INFUSION PUMP

Hi, I'm driving a "Syringe Pump PILOT C made by Fresenious, using the Labview.using RS232 Protocol and I was wondering if I could use the software driver NI-VISA to drive these pumps? Can you provide me driver driver c pump? I have attached a diagram whereby I order the pump but I'm unable to change the flow rate.

First and most important, what is the Protocol of coimmunications used by the pump? RS - 232 is not a Protocol, but simply a Standard (recommended) for voltages, currents and character framing. The communication protocol, which is set by the manufacturer of the pump includes the timing and options for framing and also things like ending characters, specifications of length of messages and other things.

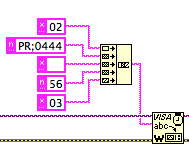

Looking at your code, it seems you misunderstand the Protocol. Some of the messages that you send are beginning and ending with hex 02 and 03. Others appear to be unique (x 06 and x 14) orders. Except for expecting a single character (x 05) on some reades, there is no indication in the code what received messages look like.

The use of the power line (A hex or decimal 10) as a stop character is enabled by default. When you use a character from endpoints, you must never use bytes to the Port! They will fight with each other and produce difficult to interpret the results. When you use characters of endpoint as useless odds.

VISA in LabVIEW does not add default endpoints on writing any character. If a character is required by the Protocol, you must add it explicitly in code. You can do this by adding the character strings in writing or via a property node.

Comments on your coding style:

1. the style guides recommend that you keep both the façade and the block diagram of a screen size. All about scrolling to find things is both unproductive for the programmer and makes it much more difficult to say what is happening in the program.

2 wire should generally go from left to right and avoid to be hidden behind other objects.

3. some of your string constants are displayed in normal mode, while others are in hexadecimal display mode. Right-click on one of the constants and select visible items > display Style. That will display a small glyph on the left edge of the constant making it apparent what display style is used. This can significantly reduce the confusion. Note that in the image below 4 of 5 constants are ambiguous - they are valid in either regular expressions or hexadecimal display styles and have different values. Whay does this empty string in this code?

4. There is no need to have a node to concatenate string following a single string constant.

5. the meters must use the I32 rather than the double data type. Although probably OK in your case, is equal to? double comparisons can be a problem due to the over representation of floating point binary numbers. In addition, use increment instead of add 1.

6 business structures may accept integer and string data types in the terminal selector. Double nested search case structure a = 1? and = 4? could be simplified into a structure unique case with 3 cases.

7. the structure of sequence containing the time before their reading (ms) 3 parallel runways to the rest of the code inside the whole loop and cannot do what you expect.

Lynn

Tags: NI Hardware

Similar Questions

-

Disabled accounts of internal users of ISE

Hello

I noticed this morning that, rather than the regular minimum number of users during the night on our wireless network from about 200 we had 68. Missing customers were some infusion pumps Hospira that have been set up with accounts of local user on the system, then I looked at the accounts. Most of the accounts for hospira pumps have been disabled but not all and no other accounts have been disabled, except a few that are no longer necessary and have been disabled by me.

What could cause multiple accounts off without manual intervention?

Thank you

Martin

Martin,

You can check the user password policy settings, there is a default parameter to disable the user account after 60 days. See if you can stop this.

Thank you

Tarik Admani

* Please note the useful messages *. -

GenieTouch Syringe Pump controls does not not in LabVIEW

I'm doing research using the scientific GenieTouch by Kent syringe pump. I talked to the company LabVIEW does not and they were not very useful after a certain point. I have attached the Guide, and it has the ASCII commands on the last pages. It is the first time that I have ever worked with LabVIEW and I'm not sure a lot of the terminology. So here's the problem:

I use the basicserialreadandwrite vi of examples. I changed baud rate to 115200 and adjustments, which was told me by scientific technical support in Kent. I downloaded a 'Free Serial Port Terminal' to test orders and all orders of the guide worked perfectly. However in LabVIEW only codes, I can go to work are "run\n" and "stop\n". I'm not sure what it wrong.

What I miss is the following: do infuse a small amount of water quickly, and withdraw the amount after a certain time. It is to be integrated into a larger program, later, but for now, I would like to than this piece of code to work before moving on.

