DAQmxCfgSampClkTiming sampling rate for external sources

I'm looking at the example of Synchronized_AIAO_Shared_Clock.c to http://zone.ni.com/devzone/cda/epd/p/id/2352 . This example creates a string of tension that HAVE streams at 10 kHz, and then creates a tension AO channel that is bound to the sample clock HAVE to synchronize channels. I use this example to understand the use of DAQmxCfgSampClkTiming here. This is the corresponding code (comments are mine):

Create a channel of tension HAVE will work continuously at 10 kHz

DAQmxErrChk (DAQmxCreateTask("",&taskHandleRead));

DAQmxErrChk (DAQmxCreateAIVoltageChan(taskHandleRead,"Dev7/ai1","",DAQmx_Val_Cfg_Default,-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleRead,"",10000.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000));

Create a tension AO channel, and then attach the clock of the chain in tension of the AO for the sample clock HAVE

DAQmxErrChk (DAQmxCreateTask("",&taskHandleWrite));

DAQmxErrChk (DAQmxCreateAOVoltageChan(taskHandleWrite,"Dev7/ao0","",-10.0,10.0,DAQmx_Val_Volts,NULL));

DAQmxErrChk (DAQmxCfgSampClkTiming(taskHandleWrite,"ai/SampleClock",1000.0,DAQmx_Val_Rising,DAQmx_Val_ContSamps,1000));

.. So what I'm trying to understand here is how to interpret (1000.0) sampling rate argument in the second call to DAQmxCfgSampClkTiming, where the canal AO is related to "AI/sampleClock. It seems to me that this argument must be meaningless, other than perhaps to determine the size of the buffer, since by definition this AO channel will clock on a sample of every time that AI/SampleClock rises. Then maybe someone can help me understand how this argument is used...

But in all cases, the docs say "If you use an external source for the sample clock, set this value to the maximum expected rate of the clock." In this case, the clock is set up a few lines earlier at 10 kHz, so is not this 'evil' in the second call to DAQmxCfgSampClkTiming, a sampling rate of 1 kHz is specified (much less than the maximum rate of sample expected)? What is the consequence of this?

Thank you!

-Dan

Hey Dan, some big questions you've got.

You pretty much put the nail on the head with your guesses. The size of the buffer is based on the resolution of data acquisition in combination with the sampling frequency that you specify. Think of it as an implicit in the size of the buffer declaration (but it is certainly an explicitly define that, if you wish).

As for your second question, which relates to new back to the size of the buffer, except that this time it is for the use of an external clock source. Given that the material has no implicit way to know the frequency of clock of this external source, it asks you to specify explicitly the maximum frequency so it can create a buffer of the right scale size.

Tags: NI Hardware

Similar Questions

-

High sampling rate for 18 strings in a single task - DAQmx

Hello

My current experiences require the acquisition of 18 channels (6 HAVE custom voltage with excitement, voltage AI 12) data at a sampling frequency of 50 kHz. My question is if it is faesible using a single cDAQ-9172 chassis. Used modules are 2 x NI 9237 and 4 x NI 9215.

The previous researcher on this project used 2 different Renault to do this, but I was hoping that I could reduce it to a single DAQ to simplify the synchronization of all channels.

I wrote a *.vi (attached) to do this and write to a TDMS file using a structure of producer-consumer; However, when I run the * .vi, I can run for minutes, but the number of samples recorded for the PDM is rarely more than 100 k. Subsequently a buffer size error (attempted to read from the samples that have been overwritten) with less than 200 k samples ever record. I checked the max sampling rate (using a property timing node) with the configured task as in the * .vi and it shows a maximum of 235kHz.

I can't say if I make just the structure of the producer consumer incorrectly or if I ask too much of the cDAQ-9172 unique?

Any help would be much appreciated.

See you soon

Bart

Hi bart.s,

TiTou speaks sampling aggregate not simultaneous, so sampling rate 50kS/s is the same for all channels.

I see the problem in the loop of the producer. If your sampling frequency is 50kS/s/ch and you read that a single sample/ch you will lose data because the producer loop cannot run so fast. You should read more than one sample. I recommend you also to move your tracing to the consumption loop code and work with larger amounts of data.

The second problem may be with the error handling in your loop of consumer. Merge the mistakes of loop of consumer and producer and also add a few general for two loops off if the error occurs (for example, using local variable).

