connect LabVIEW to PLC

Hello

I try to connect LabVIEW to controller using an OPC server of NOR. Its a controller logix (Allen Bradley) L23E Compact and I find it difficult to obtain the device driver. Please help me with this topic and a link explaining how it would be useful to connect labVIEW to PLC.

Thanks in advance,

Sunil

Hi Sunil,

Regarding the driver: See the taken list supported device & driver plug-in for NOR-OPC Server

Regard to the connection in LabVIEW: You have two main options that depend on the question of whether or not you have the LabVIEW DSC Module. As seen here, you can either use variables shared with DSC to access your OPC tags, or you can simply use DataSocket VIs contact them directly as an OPC client. Some documents that may be useful by adding your specific hardware can be found here and here.

I hope this helps!

-Greg J

Tags: NI Software

Similar Questions

-

How to connect Labview to PLC Modicon Quantum (140 CPU 311 10) with Modbus

I was wondering if someone could give some tips on how to connect Labview to Modicon Quantum plc (the card is 140 CPU 10 311). I am eager to serve a Labview HMI to control the controller that is used to implement the control PID with a VFD. Currently I can communicate via Modbus to the API for programming using UnityPro XL, but I have no idea how to connect Labview. I read the article on place OR "connect Labview to any PLC via Modbus", but I don't know yet. Any help will be greatly appreciated.

Hey Greener.

Communicate with the PLC via Modbus usually requires the Datalogging and Supervisory Control (DSC) Module to have this feature available in LabVIEW. The white paper which indicated you using this module, which may explain why you can't get the communication at work. If this is something you don't have, and purchasing a license is not an option, then you might be able to use Modbus unofficial libraries to get the functionality you need. I have included a link below to a Modbus for LabVIEW library that you can try.

DSC module:

http://sine.NI.com/NIPs/CDs/view/p/lang/en/NID/209851

Modbus Library:

http://www.NI.com/example/29756/en/

Kind regards

Ryan

-

Connect LabVIEW to Schneider Electric M258 Logic Controller (TM258LF42DT4L) error - 1967353901

I was wondering if someone has never connected this particular PLC before LabVIEW. I'm trying to control instruments connected to this API. These instruments aren't NEITHER, therefore they that I could not directly connected to the device via USB, GPIB or VISA. Whenever I have try t connect following this tutorial OR (http://www.ni.com/tutorial/13911/en/), I have an error message to my shared variable.

The possible reasons: LabVIEW DSC: (Hex 0X8ABC8FD3) the I/O modbus server cannot connect to the Modbus Ethernet slave device. Make sure that the slave Modbus Ethernet device working properly and that the connection between the master devices and Modbus slave is configured correctly.

Any help on this approach or suggestion for others would be greatly appreciated.

NOTE: This controller communicates with the CPU I use via a RS485 / RS232 serial port.

SAM

Right, but if the unit will not pass a review of the communication of its native software so it is not really a chance that LabVIEW will be able to communicate with him. I could contact Schneider and see if they can help you make contact with their software, we can worry about communicate using LabVIEW.

-

Greetings,

Please can someone tell me how to connect LabView to LOGO! 0BA7, is there a LabView for PLC interface or some other toolkit?

Thank you.

For an automaton, you have the option of the DSC Toolkit or the modbus library - https://decibel.ni.com/content/docs/DOC-30140

-

How to connect labview to proteus in order to send commands to the microcontroller AVR, there a useful link or source code?

I've heard talk about VISA can you help me with a code example or source?I don't know anything specific to the APR, but Finder of LabVIEW example has many examples on the realization of serial communication ("Help-> Find examples.." then look for series). If you know the Protocol, then you can use the samples to create right necessary read and write commands.