The manual says that it is not case sensitive.

This manual is not the best programming manual I've ever seen.

Since you find that some things work, you will need probably to work through the whole order. Try is that you think that the books said it should be. Then, try different combinations such as spaces or commas between the parameters. \n or \r or \r\n. The manual mentions all the endings. It is quite uncertain as to who may be preferable. Set up a VI of reading which operates in a loop to see what can be returned. The manual indicates that several or all commands may generate a response. Also, he mentions the error messages but does not describe them.

By making this retro-engineering, systematic and record what you try. What works and what does not. Also, make sure that you understand how the instrument works manually. If you send an order via USB, you want to know how it would behave when you already told him to do the same thing manually. If if it's the same, then you have identified a command that works. If it is something different, you understand why.

Unfortunately, this kind of thing is not something where we can a lot. You must have the device.

Good luck.

Lynn

-

Screen error bed

xc05doo82, engine of the pump at a standstill. Press the icon (inability to recognize or describe). How to fix it, or can I still fix this?

xc05doo82, engine of the pump at a standstill. Press the icon (inability to recognize or describe). How to fix it, or can I still fix this?Hello @Munga,

Welcome to the forums of HP.

I understand that you have found an error ' 0xc... "on your printer.

I would like to help.

Try to go through the following document.

On the off chance that you meant 'choose the motor at a standstill', please see the following document.

HP all-in-One printers - 'Out of Paper' error and the printer is not get paper

If you need other assistance please let me know.

-

Voodoo Omen with regard, water pump is longer supported by HP - help! : p

Hi all

I have an old omen Voodoo (water cooling system) - here is a link to a review of this version: http://reviews.cnet.com/desktops/voodoo-omen/4505-3118_7-31292135.html which was purchased from voodoo before its acquisition by HP. HP supports more Voodoo telephone products. My former client ID attached to the omen is 37047 (HP Voodoo team recognized that a few years - if you were on this team, I really appreciate your help!).

Problem: when I start, there is a horrible noise that I've isolated as coming from the pump to water. After a bit, he calms down, but I think that it is a 'sign' of bad things to come. Looking closely, I suspect that the cooling liquid does not flow even in the tubes. Thus, the pc stopped several times during the boot sequence.

Question: I think it is a good idea to replace the pump sick before he died. I'm having a lot of trouble finding any computer repair shop in the san francisco Bay area (I'm in the east Bay) who knows even that there is a such thing as the water cooled pc.

- How can I find the mark of the pump that was installed so that I can order a replacement?

- I'm looking for a local preference pc technician who is at ease of repair / replacement of water cooling systems.

- Is anyone out there?

It is possible that I just need to replace the pump - hose seems fine.

Thank you!

Robert

The solution involves a complete rebuild of the system with all new parts, except the excellent Voodoo chassis. I would have added a cooling system, the water but there was no need - and here is a picture, finally. There is some dust, but you get the idea - it's an approach minimalist and clean wiring. You can see the fan of collmax takes a lot of space, sitting on top of the cpu - but the entire Setup is silent and ultra reliable.

It was perfect for my needs, and very quickly - I push it more difficult with several processes going on in lightroom, photoshop and the plugins. I tried a few games as well and was very impressed - there was no need to overclock.

I always have this problem with the locations of card reader is not recognized - don't know how to solve this one - and as I said, I can live with that by importing directly from the camera.

System information:

Case of Voodoo curse

ASUS rampage motherboard

Intel cpu i7 - 4930K

32 GB of fast ram

Graphics GeForce GTX 780 Ti

Power 1200 Watt

in the solid state boot drive.

For cooling, I went later with a generic double fan coolmax system instead of water.

Verdict: it is silent, reliable and fast without overclocking; the system is basically brand new. The only thing that remained was the case of Voodoo Omen very excellent and very heavy.