Best regards

CaravagGIO

-

So maybe this is a stupid question, but I need to know because I train for a specific sound. Is there a way [to logic] to shoot/change of a certain frequency sampling rates. I can imitate the sound I'm looking for with a low pass filter, reverb and a distortion. But I don't want to 'emulate', this sound, I want to create. Then I can put my own effects and play with it like I want to. If I have to use a bunch of effects to make it sound like I want that also the addition of said effects remove the sound and sound horrible. as to where pulling the sampling frequency of the high frequency and no downs will make me THE noise that I need and always allow to add nice effects to make MY sound instead of someone else. I hope you know what I mean. Let me to you specific real once more. I want to pull or carry a certain frequency sampling rates for a sound under water. I don't want to use filters to make the sound. So can you please help me. I invited everyone locally on how to do it and nothing works. Also if this is not possible in the logic of tell me if there are third party plug ins or maybe even a different DAW that could do like komplete Kontrol or audacity.

See if this thread is helpful at all...

-

With the NI 9205 module Max sampling rate - problems

Dear friends,

I develop a project of lv, which makes and control system of engine dyno. The material is CRio-9022 with other cards and also 9205 for AI. There is an encoder for angle attached to the motor shaft with 3600 chatted by Tower as well as an index to indicate the end of a revolution. the output of the encoder is measured by card 9411. The speed of the motor is 1500 rpm. I measure pressure data and couple when I receive a 'tick' of the wheel. This means my sampling rate for pressure and torque each is 90KO/s.

but I was not successful to lead it. The program is great and I can show them, but I believe that there is a problem in the choice of material for the task. With the data of pressure and torque of the 9205, I also measure other channels for the controller output mass flow and temperatures. So in all I use 8 channels of the 32 available. But only the pressure and torque are acquired at the wheel-driven sampling rate. the rest are acquired about 5 times per second.

Since the 9025 is a multiplexing ADC, 250K sampling frequency is divided by the number of channels accessed = 250 K/8 = 31 K samples/channel. With this in mind, I decided to acquire data of pressure and torque with each beat 3rd rotary encoder, essentially on 30K samples/s sampling. However, I see a large amount of noise.

So I decide to average more than 1 second cycles (so the engine runs at about 25 cycles/sec, I averaged over this issue). The resulting pressure and torque graphics do not match with those measured by an oscilloscope in terms of amplitude but the frequency and shape is correct.

I noticed an interesting feature in the charts. When I pass interpolation between the points, I see several curves made by points instead of a continuous locus of points. Accordingly, I find that the acquisition is slower than necessary, and so there are less number of points sampled as required. These points are not synchronized 25 cycles I have on average and therefore the separate "curves". It is because of the possibility that some points receive a higher number of 'contributions' several times (when you add), the neighbouring points.

so I conculde that the 9205 is not fast enough to do the job. also noise, perhaps due to crosstalk or gosting when the mux changes channels. the impdences output pressure and the couple are of the order of 10 K ohms.

the Labview code outline: well, there is a vi FPGA, which takes the rotary encoder ticks and sends a signal to the case of each 3rd tick. The signal contains a 16-bit integer, indicating the number of ticks. This signal is sent to a 1 element FIFO. This fifo is read in a parallel while loop, where it remains awaiting a new element. The while loop bed fifo, where data are available, takes a measure of pressure channel. A node memory of the method is called to provide data according to contained in the index number equal to the number of ticks to signal fifo. Then he adds the current pressure reading to the reading of the memory and stores the sum in the same memory location. Thus, an array of elements of 1200 is formed, where each elemnt is a sum of the values taken of more than 25 cycles. This memory is transferd to a dma fifo and reading side host. is done similarly to involved couple. host-side the fifo is read and divided by 25 to get the average. This average is displayed on a waveform graph.

Please check the attached file to get an idea of the problem. Sorry for the long post.

Please suggest if you understand the problem and suggesstions or solutions.

-

Different sampling rate with the same connector AIO, Labview FPGA

Hello

I use LV 2009 with the new Toolbox FPGA and an NI PXI 7854R. I acquire an analog signal with a sampling frequency of 600kS / s. I need as the sampling rate for the processing of the data, but I also need the signal sampled with a much smaller, variable sampling frequency to a FFT.

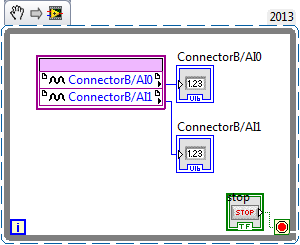

I've attached a picture to clarify, in a simple example, I'm looking for.

