than 25 ns sets sampling rate...

Hello

I'm trying to test the sampling rate of chassis cRIO 9103...

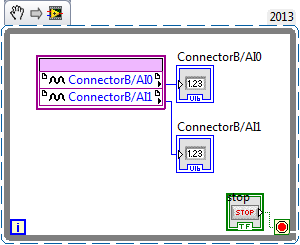

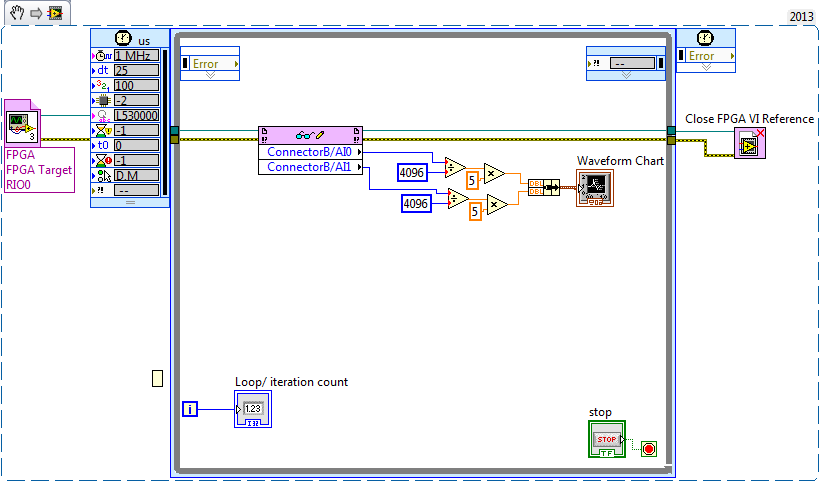

I created a simple FPGA project, for sampling sign this clock frequency of the FPGA equal to 40 Mhz (on by default). I applied 1 Mhz square wave to pin MISO DIO6/SPI, place one of the slots on the frame... I put a tick 'loop timer' in ' ' loop for every moment of picking (totally 32 sampling point).

input signals a cycle = 1000 ns (1 MHz) and I m planning see samples every 25 ns (40 MHz) on the graphical waveform. But the chart shows me only 10 points for 1 cycle like taking samples of every 100 ns instead of 25ns. (FrontSamplingRateObservation.png)

What is to be? If so, how can I get faster sampling rate...

I joined .vi photos of the project...

You can consider that the only timed cycle lines and the pipeline of the operation.

Tags: NI Software

Similar Questions

-

DMM (NI 4070), how to correctly set AC Freq (bandwidth) by the sampling rate

using a NI4070 multimeter and I see the max connection is 300 kHz by respect it. But I don't understand how to set the min and max, acFrequency according to the sampling frequency or speed reading.

6 1/2 digits resolution, the speed can vary from 0.25 s/s to 100 s/s and this range corresponds to a lower end on the connection (minimum acFreq) from 1 Hz to 400 Hz.

(Q1a) - is the playback speed, controlled by the minimum setting of IviDmm_ConfigureACBandwidth? or vice versa?

Otherwise, I do not see how to control the rate of reading or the sampling frequency. IviDmm_ConfigureMeasurement only allows you to control the range and resolution.

(Q1b) - is there a way to directly control the sample rate (digitizer) or playback speed (dmm)?

(T2) - the upper limit of the bandwidth of AC always seems to be at 300 kHz... is there still a reason to reduce this maximum value?

(T3) - Finally, unlike the traditional niDmm function, the resolution via the IVI configuration should be passed as absolute value; does directly when number of digits and the beach? For example if I want to 6 1/2 digit to 300V range, I guess that by the specifications that the resolution should be set at 0.001 V... followign, if I want 5 1/2 digits to 1V range, the resolution should be set to 0.00001 V?

