PLC

I am trying to connect 14ss2 plc delta with labview but an error is coming about serial communication

the error that says that it is a valid resourse but visa currently cannot access, I tried also to opc, but when I click Add device it does not show delta PLC

the error codes are VISA (HEX 0XBFFF0072)

Tags: NI Products

Similar Questions

-

Toshiba EX_100 PLC program Windows.

Hello, I am looking for programming of PLC Windows software that can be used for the controllers of EX_100 from Toshiba. I have the DOS program, but I need a Windows program. I need a way to program several old Toshiba EX_100 automatons of laptops running Windows 7.

Thank you.

Hmmmm... In my opinion, it will be difficult for you to find something like this, especially here on the user forum. I'm afraid, you need professional help with this m.

I recommend you contact the nearest Toshiba service provider and ask for help. They directly go to Toshiba and can send some sort of request to the right people.

-

Hi all

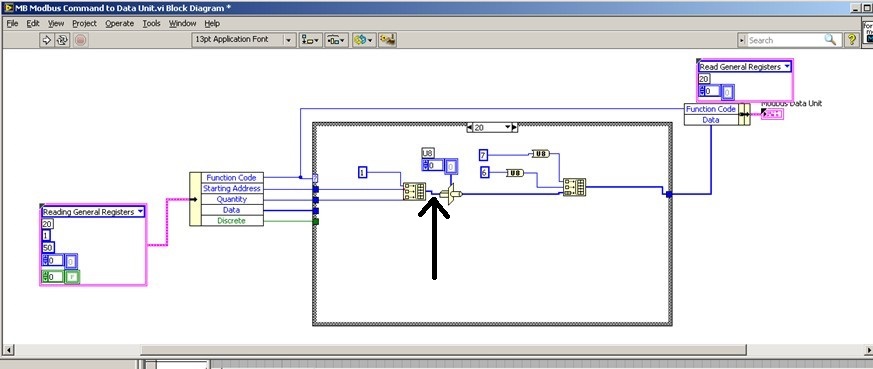

We try to add 20 saving file read function code in order to read the brief in bulk from PLC. We used the modbus for Labview library to communicate with the PLC with Modbus TCP/IP, but when I addes the code function 20 to the cluster of the MB Ethernet Master query entry reading registry Palette entry, the program displays an error. I'll be really appreciated if someone could help with this problem!

We hope all have a good weekend.

Best regards

Sophie

Actually... that is a constraint on the second entry to "build the table? ' It is difficult to tell from the image. If so, what is the data type of this cable?

That must be an array of U16s, because the "quantity" and "home address" are U16. However if the value '1' is a larger data type as U32, labview perhaps at upconversion of the whole table that would result in a larger data set than expected and could cause error 2. You can check on this?

-

Hi guys, I am trying to build the commucation between my CRIO9066 and PLC300, which means I want the CRIO to get data of PLC, but I don't know how to implement it, could someone give me a hand? Moreover, I did possible communication between Labview and PLC by using an OPC server, I wonder if this also works in the communication between PLC and CRIO.

To my knowledge, you cannot connect to a server OPC DA of a cRIO because it isn't a windows target and OPC DA uses DCOM to communicate. If it is an OPC UA Server, you can certainly use the LabVIEW API of a cRIO.

You can also check if there are other ways to communicate to the controller as Modbus.

-

PUERTO PARALELO MICROLOGIX PLC

Connect as a PLC a sin usar OPC, DSC labview. Corpos UN Micrologix 1200 he read a travez of ModBus, pero no encuentro UN VI y UN programa PLC example than me to idea of como is con este protocolo pues nunca he trabajado don't con el the application that I'm developing none are very complex even could ser por el puerto paralelo. MI duda are TR el puerto paralelo four para funcionar manera esta continued 10 horas manera L - V safe deposited, are decir an industrial level

Buenas tardes DJSerafin,

If are posible comunicarse con UN PLC sin necesidad utilzar OPC servers o Module DSC, lo what hace are using NI VISA y con el protocolo ModBus is communication t, Sin embargo, esto're muy tardado, there are studying como works foot ModBus a cabeza.

Ahora is una libreria para con Comunicación ModBus as puedes descargar Aquí, el unico lost what esta tiene page are that no esta launched soportada. Esto means that if tiene alguna complicacion lo atenderemos, pero el tiempo respuesta no sera el mejor are no hay information relacionada a esta libreria en nuestra base data.

Aprovechando el foro, you Le tambien than exite UN KB than the manual instalacion of esta libreria sober habla. Para poder access one da El in click here. Con esto con comunicarte sin problema any hope.

Por cierto, you recommend what made the detailed each of screws libreria problemas para ayuda y you ensenaran a utilizarlo.

Saludos, y mucho exito en you application.

-

Programming of camera or 1744 with PLC

Hello

I have a N I 1744 camera. It scans the length and position of the pins. There are several lengths of pins. So, there are + 10 programs needed. The programs were made with NI Vision builder. The right program to fix the right axis is now inserted in the device with visionbuilder. I expect to get rid of the laptop and be able to choose the program with PLC S7-1200 installed. This would save some time.

