sampling rate, time stamp

See below.

Tags: NI Hardware

Similar Questions

-

file lvm recorded with time stamp graphic display

Hello

I have headaches display my data with correct timestamp. There are so many methods to save the data. Here, I decided to save it in a text delimited as lvm. a screenshot of my vi segment is attached. I want to use this way rather than other methods is the flexibility it offers. I'll be able to add more data to store that I develop the vi. (So I'm storing data of the DAQ assistant and my calculated values.) I've attached a screenshot of the file I also read.

I would use another vi to open this file and it draw a chart/graph to show a trend of the acquired data. Can someone pls Advisor mid on which is a better way for mi to do?

Thank you very much!

POH

Hi Malou,

Sorry for the late reply, I was rushing to complete my project, has not been able to answer.

Yes, I managed to solve it. In any case, I've used this high rate in the acquisition of data wizard is to allow the acquisition of continuous mode & use a software filter instead of filter material. However writes to the folder this way - write string in .lvm, max is 10 samples/s unless I have use tdm (I'll then everything in the newspaper).

I was not able to display the correct timestamp was due to the fact that I have does not add to the timestamp of the start time for the timestamp in waveform display. I won't be able to go down to my lab, & my machine have no LabVIEW, so what I do is to extract some parts of my report to share.

For the part that I used to display the graph (can be seen on the attachment), I deleted the 1st column, which is the time stamp (for display of the spreadsheet), but extract the 1st element - convert timestamp DBL it when I start recording in the DAQ vi (written with the header).

This excerpt (which could be considered as a group of numbers in the file lvm) and converted to the type timestamp and wired for generating waveform block, providing the start time of the wave.

Then I replace the use of the chart with graphic, graphic is suitable for data acquired and graphic tracing is better for the time of execution of the data display. now it seems to work fine for me, except for the load time may take some time for larger files.

Thank you for your participation in this thread!

See you soon!

POH

-

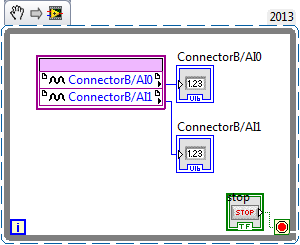

I'm new to myRIO and use it to measure sine wave (0V to 5V) of up to 10 Hz 20 KHz. I also quickly transformed of Fourier (FFT) of the signal measured in real time.

Sideways FPGA of things, I try to keep things pretty simple, just read 2 channels of AI (connector B: AI0 and AI1), therefore potentially able to read each HAVE 250 kech. / s (as the unit has a capacity of 500kS/s). Does that mean this program gets a two analog inputs data exactly every 4 microsecond? If this is not the case, how can I make sure that the data is acquired through a fixed sampling rate?

I realized that we can add to the FFT in FPGA function, but I wanted to manipulte the acquired data of analog inputs before it is sent to the FFT, which I don't know how to do now. Can someone explain me how do the arithmetic data (muliplication, division and so) on the acquired data and analog inputs to reducde the 12-bit resolution 10-bit to program FPGAS.

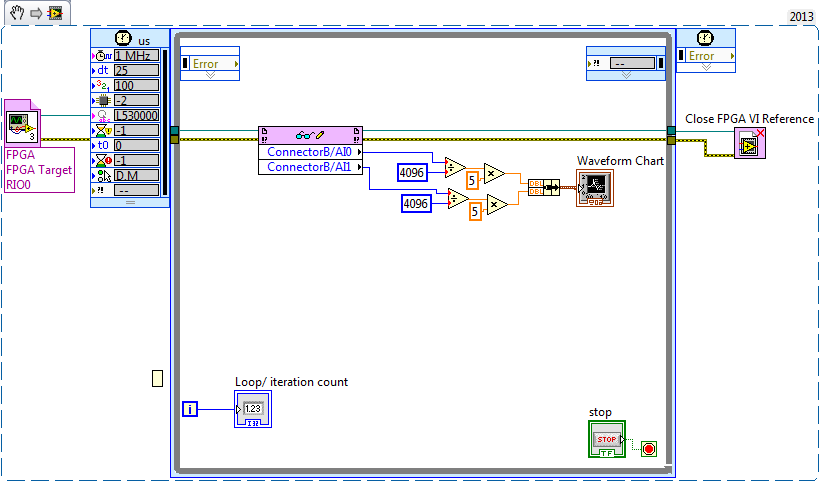

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

If I read in the forum for help, I couldn't have the full answer to my doubts

Discussions at the Forum I did reference:

A lot of good questions here, I will try to answer as much as I can so as to offer a bit of advice.