Hi Rjohnson,

I'll try to answer your questions as best as I can:

Q1A. The ConfigurACBandwidth function is used by the driver OR DMM to calculate the good aperautre for the measure. So yes, by adjusting your minimum frequency, you will affect your reading speed.

Q1B. Your reading rate will depend largely on your measuring cycle. To get a fast measuring cycle, there are a few things that you can adjust. You can programmatically control your time aperature, as well as your time to settle.

Q2. I can't find a reason to change. This parameter is only used for error-checking and verifies that the value of

This setting is less than the maximum frequency of the device.Q2B. I think what you say is right, but I'll need to check on that - I'll let know you as soon as.

Hope that helps. "" "I would recommend checking the explanation of the Cycle of the DMM measurement in DMM help' devices ' NI 4070" DMM Measuments "DMM measurement Cycle.

Take care!!

-

I just got hearing CC 2014 and when I try to record it says the frequency of sampling of the input and output devices do not match. How to set those rates at the point 8.1 of Windows?

Very well. You must go in the Windows sound control panel, and then select the Read tab. Select your output device (if you have no external card it although that may not be), and then select Properties. Then click on the Advanced tab and there will be a drop-down list for flow of sample and depth. I would say 16 bit / 44100 Hz (CD quality) for pure audio which will end by if he's going to end up in video on CD or MP3 or 16 bit / 48000 Hz.

Then, go to the Windows Sound Control Panel, click the recording tab and follow the same procedure (highlight, properties, advanced) and select the same settings in the drop-down list

This should sort out you. Longer term, consider an external USB audio interface - it'll be a lot better, and if it has ASIO drivers, it will stop Windows applications to change the audio settings without telling you.

-

I'm new to myRIO and use it to measure sine wave (0V to 5V) of up to 10 Hz 20 KHz. I also quickly transformed of Fourier (FFT) of the signal measured in real time.

Sideways FPGA of things, I try to keep things pretty simple, just read 2 channels of AI (connector B: AI0 and AI1), therefore potentially able to read each HAVE 250 kech. / s (as the unit has a capacity of 500kS/s). Does that mean this program gets a two analog inputs data exactly every 4 microsecond? If this is not the case, how can I make sure that the data is acquired through a fixed sampling rate?

I realized that we can add to the FFT in FPGA function, but I wanted to manipulte the acquired data of analog inputs before it is sent to the FFT, which I don't know how to do now. Can someone explain me how do the arithmetic data (muliplication, division and so) on the acquired data and analog inputs to reducde the 12-bit resolution 10-bit to program FPGAS.

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

If I read in the forum for help, I couldn't have the full answer to my doubts

Discussions at the Forum I did reference:

A lot of good questions here, I will try to answer as much as I can so as to offer a bit of advice.

First of all, if you are looking to acquire data at a very specific rate on the FPGA, you'll want to use the Timer VI. You are also going to use a FIFO of DMA to transfer data of FPGA in real time. A node read-write using as you do now means you'll run out of samples, or read the sample even several times. The link below is a very good tutorial on how to do what I described above.

http://www.NI.com/Tutorial/4534/en/

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

In general, you should not run a timed loop much faster than 1 kHz. Using timed inside loop knots, you can monitor the real rate of loop during execution to see if f you meet your needs of the moment.

The portion of your myRIO RT is slower than an FPGA in the sense where it cannot manage the rates of lines 40 MHz (he makes up for it by being able to work with much better pictures) and it is important to remember that it is just a computer. The advantage of a real-time operating system, is that you have more control on the Scheduler, not that he is faster (less jitter, not faster code). There is more good reading below.

http://www.NI.com/white-paper/3938/en/

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

I would say that it is generally advisable to treat your FFT on the side FPGA as long as you have the resources available, but for many applications probably little matter ultimately.