-

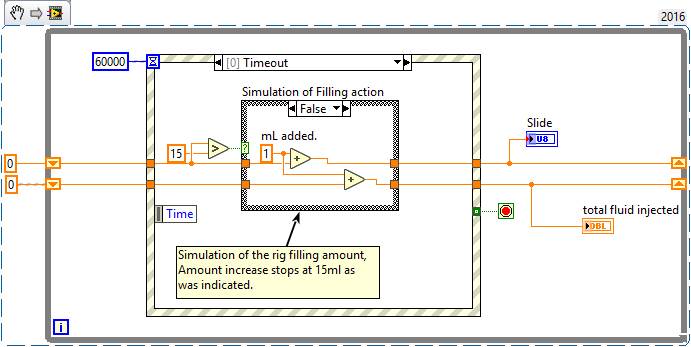

Reset a sliding bar without losing the amount of pumped fluid

Hello

I'm trying to summarize the total amount of liquid that my pump will inject in my rig. I need also a sliding bar that shows me that the amount of fluid being pumped, knowing I need to taste each 15mL injected (so the sliding bar is between 0 and 15).

I thought that my VI might work, but for some reason that I don't know he does not behave correctly. I can not really given the bar again, and if I do, it no longer meets.

would you please help me defining a VI that could allow me to see the progress on the bar, and when it's full, leaving me the opportunity to reset (in order to begin to fill again) by clicking a button?

See you soon,.

Flo

Basically, in the above example, together worth entering the structure of 1000 to 60000 input event timeout, causing the Structure of the event to trigger the "Timeout" event once every 60000 ms (60 years), then you would put your code sample within the event "Timeout". Copy the image below in a diagram, for example.

Edit: Image Correction appears 60000 ms delay.

-

Flickering screen or pumping on G560 during execution of a stack

Hello

I have a G560 with Windows 7 64 bit. When the laptop running on battery power the screen quite often wavers (especially in the half lower) or it looks like a light pumping. The laptop has an Intel HD graph installed. I installed the latest drivers from Microsoft Update, but it did not help.

Any ideas? Maybe install the Intel HD (older) drivers from the Lenove homepage?

There is a difficulty in the graphics driver's control panel. Under "Properties", go to the power. Then, under power settings, change "Power Source: for"on battery", uncheck" Display power saving technology'. " Click on apply.

-

Configuration series pump syringe ONLY-1000

Hello everyone,

For my graduation project, I find how to connect a syringe ONLY-1000 pump (the brand is Prosense). I tried to connect through the RS-232 input on the back of the pump (one with 5 points of connection on the top line and 4 in the lower row) to the USB of the PC input.

This PC is an ASUS EEE (not my first choice, it is pretty slow), but it doesn't have the RS-232 socket. So, it looks like this:

PC--> USB--> RS - 232--> shoot-syringe

The PC detects "new hardware" but impossible to install them due to lack of information. When I open MAX I can only find an unknown device, what VISA test panel can not be opened, prompting an error:

"

Error opening resource:

ARSL 10: INSTR

VISA (HEX: 0xBFFF0011) location insufficient information or the device or resource is not present in the FAT32\

"

The installed version of LabView is version of 2013.

Does anyone have experience with programming series in LabView? Maybe I need a PC with RS-232 instead of the USB port?

Any help or advice would be appreciated a lot.

Kind regards

San

Hi guys,.

First of all, thanks for the offer, but I'm not interested. I think the purpose of this forum is to find a solution for the problems that are are using LabView, rather than work around the problem.

However, I found the solution for this problem. After all, this is the driver for the USB-RS232 converter that could not be installed. So I bought a new converter with which I have installed the software. It is the electronic converter König (bar code 5412810074822). After installing the driver (which came with a small cd) and restart the PC Max recognized ports and there was not yet any necessary configuration.

This topic can be closed.

-

HP Photosmart C7280 pump motor stalled

I have a HP Photosmart C7280. I received a Message from "Pump motor stalled with OK" on my screen. When I press 'OK', the printer goes through a series of clicks and what looks like the head slide back. Then I get a message "ink system failure". (0xc05d0082 error code). The message tells me to turn off the printer and then new. After that, by using the power button, I received the following: "incorrect stop" you did not properly stop the computer... Then the printer will automatically adjust the cycle to the motor 'Pump' message to a standstill

I'm not real with these things so I write in the hope that a guru out there can help me. My husband who is refused a "waste of time" and just wants to throw it and buy a new. This printer is not quite 2 years old. I can't believe it's the end of his life. He received the messages to clear only once, but in the day, the cycle had recurred.