Also a quick search on Google for 'Labview APR' had this as the top most successful:

-

Connect LabVIEW with a via USB pic 18f4550

Hello everyone, as the title suggests, I would like to have communication with the PHOTO above, in order to to use as a sort of buffer control. Nothing complicated or fancy, I would use it as a sort of buffer, with LV, do all the calculations and lifting heavy objects, while the PEAK only manages communication and nothing else. Specifications are:

-I would like to order 2 Motors step by step, I already have the drivers who are driving binary pulses (1 pulse = 1 step)

-May or may not require an analog (0 - 5V) encoder feedback, so for now, let's assume that Yes

-As mentioned, nothing complicated like PID or advanced control in the PIC, just send and receive some movement, LV will do most of the work as it's the only one I'm more familiar with

-I am well informed, but not particularly good in programming C (not my cup of tea), but I'm pretty adept at BASIC, my particular environment is PIC Simulator IDE of Oshonsoft and his recent iteration, the Basic compiler.

I've done a substantial amount of research, but most of the info is pretty obsolete, and most of the download links no longer work. I know I should use General dll of Microchip (already had), but would like to know if someone has done something similar, or could give me a starting point. I also read the white paper found here: http://www.ni.com/tutorial/4478/en/#

So basically, if anyone has the tracks on a good starting point, tutorials, I have to take or bases miss me, they would be welcome. Thanks to a bouquet.

I think it would be simpiler using a virtual COM port device such as the ones FTDI

Then schedule a connection series on your PIC and just use VISA in LabVIEW to communicate with the captain like communicating with any other serial device.

-

How to connect Labview to a USB sensor without existing driver?

Hello

I'm currently trying to a pressure transducer Omega PX409 USBH will display a reading in Labview. The transducer is USB connected, and the software that provides the Omega shows a reading and therefore indicates that the sensor is connected to the computer. However, it is not recognized by Labview or NI MAX. Although the pilot NI VISA Wizard recognizes the USB connection, it I cannot install the INF files that it generates on my computer. I'm pretty stuck on how to proceed in order to write a driver that displays the data in Labview. Any help would be appreciated!

malsko15 wrote:

Yes, I have updated the drivers FTDI and am able to contact my device via Hyperterminal. How can I integrate Labview into that?

Well, you have your hardware tested and working, half the battle is won.

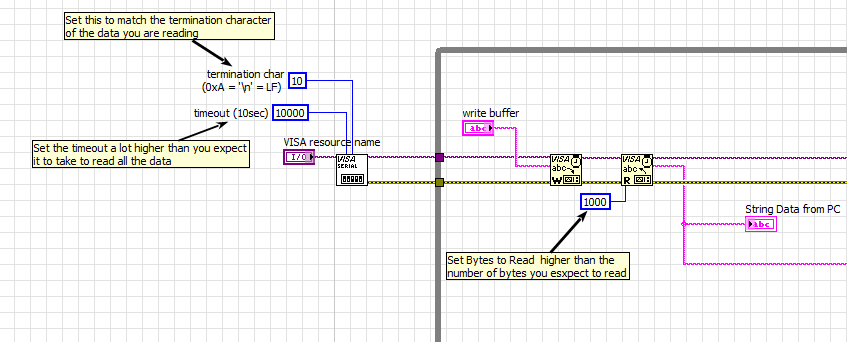

Series communications are quite simple in LabVIEW using VISA.

Here is a small example of how to write and read from a serial device.

-

How to control and monitor labview omron plc

Hello

I am able to do to communicate with labview 2009 using plc NOR a CPB and Module DSC server via ethernet, but I don ' t now to control and monitor data Boolean plc from labview.

the machine I use is CPU11 CJ1M Omron CJ1W-ETN21 with. I'm still very new to labview and I hope someone can help me with this and give me some advice on how to proceed. It should also be noted that I can't change the status of the labels directly from NI OPC server itself.

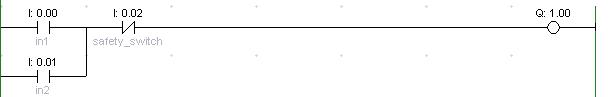

Here is the simple circuit that I would use as a starting point for the control and monitoring of the data of the PLC from labview:

Thanks in advance for the help.

You can read from the entry, impossible to write.

For output, you can read or write.

However, if you have a scale controlling this line out.

There will be a conflict.

-

I am tring to connect with my PLC S7-1200 but it gives error of Protocol.