-

I am using a cDAQ 9172 with modules NI 9219, NI 9264 and three NI 9211. I'm looking to acquire signals out of the acquisition of data within a loop under continuous sampling. My program works fine if I set the number of samples to read 1-2 Hz, but I need to go faster than that. If I change the sampling rate, the loop is executed at this speed but sensors still read only in samples at 2 Hz and then duplicating over and over again. I was wondering if it was possible to read on 1 sample at the time of the acquisition of data at a faster rate. I know that the frequency of sampling on the sensors and data acquisition are much higher than that. 1 sample at the time of the Board of Directors has the limitatioins of being only able to run at 2 Hz? Please let me know

Thank you

Craig

Hi Craig,.

I don't know exactly what you describe. Are you feeding the DAQmx Read output in an express VI? Or are you using the express VI DAQ Assistant for the analog input task?

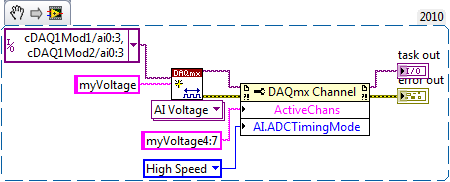

If you use the DAQ Assistant, you can set the ADC synchronization mode without changing your code:

If not, use the 'Active channels (if subset)' property to control the subset of channels on which your VI defines AI. ADCTimingMode.

For example, the following code snippet creates 8 virtual channels named myVoltage0 by myVoltage7 and sets HAVE them. ADCTimingMode on myVoltage4 of virtual channels through myVoltage7. These are in the cDAQ1Mod2/ai0 physical channels via cDAQ1Mod2/ai3:

If you leave off of the entry "name" on the string to create VI, then the virtual channel names are the same as the names of physical channel, so it's the equivalent:

And by the way, a right-click on the property and selecting "create > Constant ' context menu saves you from having to hardcode a number like 14712.

Brad

-

fast sampling rate question...

Hello

I use USB-6009 and max sampling rate is about 48 K samples/s according to

the specification...

Question 1.

48 K samples/s means... only when you receive 1 analog input?

If I have 2 analog inputs then forge would be just half of the 48K?

Question 2.

using the daq assistant.

I would like to get about 50 samples between 10ms

If I do the math I get 5 K samples/s, which is enough for me

However, I played with samples to read and throughout the day, the sampling rate,

do not get this rate... (I'm outputing in file with LVM)

I searched on the sampling frequency, and people here said

samples read and sample rate do not havea correlation...

but I see clearly that they are relevant. When I change a setting

I get a different number of acquisition... I do N smaples.

Please help:)

Q1. Yes, except that the switching of channels takes awhile so the net price per channel is slightly less than half the rate of single channel. The USB-6009 specification document does not indicate what is the switching time. You should be able to get 5 kHz on both channels. 20 kHz might be close to the upper limit, but that's just a guess.

Q2. The DAQ Assistant is often not the best choice for maximum performance. I do not have the DAQ Assistant, so I can't be more specific. If you get the data as an array of DBL, rather than dynamic data type, it can be recorded directly, without conversion. The other thing that can make a big difference is a loop two architecture of producer/consumer. This allows the acquisition of data and save it to the file to run it at different speeds so that each can be optimized separately. If you are trying to acquire 50 ms of data at a time and then, he writes to the file, you write to the file twenty times per second. The first time, the operating system must reallocate some file space or do something else what delays write the file, your timing loop is disrupted.

Lynn

-

. VI filtering IIR and response: response of Butterworth filter size depends on sampling rate - why?

Hi people,

I'm not an expert in the design of the filter, only a person in applying them, so please can someone help me with an explanation?

I need to filter signals very infrequent using a buttherwoth filter 2. or 3. order of the bandpass 0.1 to 10 Hz.

Very relevant amplitudes are BELOW 1 Hz, often less than 0.5 Hz, but there is as well the amplitudes beyond 5 Hz to observe.

It's fixed and prescribed for the application.

However, the sampling rate of the measuring system is not prescribed. It may be between say between 30 and 2000 Hz. Depends on the question of whether the same set of data is used for analysis of the higher up to 1000 Hz frequencies on the same measure or this is not done by the user and he chooses a lower sampling rate to reduce the size of files, especially when measuring for longer periods of several weeks.