Thanks in advance for any guidance.

Have a C7280. Powered on and "Pump motor stalled" message came. Removed all ink cartridges, closed the printer and click ok. The printer has failed until the cartridge error. Put the cartridges, closed the printer and click ok. It works again.

I hope this helps.

-

I need up to 7 separate channels for this so each pump can be driven independently. Can anyone suggest what equipment to use to achieve this?

George

You can use the 9474, he needs power external 24V and one of the cDAQ backplanes (e.g. 9171).

Best regards

-

Plug and Play drivers: Instrument of Identification error (pumps Ultra PHD at Harvard)

Hi all! I use the LabView drivers to control a unit of Harvard pump 70-3007 and fall on some issues. (I'm controlling through the USB port).

Driver:

http://sine.NI.com/apps/UTF8/niid_web_display.model_page?p_model_id=16026

Plug-and-Play site:

http://www.NI.com/white-paper/3271/en/

So I downloaded and installed the drivers and made sure that I have ALL the necessary software (USB virtual COM and VISA) installed. I then used teraterm (serial port communication software) to make sure my computer can communicate with the pump. He could.

I then moved in labview, to make sure that my computer can control the pump. He couldn't. As soon as I try to screw attached with the drivers, I get an error. The first step in each VI is to call an Initialize.VI that makes a 'Identification of Instrumentation' stage, which always generates an error. He tells me that either I have wrong COM port (I assure you, I did not) or that the instrument drivers are not updated. HM.

Any ideas? Of course, I know probably no one here has used this series of pumps before, so if there is no additional information / screws I can join, please let me know.

-

Fail to communicate with the controller of pump ISCO D series

Hey everybody,

I have an ISCO D pumps controller (which is connected to a syringe model 100DX ISCO pump) series I want to control using RS232 on Labview. I don't have their LabView Toolkit that Teledyne has mentioned in their technical Bulletin (TB06). In addition, I would like to automate my test, so using the Labview Toolkit will be not too useful.

The problem I face is not being able to communicate with the controller via hyperterminal or LabVIEW.

I ran their (mentioned in TB06) integrated series test and communicate as expected. I also tried to run their program remote pump (mentioned in technical Bulletin 19 of Teledyne - TB19) which seems to do what is expected as well.

I tried to talk about using LabVIEW first using the vi that I joined, and I saw nothing on the buffer. So, I moved to hyperterminal.

But when I try to send the command 'remote' listed in TB19, it doesn't seem to do anything. There is no answer on the hyperterminal.

There is mention of a DASNET Protocol, and I found the .dll file that I also moved in my Windows System 32 folder. It did not work even after that too.

I have attached TB06 and TB19. Let me know if you have other ideas how to do to test it.

Please let me know if you need further information.

Thank you

Sandeep

Hey everybody,

After going through their best manual, I found the way to correctly send a frame. The manual at, www.isco.com/pcfiles/PartPDF/SL000004/UP00194U.pdf, section 7 specifically, it is intended.

For the purposes of anyone who stumbles across this thread, here's an example.

If you have your.

Destination (the pump regulator) ID = 1

the source of the (computer) message = 00

and you try to send the message to DISTANCE that would turn the controller in "REMOTE" mode

Then you would send '1R006REMOTE1B', where 1 is the ID of destination

R is right to recognize the previous received message00 is the ID of the computer

6 length of command

"REMOTE" the command itself, must be uppercase

Checksum 1 b (which changes with the command of course)

And you can do the same thing in LabVIEW, you can enter '1R006REMOTE1B' in the VISA write while keeping everything else the same as the snapshot of the vi I sent previously.

Dennis, actually do not have the CD itself, but I assumed, would nothing more than an executable since I downloaded the demo driver for LabVIEW (http://www.isco.com/products/appnotes.asp?PL=105 under utilities) pump. I am currently trying to locate the CD here at the lab, and I will update this thread if I find something useful.

I guess that my problem has been resolved.

Thanks for your input in this Dennis.