First of all, if you are looking to acquire data at a very specific rate on the FPGA, you'll want to use the Timer VI. You are also going to use a FIFO of DMA to transfer data of FPGA in real time. A node read-write using as you do now means you'll run out of samples, or read the sample even several times. The link below is a very good tutorial on how to do what I described above.

http://www.NI.com/Tutorial/4534/en/

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

In general, you should not run a timed loop much faster than 1 kHz. Using timed inside loop knots, you can monitor the real rate of loop during execution to see if f you meet your needs of the moment.

The portion of your myRIO RT is slower than an FPGA in the sense where it cannot manage the rates of lines 40 MHz (he makes up for it by being able to work with much better pictures) and it is important to remember that it is just a computer. The advantage of a real-time operating system, is that you have more control on the Scheduler, not that he is faster (less jitter, not faster code). There is more good reading below.

http://www.NI.com/white-paper/3938/en/

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

I would say that it is generally advisable to treat your FFT on the side FPGA as long as you have the resources available, but for many applications probably little matter ultimately.

-

Hi all

I use a module 9237 for certain measures of the load. My experiences last over time and so I'm generating a lot of data due to the minimum sampling frequency. I can't define an external time base so I can lower my sampling rate to something easier to manage? Even just a sample rate of 500 s/s would make a huge difference.

Thank you

Hi cannisbellum,

9237 specifications frequency range of minimum data (fs) using the internal master time base is 1,613 kech. / s and external use master timebase is 391 s/s. The simplest would be to sample at 2kS/s and decimate your data by 4. This can be done by using 'Decimate 1 table D' or ".vi Decimate (continuous).

Rates valid for the NI 9233 OR 9234 sampling and NI 9237 - http://digital.ni.com/public.nsf/allkb/593CC07F76B1405A862570DE005F6836?OpenDocument

Best,

CARISA

-

Hello

What is the sample rate max 5154 PCI for two channel inputs? The manual States the 2GS/s is for one channel only. So, am I not able to get a bandwidth of 1 GHz for the simultaneous measurement of two channels? Thank you!

Hi gbhaha,

First of all, TIS mode up to 20 GECH. / s using an ADC, while your real time sampling uses two converters a/n at the same time to a single channel. Take a look at these diagrams that I linked in my first post for more details on this architects.

About the difference in the bandwidth between the 5153 and 5154 - the 5153 has 500 MHz of bandwidth in its circuits, even when acquiring at faster sampling rates. The 5154 1 GHz of bandwidth, this is why it is more expensive.

Kind regards

-

DMM (NI 4070), how to correctly set AC Freq (bandwidth) by the sampling rate

using a NI4070 multimeter and I see the max connection is 300 kHz by respect it. But I don't understand how to set the min and max, acFrequency according to the sampling frequency or speed reading.

6 1/2 digits resolution, the speed can vary from 0.25 s/s to 100 s/s and this range corresponds to a lower end on the connection (minimum acFreq) from 1 Hz to 400 Hz.

(Q1a) - is the playback speed, controlled by the minimum setting of IviDmm_ConfigureACBandwidth? or vice versa?

Otherwise, I do not see how to control the rate of reading or the sampling frequency. IviDmm_ConfigureMeasurement only allows you to control the range and resolution.

(Q1b) - is there a way to directly control the sample rate (digitizer) or playback speed (dmm)?

(T2) - the upper limit of the bandwidth of AC always seems to be at 300 kHz... is there still a reason to reduce this maximum value?