I found the solution. You should check the access allowed "with PUT / GET remote partner communication (PLC, HMI, OPC,...). After that, I compiled the project and accessing the controller.

-

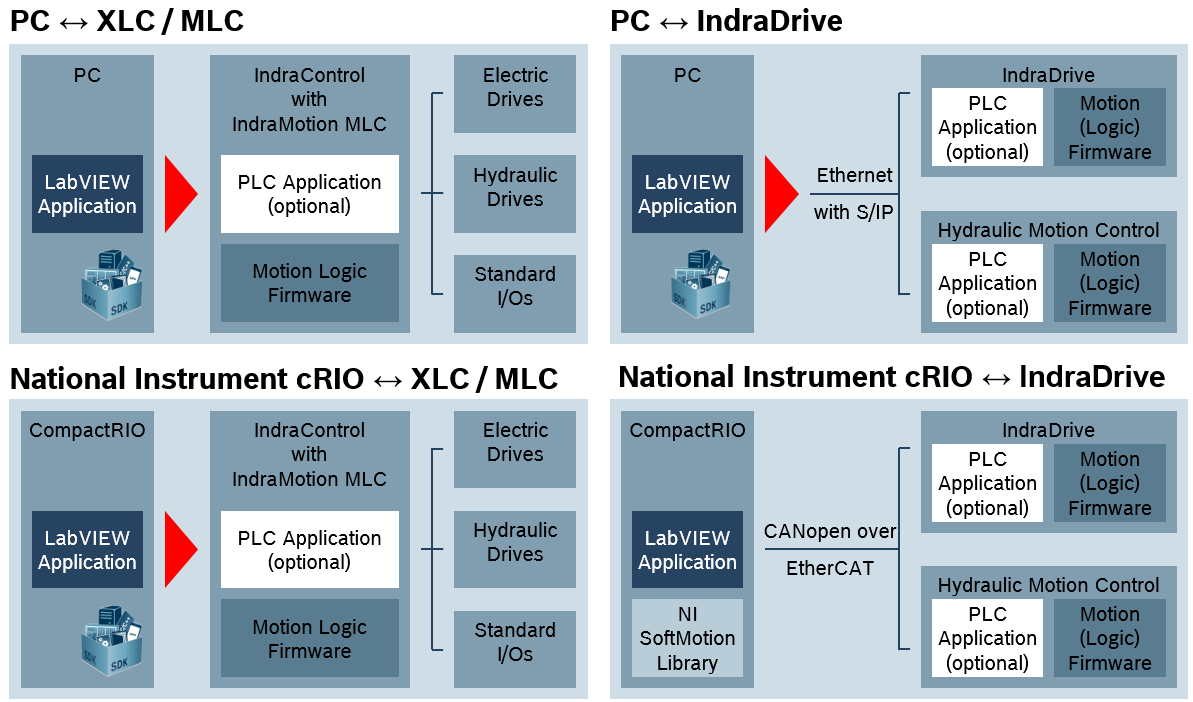

Use of LabView for exploitation of Bosch Rexroth HCS01

Hello people,

I am a student assistant and my current project is to complete what was launched in a work of degree more than a year ago: to build an experimental platform to test the effect of superconductivity on maglev technology. Part of this experimental platform is a precision three-rail network operated by compact inverters HCS01 (IndraDrive Cs) by Bosch Rexroth.

My question is: is it possible to use LabView to operate the three axes of a central VI?

I have already connected all three compact inverters to a computer and I am able to operate using most Ds-startup-easy mode, but I can only operate separately and not of a single window.

Thanks in advance, any help would be appreciated!

Greetings,

Paul Masuch

Hello world

I just found this forum article on control components Rexroth with LabView and as a representative of Rexroth, I disagree that West no way is easier to control than using Ethernet/IP.

