PCI-6110 continuous data

I am trying to take data continuously from 4 channels maximum 5Msamples per second and writes at the same time as the data on the drive using the TDMS writer. I use daqmx LabVIEW tools to read and write data. I get failry good flow, but it is not completely continuous.

1 is it possible in Labview?

2. is it possible with NIScope? NIScope is at all related to labview?

Thank you

Ben.

I'm not an expert DAQmx, but it is a fairly common use case covered by the API. You can configure DAQmx so that when the data are collected, it is written as efficiently on the disk. You can do it for a continuous data stream. You can find an example of this here (and more examples using the LabVIEW example Locator: Help-> find examples...):

This VI uses the data at the level, so you will want to choose not adjusted I16 data for the type of output to the maximum speed. Alternatively, you can use a producer/consumer architecture, acquire data in a loop and it continuously to the PDM in another. It is essentially this as the example above, but much easier and more quickly, because it involves fewer copies of data. Good luck!

Tags: NI Products

Similar Questions

-

Excerpts from continuous data acquisition

Hello

I want to make an acquisition of continuous data with a NEITHER-6133 @ 1ms per channel. The data must be stored on hard disk. At the same time, I want to take excerpts from acquisition to calculate different values. The acquisition of the extract must be triggert by an external digital trigger. Are there examples, which combine continuous data collection and collection excerpts?

Thank you very much.