This would be possible or is there any otherway to make an easier selection of the program?

Thanks in advance.

If I understand correctly, you want the controller to tell what program to load the smart camera.

Vision Builder AI support various industrial communication protocols which can be used to communicate with an automaton, like the series, Ethernet, Modbus, Ethernet/IP, OPC UA.

You could also use e/s and send signals to the PLC to the smart camera.

In the Vision Builder, select view > view complete on the inspection facility.

Select then view > toggle main view window.

On the left bar that is displayed, click the icon of the Inspection to select.

Now click on the steps of Inspection: tab of the palette on the right to communicate.

Select the step corresponding to the communication protocol that you have chosen to use with your PLC, for example, the TCP protocol.

With this step, you want to read the command sent by the controller.

Then go through the steps of Inspection: using tools additional tab scroll down and click on the select Inspection stage.

This step allows you to specify which control to run according to the result of the stage of communication that you just inserted.

Click Add to specify a new inspection. Specify a (value - Inspection) pair.

Activate the checkboc 'Activate the selection of Inspection' and click OK.

Go to the inspection of the VBAI mode and open an inspection.

When control reaches the final State, the inspection status select will turn to see if a new inspection has to be charged.

I hope this helps.

Best regards

Christophe

-

Communication to S7 300 PLC using the A2 CP5611 map

I need to collect data from PLC S7 300. I am havin the PC with card Siemens CP 5611 A2 Profibus. I don't want to use any OPC on this.

is there any avilable pilot or a colecting data library.

Concerning

Sivakumar

You may be able to communicate to this forum using DLL (call library in LabVIEW function) calls. Contact Siemens for such an option.

If you are looking for a device Profibus with a native API for LabVIEW, you can use this card instead.

Kind regards

Jochen Klier

National Instruments

-

Hello

I try to connect LabVIEW to controller using an OPC server of NOR. Its a controller logix (Allen Bradley) L23E Compact and I find it difficult to obtain the device driver. Please help me with this topic and a link explaining how it would be useful to connect labVIEW to PLC.

Thanks in advance,

Sunil

Hi Sunil,

Regarding the driver: See the taken list supported device & driver plug-in for NOR-OPC Server

Regard to the connection in LabVIEW: You have two main options that depend on the question of whether or not you have the LabVIEW DSC Module. As seen here, you can either use variables shared with DSC to access your OPC tags, or you can simply use DataSocket VIs contact them directly as an OPC client. Some documents that may be useful by adding your specific hardware can be found here and here.

I hope this helps!

-Greg J

-

Difference between RTU, PLC & HMI VS SCADA

Hello

Can someone please explain what is the difference between RTU (remote terminal unit) and PLC (programmable logic controller)?

As well as the difference between HMI & SCADA? I'm so confused.

Is not fundamentally the RTU PLC? Thank you.

Hello

I hope I can clear things for you. RTU (Remote Terminal Units or remote telemetry units) and of the PLC (PLC) perform similar functions, they share some features. However, RTU is often considered to collect telemetry over large geographical areas, because they use wireless communication. PLCs are generally implemented in situations where local control is necessary, as the Assembly lines and ammusment wrinkles because they are designed for multiple inputs and outputs.

Your confusion with SCADA and HMI is common. HMI (Human-Machine Interface) is a part of SCADA (Supervisory Control and Data Acquisition). SCADA is used to monitor or control specific parts of a large system. For example, a SCADA system may be used to optimize and control a water treatment plant. A GUI is just a UI of the SCADA system. For example, if someone wanted to change the rate at which is certain measures were taken, it would use the HMI.

I hope this helps. If you want more information, you can read the information on the links below.

http://www.differencebetween.NET/technology/industrial/difference-between-PLC-and-RTU/

http://www.differencebetween.NET/technology/industrial/differences-between-SCADA-and-HMI/

Best regards

Thomas B.

-

Cannot communicate with the 2nd PLC

I am trying to run RSlinx OEM classic and two Allen Bradley PCLs in my LabVIEW 2010 application. I can see automata and their labels in my o my project server, but the 2nd shared PLC variable values do not receive in my code. Shared variables are theirs and they are connected to the correct tag names but no values. 1 PLC and associated tag and to share variable values have always worked fine. Suggestions? Thanks in advance.

Ben wrote:

Double check everything with the second PLC and if nothing obvious, I'd be OR composition and recording of a new service request.

That's all I can offer,

Ben

I called NOR and they thought it was the device ethernet controller driver. But it is the most recent version. I tried implementing a 2nd remote server I/O for the 2nd PLC and that fixed it. It's confusing because all tags appear in the two I/O servers but I can only read the labels on the PLC 1st with the first server and the 2nd set of tags in the 2nd PLC in the 2nd Server.

