level of xml in the Tree control?

I want to display xml nodes in the Flex tree control. for example, the XML file to display contains the nodes of level 5, level 1 (root node), level 2,..., 5 (leaf) level, but I want to only display level 1, level 2, level 3 without display of level 4, level 5 knots, anyone can tell how realize that with tree control? Thank you.

Ward

Custom ITreeDataDescriptor. Probably substitute getChilden() and

hasChildren()

-

Control of the status/OS-level database connectivity (* nix)

Hi all

What is the most complete of the singular* check to monitor the status "running" and "connectivity" of an ORACLE database on a Unix-like platform?

Checks the State of SMON ps - ef | grep smon confirm these two statements:

(1) database is running. and,

(2) can be connected locally using sqlplus

Or requires separate at the OS level controls? If so, which?

See you soon.Does checking the status of SMON ps -ef | grep smon confirm both statements: 1) Database is running; and, 2) Can be locally connected using sqlplusIf smon is running, my minimum hypothesis will be... database is started in nomount State.

SQL> conn santu/santu Connected. SQL> conn /as sysdba Connected. SQL> shu immediate Database closed. Database dismounted. ORACLE instance shut down. SQL> startup nomount ORACLE instance started. Total System Global Area 1073741824 bytes Fixed Size 2034376 bytes Variable Size 264246584 bytes Database Buffers 801112064 bytes Redo Buffers 6348800 bytes SQL> !ps -ef|grep smon ora10g 23625 23587 0 09:31:06 pts/1 0:00 /bin/sh -c ps -ef|grep smon ora10g 23626 23625 0 09:31:06 pts/1 0:00 grep smon *ora10g 23615 1 0 09:30:46 ? 0:00 ora_smon_rtest* SQL> conn santu/santu ERROR: ORA-01033: ORACLE initialization or shutdown in progress Warning: You are no longer connected to ORACLE.Kind regards

S.K. -

Image not displayed does not correctly in the image control to the small zoom level

I display a picture in an image control with a zoom factor of ~0.015 and it is displayed as shown in the picture 1.jpg. When I Zoom in a little bit more to ~0.016 the image is displayed correctly, as shown in the picture-2.jpg. The two images are attached.

Why the image is displayed as a "gray band" in the first picture? What should I do to have the picture displayed correctly at any zoom factor? I use LV 2011 with the module for development of vision associated with Windows 7.

Thank you

Jonathan-LV

-

-What this means and how can I solve this problem? I have Windows 7 and I use Remote Desktop connection to access a server where I do all my stuff. I need to solve this problem as soon as POSSIBLE.

Hi Nicole,.

The question you have posted is related to computers connected to a server and it would be better suited to the TechNet community.

Please visit the link below to find a community that will provide the support you want.

http://social.technet.Microsoft.com/forums/en-us/w7itpronetworking/threads

I hope this helps!

-

Flip sign for non members at the level of zero in the Measures dimension

Hi Essbase gurus,

I'm trying to convert dynamic hierarchy of measures hierarchy stored (account) to take advantage of the aggregation of the aso. This hierarchy has + and - bindings so I'll be converting all to + and assigning the UDA as FlipSign to load the data with - ve value in good standing of the load.

lesson plan:

NET installs no. (value = 2)

-> No. install reconnects (value = 5)

-> No. install disconnects (value = 7)

New contour

NET installs no. (value = - 2)

-> No. install reconnects (value = 5)

-> Not install disconnected (FlipSign UDA) responsible for value = - 7

I am facing challenge where I have no no member of level in this hierarchy needs to be presented in the form + for users of. How can I make Net No. installs even present as previous + 2?

You have until the tag all members you want sign flip, then create an extra dimension of 'View '. It will contain only one stored, 'Enter' or 'Data' as it does not affect the size of your cube. Then, you add a dynamic member with an MDX formula to return the sign of marked members. Reorganize the dimension so that the 'flip sign' display the Member is the default if the user makes no selection, that is to say that the "sign flip" Member rolls up to the top.

You add a very small overhead of MDX, but it should be useful if you can do your accounts any dimension of a stored hierarchy.

-

at the level of Calclating base of measure

Hi all:

I have a requirement where I need to calculate a shaved basic measure. Here's one thing well.

Let me you SAMPLES. This is what the data in the database table

company | account | product | by-product. quantity | amount

http://i.imgur.com/1CfXd.PNG

Column Amount is at the level of the company-account-product combination... (It is loaded in the table of data as even for each combination of account-product company. If you see the first image, amount is 100 for this level of combination of accont-products company...

Quantity is at the level of the sub product...

I need to view a report with these columns:

Company | account | product | by-product. quantity | amount | total quantity

http://i.imgur.com/KLgBg.PNG

The last column total quantity must be at the level of the company-account-product combination. Not the upgraded product.

See the photo above for a detailed idea. Total amount for first company-account-product combination is 5 and for the below a, 10

One thing is I have donot have Dimension tables, product, company account. They come from the fact itself.

I assumed that function level measure will solve the problem. If so, how to create a base for the total quantity column shaved measure when there is no dimension table?Create a measure in the "Total quantity" responses as SUM (quantity per product, the company account,), this measure will give you what you are looking for.

