Many DAQ cards synchronize hardware for PXI

I recently went through the process of getting several PCI DAQ cards in a computer and synchronize them together using a RTSI cable. I just bought two similar cards in PXI. I had to add a RTSI cable DAQmx devices manually in the measurement and automation software, and connect the cable with the PCI cards. I want to just make sure that I don't have to do the same with the PXI cards because there is no necessary RTSI cable for PXI.

Thanks for any help,

Mike

The PXI chassis has backplane triggering and clock lines so that you don't need the RTSI cable.

Tags: NI Hardware

Similar Questions

-

PCI DAQ cards are suitable for 24 x 7?

I have an application that must run non-stop for 6 to 8 months.

Its a bench of Endurance for the bike a solenoid and the tracing of the switch ON / OFF times. The main code (LV 2009) runs in a loop of material timed 10ms. With a pulse frequency of about 1 Hz, I need to cycle for about 20 million times. (There no missing iteration as the average is 4-5 ms only.)

Using cards PCI-6229 and 6514 PCI inside an industrial PC of Advantech and running on the platform of WIN - 7.

So far the system has worked for about 3 weeks without problems. Will this work for the rest of the period? In other words the my approach is correct with the mentioned combination H/W and LV2009? Or if a RTOS with cRIO more fit here?

Thank you

Long-term running test can be very difficult! There's just too many things that can hurt-outages, failures, operator errors or managers even drop a cup of coffee in the set-up (trust me, its happened).

When I met this requirement type, I try to think about how "Fail" the system so that, even if the PC blows up I can recover the data and to continue the experiment. In your case, it does not sound as if each of the cycles of 20 M is absolutely necessary. You could still learn about the lifecycle of the solenoids of the trends in the data. I guess that you are interested in breaking in, long term trends and indicators of end of LIFE. If logging of regularrly with an additional event log data (event: arrested - power faulure cycles 10,787,690 complete system to YY/MM/DD/HH: mm

S etc.) would probably keep any conclusion you draw valid data analyses.

S etc.) would probably keep any conclusion you draw valid data analyses.But most of that is software design requirement and design for the fault tolerance. Material list you seems appropriate for this experience (and close enough that I can tell from the spec limited discription, I have focused on for this type of solution).

-

Hello

I am moving forward with my project with the help of these forums and I try to not post on here asking for help, but I can't find an answer pretty clear to my last issue.

I have several still model USB DAQ. However, when writing my labview programs, they refer to Dev2.

Is it possible through labview each poll for connected cards, or to group of NI Max DAQ devices so that they have the same virtual name?

You can use a property DAQmx node for a list of all the features implemented. Each device must have a unique name.

-

Synchronization of several high at different frequencies of sampling DAQ cards.

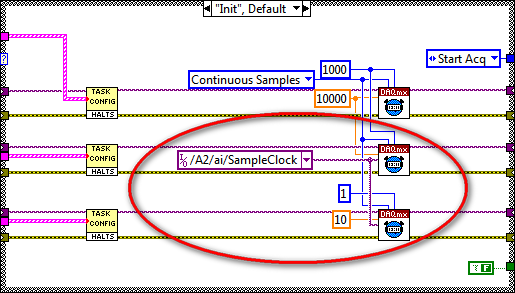

I'm having sync problems 3 high DAQ cards with different sampling frequencies. I use 2 cards PXI-6259 nec 10,000s samples and 1 PXI-6221 Board to interface for my SCXI modules in 10 samples/second. The problem that I discovered is the time related with the waveforms of the NI PXI-6221. When I run the code on a development computer using virtual devices in MAX, it works as expected. When I run the same code on real hardware, the stopwatch turns approximately 25 X faster than normal. I enclose the code and the config that I use.

Any ideas?

Hi NGNN CAD.

First of all, let me say that your code is very nice!

The problem is that you are using the fast sample for the device that is supposed to be slow clock:

Even if you specify the rate as 10 Hz, the clock itself is still at 10 kHz (by specifying the right rate allows the DAQmx driver determine the size of buffer etc and don't actually change your external sample clock speed - however, it changes the rate of the simulated device).