(T3) - Finally, unlike the traditional niDmm function, the resolution via the IVI configuration should be passed as absolute value; does directly when number of digits and the beach? For example if I want to 6 1/2 digit to 300V range, I guess that by the specifications that the resolution should be set at 0.001 V... followign, if I want 5 1/2 digits to 1V range, the resolution should be set to 0.00001 V?

Hi Rjohnson,

I'll try to answer your questions as best as I can:

Q1A. The ConfigurACBandwidth function is used by the driver OR DMM to calculate the good aperautre for the measure. So yes, by adjusting your minimum frequency, you will affect your reading speed.

Q1B. Your reading rate will depend largely on your measuring cycle. To get a fast measuring cycle, there are a few things that you can adjust. You can programmatically control your time aperature, as well as your time to settle.

Q2. I can't find a reason to change. This parameter is only used for error-checking and verifies that the value of

This setting is less than the maximum frequency of the device.Q2B. I think what you say is right, but I'll need to check on that - I'll let know you as soon as.

Hope that helps. "" "I would recommend checking the explanation of the Cycle of the DMM measurement in DMM help' devices ' NI 4070" DMM Measuments "DMM measurement Cycle.

Take care!!

-

I am using a cDAQ 9172 with modules NI 9219, NI 9264 and three NI 9211. I'm looking to acquire signals out of the acquisition of data within a loop under continuous sampling. My program works fine if I set the number of samples to read 1-2 Hz, but I need to go faster than that. If I change the sampling rate, the loop is executed at this speed but sensors still read only in samples at 2 Hz and then duplicating over and over again. I was wondering if it was possible to read on 1 sample at the time of the acquisition of data at a faster rate. I know that the frequency of sampling on the sensors and data acquisition are much higher than that. 1 sample at the time of the Board of Directors has the limitatioins of being only able to run at 2 Hz? Please let me know

Thank you

Craig

Hi Craig,.

I don't know exactly what you describe. Are you feeding the DAQmx Read output in an express VI? Or are you using the express VI DAQ Assistant for the analog input task?

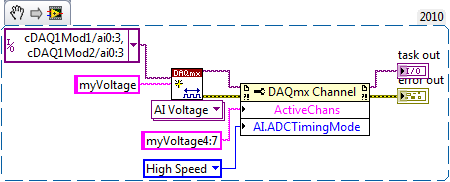

If you use the DAQ Assistant, you can set the ADC synchronization mode without changing your code:

If not, use the 'Active channels (if subset)' property to control the subset of channels on which your VI defines AI. ADCTimingMode.

For example, the following code snippet creates 8 virtual channels named myVoltage0 by myVoltage7 and sets HAVE them. ADCTimingMode on myVoltage4 of virtual channels through myVoltage7. These are in the cDAQ1Mod2/ai0 physical channels via cDAQ1Mod2/ai3:

If you leave off of the entry "name" on the string to create VI, then the virtual channel names are the same as the names of physical channel, so it's the equivalent:

And by the way, a right-click on the property and selecting "create > Constant ' context menu saves you from having to hardcode a number like 14712.

Brad

-

6255 sampling rate causes the dc offset

I see a dc offset in the measures of analog input I select different sampling frequencies.

I have USB-6255 (mass termination) multifunction data acquisition and I use measurement and Automation Explorer to put in place my entries.

My raw analog input is-0, 6250 volts dc, I have set up a task that uses 4 differential channels with no custom scale.

I have defined the scope of the input signal to +/-0 .8v for you sure I get good resolution.

Acquisition mode is continuous, samples of read is 1 k and I play with the order of 10kS/s rates 50kS/s.

While this task runs in the MAX, I can put my cursor in the rate field and use the top and down arrow keys to change the sampling frequency. As I do, I can see the light changes reported as much as 150 MV rate from one to the other.

It is a significant change when the total time of entry is lower to +/-1v.

The direction of movement is independent of the increase or decrease of the sampling frequency.

For example,.

23kS/s, the declared value is - 0.540v,

24kS/s, she moves to-0.620v.

25kS/s, she moves to-0.690v.

26kS/s, she moves back to-0665v.