-

Control of data rows Excel (write on a file of measure)

Hi all

Objective:

Get a bit of a live waveform of two pressure sensors, as well as calculate the differential pressure. The LabVIEW VI is intended for students for an exercise in module, in which data are exported to an excel file for the students to perform other calculations. Excel file must contain data from the beginning to the end of a race.

Problem:

Pressure sensors work well, waveform table works well, but when you stop the collection of data, the amount of lines in the file Excel output will reflect the number of samples per channel of the DAQmx Read Block (10 = 10 rows of data, 100 = 100 lines, etc.).

I would appreciate some advice on how to conduct the data collection in the part worksheet from start to finish, without this affecting the aesthetic experience of the student (by that I mean the number of channels of the > 10 sample will cause some lag in the waveform, jerky). I tried to resolve this issue with something in the sense of Tank1Solution.png without success. I've included a photo of the original block (Tank2Block.png) and so I worked the file VI. Once more, any help would be much appreciated, I'm not well versed in LabVIEW and I do not know how to address this problem effectively.

Some guys are always doing things the hard way

Of course, you need a son to ai0 - ai2 and ai1 - ai9. This linear scale DAQmx is of course very convenient! and hey, the TDMS files import beautifully into Excel! the addon is there then why not just open a session data? TDMS is much more portable than xlsx.

A few additional remarks. (a) you can't stop this vi before you press Go-who needs a fix. (b) Create scale is likely to return an error as it is the name being illegal. I named it that to show the source of the scale and offset values.

-

User names found using the command run "control userpasswords2" do not match my user accounts

Hello, on the #4 computer, when I use the command run, I get a list of 4 users. A, B, C, and comments.

When I look in Control Panel I see 4 users, A, C, D and comments.

When I go to C\:Users I see B, C, D and comments.

I have problems with this computer #4, I get access denied, check the spelling, error code 8007005 0 x.

All of these accounts should not match in computer #4?On my 3 other computers that can network with each other the results of the run command, results of the Panel control and C:\User results all correspond to A, C, D and are same as seen in Control Panel of the computer #4 comments.

I think that the problem lies in computer #4 and is linked to the user names/accounts do not match. 4 computers user accounts all corresponding in Control Panel, so no problems.

Don't you think that this problem of networking is related to incompatibility I describe? How can I fix this? Gift of TIA

Hello, on the #4 computer, when I use the command run, I get a list of 4 users. A, B, C, and comments.

When I look in Control Panel I see 4 users, A, C, D and comments.

When I go to C\:Users I see B, C, D and comments.

I have problems with this computer #4, I get access denied, check the spelling, error code 8007005 0 x.

All of these accounts should not match in computer #4?On my 3 other computers that can network with each other the results of the run command, results of the Panel control and C:\User results all correspond to A, C, D and are same as seen in Control Panel of the computer #4 comments.

I think that the problem lies in computer #4 and is linked to the user names/accounts do not match. 4 computers user accounts all corresponding in Control Panel, so no problems.

Don't you think that this problem of networking is related to incompatibility I describe? How can I fix this? Gift of TIA

I finally thought to it. They wore all the user names that came when I ran the command "control userpasswords2". As I said in my original post, user names in all the names of the Panel user control over all matching computers. The only conflict I've had was in the list of user names in the list found when I ran "control userpasswords2". I went to highlight the 'B' account after that I ran the command, you click Properties and changed his name to 'A'. This solved my access denied problem once and for all. Apparently he does not have all of the accounts in the control panel.

Don

-

Need a Script to extract information for HA, DRS levels and admission control policy.

Hello

I'm looking for a Cli Script to get out information for HA, political admission control and the level of the DRS for each Cluster in the CSV format with the name of the Cluster

(1) it must be HA information, they are handicapped his license, for each Cluster in vcenter.

Admission control 2) enabled or disabled.

(3) policy admission policy admission control type speciying control

(4) DRS Automation level as manual, partially automated and fully automated.

Need this info to keep track so we have several Cluster

Thank you

vmguy

If you want to select only the groups whose name starts with Cluster, you can then change the command Get-Cluster in the first line of the script in:

Get-Cluster-name Cluster *.

Maybe you are looking for

-

Compaq mini 110 c-1120SS: ERROR CNU9440DWS

Help, please!I can't boot my laptop.It requires a password.No way to access the BIOS.This is the message after trying to any password for 3 times.Password check failedFatal error... System stoppedCNU9440DWS

-

Satellite Pro A120 - screen upside down

Hi all I have a toshiba satellite pro A120 and my son took his hand on the keyboard and now the screen flipped over any ideas on what I can do thank you very much...

-

I have Vista and the function address seems to have disappeared.

-

Once connected, the first time I click on a selection from a drop-down list, the selection I choose freezes on the screen, and I can see it until I restart my computer. It is an example, because it's a little hard to explain. I connect.I open a progr

-

Get the error code 10 - LSI MegaRaid SAS 9261-8i device cannot start.

How can I solve my problem of storage controllers? Get an error message stating: LSI MegaRaid SAS 9261-8i - device may not start (code 10)