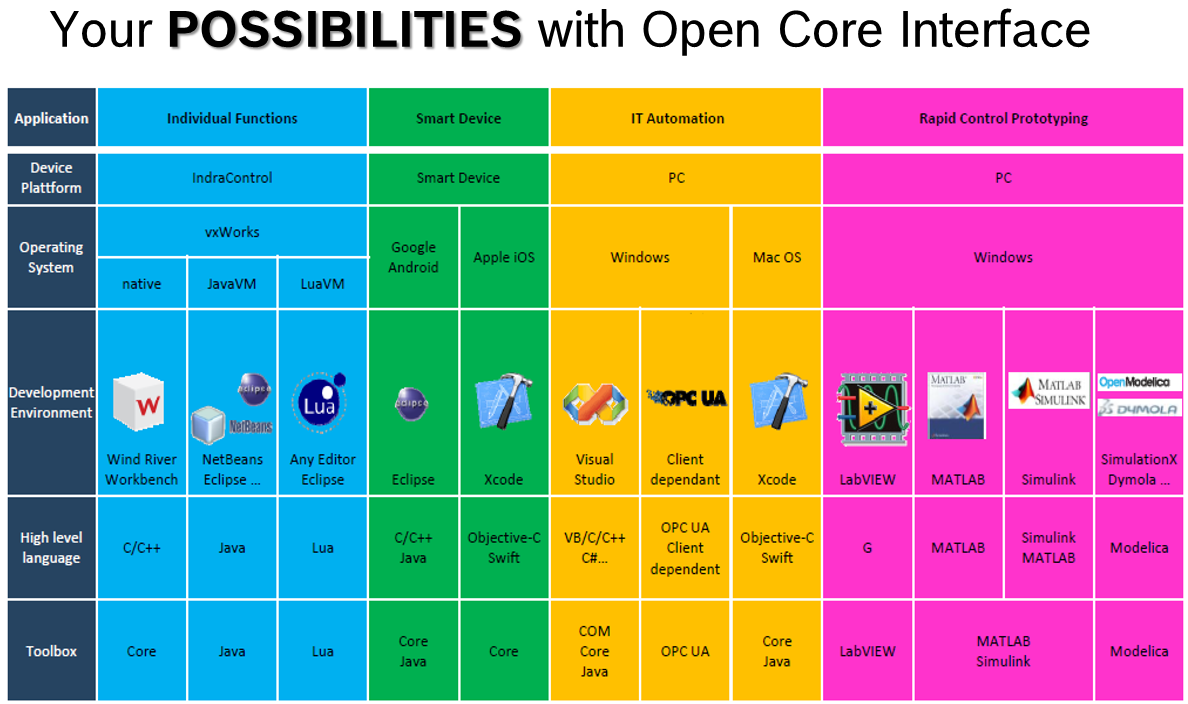

We have an official partnership with National Instruments, and offers a complete Package of VI for all our components (IndrDrives and IndraControl automata) to access all the features of a PLC or lead of Bosch Rexroth. This is possible thanks to our Open Core of Bosch Rexroth and our open approach we take with our automation components. For controllers the VI contains more than 850 screws to communicate directly from your LabView execution to the controller. These packages are completely free for you and you can download the packages from our Web site

http://www.boschrexroth.com/OCE

(access after registration in our network in engineering).

In addition it s also possible to control our readers a cRIO OR using the Council of Europe.

Here's a sneak peek of our open main Interface feature. There are SDKS for several languages of programming and several technologies including National Instruments Soft - and hardware.

So you see, West don't need to learn PLC programming, when you want to connect LabView to Automation from Rexroth.

If you have any trouble Don t hasitate to contact me!

Best regards

Tammo Schwindt

Application engineer

Bosch Rexroth AG

-

Hi guys, I am trying to build the commucation between my CRIO9066 and PLC300, which means I want the CRIO to get data of PLC, but I don't know how to implement it, could someone give me a hand? Moreover, I did possible communication between Labview and PLC by using an OPC server, I wonder if this also works in the communication between PLC and CRIO.

To my knowledge, you cannot connect to a server OPC DA of a cRIO because it isn't a windows target and OPC DA uses DCOM to communicate. If it is an OPC UA Server, you can certainly use the LabVIEW API of a cRIO.

You can also check if there are other ways to communicate to the controller as Modbus.