To compare the response amplitude of 2nd and 3rd order filter, I used the example of IIR filtering .vi and response:

I was very surprised when I found that the response of greatness is considerably influenced by the SAMPLING RATE I say the signal generator in this example vi.

Can you please tell me why - and especially why the filter of order 3 will be worse for the parts of low frequency below 1 Hz signal. Told me of people experienced with filters that the 3rd oder will less distort the amplitudes which does nothing for my the frequencies below 1 Hz.

In the attached png you see 4 screenshots for 2 or 3 command and sampling rate of 300 or 1000 Hz to show you the answers of variable magnitude without opening labview.

THANK YOU very much for your ANSWERS!

Chris

Hello Cameron and thanks for my lenses of compensation.

I can now proudly present the solution of my problem.

It seems to be purely a problem of the visualistion information filters through the cluster of the scale.

After looking in the front panel of the IIR, I suddenly noticed that the "df" of the pole size is changing with the Fs of the input signal.

For a Fs to 30 Hz, the "df" is 0.03 Hz so you see the curve of the filter with more points, see png.

For a Fs 300 Hz "df" is 0.3 Hz, so the curve is larger with only 3 points between 0 and 1 Hz.

For a 1 kHz Fs the df is 0,976 Hz, so there is no point in the graph between 0 and 1 Hz.

It's strange that for constant Fs, df of this cluster NOT reduced with the increase in the number of samples, as it does in an FFT.

However, I hope now the filter used now for the curves obtained with the proposed Lynn way and the response of greatness from the filter information fit together.

Thank you for your support.

Merry Christmas and a happy new year to all.

Chris

-

Hi talented engineers OR,.

I use PXI 5015, measurement studio and make acuqisition of data sampling rate 40 MHz. The command

niScope_ConfigureHorizontalTiming (vi0 40000000, 40, 50, 1, VI_TRUE)

is used to set the sampling frequency. However, when we check the signal of sampling, it is 60 MHz rather than 40 MHz. same thing happened when it is set at 50 Mhz. The actual sampling frequency is always 60 MHz. But when we created the frequency goes low to 20 MHz or 10 MHz, it works fine. We use an external 10 MHz reference clock, and I'm sure that the PLL is locked. We are a State control.

Everyone comes up with the same problem? Please let know me if you need more information about it. Thanks in advance.

Sincerely,

Bin

Hi Ben,

Unfortunately, the only way you can use a 40 MHz sampling frequency is if you import it into 1 PFI. The ditch down the method that we use with our advice on sample clock gives you only the integer values 1 and more. 60 MHz is your next best option.

Kind regards

-

Specified sample rate clock works do not

I hope that I was right to post on this forum. I have a problem that I had not previously in the acquisition of data on a chassis 9172 cDAQ using a 9234 for 2 analog inputs and a 9219 for four thermocouple inputs. The 9219 is obviously not ideal as it has a rate relatively low sample (and I have a 9213 on the way), so I'll have to use to HAVE. ADCTimingMode to isolate channels on this module for "high speed" mode if I can get an adequate sampling for my load. The question that arises is that no matter what I do to specify a sample rate, the actual sampling rate ends up being 1651,61 Hz, higher than the features of the 9219, if I get an error. I tried to use the DAQmx property node to set the calendar and the clock sampling VI but neither work. The only source that I can choose is on board, but when I check the source used is cDAQ1Mod1/AI/SampleClock, even if I get an error when I try to provide as a source of sample VI clock.

As it is, my VI runs despite this error and seems to produce accurate data, but the original problem is with long testing I will have unnecessarily large data sets unless I start to decimate my other data, and the secondary problem, it's that I can't get the program to run when I try to incorporate my task of counter. In this case, the error ends the execution and he acquires no data.