Kind regards

Sandeep

-

Control of the pump using NI 6216

With the help of NOR-6216 and LabVIEW.

The pump has these control signals:

Contact power entry

0 or 5V

Direction: Right / hour meter Contact entry

0 or 5V

and speed

0-1 V

My query is can you please let me the connections required 6216 NOR for the contact entry.

I guess a SPDT relay must be used. Can you show the connections required

I could understand this and is now set. The signals are TTL control pin 3 pin 1 with work of digital signals. I was wondering earlier because the manual mentioned as contact entries.

Thank you

-

Send the signal current/voltage/USB DB25 to regulation of pump to

Hi all!

I want to control the speed of a pump with LabVIEW (Thermo Fischer FH100M, Manual) and so I have to send a current or a voltage signal to the pump. The pump has only one DB25 port. As my laptop is not a port DB25, I tried to control it with a USB converter.

I had only a converter USB to DB9, so I started with (laptop) USB-DB9-DB25 (pump) > >.

When I connect the pump on the USB port, it is instantly put in market, but in a strange way.

Is it possible to use this configuration? Or is it possible to use at least USB-> DB25 (I have the Setup, see manual page 45/3-19)? Then, I would order that the cable companies.

Or do you have other suggestions?

Thank you very much in advance!

Tobi

Tobi,

Stop it! Do not connect your converter to this device.

When you say "Converter USB to DB9" are you referring to a USB converter to RS - 232? DB9 is just a connector and therefore DB25. TOU can wire anything to this connector. Your converter is probably wired as a serial RS-232 port.

The manual shows clearly on page 3-19 and the following pages that the control of the pump is NOT wired for RS - 232! By looking at the speicifications for the inputs and outputs you shown on page 3-20 and 21 may damage the USB to RS-232 conveter or the controller of the pump by connecting them.

To control this device you will need to a DAQ with analog input, analog output, material inputs digital, digital, outputs a counter. You will also need some external circuits such as transistors or relay static solod DC in proportion.

