FPGA interface of data acquisition

I have a repetitive loop in a PXI-7813R producing reasons. The output of the PXI-7813R is TTL, but I need 0-15V levels. In the same PXI chassis, I have a DAQ (PXI-6528) hardware that can handle the voltage levels. The question is, can I somehow link the the 6528 7813R patterns using PXI backplane and leave this market while I wear the use of PXI rack for other functions?

Thank you

Andy Quick

The problem with the PXI-6528, is that it is software programmed. Which means trigger won't help you here.

What you need to do is to do some work of material. You can have the PXI-7813R output profiles and drive an opto-coupler or FET circuit to change the level of voltage of 15V. Or maybe there is there a digital stamp which can output 15V for you.

Tags: NI Software

Similar Questions

-

the 1900 myRIO FPGA multi channel data acquisition

Hello world

I would ask you for help in my program acquisition and generation of data. The main task of this program is to measure 4-channel adjustable sampling rate (2 kHz and less) and to generate an analogue signal in up to 50 kHz sampling frequency.

I created two loops and everyone is dedicated to different operation. The first loop is to measure data, or in writing to the DMA FIFO and the second loop is dedicated to the generation of signals. I adjust the main parametrs of the two loops in a host of vi.

But what is my problem. I compile the program in the FPGA of myRIO without any problems and I can run too but the problem is that sometimes, especially when I adjust the lower sampling frequency of the loop to measure to the rank of channel changes measured and I see that the signal that is connected to osciloskop AI0 channel on channel AI3. When I stop the program, set the higger sampling frequency and run it again, it works well and the signal is on the right channel. Could someone help me with this problem? I tried to check all the forums that I know, but I did find an article or a discussion of a similar problem.

Thanks a lot... :-)

Andrew,

I just solved the problem. I thought about it again and I got the idea to change the size of the DMA buffer on the side of myRIO. I expanded the buffer of 1023 elements in 2047 and it works well and I can change the sampling without problems.

-

Where are the guidelines on how to interface custom for LabVIEW data acquisition equipment?

I have a need to do some very specialized data acquisition that may require special hardware for the building. I would still use LabVIEW as the front end and maybe even wear parts of the interface of the final product. However, I can't find the documentation. Where is that is kept? I've seen references to a number of generic protocols, no links back to the details, which may be appropriate. The data are a band high bandwidth, but bursty with sampling frequency up to 40 MHz and events that lasts about 100 milliseconds. Can anyone recommend various methods would be most suitable for this application?

You can use the instrument driver model and guidelines.

http://www.NI.com/white-paper/3271/en/

Use google to search not for OR

I searched

national instruments instrument driver guidelines

-

Card FPGA and data acquisition synchronization

Hi, we are control and data acquisition of several hardware devices (including Photodetectors and translational stages). Until last week, we used all the controls and acquisition using a PCIe-7852R FPGA board. However, we decided to move the acquisition part to a PCIe 6363 DAQ card to improve the sharpness of the tension. During the test, I found that the internal clocks in the FPGA and the DAQ cards are slightly inconsistent (not just a phase delay, but a difference in the period).

I know because I have generated a square wave (period = 20) using the FPGA and gains using the data acquisition card (at a rate of 200 kHz, that is, 1 taste every 5). I have observed acquired place shifts 5 every 5 seconds approximately. Such a change does not occur if the production and acquisition is done using the same Board. Therefore, the only explanation is that the data acquisition and FPGA cards clock frequencies are different. According to my calculations, the percentage difference between their time clock must be 5/5 s = 0.0001%.

Therefore, I wonder if there is anyway to synchronize clocks between them. Or, is it possible that I can drive the FPGA clock-based DAQ hardware, or vice versa? Also, please let me know if there is something trivial as I fix.

Thank you very much.

Kind regards

Varun

Hi Varun,

my post was only one solution...

Your data acquisition card may take an entry to control sampling of trigger. In this mode, samples draw on a rising edge of the external clock signal. As long as you stay within the limits of the DAQ (100 MHz for your card) material sampling works perfectly. There are even examples coming with LabVIEW explaining how to program your data acquisition card...