27kS/s, she moves back to-0.625v.

and 28kS/s, she moves to - 0.535v.

At first, I thought that the sampling change made a change of the input impedance and change the load on my source, however, all the time, my dc signal source remained at the - 0.625v (as measured with a multimeter fluke at the connection point to data acquisition).

Why this is happening and what can I do about it? I want to give my users the ability to choose their desired sampling frequency.

My guess is that I need to add an amplifier to fixed gain with a gain of 5 to 10 to make the input signal to use the maximum of the analog input level (+ / 10v).

I use MAX version 5.0.0f1

Thanks for any help,

Tobin

Hi Tobin,

What do you use to generate the signal-. 625 volt? If you are using a switching power supply, you can experience aliasing where the power supply is turned on and stop.

In addition, are see you the same tensions at the same sampling rate? See you always - .540v to 23kS/s or vary over time?

Finally, you have a second 6255 you can try to replicate this on? It could be that the unit is defective.

N

-

fast sampling rate question...

Hello

I use USB-6009 and max sampling rate is about 48 K samples/s according to

the specification...

Question 1.

48 K samples/s means... only when you receive 1 analog input?

If I have 2 analog inputs then forge would be just half of the 48K?

Question 2.

using the daq assistant.

I would like to get about 50 samples between 10ms

If I do the math I get 5 K samples/s, which is enough for me

However, I played with samples to read and throughout the day, the sampling rate,

do not get this rate... (I'm outputing in file with LVM)

I searched on the sampling frequency, and people here said

samples read and sample rate do not havea correlation...

but I see clearly that they are relevant. When I change a setting

I get a different number of acquisition... I do N smaples.

Please help:)

Q1. Yes, except that the switching of channels takes awhile so the net price per channel is slightly less than half the rate of single channel. The USB-6009 specification document does not indicate what is the switching time. You should be able to get 5 kHz on both channels. 20 kHz might be close to the upper limit, but that's just a guess.

Q2. The DAQ Assistant is often not the best choice for maximum performance. I do not have the DAQ Assistant, so I can't be more specific. If you get the data as an array of DBL, rather than dynamic data type, it can be recorded directly, without conversion. The other thing that can make a big difference is a loop two architecture of producer/consumer. This allows the acquisition of data and save it to the file to run it at different speeds so that each can be optimized separately. If you are trying to acquire 50 ms of data at a time and then, he writes to the file, you write to the file twenty times per second. The first time, the operating system must reallocate some file space or do something else what delays write the file, your timing loop is disrupted.

Lynn

-

NI 6552 Signal Express sampling rate

I'm generating multiple signals for Signal Express. When I run them, some work well and others not, in other words, for some changes in sampling rate signals! Thera are two options in Signal Express: 1. read file waveform 2 sampling rate. to manually set the sampling frequency. In both cases, the rate is changed when I run the waveform of my 90 MHz to 100 MHz.

Any ideas?

Hello

The internal clock on the 6552 is generated from 200 MHz time base; Is that you can generate the frequency of 200 MHz/N where N is from 2 to a large number which takes up to 47 Hz. The driver for the Board of Directors will force the neerest value, so if you swipe from 90 Mhz to 100 MHz frequency, you will get 100 MHz in all cases. There is more information about the synchronization on the specs here:

http://digital.NI.com/manuals.nsf/WebSearch/E4C93B141B71ED93862573CC005E8EA1

Once, you run your project, Signal Express should show you the corced value, you can use this to read the actual frequency generated.

I hope this helps.

Juan Carlos

-

Save the high sampling rate data

Hello!

I use NI PXI-4462. (204.8kS, input analog 4 / s sampling frequency)

I want to collect data from "load" (channel 1) and "acceleration sensor" (2nd, 3rd, 4th channel).

I also want to save data to a text file.

So I do a front pannel and block diagram. You can see in the attached file.

The program works well in a low sampling rate.

However, when I put up to 204800 s/s sample rate, the program gives me "error-200279".»

I don't know what means this error, and I know why this happened in the high sampling rate.

I want to know how I can fix it.

Is there any problem in my diagram?