Lynn

-

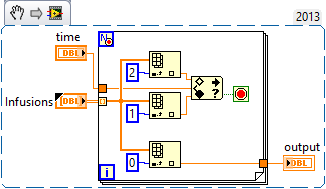

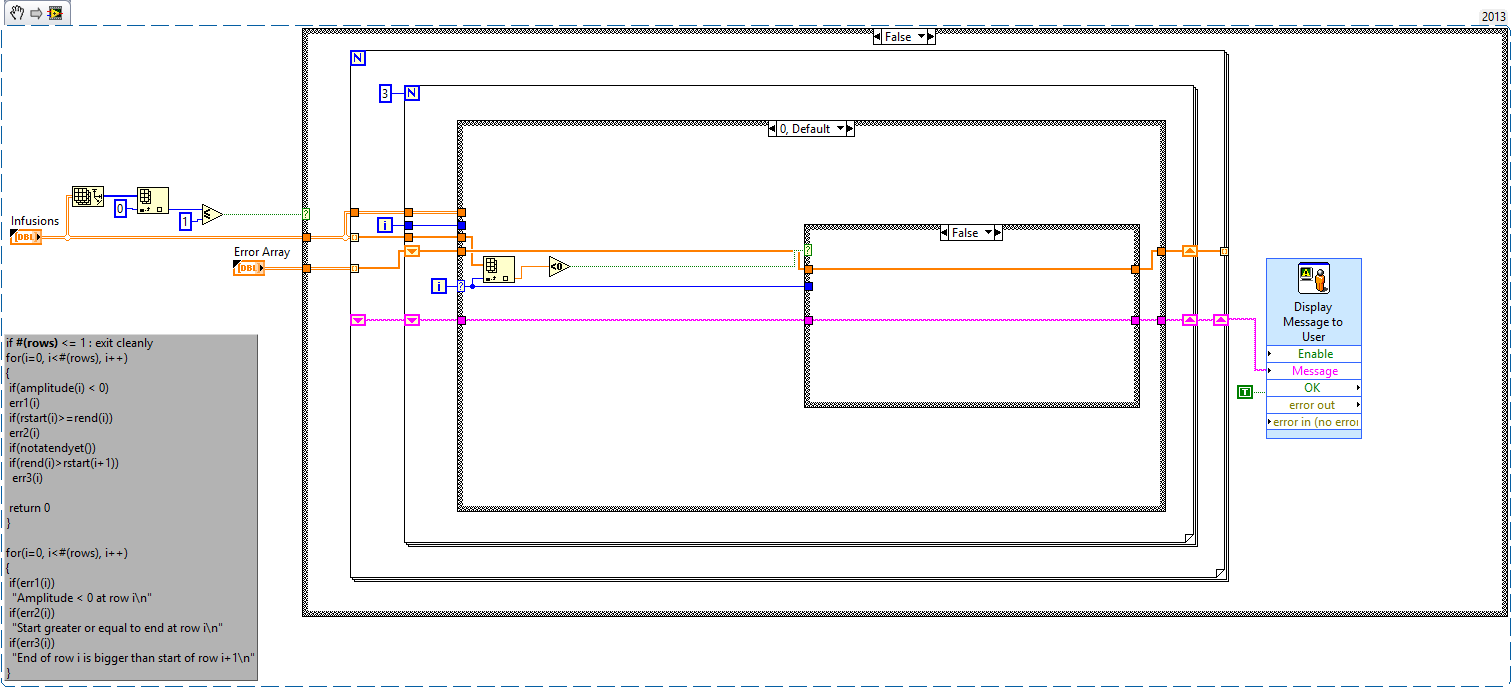

I want to allow the user to specify a curve like this:

Such as some under - VI shows the A2 value when a variable of time is between R1, A1 when the time variable is between A2 and A3 when time is in the range A3.

My design looks like this:

With the error checking that looks like this:

My question is, is the approach of the table according to optimal? Otherwise, how could combat this?

I think I can summarize the conversation on this point as a response to the original question (what is the best way...) -to start writing code, to think about what you want to accomplish and write it down (otherwise known as 'Write the first Documentation'). One of the points of a good User Interface is that it is not allow users to "stupid mistakes" - it leads the user "by hand", limiting the entries to the "legal values" and demanding that the entries be made logically.

If you were going to have a list of Infusions to enter, it is therefore logical to decide or not to enter into time intervals (which are always > 0) or order the times (which, logically) are still growing. You can (and should) decide that you (or you may have a control that allows the user decide, but maybe it's too flexible) and then apply your "rules".

Let's say you've decided on "Intervals" (which seems to me to be more User Friendly). After the user has entered the intervals (and you've provided a nice plot of perfusion vs. time), pouvez allow you the user to an interval of 'split', 'Delete' an interval, or "Edit the Infusion" interval, or you can decide to have a choice more simple "accept or start again" - If you have only a few intervals, the last would be the simplest (and therefore best) design choice.

Spend more time thinking before coding usually pays Big dividends!

(Speaking of sad experience) Bob Schor

Maybe you are looking for

-

Photos.app: Are the functions 'culture' and 'rotation' jpg lossless?

For jpg files, there are ways without loss to change. https://en.Wikipedia.org/wiki/JPEG#Lossless_editing For example rotations and cultures. My question:Are the functions for jpg lossless ' rotation' and 'culture'? Thanks for your help.

-

Qosmio x 500-118 - the high temperature of the processor

Very odd behavior that I found was that CPU temp reached 100 degrees Celsius and the fan speed remains at 81%. 81% is the fan speed when the CPU is at 80 degrees Celsius and 100 degrees, too. Is this normal?Finally, when the CPU reaches 100 degrees i

-

SearchProtocolHost issuing a warning sound

I was able to isolate a PC XP searchprotocolhost, who played a warning sound as soon as possible. Any ideas as to why this is happening?

-

I am the administrator total privileage still i'm getting the following error... MMC cannot open the file C:\WINDOWS\system32\compmgmt.msc It is perhaps because the file does not exist, is not an MMC console, or was created by a later version of MMC.

-

HP Officejet 8610: Scanning multiple photos at once

I have a HP Officejet Pro 8610 and I cannot figure out how to scan several photos at once... My old HP I could ask 8 photos on the glass and scan and then I could select each photo and all have once the file scan, the 8610 makes me scan, then selec