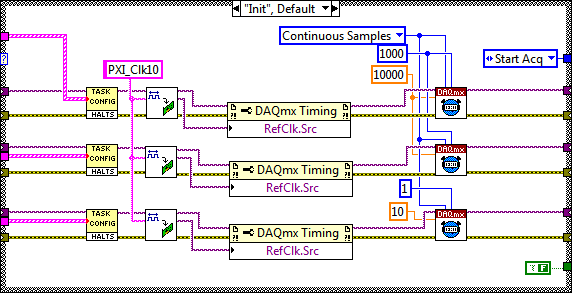

My recommendation to synchronize devices would use the built-in PLL and lock to the reference clock 10 MHz of your PXI chassis. Your devices would always share a trigger to start, but each would generate its own sample clock based on its time base that is locked to 10 MHz reference.

The code should look like this:

I hope this helps, let me know if you have any questions!

Best regards

-

Data acquisition in LabView for other suppliers DAQ cards that NEITHER

Hello

I am a beginner in LabView programming. I have a 32 channels base PCI card DAQ (i.e. PCI-1602 of the manufacturer, ICPDAS) and I want it to interface with Labview 8.5.

So how cards DAQ in Labview 8.5, which are manufactured by other suppliers that NEITHER? Should I DAQmx (or some other driver) for that?

What are the other drivers/components required to access of data PCI-1602 (device) of LabView 8.5 acquisition card?

(1602-PCI card driver are installed in my win XP and dispalyed in Device Manager).

Please provide some tutorial above mentioned the problem to interface.

Please guide me in this regard. Thank you

Waqar123 wrote:

Hello

I am a beginner in LabView programming. I have a 32 channels base PCI card DAQ (i.e. PCI-1602 of the manufacturer, ICPDAS) and I want it to interface with Labview 8.5.

So how cards DAQ in Labview 8.5, which are manufactured by other suppliers that NEITHER? Should I DAQmx (or some other driver) for that? You will need the drivers from the manufacturer, of the Board of Directors. In your case, "ICPDAS.

What are the other drivers/components required to access of data PCI-1602 (device) of LabView 8.5 acquisition card? Same as above.

(1602-PCI card driver are installed in my win XP and dispalyed in Device Manager). Ok. Then take you care of my 2 answers above.

Please provide some tutorial above mentioned the problem to interface. To learn more about LabVIEW, I suggest that you try to watch some of these tutorials.

Please guide me in this regard. Thank you

According to what you do with the DAQ cards, they can do the job however, from experience, there are some functions that I could achieve with the cards NOR that I couldn't with 3rd-party maufacturers. This does not mean that this is your case. However, it is worth noting that it took me a while to understand why the code has worked with a single data acquisition card (NOR) but not another (Non-OR).

The drivers that you have installed may or may not include examples and code in VI. They may be DLL. If this is the case, you can write LabVIEW "Wrappers" around these functions, as it will simplify your life. If the drivers are in the form of DLLs, and there are no examples of LabvIEW or available VI, you must read on node library function call.

R

-

LabVIEW code for two daq cards

Hi all

I'm reading the analog signals using the USB-6210 device and function DAQmx. How to write my code so it would work with the NI USB-6210 or USB-6218 since both a pinout similar devices.

Thank you

dp128

Do not write anything to recognize a different DAQ card. It's as simple as that. They both have the same number of input channels, and they both have the same maximum sampling frequency. You will only need to worry if your program was out analog.

When you install a sinlge on a pc data acquisition card, MAX lists it as dev1. If you do the same thing with a different DAQ card on another pc, it is listed here as dev1. As I said, there is no difference to explain.

-

MAX with replication DAQ cards

Hello

Hope someone could shed some light on this

Its a long time since I've used Labview & MAX and am a little rusty right now.

I'm trying to upgrade an old data acquisition system to a newer version.

This is because originally one full working backup system was necessary, but because the old DAQ cards are obsolete,

a simple update was necessary.

Old system:

LabVIEW 7.1

MAX 3.1.1

Data acquisition card: PCI-6023E

New system:

LabVIEW 7.1

MAX 5.0

Data acquisition card: PCI-6220

There is no change in the Labview application.

In the new 5.0 MAX.

I'm trying migrate/replicate all virtual channels & settings of the old system.

I managed to set up a new configuration using file for the acquisition of data from the old system.

This resulted in the creation of chains of virtual of NOR-DAQ traditional under the District of data, which is what I wanted.

But the problem is, all the channels received a red cross.

Clicking on properties of the individual chain shows that no device is selected in the hardware section. There is none to choose from.

Under devices & Interfaces,.

The new card is correctly installed and running.

Appears as > NI PCI-6220 'Dev 1.

How can I make this device available in virtue Traditional NOR-DAQ virtual channels in the data area?