Best regards

Michael

System

Windows 7

LabVIEW 2012

NOR-6133

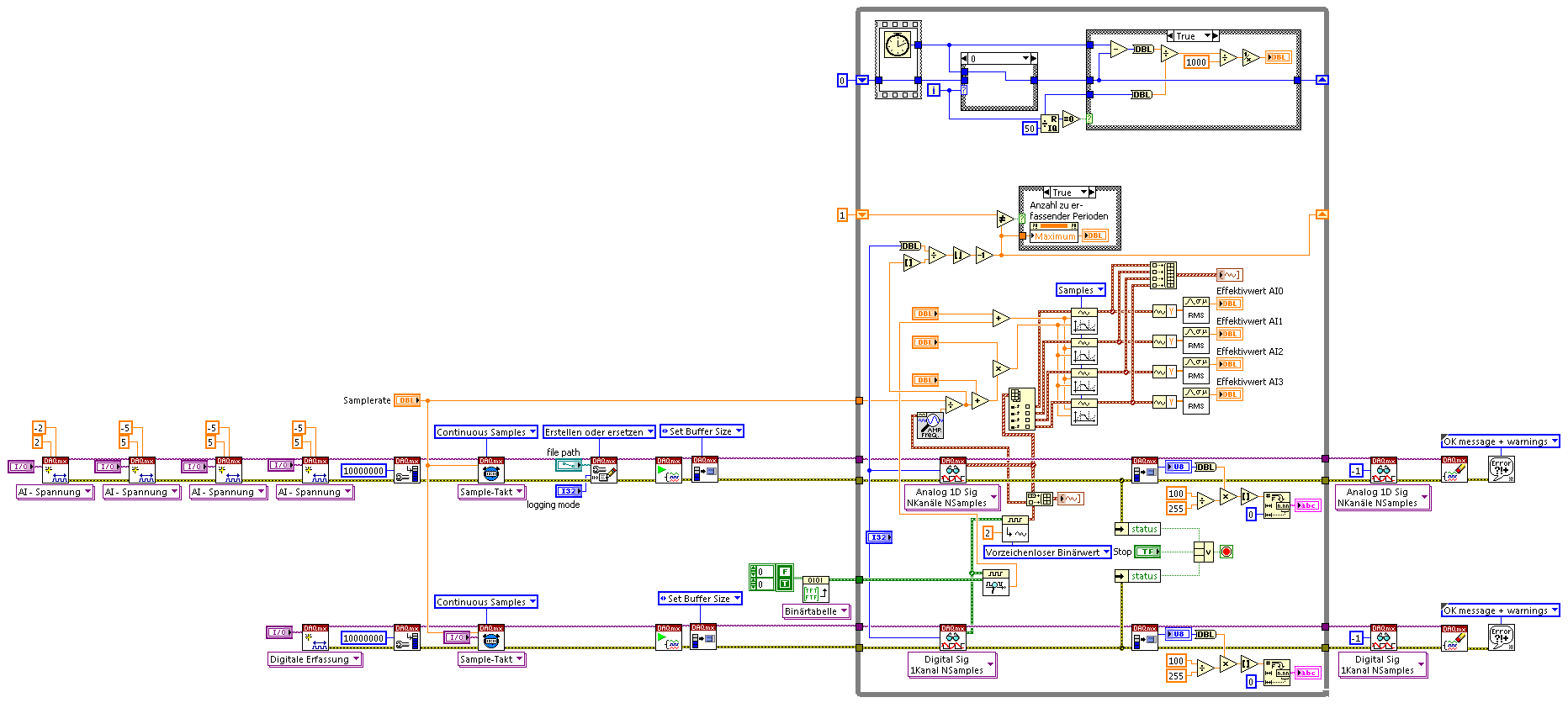

Thanks to the support of NOR-Germany, I found a solution for me:

1.) continuous trigger switch

Connect 2) the trigger for the signal to a digital i/o

3.) synchronize AI and DIO

Excerpt 4.) the samples needed by the search within the digital waveform pattern

Result:

The example shows 4 IA channels Cup (tested on Win7, NI PCI-6115, 4 channels each 5. MECH / s) and calculation on extracts from each channel signal triggered parts.

-

Minimum width of the PCI 6110 AI signal

Hello

I have a fundamental question on channel PCI 6110 AI. What is the sample and hold time of the ADC used inside the map? Or how much time I have to keep my constant input signal for the true conversion of data.

Thank you very much in advance for your help.

TOROs

Hi TOROs,

You can find details on the ADC of 6110 here.

I hope this helps!

Bye,.

Licia

-

PCI-6110 to change analog input range

The analog signal I want to measure is 24 volts and the maximum PCI 6110 is Volt.However 42, analog inputs that appear in the device under device NOR-DAQ traditional (old) configuration is 10 volts (single selection). I'm using LabView 7.1, DAQmx 8.6 and there is no function for allowed me to modify and change the analog device input range (Please find the print screen of the attachment). Can I know how can I change the analog inputs range?

I think that's what you're looking for:

S how to set up a data acquisition card series for the entry level so it does not Clip?

You must set up an appropriate gain so that the other ranges of voltage is displayed.

In addition, you can post on the forum instead of Labview data acquisition in the future, because the chances are that you will get better/faster responses there

Good luck!

-

Would it not correct to say that the PCI-6110 can be set to 'redeclenchables' but the PXI-6115 module cannot use this property? If Yes, where is it documented the series cards can do trigger? For example, is it possible to configure the trigger on the PXI-6124?

Hi Joel_Neptune,

The PCI-6110 and other materials as the PXI-6115 S series and SMU-6124 do not natively support NOR-DAQmx analog input alarm. However, you can use one of the generalist counters/timers of the Council to generate a reenclenchees pulse train, then use this as the sample clock pulse train. This transportation example shows how:

LabVIEW\examples\DAQmx\Synchronization\Multi-Function.llb\Multi-Function-Ctr Retrigg Pulse Train generation for the Clock.vi sample

In addition, the new material of the simultaneous sampling X series are supported trigger analog input without using a separate task of counters/timers.

Brad

-

How to calibrate the PCI-6110 with NOR-DAQmx

Hello

I am a new user of the PCI-6110 Council tries to run the calibration using LabVIEW procedure. I look at the document "Calibration" on the page of the manuals for the Board of Directors,

http://sine.NI.com/NIPs/nisearchservlet?nistype=psrelcon&NID=11888&lang=us&q=FQL: 28locale % 3Aen % 29 + AND + % 28phwebnt % 3 A 1081 + OR + phwebnt % 3 A 7075% 29 + AND + 28nicontenttype % 3Aproductmanual % 29 + AND + % 28docstatus % 3Acurrent % 29% 20RANK % 20nilangs: en & title = NOR + PCI-6110 + manual

One of the first steps in the document is to call the AI_Configure command to set the input mode, beach, etc. I'm using LabVIEW 8.5 with the NOR-DAQmx software, and I can not find the command (which, in LabVIEW, seems to be "AI Config.vi") anywhere. The calibration paper was written in 2003, and I gather from Google searches (please, correct me if wrong) that this command is actually a part of NOR-DAQ traditional, who was replaced by driver OR DAQmx.