I have attached my VI under the task of counter (I'm on 8.5 and have the coming upgrade as well), but also an image of a simplified version of the VI only try to specify the settings of a channel of AI. I get the same result with it. I'm a bit of a loss here because I've never had this problem before, and it seems that there is something beyond rudimentary that I'm missing, so I would really appreciate any help anyone could provide. Thanks in advance.

-

DAQmxCfgSampClkTiming sampling rate for external sources

I'm looking at the example of Synchronized_AIAO_Shared_Clock.c to http://zone.ni.com/devzone/cda/epd/p/id/2352 . This example creates a string of tension that HAVE streams at 10 kHz, and then creates a tension AO channel that is bound to the sample clock HAVE to synchronize channels. I use this example to understand the use of DAQmxCfgSampClkTiming here. This is the corresponding code (comments are mine):

Create a channel of tension HAVE will work continuously at 10 kHz

DAQmxErrChk (DAQmxCreateTask("",&taskHandleRead));

DAQmxErrChk (DAQmxCreateAIVoltageChan(taskHandleRead,"Dev7/ai1","",DAQmx_Val_Cfg_Default,-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleRead,"",10000.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000));

Create a tension AO channel, and then attach the clock of the chain in tension of the AO for the sample clock HAVE

DAQmxErrChk (DAQmxCreateTask("",&taskHandleWrite));

DAQmxErrChk (DAQmxCreateAOVoltageChan(taskHandleWrite,"Dev7/ao0","",-10.0,10.0,DAQmx_Val_Volts,NULL));DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleWrite,"ai/SampleClock",1000.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000));

.. So what I'm trying to understand here is how to interpret (1000.0) sampling rate argument in the second call to DAQmxCfgSampClkTiming, where the canal AO is related to "AI/sampleClock. It seems to me that this argument must be meaningless, other than perhaps to determine the size of the buffer, since by definition this AO channel will clock on a sample of every time that AI/SampleClock rises. Then maybe someone can help me understand how this argument is used...

But in all cases, the docs say "If you use an external source for the sample clock, set this value to the maximum expected rate of the clock." In this case, the clock is set up a few lines earlier at 10 kHz, so is not this 'evil' in the second call to DAQmxCfgSampClkTiming, a sampling rate of 1 kHz is specified (much less than the maximum rate of sample expected)? What is the consequence of this?

Thank you!

-Dan

Hey Dan, some big questions you've got.

You pretty much put the nail on the head with your guesses. The size of the buffer is based on the resolution of data acquisition in combination with the sampling frequency that you specify. Think of it as an implicit in the size of the buffer declaration (but it is certainly an explicitly define that, if you wish).

As for your second question, which relates to new back to the size of the buffer, except that this time it is for the use of an external clock source. Given that the material has no implicit way to know the frequency of clock of this external source, it asks you to specify explicitly the maximum frequency so it can create a buffer of the right scale size.

-

sample rate real vs min sampling rate

I'm sure it's an obvious answer, but here goes.

I have a USB-5132 ' scope and using niScope horizontal configuration Timing.vi I put, among other things, the minimum sampling rate. In my case, I chose 20 MHz, which of course gives a sampling of 50 ns period.

I use niScope reading (poly) .vi with the WDT variant to read waveform data. I noticed something very strange - waveform limit testing throw error 1802 "signals have a dt of different values '-if I put a waveform components unclusterizer Get on the wire of waveform and looked at the value of dt of the wave." He told me that my dt is 40 ns, which of course is of 25 MHz. I also plead for only 2000 samples.

So what causes this shift? Why the digitizer does not accept everything just my desired sampling frequency?

Austin Walton wrote:

Andy,

The setting of minimum sampling frequency is the frequency at which digitized

the samples are stored, expressed in samples per second. This setting is rounded

up to and including the next legal collection that supports your device. Ownership of the actual sampling rate calculates the actual sample used for the acquisition rate.Unless you specify another source of the clock, the digitizer uses an internal oscillator as clock source. For the 5132, this oscillator is clocked at 50 Mhz. When using the oscillator internal as the sample, the digitizer clock source can use versions split to the bottom of this clock, for certain sampling frequencies are not possible.