Is it because the new MAX/data acquisition card requires the method task NOR-DAQmx to create virtual ways?

I want to migrate channels instead of recreating that there are a fair few and each with their own settings.

In the old system.

Under devices & Interfaces,.

That's what it shows:

-Devices of NOR-DAQ traditional

PCI-6023E (1 device)-OR-DAQmx devices

-PCI-6023E: "Dev 1.The device is recognized under the District of data - Trad VC through NOR-DAQmx devices.

I can attach a screenshot for systems if it would help at all.

Thanks in advance!

-Ram of Aust

Bad news... Your most recent 6220 is a M-series it is * not * supported by NOR-traditional DAQ. This is why it does not appear as an option under the traditional OR-DAQ driver. To use the most recent data acq card, you * must * swtich above DAQmx.

Your old 6023E Board should be accompanied by one or the other pilot (but never both at the same time), so it may be be jointly installed a print while you set on the (tedious) company to recreate channels for your new Board in DAQmx.

-Kevin P

-

Acquisition of data using the DAQ card

Hello everyone

I need assistance with the acquisition of data of the generator of signals through DAQ cards. I plugged the signal to the SCB-68 generator where the analog inputs of the generator are connected to AI CH5 and AIGRND of the Terminal Board. Then the output of the block is connected to the DAQ card. The maximum sampling frequency of the card is of 250 kech. / s. The problem is for reason that I am not able to see the waveform on the labview. I looked at other examples to find the problem, I am, but I am not able to understand this. I want to be able to choose the sampling frequency. I attatched my code as an attatchment for you all to help me know what the problem is. Any suggestions will be appreciated.

There is no task! You have not specified any hardware (i.e. your data acquisition card) anywhere.

Here's a suggestion. MAX aperture. Find your DAQ hardware. Open a Test Panel. Implement a continuous sample of N Points to some sampling rate. Press Run and convince yourself that you get the data.

Now, while remaining in MAX, to create a task, using the same settings. Call for example something sensible ("MyFirstDAQTask" is not a good reputation).

Now, go back to your code. Eliminate the first two functions DAQmx. Wire a constant task to the DAQmx Start feature. See the little triangle down? Click it, and it should show you the tasks he 'sees', the only one should be the task that you created in MAX.

Note that 'Samples Visible' is now 'hard coded' in the task. To get its value back out, you need to put a property node Timing DAQmx after the task start and pull on the quantity of the sample, samples per channel (which, for reasons that escape me, is a Dbl, you need to convert to an I32 before importing it into the while loop).

Bob Schor

P.S. Thank you to join your code.

-

DAQ cards not selectable, that listed in MAX

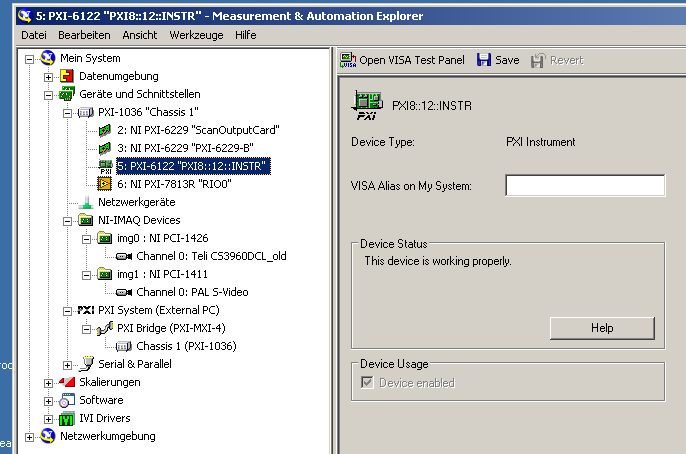

I have (re-) installing a PXI-6122 card on my computer. The device is then entered in the measurement and Automation Explorer, but differently from what I'm used to:

-It's another symbol than two PXI-6259 cards I have (see image below).

-It is not possible to create a task for the device using MAX because there is no such button.

In addition, in LabVIEW 2010 "device" or "physical channel" enumeration control, it is not listed (unlike the two PXI-6229 cards).

First of all, I knew that the card is broken. But it works correctly on another PC (with its own PXI chassis). Also, if I replace the card 6122 by another of the same type, the problem remains.

Then, I uninstalled all National Instruments software on my PC, deleted the "c:\Program NIUninstaller Instruments' file and some registry entries NOR related and reinstalled LabVIEW 2010 and device drivers. Now, the problem I had with the PXI-6122 now occurs for all three DAQ cards on the system (i.e., the two 6229 maps AND map of 6122): MAX icon is one that has the 'label PXI', tasks cannot be created in MAX and no device / or physical channels is displayed in the respective controls of LabVIEW.