My question is this: what is the equivalent to AI_Configure command in the latest software? Is it perhaps a subsequent document describing how to calibrate using NOR-DAQmx?

Thanks much for any help.

Tom McLaughlin

Hi Tom,

The calibration Procedure series B, E, M, S, which is also linked from this page, describes how to calibrate the PCI-6110 with NOR-DAQmx.

Brad

-

PCI-6111 is recognized as PCI-6110

I have a Board OR marked as PCI-6111, but when I inserted in a PC, it has been recognized as PCI-6110. Subsequently, none of the inputs or outputs work. The analog inputs still show a flat 10V line, while the exit is blocked to 500 mV. The card go through self-control, however fails self-calibration. Reset of the card does not resolve the problem.

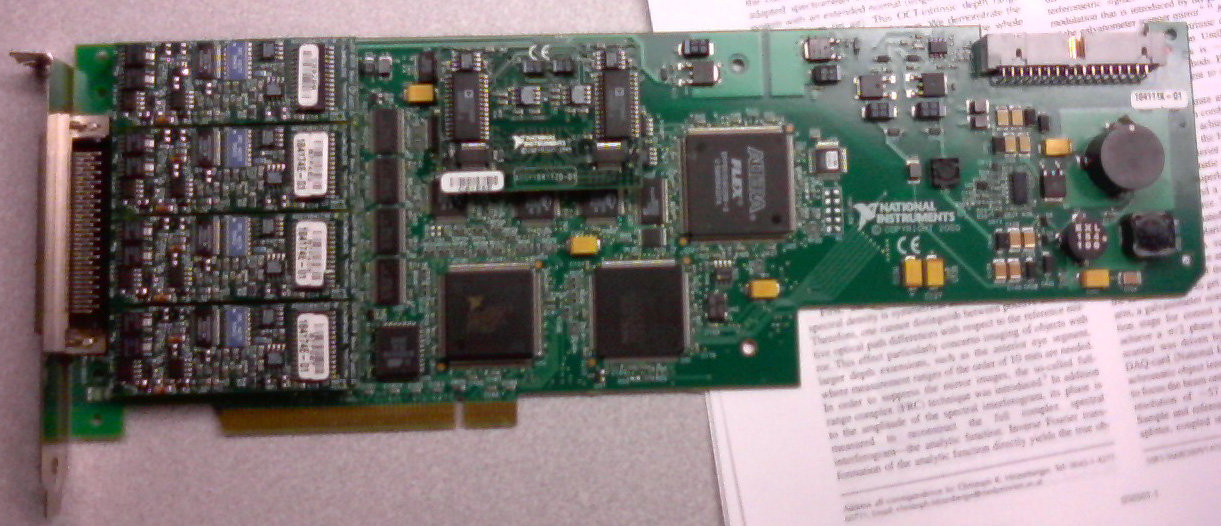

Based on the images below, what a card 6110 6111? Could he just scored, in which case the card is probably damaged?

It looks a little dfferent PCI-6111 cards available to us, but perhaps that is a previous model (it had been built, it seems, in 2000).

Or might pose the problem with inputs and outputs that the PC does not correctly recognize it? If this is the case, is there an easy solution (in relative terms) of the problem, sending to OR for repairs?

Thank you for reading.

Filipp,

Where did you got this card? It is a very strange problem. 184111 K-01 part number is for a 6110. The part number 184111 G-02 is for a 6111. The jury is without a doubt a 6110 as you can see the 2 of the 6111 4 chips on the left hand side related to the 4 channels of the 6110 vs. So I recommend you all what's wrong with that you send it back in OR for repair. You can give me a call at 1-866-275-6964 SEO SR #: 1436085 and I can help you through the process of RMA from here.