This mode use you your FPGA as clock source sampling for data acquisition. Both will run on the FPGA clock in sync. When the FPGA is a bit out of 40 MHz, so it won't matter because both devices are triggered on the same clock signal...

-

LeCroy Waverunner 640Zi - Data Acquisition

Hello... I'm trying to set up my oscilloscope waverunner with LabVIEW SignalExpress for data acquisition.

I took the steps so far:

1 pulse generator hooked to scope of signal generation

2 USB scope to the installed computer with LabView

3 downloaded lecroyscope driver 3.2.9 - x 64

I turn on the scope and plug in the USB to the computer and SignalExpress begins.

a. start by using data acquisition

b. Add step/aquire signal / IVI aquire / IVI brought aquire

c. create new IVI session... resources descriptor (I choose my USB device ' USB0::0x05FF:0 x 1023: 2812N61507:INSTR '), I select the right driver (lcscope), and I do not click enable simulation data, press ok

d. I still receive configuration errorse. did the research... some forum said goto MAX, find drivers and uncheck the Cache and the exchange of check

f. attempt to initialize... always get config errors.

g. return to MAX... change to simulate with specific driver.

h. initialization works... NO errors, BUT no data are acquired.

Help, please!

Hello

Sorry to jump in if I was out of the country for a while and am still catching things in my office.

I think you are looking for someone to say yes, "you can connect to the scope with NOR-MAX and VISA, and here's how interactive tool do"

A few things:

LabVIEW for XStream extended driver is the right one. It works with all the TeledyneLeCroy Windows based scopes.

As I see has already been noted. (I'll give Kudos soon), the scope of application must be configured to use interface USBTMC. To do this, go to the drop down Utitlites on the scope menu and select "utilities configuration... '. "in the tabs that appear at the bottom of the screen, select the 'Remote' tab and make sure that the interface type is set to USBTMC. This will also show you the VISA resource (I see it in the title of the image of VISA interactive tool indicated in a previous post).

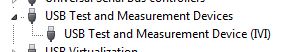

Once this field is selected, the PC should detect the USB connection and install the device. (you can see in your device manager as a Test of USB and the measurement device):

Once this is done, you can then enter the NOT-MAX and it will detect and display resources. You can now communicate with the device:

If you have problems, do not hesitate to give me a call and I'm happy to walk through it over the phone.

Kind regards

Leonard Brown

Technical sales engineer

Teledyne LeCroy

1-800-553-2769 -

USBTMC Data Acquisition Device Firmware

Hello

I'm trying to develop a simple data acquisition equipment which can interface with Labview using USBTMC Protocol. The rest of the sheet USBTMC and USBTMC-USB488, I have implemented the code to treat endpoints in bulk-Out with all the message ID. However, I am a little confused on how NI-VISA actually interracts with a device. When a command viWrite or viRead is given, what are the specific messages are sent to the device on which endpoints, and what is the expected response of the device? What would the classic process to acquire large quanties of data from a USBTMC device? If you can clear all this for me, it would be greatly appreciated!

Thank you

Mike

When the host issues viWrite call, the header USBTMC_BULKOUT of 12 bytes followed by your channel SCPI is sent to the endpoint of your firmware BULKOUT. In this case, USBTMC_BULKOUT header contains MsgID = 1.

When the host issues appeal of viRead, USBTMC_BULKOUT of 12-byte header must be sent to ask for playback to the BULKOUT endpoint. In this case the MsgID = 2 and the length is only 12 bytes of all. Then your firmware, if a response string is ready, must set the header USBTMC_BULKIN followed by the answer of the SCPI endpoint to send BOULKIN.

viWrite generates a transaction BULKOUT and viRead generates a transaction BULKOUT more BOULKIN transaction.

example:

viWrite ("* IDN?") \n') - generates a transaction bulkout in the form of bytes [12 + 6 + 2]. (the last 2 bytes are padding to align the 4 bytes)

Correcponding viRead () - generates a bulkout in the form of bytes [12], then the firmware fixed Boulkin data [12 + response + padding].