Anyone have any idea how can I proceed?

-

programming for PXI-6071e with SCXI1125

Dear all,

I connected the SCXI-1001 chassis with card Conditioning SCXI-1125 and SCXI-1327 block with PXI-6071E PXI-8176 with SH1006868 cable controller card. I chose the SCB-100 for PXI-6071 accessories, as there is no option to select SH1006868. I connected the Thermocouple on the SCXI-1327 block terminals.

I am new to LabView, can someone guide me how to program. If anyone have example program, it will be useful to start learning

Thanking you

Concerning

-Vishnu

I don't think that you can select your accessory cables. Only the blocks for DAQ cards will be available on your list. Instead of the SCB-100, you can select the terminal box 1327? For starters, labview has a number of application examples. Go to the Help menu and select 'Search examples' then search for thermocouple. There should be examples on how to acquire tension of a thermocouple, graphic of your data readings, etc..

-

selection of the daq card to get the angular position of 6 motors with encoder

can you suggest me best daq card to use 6 positions of engines as outputs using encoders attached to the engines. I'll use single window for each engine. Or what can I use a single window for all the coders of engines?

Hello Prabhakar7117,

You need a counter for each encoder. Because you are going to use 6 encoders, you should get a DAQ hardware with 6 or more counters. Take a look at the PCI-6624 or PCI-6602. Another option would be a CompactDAQ chassis with modules that are able to access counters. Take a look at them.

KB which cDAQ Modules can be used to access the counters of the shipped?