-

6255 sampling rate causes the dc offset

I see a dc offset in the measures of analog input I select different sampling frequencies.

I have USB-6255 (mass termination) multifunction data acquisition and I use measurement and Automation Explorer to put in place my entries.

My raw analog input is-0, 6250 volts dc, I have set up a task that uses 4 differential channels with no custom scale.

I have defined the scope of the input signal to +/-0 .8v for you sure I get good resolution.

Acquisition mode is continuous, samples of read is 1 k and I play with the order of 10kS/s rates 50kS/s.

While this task runs in the MAX, I can put my cursor in the rate field and use the top and down arrow keys to change the sampling frequency. As I do, I can see the light changes reported as much as 150 MV rate from one to the other.

It is a significant change when the total time of entry is lower to +/-1v.

The direction of movement is independent of the increase or decrease of the sampling frequency.

For example,.

23kS/s, the declared value is - 0.540v,

24kS/s, she moves to-0.620v.

25kS/s, she moves to-0.690v.

26kS/s, she moves back to-0665v.

27kS/s, she moves back to-0.625v.

and 28kS/s, she moves to - 0.535v.

At first, I thought that the sampling change made a change of the input impedance and change the load on my source, however, all the time, my dc signal source remained at the - 0.625v (as measured with a multimeter fluke at the connection point to data acquisition).

Why this is happening and what can I do about it? I want to give my users the ability to choose their desired sampling frequency.

My guess is that I need to add an amplifier to fixed gain with a gain of 5 to 10 to make the input signal to use the maximum of the analog input level (+ / 10v).

I use MAX version 5.0.0f1

Thanks for any help,

Tobin

Hi Tobin,

What do you use to generate the signal-. 625 volt? If you are using a switching power supply, you can experience aliasing where the power supply is turned on and stop.

In addition, are see you the same tensions at the same sampling rate? See you always - .540v to 23kS/s or vary over time?

Finally, you have a second 6255 you can try to replicate this on? It could be that the unit is defective.

N

-

Hello

I'm looking at possible solutions for data acquisition. I use 4 or 5 entries analog and two digital inputs. During the analogue entered most of them will not need sampling extremely quick rate except for one who needs the least 100ks/s. I noticed solutions cost-effective have overalls sampling rate (eg. 250 ksps / s) which extends on all channels. For these products, such that the NOR-9205 compactRIO module, is possible to distribute unevenly sampling rate between channels (ie. could I give up 100ks/s for a single channel and spread the 150ks/s rest between the remaining channels in use)? Thanks in advance for any help,

Adam

Hello Adam,.

To answer your question on the sharing of the sampling rate, it is not possible to have a single module different sampling frequencies, as described in this KB: here (http://forums.ni.com/t5/Multifunction-DAQ/Aggregate-sampling-rate-and-Multichannel-Scanning-Rate/td-....)

In the case of the 9205 this module multiplexes between all channels (32 cases set up in single ended mode or 16 in differential) this means that the sampling rate of 250 kech. / s matches total on all channels.

If you are using the differential mode then the samples per second on each channel will be 250 kech. / s divided by 16, IE 15KS/sec. However if you only specify 4 channels max sampling frequency will be 250 kech. / s divided by 4, IE 62.5 kech. / s.

One way around this is to use 2 x 9205 in one of our new CompactDAQ chassis, which has 3 engines of timing to HAVE. This allows to set different timings in 3 different modules. What is described in this KB: here (http://digital.ni.com/public.nsf/allkb/E7036C1870F6605686257528007F7A72)

I'm sorry of this reply took so long, and I hope the above information helps.

Please do not hesitate to answer questions.

If you want I could get one of our technical sales engineers to give you a call to discuss further with you data acquisition system?