Makoto

-

Several timers loop data acquisition

Hi all

I am developing a VI for FPGA Deployment. My equipment consists of a chassis/controller for cRIO-9072 with module 1-9211 thermocouple, card SD-1 module, 3-9215 HAVE modules and universal modules 2-9219. I will collect data of two thermocouples on the 9211, 14 channels on 9215 channels and 6 on 9219 modules. This system communicates to the host via ethernet.

I have prepared a vi (see attachment), which used two DMA FIFO for writing data to data acquisition at a different speed. I will be sampling the s and 9211 9219 much more slow (500ms by samples), than other channels (40 ch/kech. / s). Currently, my FPGA vi trying only to taste two different modules. When I run the present on the host vi and try to read the data, I get only extracts of the data at different intervals. If either of her would reveal latency with the connection or the host vi failed to refresh quite quickly? I am relatively new to labview, so any help is appreciated. Thank you.

Gaussy

Hi Guassy,

There are a few things that you need to change:

(1) you must separate your acquisition in the FPGA in two separate loops if they have to operate at different speeds. As it is, probably will run at the slower speed of the two parameters.

(2) you must do the same in your VI in real time, or set up the DMA readings so that they will be read at the same pace. For example, suppose that a single module acquires 1000 hz and the other at 200 hz. If you want to read 100 samples from the first module (so your reading will occur at 1000 hz / 100 samples = 10 hz), you will need to read 20 samples from the slower module, so it is synchronized with the first module.

(3) your timeouts are too short on your DMA readings. Your slow acquisition is 500 us. It will take 50 ms to read 100 samples requested, but the delay is set for 10 ms, so 4 times over 5 playback will return nothing.

(4) you use graphics and no graphics. A chart will only show the current data buffer that was written for her. Refresh rate of the façade is nondeterministic, so that you can't see every update. If you use a chart, the chart will record all data written on it to the indicated depth (default is 1024 elements).

Also remember that you can have three FIFOs DMA between the host and the target FPGA, so use them wisely. It is often easier to perform your purchases on the FPGA at the same pace and send them through the DMA FIFO even in VI in real-time. If you need a few channels to connect at a lower rate, you can always throw the excess samples (there are some decimate wave screws that are perfect for this).

I hope that helps!

-

Data acquisition in LabView for other suppliers DAQ cards that NEITHER

Hello

I am a beginner in LabView programming. I have a 32 channels base PCI card DAQ (i.e. PCI-1602 of the manufacturer, ICPDAS) and I want it to interface with Labview 8.5.

So how cards DAQ in Labview 8.5, which are manufactured by other suppliers that NEITHER? Should I DAQmx (or some other driver) for that?

What are the other drivers/components required to access of data PCI-1602 (device) of LabView 8.5 acquisition card?

(1602-PCI card driver are installed in my win XP and dispalyed in Device Manager).

Please provide some tutorial above mentioned the problem to interface.

Please guide me in this regard. Thank you

Waqar123 wrote:

Hello

I am a beginner in LabView programming. I have a 32 channels base PCI card DAQ (i.e. PCI-1602 of the manufacturer, ICPDAS) and I want it to interface with Labview 8.5.

So how cards DAQ in Labview 8.5, which are manufactured by other suppliers that NEITHER? Should I DAQmx (or some other driver) for that? You will need the drivers from the manufacturer, of the Board of Directors. In your case, "ICPDAS.

What are the other drivers/components required to access of data PCI-1602 (device) of LabView 8.5 acquisition card? Same as above.

(1602-PCI card driver are installed in my win XP and dispalyed in Device Manager). Ok. Then take you care of my 2 answers above.

Please provide some tutorial above mentioned the problem to interface. To learn more about LabVIEW, I suggest that you try to watch some of these tutorials.

Please guide me in this regard. Thank you

According to what you do with the DAQ cards, they can do the job however, from experience, there are some functions that I could achieve with the cards NOR that I couldn't with 3rd-party maufacturers. This does not mean that this is your case. However, it is worth noting that it took me a while to understand why the code has worked with a single data acquisition card (NOR) but not another (Non-OR).