Best regards

Alina M

-

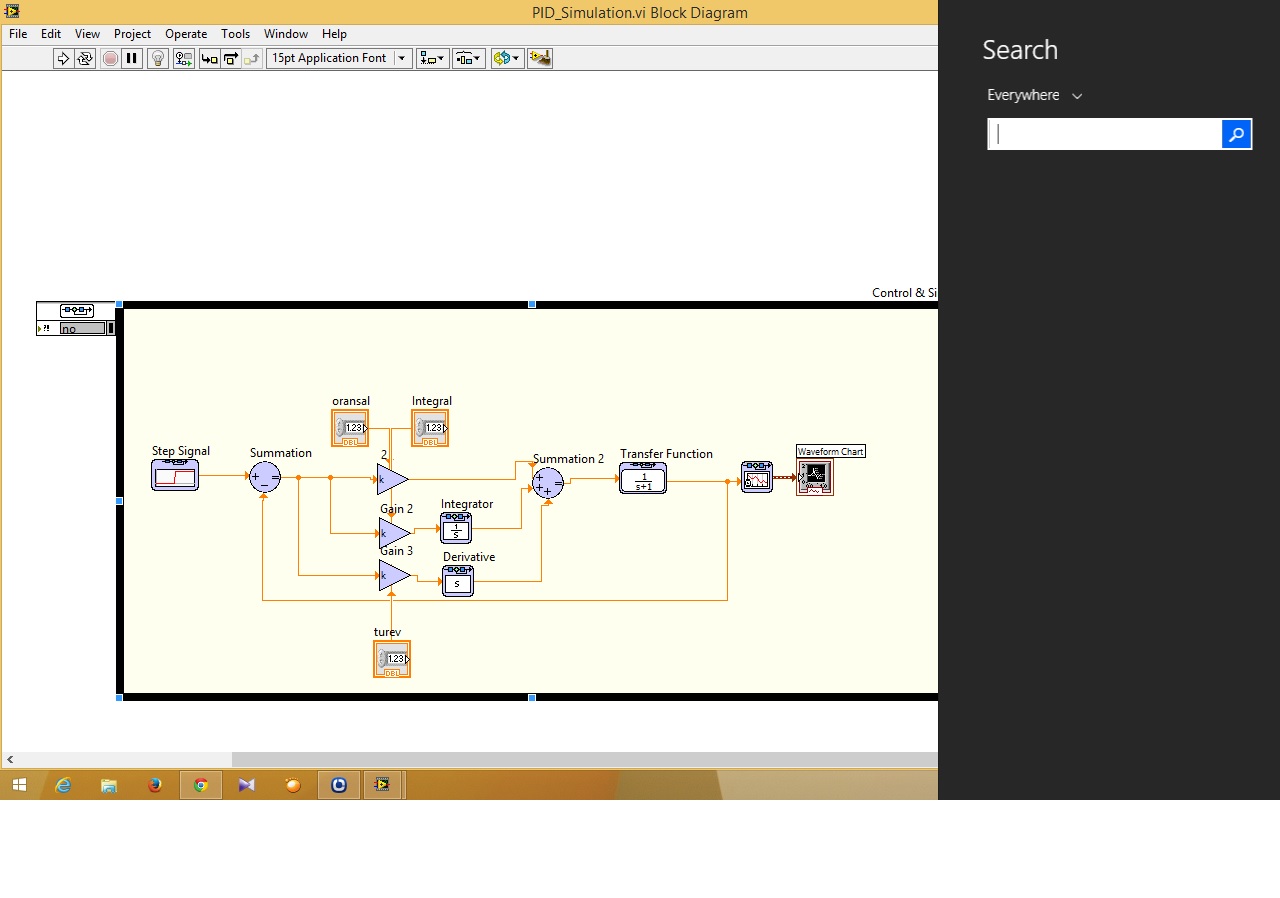

How to connect a simulation on the design of controllers to DAQ card?

Hi guys... I have problems about control and design on the way to the simulation I just do simulation PID and I can not to connect to the path of the simulation DAQ card in the control design (function)... can someone help me how to connect that?

Ayubi,

First of all, remember that the control and the Simulation has a PID in the Palette "control and Simulation > Controllers.

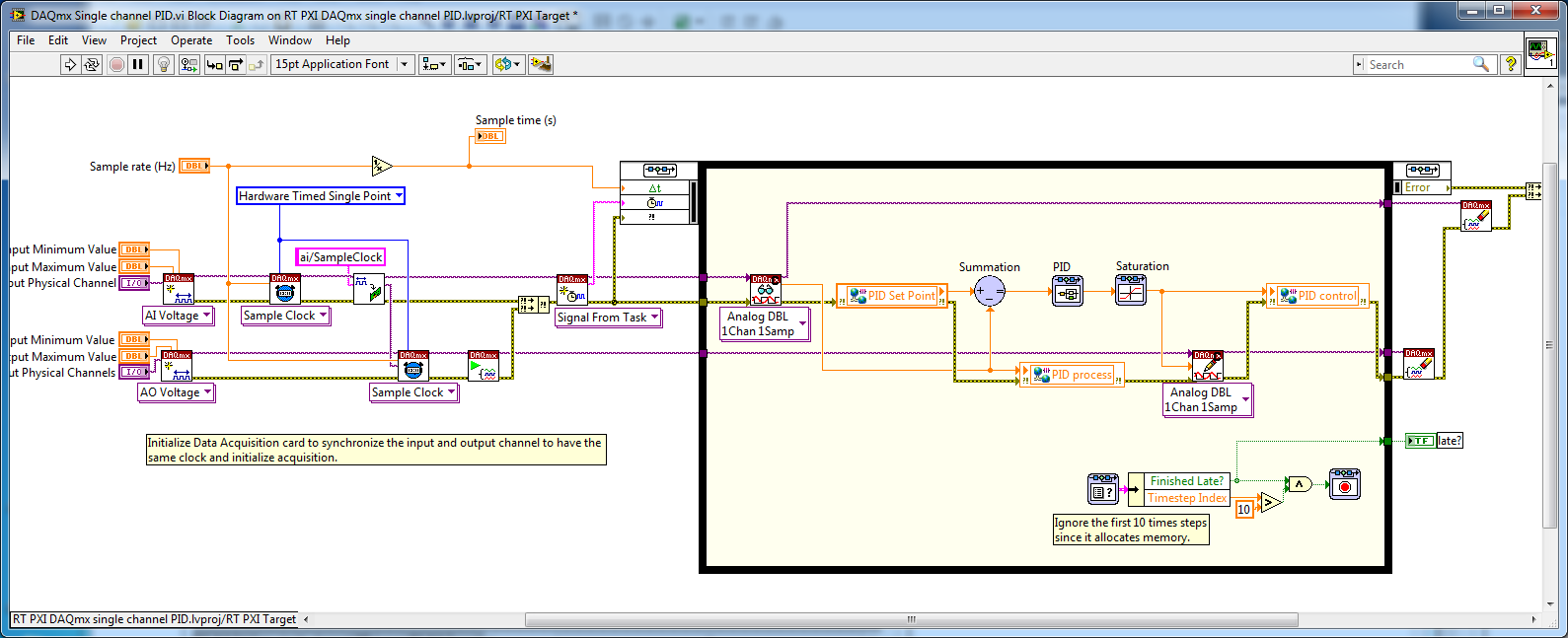

Then, to connect to a data acquisition card, you must use the DAQmx interface is there to connect. In general, National Instruments recommends allows you to deploy a controller a real-time system, but most likely your Windows computer should be good enough for your application. Please see the example of the expedition (in 2013):