I tried with the structure case only take each ' iht iteration, but did not get the expected results.

Does anyone have another idea how to solve my problem? Of the, "Resampling" express VI in the funtion FPGA palette does not help me.

Thanks in advance,

Concerning

Hello

the connector for the analog input is a "shared resource", so you should he alone in your FPGA Code.

Find attached an example that shows how to perform this task of analysis.

Concerning

Ulrich

AE OR-CER

-

Several identity AD External Sources in ISE 1.2

First of all I guess it's possible to have several entries AD for external Sources of identity in the ISE 1.2? When I view Active Directory (AD1) it displays my four ISE servers with the connected state, but I do not see where to add anything extra. I did not originally define this figure so miss me something somewhere if possible. I have however maybe add under LDAP and then he would roll in AD or something, but I have nothing listed on LDAP either.

What I'm trying to do is find a way to have the ISE to cover our two different areas. We have a large forest but currently that is divided into two areas AD based on our two divisions. I'm trying to see if possibly I can just get through the existing configuration to take security on the other groups domain in the dictionary, but so far that has proved do not capable.

Brent

The ISE v1.3 allows you to add 50 domains diff., please update v 1.3

http://www.Cisco.com/c/en/us/TD/docs/security/ISE/1-3/ISE-ADIntegrationD...

-

Sampling rate higher for the measurement of precision meter

I have a BNC 6259 M Series DAQ USB. I am currently using the DAQ Assistant to perform simple cash rising measured with the measuring mode single sample on request. I tested my VI with a known square wave with a function generator signal and it clearly lacks a few edges. I think that the solution lies in faster sampling. However, I was not able to understand how to use clocks to set up continuous sampling mode. I tried the forums and I found articles that were close, but not quite exactly the problem I am facing with as (http://forums.ni.com/t5/Digital-I-O/trying-to-use-NI-6251-s-DIO-port-as-input-and-output/m-p/448035#...) or (http://forums.ni.com/t5/Multifunction-DAQ/Using-Counter-of-PCI-6024E-with-Quadrature-Encoder/m-p/984...). Any guidance here would be great.

In fact, the calendar should not have anything to do with the edges being detected. Configuration of a sample clock for a county of just edge task allows you to enjoy deterministically in the account register and has no impact on the edges which can be counted. Also, the analog examples really have nothing to do with what you seem to be asking questions on.

... So it leaves the question unanswered as to why you might miss the edges. Perhaps the following information could shed some light on the question:

1. it is possible that you do not configure the counter exactly as you think you are. Can you post the VI you use? As a point of reference, count digital events shipping example does not use any clock sample timing and just questioned the value of the register count with a software loop, but the meter should not miss all this edge on the input source. There are examples that are timed by the material available as well, but this is not necessary, unless you need a constant specified dt between your counter samples. To use the examples of the timed sample, you will need to generate a clock of either another subsystem on the map or use an external clock.

2. assuming that the configuration of the counter is not the issue, there may be a problem with the method that you use to determine if you are away from the edges. How do you know that you are away from the edges? The function generator produces only a finite pulse amount? You start the meter before start out impulses?

3. If the two points above do not raise red flags, it seems likely that the meter is registered just not some of the impulses of your FGEN. Can I assume that the output of the FGEN is 0 - 5V TTL? What is its frequency and duty cycle? The maximum external source for the meter on the M-series products: DAQ (like the 6259) is specced at 20 MHz, but this depends on a clean signal with good connections. At frequencies above it, the bandwidth of the front-end of the PFI lines becomes limiting. If you have an available specification document for your FGEN I'd like to be able to see it.

I hope this gets you throw on the right track to solve the problem - impatience comes back with more information.

Best regards

-

Getting the error «for input and output sample rate does not match...» »

I am trying to create an audio file, but when I click on the record button I get this error:

«The sampling rate of the audio output devices and audio don't match.» Audio cannot be recorded until this problem is corrected.

Use the appropriate operating system or control panel of audio device to adjust the sampling frequency of the output devices and audio entries to use the same settings. »

I have the preferences set to use operating system controls and it seems to work because when I change in the Win 7 Pro CP it adjusts at the hearing.

So I do not know which need to be addressed. I use the video card as the source and not the speakers thus mean the output must be la carte too?

Please help, I'm confused.

Thanks for your time!