-

How to connect Labview to PLC Modicon Quantum (140 CPU 311 10) with Modbus

I was wondering if someone could give some tips on how to connect Labview to Modicon Quantum plc (the card is 140 CPU 10 311). I am eager to serve a Labview HMI to control the controller that is used to implement the control PID with a VFD. Currently I can communicate via Modbus to the API for programming using UnityPro XL, but I have no idea how to connect Labview. I read the article on place OR "connect Labview to any PLC via Modbus", but I don't know yet. Any help will be greatly appreciated.

Hey Greener.

Communicate with the PLC via Modbus usually requires the Datalogging and Supervisory Control (DSC) Module to have this feature available in LabVIEW. The white paper which indicated you using this module, which may explain why you can't get the communication at work. If this is something you don't have, and purchasing a license is not an option, then you might be able to use Modbus unofficial libraries to get the functionality you need. I have included a link below to a Modbus for LabVIEW library that you can try.

DSC module:

http://sine.NI.com/NIPs/CDs/view/p/lang/en/NID/209851

Modbus Library:

http://www.NI.com/example/29756/en/

Kind regards

Ryan

-

Hello

I do test with NI Veristand HIL. My hardware is a cRIO 9075 siemens AND 200 s PLC. I found an address ethernet/IP add it to veristand:http://zone.ni.com/devzone/cda/epd/p/id/6337

However, if I understand correctly, it will not work with siemens plc. Are there patterns that I can do on the add-on ethernet/IP, which allows to work on siemens PLCs?

any help is deeply appreciated.

Do not confuse Ethernet/IP (Ethernet industrial Protocol) with "Ethernet" (the physical layer, it is built on). Both Profinet and Ethernet/IP are protocols built on top of the Ethernet physical layer, but apart from that, they are completely different protocols.

Regarding your question, NI VeriStand consists of a runtime of models yout, IO, etc... and an application for configuring host-side and communicates with the engine. Generally, the engine will run on a system in time real (for example a CompactRIO or PXI system), but it is also possible to run the engine on your WIndows machine. The downside to this is that Windows is not a real-time operating system, so you can't wait operation is deterministic, free of jitter, which is usually required by the test of RT applications.

Insofar as the implementation differences, your target cRIO runs a VxWorks operating system, which is unable to call DLLs. Instead, you'll have to comile your models in a .out file. If you use the Mathworks Simulink®, NI VeriStand comes with a .tlc of VxWorks file that can be drawn from the real-time Workshop. If you compile your own C-base model, you will need to use the chain for VxWorks GNU tools. You can find instructions on how to do it here.

If you use the cRIO VeriStand engine, you will need to use a C series Profibus or Profinet module for communication with the controller. I don't have any experience with these, but you need to program the FPGA and probably write a device customized to interface the NI VeriStand code. If you use the Windows engine, there may be 3 third-party drivers available for this type of communication that you could then conclude with a custom device.

-

Communication between VBAI 3.6.1 and 1200 Siemens PLC

Hello, I use Vision Builder AI 3.6.1 to perform an inspection of PuTTY to black color in the back of a vehicle in the chain of production of a car company. The device that I use for inspection is a Basler scout camera (scA1000). Once the inspection is complete, I need to send a signal to a Siemens PLC 1200 I use. If the inspection has passed, it should send a signal to the controller that will power to turn a green ligth, indicating that the inspection has passed. When the inspection has failed, a signal be sent to the controller who should turn on a red light. Can someone tell me please on this?

Thank you.

-

Lookout Modbus Ethernet driver for-More PLC?

I see that automationdirect is now out with a CPU of PLC of more that uses material from DirectLogic 205. Their documentation indicates that the new CPU Ethernet port communicates with the protocols that include:

Modbus/TCP Client (master) and

Modbus/TCP (slave) Server

This will be contacted by the Modbus Ethernet Lookout driver?

Yes, Modbus driver support ethernet

We we the ECOM-100 "and" bridge MB

-

How to connect and communicate between PXI1031 and PLC Controllogix?

I would like to know how to develop communication between the CAP/PXI with PLC, using the Ethernet switch.

What is the add-on hardware or software necessary?

I found some useful information through a video:

http://zone.NI.com/WV/app/doc/p/ID/WV-11/nextonly/y

Please do not hesitate to give your suggestions and any other information or thing for the same experience.

Maybe you are looking for

-

How to disable the new Thunderbird 24.2.0 e-mail notifications

I need to stop biff type popup notifications. Some solutions exist including the help of Mozilla, but none seems to be valid for my version which is 24.2.0 for linux. There seems to be nothing like 'General Options '. Thank you.

-

Can I use third party Windows CE based touch panel to control my system?

I want to use a touchscreen to WindowsCE based to control my system by connecting a CompactDAQ by USB and install the.exe file built from LabVIEW and CompactDAQ driver installation. It seems doable, but I don't know if Windows CE supports .exe files

-

0x8024400A error when trying to install updates in the Windows XP computer.

Original title: Foutnummer: 0x8024400A. After new installation of windows XP, I want to update the system and get a Foutnummer (erro): 0x8024400A I can't update the system

-

I wanted to update my messenger on my computer and it won't let me

How can I upgrade my Messenger?