-

I32 flipping index iteration continuous data acquisition

I'm doing some continuous data streaming with Labview FPGA and periodically generate a trigger signal

the timestamp after a number fixed iterations.

The strategy I would try was to review the iteration index in the timed loop and whenever he tipped a fixed number I would generate a trigger of the FPGA.

I tried to find out what happens when you get to 0x7FFFFFFF samples on the register of I32 and apparently

the index does not roll... It just remains to count max once reached it.

Is there a way to derail the index on a timed loop? Otherwise I wil just add another

U32 variable and increment it each cycle and let it roll on.

the iteration count does not roll. Therefore at this historic moment, but just use a registry node, local or feedback shift instead.

-

Hi, I have problem with my block diagram. I plan to display data (from temperature probe NICrNi) of several channels and memorizing the data in csv and tiara permanently file. Now the problem is how to say continuous data 2D (double data types)? because the result of the measurement are very unstable... I try using the function means PtByPt VI but she need to double entry of data types... Are so there is another way to describe the data? for example I need an average of data for every 20 samples.

-

I try to combine the dates a day continuously and display the output as mentioned below. Here is the data model and expected results. WITH t AS (select to_date (' 01/1/2005 ',' mm/dd/yyyy') as start_date, to_date (January 31, 2005 ', ' dd/mm/yyyy') as end_date, 1234 as val from dual union all select to_date (' 02/1/2005 ',' mm/dd/yyyy') as start_date, to_date (February 27, 2005 ', ' dd/mm/yyyy') as end_date, 1234 as val from dual union all select to_date (1 March 2005 ' ' mm/dd/yyyy') as start_date) , to_date (March 31, 2005 ', ' dd/mm/yyyy') as end_date, 1234 as val from dual union all select to_date (' 1/05/2005 ',' mm/dd/yyyy') as start_date, to_date (May 31, 2005 ', ' dd/mm/yyyy') end_date, 1234 like val double union all select to_date (' 07/1/2005 ',' mm/dd/yyyy') start_date to_date as (July 31, 2005 ') (, ' dd/mm/yyyy') as end_date, 1234 as val from dual union all select to_date (' 08/1/2005 ',' mm/dd/yyyy') as start_date, to_date (August 31, 2005 ', ' dd/mm/yyyy') as end_date, 1234 like double val); Expected results: val START_DATE end_date 123 123 05/01/2005 123 01/01/2005 03/31/2005 07/01/2005 08/31/2005 thanks for your help.

Hello

It is impolite to post the same question more than once. Mark this thread as "Response" and you keep your other thread:

Re: Combining continuous dates

who already has an answer.

-

How to count the continuous dates in oracle 11g

Hello

I need to count the continuous more than 9 days between given dates below is my example

Are my data like this

MAY 1, 2013

MAY 2, 2013

MAY 3, 2013

MAY 4, 2013

MAY 5, 2013

6 MAY 2013

MAY 7, 2013

MAY 8, 2013

MAY 9, 2013

MAY 10, 2013

Now I want the number of days between these continuous days of more than 9 days now, I will get the result for the above data is 10 days

If any date is not in the list then days would not result if it is less, then are equal to 9 days

Here is an example of another

MAY 1, 2013

MAY 2, 2013

MAY 3, 2013

MAY 4, 2013

MAY 5, 2013

6 MAY 2013

MAY 7, 2013

MAY 8, 2013

MAY 10, 2013

11 MAY 2013

number of days here is 10 but may 9, 2013 is away at the moment, the county should not show as 10 because continuous date (May 9, 2013) is absent, that's what I need, please suggest the solution.using the {: identifier of the thread = 1005478}