Got an answer to a previous question asking how to record and thought, this could be useful for others.

It takes a Windows setting and a setting of the hearing.

You will need to go into your settings from Windows recording devices - if you see a speaker in the lower right of your screen, right-click on it and choose recording devices. Find your audio input source, select Properties, go to advanced. You should see a drop down menu with options for the quality and frequency of sampling, mono/stereo. In general, you'll want to 44.1 kHz for audio; 48 Hz for the video.

At the hearing, go to Edition/Preferences/Audio Hardware and select the same frequency of sampling for output. I went through the same question a few months ago, and it worked for me. Good luck!

-

I used to export clips cuts to the Ribbon (version 9.0), but recently I bought version 13.0 of FIRST and - to keep the exact same video quality as source (analog)! -J' I export simply for external HDs (so actually at the computer)... but everything I try, I noticed that when I check the hardware with the original of the first export clip is NOT ONLY SMALLER but ALSO FACT do NOT SEEM to HAVE THE SAME RESOLUTION, DETAILNESS, SHARPNESS (or whatever you call it)... What I am doing wrong? WHAT SETTINGS should I HAVE to DO in order to KEEP the SAME IMAGE QUALITY (or even improve) to be STORED on the COMPUTER? Thank you, RVH

How do you export?

-

NI 5122 range Variable sampling rate

Hello

I use a digitizer card high-speed NI 5122 to acquire data and synchronize the sampling frequency of the frequency of the data card. For example, my first set of data will have a frequency of 13.6 MHz so I would taste 13.6 MHz. When I connect a signal 13.6 MHz to the CLK IN on the front panel of the card and write Labview code to taste at this rate (for the sample clock or reference clock), I get error message. Anyone know if its possible to have a sampling rate variable really for this card?

Thank you

Steve

Hi Steve,.

I understand that you are using a digitizer high-speed 5122 and try to use an external sample clock. What kind of error messages received when you doing? In addition, how you set up the device to use this external clock?

"" "" I would also like to point out that there is a very useful example program in the example Finder LabVIEW ('Help' to find examples) found in e/s material "Modular Instruments ' OR-SCOPE" features ""niScope Clocking.vi external EX' that allows the user to make a simple acquisition using an external clock source. To specify the source of external clock, rate and divisor, a knot of niScope property is used. You should be able to try this example and use the same method in your program. Hope this helps,

-

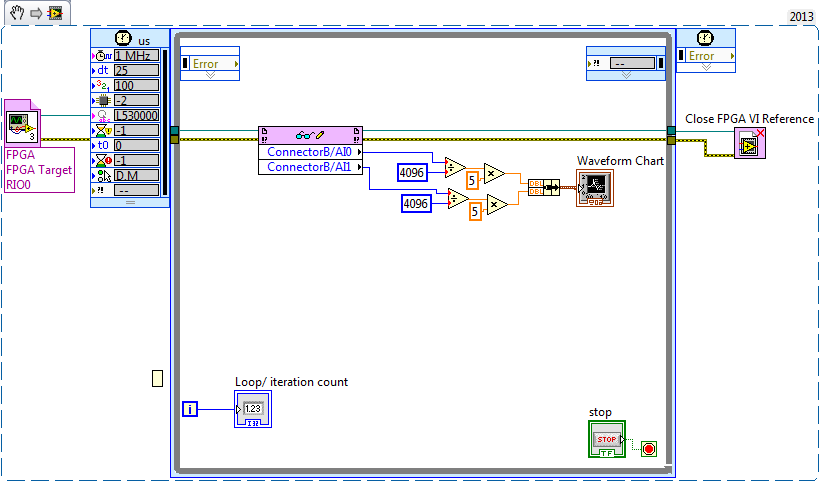

I'm new to myRIO and use it to measure sine wave (0V to 5V) of up to 10 Hz 20 KHz. I also quickly transformed of Fourier (FFT) of the signal measured in real time.

Sideways FPGA of things, I try to keep things pretty simple, just read 2 channels of AI (connector B: AI0 and AI1), therefore potentially able to read each HAVE 250 kech. / s (as the unit has a capacity of 500kS/s). Does that mean this program gets a two analog inputs data exactly every 4 microsecond? If this is not the case, how can I make sure that the data is acquired through a fixed sampling rate?

I realized that we can add to the FFT in FPGA function, but I wanted to manipulte the acquired data of analog inputs before it is sent to the FFT, which I don't know how to do now. Can someone explain me how do the arithmetic data (muliplication, division and so) on the acquired data and analog inputs to reducde the 12-bit resolution 10-bit to program FPGAS.