Kind regards

-

High sampling rate for 18 strings in a single task - DAQmx

Hello

My current experiences require the acquisition of 18 channels (6 HAVE custom voltage with excitement, voltage AI 12) data at a sampling frequency of 50 kHz. My question is if it is faesible using a single cDAQ-9172 chassis. Used modules are 2 x NI 9237 and 4 x NI 9215.

The previous researcher on this project used 2 different Renault to do this, but I was hoping that I could reduce it to a single DAQ to simplify the synchronization of all channels.

I wrote a *.vi (attached) to do this and write to a TDMS file using a structure of producer-consumer; However, when I run the * .vi, I can run for minutes, but the number of samples recorded for the PDM is rarely more than 100 k. Subsequently a buffer size error (attempted to read from the samples that have been overwritten) with less than 200 k samples ever record. I checked the max sampling rate (using a property timing node) with the configured task as in the * .vi and it shows a maximum of 235kHz.

I can't say if I make just the structure of the producer consumer incorrectly or if I ask too much of the cDAQ-9172 unique?

Any help would be much appreciated.

See you soon

Bart

Hi bart.s,

TiTou speaks sampling aggregate not simultaneous, so sampling rate 50kS/s is the same for all channels.

I see the problem in the loop of the producer. If your sampling frequency is 50kS/s/ch and you read that a single sample/ch you will lose data because the producer loop cannot run so fast. You should read more than one sample. I recommend you also to move your tracing to the consumption loop code and work with larger amounts of data.

The second problem may be with the error handling in your loop of consumer. Merge the mistakes of loop of consumer and producer and also add a few general for two loops off if the error occurs (for example, using local variable).

Best regards

CaravagGIO

-

NI 6552 Signal Express sampling rate

I'm generating multiple signals for Signal Express. When I run them, some work well and others not, in other words, for some changes in sampling rate signals! Thera are two options in Signal Express: 1. read file waveform 2 sampling rate. to manually set the sampling frequency. In both cases, the rate is changed when I run the waveform of my 90 MHz to 100 MHz.

Any ideas?

Hello

The internal clock on the 6552 is generated from 200 MHz time base; Is that you can generate the frequency of 200 MHz/N where N is from 2 to a large number which takes up to 47 Hz. The driver for the Board of Directors will force the neerest value, so if you swipe from 90 Mhz to 100 MHz frequency, you will get 100 MHz in all cases. There is more information about the synchronization on the specs here:

http://digital.NI.com/manuals.nsf/WebSearch/E4C93B141B71ED93862573CC005E8EA1

Once, you run your project, Signal Express should show you the corced value, you can use this to read the actual frequency generated.

I hope this helps.

Juan Carlos

Maybe you are looking for

-

IdeaPad Z570 Docking Station options

Lenovo to or recommend a compatible docking for this model? Thank you

-

On the upgrade of RAM on Aspire E5 - 471G...

Hello Just bought my first laptop Acer E5 - 471G and I would like to add another 4 GB of RAM, it is native 4 GB. I was wondering if upgrading RAM by myself will void the warranty? There are some brands of ram sticks as Acer laptops computers prefer?

-

Pavilion g6 2005ax: Bluetooth does not work on HP 2005ax

Downloaded the driver bluetooth on hp site. installed but I am not able to find any device bluetooth on my laptop, nor it is discoverable to other devices. It comes to the hardware id. Help, please. Thank you.

-

How can I boot linux from a USB stick or on a computer dvd drive windows laptop 8 Please?

Hi allCould someone describe how to configure my windows laptop 8 HP Pavilion g6 2244sa to start linux usb and or dvd player step by step please? English is my second language is so clearly please. Thank you. I have 64-bit Windows 8

-

BlackBerry Smartphones BB Bold 9900 - icons on panels are vertical HELP!

So last night I noticed that the icons on my panels are are no longer together, but now vertically aligned! Do not know how it happened... I don't know that this happened just after I was not able to send e-mails yesterday afternoon but once the phon