SQL> ed Wrote file afiedt.buf 1 with test as 2 ( 3 select date '2013-5-1' dt from dual union all 4 select date '2013-5-2' dt from dual union all 5 select date '2013-5-3' dt from dual union all 6 select date '2013-5-4' dt from dual union all 7 select date '2013-5-5' dt from dual union all 8 select date '2013-5-6' dt from dual union all 9 select date '2013-5-7' dt from dual union all 10 select date '2013-5-8' dt from dual union all 11 select date '2013-5-9' dt from dual union all 12 select date '2013-5-10' dt from dual union all 13 select date '2013-5-11' dt from dual union all 14 select date '2013-5-13' dt from dual union all 15 select date '2013-5-14' dt from dual union all 16 select date '2013-5-15' dt from dual union all 17 select date '2013-5-16' dt from dual union all 18 select date '2013-5-17' dt from dual 19 ) 20 select min(dt),max(dt),count(*) 21 from (select dt, 22 dt-Row_Number() over(order by dt) 23 as disTance 24 from test) 25 group by disTance 26* order by min(dt) SQL> / MIN(DT) MAX(DT) COUNT(*) --------- --------- ---------- 01-MAY-13 11-MAY-13 11 13-MAY-13 17-MAY-13 5 -

I get upgraded my laptop (HP for laptop - 15-r224tx) for Windows 10 but I can't find the driver for the controller of PCI Data Acquisition and Signal Processing. Please help me find the right one.

Thank you!

You are the very welcome.

It is the latest version of the W10 driver for this card model... see if this solves the problem, if you have not already installed this driver.

This package contains the installation package driver for the controller wireless LAN Realtek RTL8723BE/RTL8188EE in the laptop models running a supported operating system.

File name: sp72517.exe

-

Hello:

I'm very new to LabView, so I need help to find an idea that can help me to record data continuously in real time. I don't want the file is too big, so I would like a new file in Crete in each 32 mega bytes and clear the previous buffer. Now I have this code can save data of voltage in the TDMS files and the sampling frequency is 2 m Hz, so the amount of data very fast increase and my computer have more ram 2 G, then the computer hangs after 10 seconds, I'm starting to collect data. I need some advice you briliant people.

Thank you very much I appreciate really.

I'm a big supporter of the architecture of producer/consumer . But this is the place that I recommend. The DAQmx Configure Logging does all that for you!

Note: You will want to use a table instead of a graph here.

-

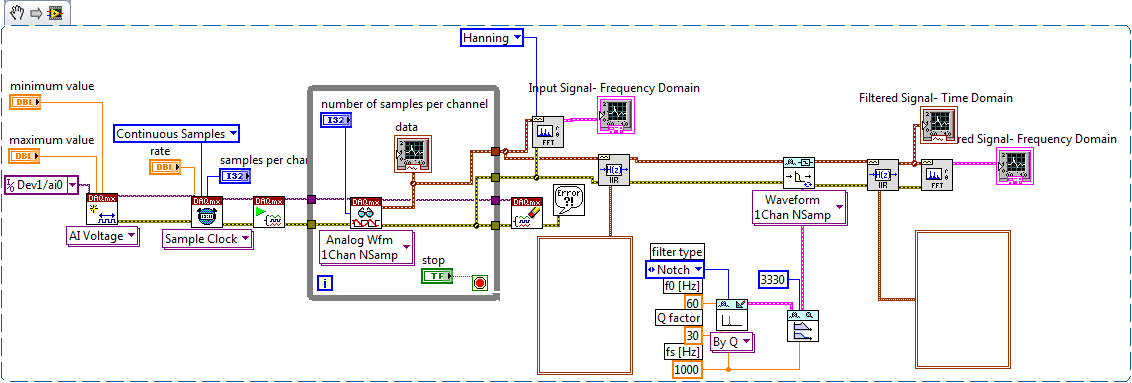

Continuous data acquisition and real-time analysis

Hi all

It is a VI for the continuous acquisition of an ECG signal. As far as I understand that the analog read DAQmx VI must be placed inside a while loop so it can acquire the data permanently, I need perform filtering and analysis of the wave in real time. How I implemented the block schema means that data stays int the while loop, and AFAIK the data will be transferred on through the tunnels of data once the loop ends the execution, it clearly isn't real-time data processing.

The only way I can think to fixing this problem is by placing another loop that covers the screw scene filtering and using some sort of registeing shift to transmit the data in the second while loop. My question is whether or not it would introduce some sort of delay, and weather or not it would be supposed to be the treatment in real time. Wouldn't be better to place all the screws (aquicition and filtering) inside a while loop? or it is a bad programming practice. Other features I need to do is back up the data I na file, but only when the user wants to do.