The drivers that you have installed may or may not include examples and code in VI. They may be DLL. If this is the case, you can write LabVIEW "Wrappers" around these functions, as it will simplify your life. If the drivers are in the form of DLLs, and there are no examples of LabvIEW or available VI, you must read on node library function call.

R

-

Sharing of Variables does not not under an FPGA interface?

Hi all

I have a controller 9074 cRIO 9074 chassis.

I defined a number of variables shared under my RIO controller and writing a UI VI in my host PC, where I feed some variables of network shared in RIO and get another return to RIO on the front panel of my host. Naturally, the VI which deals with read/write variable network data to IO channels real is under my RIO controller.

The problem is that, although everything seems to work fine when my RIO is set to the interface of the Scan Engine, the same screws give the following error message when I pass my RIO FPGA interface dependent.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Possible reasons:

CompactRIO: (Hex 0xFFFF0000) unable to communicate with the module. Re-insert the module and check the connections. If the chassis is in Interface FPGA programming mode, make sure that you have opened a FPGA reference bitfile or VI FPGA with the load of the Interface of scanning for the module you are trying to access using the scanning Interface.

This error or warning occurred when writing the following shared Variable:

\\AMR-cRIO9074\B1-DO\JCV1_C1_B1

\\160.40.15.231\B1-DO\JCV1_C1_B1-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Note that I get this error message for each channel of e/s that I call my RIO. Also note that it is there still no reference FPGA currently in any of the screws... I want to solve the problem is because later, I'll have to add some FPGA in my code, so I can not just impersonating my RIO scan interface...

Any help would be appreciated,

Harry

When you disable scanning on the cRIO platform engine, you must have some runing FPGA code.

There is noway that knows your controller on any module, and he can't read anything from any module.

If you do not have an FPGA vi, which sends the values of a port of the module on your controller, you need to do active Scan Engine.

The error message clearly indicate that you must have an open reference FPGA vi or analytical engine to be able to read the values of and to a module.

You are able to have custom analysis engine and a footstool of FPGA code at the same time on an FPGA.

Is there a reason you do not run with the scanning engine?

-

How to program dynamically data acquisition?

The question may seem, I want to dynamically change the settings of a data acquisition card (DAQmx). The idea is to have a loop event caputures GUI and the other while answering the while loop DAQ events. It's something like loops PRODUCER-CONSUMER. However, I can do all thing once, but not on the fly. Any suggestions as to how we can achieve this?

Thank you

Thanks for the comments. I solved the problem with the traditional approach. Here is the graphic interface to work.

-

choice of the model of design for data acquisition system

Hi all

I have a problem on the selection of the model design / architecture for a data acquisition system.

Here are the details of the desired system:

There are data acquisition hardware and I need to use by looking at the settings on the user interface.

the period of data acquisition, channel list to analyze must be selected on the user interface. In addition, there are many interactions with the user interface. for example if the user selects a channel to add scanlist, I need to activate and make it visible to others on the user interface.

When the user completes the channel selection, then he will press the button to start the data acquisition. Then, I also need to show the values scanned on a graph in real time and save them in a txt file.

I know that I can not use producer consumer model here. because the data acquisition loop should wait for the settings to scan channels. and it works on a given period by the user. If the loop of user interface makes higher then loop (loop data acquisition) of consumption. This means that queue will be bigger, larger. If I use notifier this will be some data loss comes from the user interface.

y at - it an idea about it? is there any model of design suitable for this case?

Thanks in advance

Best regards

Veli BAYAR

Software for embedded systems and hardware engineer

Veli,

I recommend the model producer/consumer with some modifications.

You might need three loops. I can't tell for sure from your brief description.

The loop of the User Interface responds to the user for configuration entries and start/stop of acquisition. The parameters and commands are passed to the Data Acquisition loop via a queue. In this loop is a machine States that slowed, Configuration, Acquisition and stop States (and perhaps others). The data is sent to the processing loop through another line. The processing loop performs any data processing, displays the data from the user, and records to file. A registrant can be used to send the Stop command or stop the loop of the UI for other loops. If the amount of treatment is minimal and the time of writing files are not too long, the functions of processing loop might be able to happen in the case of the UI loop timeout structure of the event. This makes things a little easier, but is not as flexible when changes need to be made.