C:\Program Files (x 86) \National Instruments\LabVIEW 2013\examples\Control and Simulation\Simulation\Real - time\DAQmx\RT PXI DAQmx single channel PID.lvproj

If you don't have a LabVIEW Real - Time (RT), you can simply open the VI:

C:\Program Files (x 86) \National Instruments\LabVIEW 2013\examples\Control and Simulation\Simulation\Real-time\DAQmx\DAQmx single channel PID.vi

Remove the shared Variables in the code and he would be executed on a computer with a DAQ card.

-

Ghost NI USB DAQ card readings

Hello

I have a question about the behavior of the NI USB-6218 data acquisition card. Right now I use Labview to take several current readings of different channels to HAVE it. I use resistors 250 ohms for each channel just as the instructions say to make the current readings. I had an incident where he has been disconnected one end of a resistance at the entrance to the port. I expected to see the reading go to zero, but instead, he began to piggback off the coast of reading one another channel give me a kind of 'reading ghost' because there was essentially no current crosses. Playback of disconnected channel displayed the current reading of the canal connected even while values went upwards or downwards. Can someone explain why the DAQ card would do that? and anyway to avoid this to happen?

Thank you.

A data acquisition uses a multiplexer to send a signal to the ADC. Due to having only 1 ADC, you will get this effect if the ability has no way to bleed. There is no way to avoid this if you disconnect the side DAQ, leaving the open input channel.

You could try adding in some amplifiers specially designed for the shunts of currents. I have used TSC103IPTwith success. This amplifier gives you a single output is completed. But I don't know what will happen with these if you disconnect one side of the resistance of the amplifier.

-

How display the waveform acquired DAQ card separately in wavefrom graphic

I NI 9239 DAQ card and it has four channels. I need to create a user interface graphic labview in which I need to display all the forms of four wave separately. If I select all four channels of the daq assistant and connect the waveform table all four waves are coming to overlap... I need separately for the treatment... what should I do?

Thank you and best regards...

Try this

-

Help! I have linux redhat 5 and installed the last base of nor-daq drivers 3.4.0f2. I see my Board from national instruments pci-6070e running lspci:

07:04.0 class ff00: National Instruments PCI-MIO-16-1

But when I run lsdaq, I he found nothing:

--------------------------------

Detect of National Instruments DAQ devices

Find the following materials:--------------------------------

Any ideas?

Andrew,

Thanks for the notice about the DDK.

Wanted to let you know by putting the DAQ cards in another workstation linux also runs HR, the lsdaq have found the cards.

I maintain there is no way to know the difference between mx and mx-Base without download them both and read the help files.

Also the word "subset of the functionality" is also misleading because you have to change all the function names.

Jonathan

Maybe you are looking for

-

The files are uploaded under D:\Downloads\ instead of as requested D:\

Hello world Although my general/downloads/save files is set to "D:\". ', rather, the downloaded files are saved in D:\Downloads. If I delete this file, it is created every time that I have download a file. Strangely, it seems to me that this happens

-

Should I use IDE or a SATA HDD in a Satellite A30 303

Hi there, I was wondering what HARD drive I can get for my laptop A30-303 because the old is dying today being a machine for 4 years, so I would like to upgrade. Y at - it a maximum size of the machine, or I can put in any size of HARD drive? Also th

-

What comments you can do the following: I have often noticed that when I am logging or by downloading Web sites in other countries, including the United Kingdom, Germany, the India... it seems to be much more long wait compared to websites here in th

-

Multiple phone numbers blackBerry Smartphones

I currently have two phones, the (personal) Blackberry Pearl 8130 and the BlackBerry 8830 (company), which is a real pain. Is it possible to add a separate phone number to the 8830 for personal calls and then switch the business number as needed?

-

Hello the Experts of Oracle.I already haveinstalled the Apache HTTP Server (with libraries)Downloaded the Plugin of Apache WLS12ccopied the plugin files into the appropriate directories.Modify the httpd.conf (see below)At the present time, I try to s