Is it possible to save high sampling rate data?

I really want to samplling more than 200000 s/s rate.

I would appreciate if you can help me.

Thank you.

NH,

You have provided excellent documentation. So what has happened is that the amount of time it takes to run the other portion of the loop results in a number of samples to be taken is greater than the size of the buffer you provided (I don't know exactly what it is, but it will happen at high frequencies of sampling high) resulting in samples are crushed. You might be best served in this case to take a loop of producer-consumer - have the loop you have acquire the data but then have an additional loop that processes the data in parallel with the acquisition. The data would be shipped from the producer to the consumer via a queue. However, a caveat is that, if you have a queue that is infinitely deep and you start to fall behind, you will find at the sampling frequency, you specify that you will begin to use more and more memory. In this case, you will need to find a way to optimise your calculations or allow acquisition with loss.

I hope this helps. Matt

-

Hello

I tried to understand how the 'number of samples' and 'rate' controls affect the frequency of sampling for the DAQ hardware. For example, say I want to acquire data from a sensor of pressure at a frequency of 10 Hz intuitively, I would think everything I do is on the desired sampling frequency, in this case 10 Hz control the 'frequency', try this, I know that's not true. I read that 'number of samples' affects the sample rate by setting a buffer value that must be reached before the VI will process the acquired data. So I also tried to set the "number of samples" to 1 and "rate" at 10, thinking this would have led to a sampling frequency of 10 Hz, and again, it is not. The only way I know to control the sampling frequency is using the wait function (ms), but then I always get buffer overflow errors.

Can somone if you please explain to me the error in my thought process and also tell me the best way to control the sampling frequency? Is attached a simple VI, I am using to measure my actual sample rate and compare it to the sampling frequency that I am trying to achieve.

The VI use the DAQ assistant to acquire data of pressure, inserts data into a table, and measure the size of the array. I'm then by dividing the size of the array by the elapsed time in seconds for the sample/s (I'm also dividing the number of iterations of the loop by seconds and using it as a comparison). I compare this value to my entries for the 'number of samples' and controls 'speed' in order to give a sense of the role they play in sampling rate. The VI also allows to choose to use the wait function (ms), as well, using this function is the only way I can control the actual sampling frequency, but then I always get buffer overflow errors. Any information would be helpful, thanks!

What is the device that you are using? My guess is that whatever you have, it does not allow such a slow pace and is failing at its minimum.

-

than 25 ns sets sampling rate...

Hello

I'm trying to test the sampling rate of chassis cRIO 9103...

I created a simple FPGA project, for sampling sign this clock frequency of the FPGA equal to 40 Mhz (on by default). I applied 1 Mhz square wave to pin MISO DIO6/SPI, place one of the slots on the frame... I put a tick 'loop timer' in ' ' loop for every moment of picking (totally 32 sampling point).

input signals a cycle = 1000 ns (1 MHz) and I m planning see samples every 25 ns (40 MHz) on the graphical waveform. But the chart shows me only 10 points for 1 cycle like taking samples of every 100 ns instead of 25ns. (FrontSamplingRateObservation.png)

What is to be? If so, how can I get faster sampling rate...

I joined .vi photos of the project...

You can consider that the only timed cycle lines and the pipeline of the operation.

-

channel and sampling rate is not updated until the next cycle

Hi all

I'm new to LabVIEW and I wrote the code for the measurement of temperature using the cDAQ-9178 or NI 9214. Could someone please look at my code and help me understand why... my names channel to sample and rate update, until the next time I run my program.

For example: if I enter the name of the channel "ONE" and "10" sampling frequency... and draw my program will be executed using previous information entered by the user. If I press the race a second time, then it will use the '10' sample rate and channel "ONE". Everyone can't see what I did wrong? I know that my code is absent, but she does everything that I need, except for the update.

I really want to use a structure of the event, but failed miserably in my attempts. Thank you

Stream. Updates the values in your Subvi are run in parallel to the Structures of your event. The simple solution is to simply put your update of the values inside the event. In this way the controls are not read until you actually press the next button.