-

PUERTO PARALELO MICROLOGIX PLC

Connect as a PLC a sin usar OPC, DSC labview. Corpos UN Micrologix 1200 he read a travez of ModBus, pero no encuentro UN VI y UN programa PLC example than me to idea of como is con este protocolo pues nunca he trabajado don't con el the application that I'm developing none are very complex even could ser por el puerto paralelo. MI duda are TR el puerto paralelo four para funcionar manera esta continued 10 horas manera L - V safe deposited, are decir an industrial level

Buenas tardes DJSerafin,

If are posible comunicarse con UN PLC sin necesidad utilzar OPC servers o Module DSC, lo what hace are using NI VISA y con el protocolo ModBus is communication t, Sin embargo, esto're muy tardado, there are studying como works foot ModBus a cabeza.

Ahora is una libreria para con Comunicación ModBus as puedes descargar Aquí, el unico lost what esta tiene page are that no esta launched soportada. Esto means that if tiene alguna complicacion lo atenderemos, pero el tiempo respuesta no sera el mejor are no hay information relacionada a esta libreria en nuestra base data.

Aprovechando el foro, you Le tambien than exite UN KB than the manual instalacion of esta libreria sober habla. Para poder access one da El in click here. Con esto con comunicarte sin problema any hope.

Por cierto, you recommend what made the detailed each of screws libreria problemas para ayuda y you ensenaran a utilizarlo.

Saludos, y mucho exito en you application.

-

connect labveiw 8.2 with nor pci-6251

I have no pci-6251 and its cd driver with labview 8. How can I connect the daq with labview 8.2 and run programs

Hello

I can't download the driver of NOR-DAQmx 8.7.1, connect labview 8.2 with NOR-DAQmx PCI-6251...

Why?

Please answer...

-

departure fom LabVIEW VeriStand

Hey guys,.

I installed VeriStand a few days ago and now I would like to connect LabVIEW and VeriStand.

I already explored how to run a profile of stimulus in an open VeriStand workspace to a LabVIEW VI.

Now I would like to open & run the workspace (like the 'performance' - button in the window of road VeriStand project is).

Does anyone know how to do?

I joined my current state, but I guess that I do not use the right screws.

Frank

There are a set of screws, you can use to do this. They are not on the palette, but you can find them in the NI VeriStand folder under vi.lib to

\vi.lib\NI VeriStand\Execution\Project. There are screws to open a project, run it, open the workspace, etc.

The screws you use only control the system definition, not the VeriStand project and workspace.

-

How much labview can do in a web solution

I am familiar with LV, but new web solution of LV

In case I need to make a web solution for the power management system or scada system.

LV makes, like linking them through the different web pages, real-time display, other web tech in general.

May I know the advantage and disadvantage of it.

Any suggestion or good samples, thanks.

There are two techniques to connect LabVIEW via the web.

1. Control Panel: it require installation of runtime LabVIEW on the remote computer and there is a right of license for more than 5 connections simultaneously, but good things are without additional code to develop and VI controllable via the web.

2. web service: this technique compile code LabVIEW as a web service and can communicate with any client that supports web service such as flash, php, silverlight and so on. The bad things are the development of client code and cannot directly control VI.

Research of ni.com with above keywords, you will find some examples.

Maybe you are looking for

-

Where to download Firefox 26? My module does not work with 27.

I use Roboform, which is not yet compatible with Firefox 27. I need to reinstall Firefox 26. Where can I download from? Thank you.

-

PC Windows 98, said, but it is Windows XP

I try to run the game, but pc says that it must be Windows 2000 or superior, I am running windows xp, how can I solve this problem

-

6 to 4 adapter does not properly

I recently bought a new HP Slimline (3720) running Vista Home Premium 64-Bit. When I run the Hardware Diagnostic tool he told me that my 6 to 4 adapter does not work properly. In the Manager of design he told me that he was not working properly beca

-

Please can you tell me what antivirus works with winFLP

-

Protection against malwares always turned off when you turn on the computer.

Windows vista Home Edition 64-bitBitDefender antivirus 2010 Whenever I turn on my computer, I am prompted with a warning that my computer is not fully protected. I click the Security Center icon and find that my Articles of malware protection are dis