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

If I read in the forum for help, I couldn't have the full answer to my doubts

Discussions at the Forum I did reference:

A lot of good questions here, I will try to answer as much as I can so as to offer a bit of advice.

First of all, if you are looking to acquire data at a very specific rate on the FPGA, you'll want to use the Timer VI. You are also going to use a FIFO of DMA to transfer data of FPGA in real time. A node read-write using as you do now means you'll run out of samples, or read the sample even several times. The link below is a very good tutorial on how to do what I described above.

http://www.NI.com/Tutorial/4534/en/

Later, I created a myRIO program to read analog data 2 FPGA program which continues to turn in timed loop. In the program myRIO, the timed loop is configured to 1 MHz clock source type by a delay of 25 microseconds.

This configuration means that the loop runs exactly every 25 microsecond?

When I set up the less than 10 micro second time, myRIO has stopped working. Why is it so?

Is it because myRIO cannot run as fast as FPGA?

In general, you should not run a timed loop much faster than 1 kHz. Using timed inside loop knots, you can monitor the real rate of loop during execution to see if f you meet your needs of the moment.

The portion of your myRIO RT is slower than an FPGA in the sense where it cannot manage the rates of lines 40 MHz (he makes up for it by being able to work with much better pictures) and it is important to remember that it is just a computer. The advantage of a real-time operating system, is that you have more control on the Scheduler, not that he is faster (less jitter, not faster code). There is more good reading below.

http://www.NI.com/white-paper/3938/en/

It is advisable to make the FFT of myRIO side analog data or FPGA?

When I tried to do FFT using the power spectrum of myRIO side, he asked for waveform data. What I acquire is data analog. How can I convert in waveform data?

I would say that it is generally advisable to treat your FFT on the side FPGA as long as you have the resources available, but for many applications probably little matter ultimately.

-

Hi all

I use a module 9237 for certain measures of the load. My experiences last over time and so I'm generating a lot of data due to the minimum sampling frequency. I can't define an external time base so I can lower my sampling rate to something easier to manage? Even just a sample rate of 500 s/s would make a huge difference.

Thank you

Hi cannisbellum,

9237 specifications frequency range of minimum data (fs) using the internal master time base is 1,613 kech. / s and external use master timebase is 391 s/s. The simplest would be to sample at 2kS/s and decimate your data by 4. This can be done by using 'Decimate 1 table D' or ".vi Decimate (continuous).

Rates valid for the NI 9233 OR 9234 sampling and NI 9237 - http://digital.ni.com/public.nsf/allkb/593CC07F76B1405A862570DE005F6836?OpenDocument

Best,

CARISA

-

sample rate real vs min sampling rate

I'm sure it's an obvious answer, but here goes.

I have a USB-5132 ' scope and using niScope horizontal configuration Timing.vi I put, among other things, the minimum sampling rate. In my case, I chose 20 MHz, which of course gives a sampling of 50 ns period.

I use niScope reading (poly) .vi with the WDT variant to read waveform data. I noticed something very strange - waveform limit testing throw error 1802 "signals have a dt of different values '-if I put a waveform components unclusterizer Get on the wire of waveform and looked at the value of dt of the wave." He told me that my dt is 40 ns, which of course is of 25 MHz. I also plead for only 2000 samples.

So what causes this shift? Why the digitizer does not accept everything just my desired sampling frequency?

Austin Walton wrote:

Andy,

The setting of minimum sampling frequency is the frequency at which digitized

the samples are stored, expressed in samples per second. This setting is rounded

up to and including the next legal collection that supports your device. Ownership of the actual sampling rate calculates the actual sample used for the acquisition rate.Unless you specify another source of the clock, the digitizer uses an internal oscillator as clock source. For the 5132, this oscillator is clocked at 50 Mhz. When using the oscillator internal as the sample, the digitizer clock source can use versions split to the bottom of this clock, for certain sampling frequencies are not possible.

-

6255 sampling rate causes the dc offset

I see a dc offset in the measures of analog input I select different sampling frequencies.

I have USB-6255 (mass termination) multifunction data acquisition and I use measurement and Automation Explorer to put in place my entries.

My raw analog input is-0, 6250 volts dc, I have set up a task that uses 4 differential channels with no custom scale.