-

With the NI 9205 module Max sampling rate - problems

Dear friends,

I develop a project of lv, which makes and control system of engine dyno. The material is CRio-9022 with other cards and also 9205 for AI. There is an encoder for angle attached to the motor shaft with 3600 chatted by Tower as well as an index to indicate the end of a revolution. the output of the encoder is measured by card 9411. The speed of the motor is 1500 rpm. I measure pressure data and couple when I receive a 'tick' of the wheel. This means my sampling rate for pressure and torque each is 90KO/s.

but I was not successful to lead it. The program is great and I can show them, but I believe that there is a problem in the choice of material for the task. With the data of pressure and torque of the 9205, I also measure other channels for the controller output mass flow and temperatures. So in all I use 8 channels of the 32 available. But only the pressure and torque are acquired at the wheel-driven sampling rate. the rest are acquired about 5 times per second.

Since the 9025 is a multiplexing ADC, 250K sampling frequency is divided by the number of channels accessed = 250 K/8 = 31 K samples/channel. With this in mind, I decided to acquire data of pressure and torque with each beat 3rd rotary encoder, essentially on 30K samples/s sampling. However, I see a large amount of noise.

So I decide to average more than 1 second cycles (so the engine runs at about 25 cycles/sec, I averaged over this issue). The resulting pressure and torque graphics do not match with those measured by an oscilloscope in terms of amplitude but the frequency and shape is correct.

I noticed an interesting feature in the charts. When I pass interpolation between the points, I see several curves made by points instead of a continuous locus of points. Accordingly, I find that the acquisition is slower than necessary, and so there are less number of points sampled as required. These points are not synchronized 25 cycles I have on average and therefore the separate "curves". It is because of the possibility that some points receive a higher number of 'contributions' several times (when you add), the neighbouring points.

so I conculde that the 9205 is not fast enough to do the job. also noise, perhaps due to crosstalk or gosting when the mux changes channels. the impdences output pressure and the couple are of the order of 10 K ohms.

the Labview code outline: well, there is a vi FPGA, which takes the rotary encoder ticks and sends a signal to the case of each 3rd tick. The signal contains a 16-bit integer, indicating the number of ticks. This signal is sent to a 1 element FIFO. This fifo is read in a parallel while loop, where it remains awaiting a new element. The while loop bed fifo, where data are available, takes a measure of pressure channel. A node memory of the method is called to provide data according to contained in the index number equal to the number of ticks to signal fifo. Then he adds the current pressure reading to the reading of the memory and stores the sum in the same memory location. Thus, an array of elements of 1200 is formed, where each elemnt is a sum of the values taken of more than 25 cycles. This memory is transferd to a dma fifo and reading side host. is done similarly to involved couple. host-side the fifo is read and divided by 25 to get the average. This average is displayed on a waveform graph.

Please check the attached file to get an idea of the problem. Sorry for the long post.

Please suggest if you understand the problem and suggesstions or solutions.

Maybe you are looking for

-

The NB100 - error message - on «WWAN» software activation

I am using the mobile broadband 3 & receive the following message if poster every time I try to connect: -."Activation of the software has made '228' unsuccessful attempts to the type of carrier"WWAN". The software will be blocked for "WWAN" connecti

-

Your comments on Mac password managers

I'm ready to purchase a password for my MacBook Air and iPhone management application. 1Password based on comments from MacWorld and others, seems to be the right choice. Unfortunately, customers of the most recent 1Password version 6 has many bugs.

-

I started getting this error message and now Google game store disappeared out of my phone its just disappeared. And no man, I'm not rooted. I am also unable to sync my Google account.

-

Distribution dynamically to user input; best practices?

Hi all Using LabVIEW 2013 (32 bit). Taking my first foray in LVOOP and I am currently designing our user input. This user of VI entry is distributed dynamically. The goal is to allow the user to "mix and match" different parts of the application as m

-

How to get help when I can't find the serial number

Hello. I myself am turned on my Chromebook this morning to find my screen was destroyed... it's totally white with a few black spots of looking stained in the corner. I try to get help but cannot do without my serial number, and apparently I have to