I'm not sure that there is a type of design for this exact configuration, but it is essentially a combination of the models Design of producer/consumer (data) and producer/consumer (events).

Lynn

-

Treatment of LabVIEW data and high speed data acquisition C

Hi all

I am designing a data acquition VI high speed of 3 cards acquition of data at the maximum speed. Data cards are PCI 2517 Measurement Computing. The sampling frequency for each card is 1 M samples/second, if the total sample of M 3/second of three cards. Problem is the LabVIEW drivers and the screws provided by the provider works very well just for a single card at maximum speed, but does not support multiple cards at maximum speed. Their technical engineer advised me to write code in c#, C++ or VB.NET for this data acquition high speed. If I use C forever, I would like to use LabVIEW for processing of the acquired data to data acquisition. I came across a few examples that suggest the creation of dll C code and then calling it a LabVIEW. But those who have programs simple and none of them speak in C data acquisition. My questions are,

1. is it possible to call a C data acquisition program high speed of labview and not work in any kind of present of buffer overflow?

2 would it not simple best to use labwindows CVI?

3. is there another alternative solution that I'm missing?

I'll appreciate all the entries.

Thank you!

Nilesh-

It's pretty easy. Arguments for CINrun must match wiring. You can wire your CIN function block and say LabView to generate the C interface code to begin.

Here's my pairs for the ASIO audio project.

All the best,

Terry

-

Data acquisition inherited Configuration MAX window

I have LabVIEW 7.1, and Max under the software it shows v8.8 NOR-DAQmx and v7.4.4 NOR-traditional DAQ. When I am developing devices and Interfaces, only from the devices listed OR-DAQmx ppears with the DAQ card (PCI-6221: "Dev1"). The VI I need to ru uses the traditioal DAQ. When I run the VI I get an error message that the jury must be configured. How can I get traditional DAQ to apear in the devices and Interfaces fall down, so I can set the jury? The VI is not easily updated to DAQmx.

Thanks for any advice.

Paul

Hi Paul,.

The PCI-6221 is a M-series card. M-series cards have no traditional DAQ driver support.

Major differences between series E and M series data acquisition devices

-

I get upgraded my laptop (HP for laptop - 15-r224tx) for Windows 10 but I can't find the driver for the controller of PCI Data Acquisition and Signal Processing. Please help me find the right one.

Thank you!

You are the very welcome.

It is the latest version of the W10 driver for this card model... see if this solves the problem, if you have not already installed this driver.

This package contains the installation package driver for the controller wireless LAN Realtek RTL8723BE/RTL8188EE in the laptop models running a supported operating system.

File name: sp72517.exe

-

PCI Data Acquisition and Signal Processing controller driver

I installed win 8.1x64 on my HP Probook 450 G2, but miss me the driver of PCI Data Acquisition and Signal Processing controller.

Can you please help?

Thank you

Leontina

Hello:

Please see if installing the Intel Chipset driver installs this device.

https://Downloadcenter.Intel.com/Detail_Desc.aspx?DwnldID=20775 & lang = eng & ProdId = 816

Maybe you are looking for

-

January 1-history will not delete

TThis morning when I clicked on 'Clear history' and 'all time' list deleted apart from January 1. Any ideas?

-

Hello Forum, My previous post is left unanswered , and so I stumbled through on my own. My goal was to perform time correlated anticipated spectroscopy. I use a 6321 X series DAQ card, a Perkin Elmer SPCM and a pulsed laser. I'm exciting a sample wit

-

Very irritating because it appears each time you start the grandy

-

Adjustable table / list for OS 6

Hello I work with Blackberry OS 6, and I would like to make a list containing both text and an icon. I want to run the table, so when one of the items is on the app will bring me to another screen. I looked into the directive 6.0 user interface, but

-

Windows App Store updates keep waiting

Hello I reinstalled Windows 8 Pro in my PC. Previously, I had problem with Windows Store app updates and even after reinstalling I am facing the same problem. All applications keep waiting and gives error 0x8024001e after a long time. I installed all