I have defined the scope of the input signal to +/-0 .8v for you sure I get good resolution.

Acquisition mode is continuous, samples of read is 1 k and I play with the order of 10kS/s rates 50kS/s.

While this task runs in the MAX, I can put my cursor in the rate field and use the top and down arrow keys to change the sampling frequency. As I do, I can see the light changes reported as much as 150 MV rate from one to the other.

It is a significant change when the total time of entry is lower to +/-1v.

The direction of movement is independent of the increase or decrease of the sampling frequency.

For example,.

23kS/s, the declared value is - 0.540v,

24kS/s, she moves to-0.620v.

25kS/s, she moves to-0.690v.

26kS/s, she moves back to-0665v.

27kS/s, she moves back to-0.625v.

and 28kS/s, she moves to - 0.535v.

At first, I thought that the sampling change made a change of the input impedance and change the load on my source, however, all the time, my dc signal source remained at the - 0.625v (as measured with a multimeter fluke at the connection point to data acquisition).

Why this is happening and what can I do about it? I want to give my users the ability to choose their desired sampling frequency.

My guess is that I need to add an amplifier to fixed gain with a gain of 5 to 10 to make the input signal to use the maximum of the analog input level (+ / 10v).

I use MAX version 5.0.0f1

Thanks for any help,

Tobin

Hi Tobin,

What do you use to generate the signal-. 625 volt? If you are using a switching power supply, you can experience aliasing where the power supply is turned on and stop.

In addition, are see you the same tensions at the same sampling rate? See you always - .540v to 23kS/s or vary over time?

Finally, you have a second 6255 you can try to replicate this on? It could be that the unit is defective.

N

-

Specified sample rate clock works do not

I hope that I was right to post on this forum. I have a problem that I had not previously in the acquisition of data on a chassis 9172 cDAQ using a 9234 for 2 analog inputs and a 9219 for four thermocouple inputs. The 9219 is obviously not ideal as it has a rate relatively low sample (and I have a 9213 on the way), so I'll have to use to HAVE. ADCTimingMode to isolate channels on this module for "high speed" mode if I can get an adequate sampling for my load. The question that arises is that no matter what I do to specify a sample rate, the actual sampling rate ends up being 1651,61 Hz, higher than the features of the 9219, if I get an error. I tried to use the DAQmx property node to set the calendar and the clock sampling VI but neither work. The only source that I can choose is on board, but when I check the source used is cDAQ1Mod1/AI/SampleClock, even if I get an error when I try to provide as a source of sample VI clock.

As it is, my VI runs despite this error and seems to produce accurate data, but the original problem is with long testing I will have unnecessarily large data sets unless I start to decimate my other data, and the secondary problem, it's that I can't get the program to run when I try to incorporate my task of counter. In this case, the error ends the execution and he acquires no data.

I have attached my VI under the task of counter (I'm on 8.5 and have the coming upgrade as well), but also an image of a simplified version of the VI only try to specify the settings of a channel of AI. I get the same result with it. I'm a bit of a loss here because I've never had this problem before, and it seems that there is something beyond rudimentary that I'm missing, so I would really appreciate any help anyone could provide. Thanks in advance.

Maybe you are looking for

-

How to change miles to km in iCloud?

Hello can I change the units in iCloud web app from miles to km (to find my friends)? Thank you!

-

Satellite P100-222: BIOS password has been set - why?

I have Toshiba Satellite P100-222 and my problem is the BIOS access. A few days ago, I bought nootbook and if I want to go BIOS F2, I have to write a password to enter. My question is do you know where I can find this password? Perhaps this password

-

Errors, addition of Win7 workstations to the domain

Greetings! I just started one already existing, although that paralyzed, installation of Windows Small Business 2011. Active Directory seems to be set up correctly, and I have no problems connecting to shared folders or devices by using the credentia

-

want to learn about this process

MBAM scan display this file as the misuse of security. Am paste this file. Please tell me if this file belongs to windows or is a virus? HKEY_LOCAL_MACHINE\SOFTWARE\Microsoft\Windows NT\CurrentVersion\Image File execution Options\NTVDM.exe (Security.

-

DeskJet 3050 j610a - new router; no longer can print wireless.

Hi all. Am 66 & new to computers and the forums. I'll try to be brief, but I want to describe my problem as precisely as possible. I have a laptop Toshiba Satellite C655, HP3050 j610a printer wireless, Windows 7, 32 bit OS and Google Chrome is my bro