Any advice would be appreciated.

You have two options:

- A. as you said, you can place the code inside your current while loop to perform the treatment. If you're smart, you won't need to put one another while loop inside your existing (nested loops). But it totally depends on the type of treatment that you do.

- B. create a second parallel loop to perform the treatment. This would be separate processes to ensure that the treatment is not obstacle to your purchase. For more information, see here .

Your choice really depends on the transformation that you plan to perform. If it's much the processor, this could introduce delays as you said.

I would recommend that you start at any place in the first loop and see if your DAQ buffer overruns (you can monitor the rear of the buffer during operation). If so, you should decouple the process in separate loops.

In what concerns or not ' it would be considered as real time processing ' is a trick question. Most of the people on these forums say that your system is NEVER in real time because you're using a desktop PC to perform processing (note: I guess it's the code that runs on a laptop or desktop?). It is not a deterministic systemand your data is already "old" by the time wherever he leaves your DAQ buffer. But the answer to your question really depends on how you define "real time processing". Many lay it will set as the treatment of 'live' data... but what is "actual data"?

-

PCI-6534 receives data to clock twice

I have a simple test developed in place to check the operation of the card PCI-6534. A written test generator a double-ended (hi-lo) word of 16 bits of zeros with one being bitshifted to the left (MSB). It is sent to a custom Board that converts the double signal over single-ended and then sends the map of PCI-6534.

Something like this:

0000000000000001

0000000000000010

0000000000000100

0000000000001000

0000000000010000

etc...

I have two different computers and each has a PCI 6534 installed with exactly the same configuration accept the driver. Computer 1 PCI-6534 driver version 1.12.0f0 (circa 2006). Computer 1 shows the diagram above as expected. Computer 2 a driver 2.0.0f0 (circa 2007). 2 computer shows the diagram below:

0000000000000001

0000000000000001

0000000000000010

0000000000000010

0000000000000100

0000000000000100

0000000000001000

0000000000001000

0000000000010000

0000000000010000

So, it looks like 2 computer gets the same data on the top and bottom of a clock cycle.

I was about to check the clock seen by 6534 on computer 1 against 2 computer the data generator trial to show the difference. However, in doing so, I discovered that now 2 computer shows:

0000000000000001

0000000000000010

0000000000000100

0000000000001000

0000000000010000

I can't reproduce the problem even if I ask the question!

Any ideas?

Thank you!

We have two different vintages of differential boards. It turns out that the newer boards have a slightly different flavor of the chips that the older 26LS32. When we swapped the chips on the latest map with those of the former, we were able to solve the problem.

So, with the non-functional chips installed, if we turn the clock low slow reeeaal, we can get multiple samples of data such as the differential line noise is enough that she takes back as clock. If we turn up to, say, 6 MHz all right. It is because at that time, the clock runs at a higher frequency than the noise and overclocking the card.

I still have yet to understand what the parameters are new chips really are the root cause of the problem, but it works.

-Shrew

Maybe you are looking for

-

Display driver for Presario CQ60 211 DX?

I need the display driver for XP... I've tried a few and none of them work... otherwise, I'm stuck with a non screen resolution that seems wrong...

-

Cannot read the timestamp of the file LVM in table or export to Excel

Good afternoon! Im having issues return timestamps from a LVM file and an excel file. Ulitmately, I have a series of files LVM with 6 channels of data and timestamps of correspodning. When I read the back files in a table, the channel values are anal

-

I can not send messages, I received

I can't send messages... I get... What do I do

-

Touch screen has only the HP logo

Now out of warranty HP Photosmart 7515. Its touch screen now displays only the HP logo. No applications. I tried everything suggested on the Forum as disconnect the power and wait 15 seconds (waited 60 sec), he didn't reset the printer. I would like

-

HelloMy .xml files all appear a Notepad icon, but it can be opened correctly by the browser Internet Explorer, feathers and other functions are normal, just the icon does not appear correctly. How can I change the icon back to its original icon?In ad