LabVIEW based

Dear Sir.

in my application I m using the structure of the event in while loop. and outside the structure of the event, I use get date and time and random generator but when I run it run evet structure but it does not run the other thing outside of the event of structural re

because it runs only once is not to update the time every second. he get only time once and if I put a plus everything to buckle in while loop then its find ok but on the other hand does not work well

Tags: NI Software

Similar Questions

-

We can I find a complete (with files) ecg under labview tutorial? Thanks for the replies

I want to do a labview based ecg system and I would find something ready for use. Thanks for the reply.

Please visit our biomedical group of users here: http://decibel.ni.com/content/groups/biomedical-user-group

There are a number of articles on the packaging of appropriate signals necessary to amplify and record EKG signals as well as articles on the treatment of the ECG signals to extract features.

Steve

-

I have a question on the implementation of the method 'Reset the Position' in smooth movement. I use the interface of axis of gentle movement. My system is setup similar to the sample project "Interface Servo (9263 & 9401 & 9411)" unbound axis. When I run a Reset Position method

It resets the position in the trajectory generator, but it does not implement the physical encoder reset. I noticed that there are a freshly calculated position offset value in the generator of path data.

My encoder in the FPGA code has an entry to reset the position, but I'm not sure exactly the right order in the application of this.

Steve

Hi Steve,.

In your VI axis interface, you should be written the position of the encoder motor SoftMotion each evaluation period. Internally, SoftMotion knows when you reset the position, and it will automatically display the position of the encoder position to reset. So after a discount to zero position, it is likely that your position of encoder FPGA will be different from the position that reports SoftMotion. This is because done SoftMotion the scaling for you. Therefore, you don't have to use the Position offset value (and in fact probably does not yet need to be exposed to the user). The reason why Position Offset is an I64 is because it actually represents a fixed point value (this has been implemented before LabVIEW based point fixed so we have set up our own FXP). I think that the most significant 32 bits represent an integer I32 and the less 32-bit significant fraction, is similar to a +/-64,32 representation.

That being said, you see an incorrect reported position after performing a reset of the position? If so, what are your light?

Thank you

-

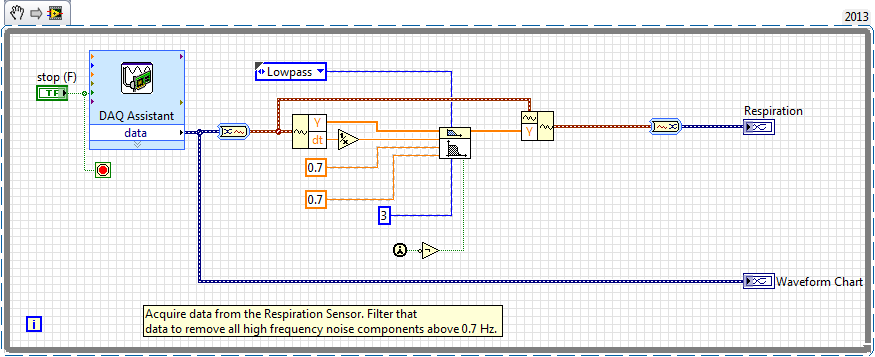

Hello! Im just a student in biomedical engineering and I need to detect the rate of breathing on labview based on accelerometer three axes, I m using the z axis accelerometer for movements of the chest and thorax breathing, but I do not see the signal of respiration. Also I use an analog butterworth filter with cutoff frequency of 1 hz (the frequency of respiration cause is between 0.1 and 0.5 hz) and a digital filter on labview. So that's my question, how can I take samples low frequencies or the signal is filtered? I am attaching the file vi that I use. Thank you!

An accelerometer is not able to travel, it measures acceleration. But I suppose the signal is oscillating so if all you want is the respiratory rate, then it will work very well. You probably need a bandpass filter with a low cutoff around 0.1 Hz frequency to eliminate any gravitational constant acceleration.

I'm not really familiar with the screw Express, but the filter there is no initialization entry, so it can be reset for each set of data that are acquired. You can use the standard filter function in the range of Signal Processing.

-

Running a Seq file when running the GUI (command line option) return an error

Hello

I use a LabVIEW based UI to run/execute a file in sequence by using the command line option. My command line is "Test DUT' D:\QF\GUI-test-Sequential.seq D:\QF\GUI-Test.exe - runEntryPoint

When I ran the get 3 popup saying that some of the perameters 'is not a valid file of LabVIEW"(see attachments). No idea how to avoid these messages? (The user interface works very well and runs the entrypoint of the USE Test)

LabVIEW 8.5

TestStand 4.1

Thank you.

Hi Tom,

When you create a new application to your specification to Build, you must set the 'Pass all arguments for application command line' in the Advanced tab.

Once you do that it should all work.

Concerning

Ray Farmer

-

installtion problem multiple application.

Hi, I'm using labview 8.5.1 and I made two different labview based application. When I try to install both applications on a PC, another application removes previously installed application. so I'm not able to install applications on a PC.

even the name of the installer, installation path, the application name, the name of the product are different in both applications.

Copy the build script should create a new GUID in LV 8.5.1. So I guess it was the same script to create the installer and changed after the creation of the first...

hope this helps,

Norbert

-

Empfehlung Lanzeitmessung data base: database (SQL) vs PDM

Hello

As eine Projekt eine Software fur einen Teststand schreiben soll ICH. Are IM trains its ist geplant, eine für die Testobjekte anzulegen data base, da sharp several stations durchlaufen, die ich im following darstelle kurz:

Recovering of the Testobjekts (LabVIEW automatisiert mit Herstellungsparametern: Dicke, big, material)

Langzeittest'm Teststand (running > 365Tage Speichern von kalkulierten werden, the Test setting: Dauer, frequency, Kraft etc..)

Weitere Test am Teststand (parameter, Messwerte etc.)

Elastizitatstest (ein weitere Teststand auf LabVIEW-based, the Test setting: Kraft, Speichern der Messwerte, Auslenkung etc.)

General weitere Tests (noch nicht genauer known)

Jetzt war meine erste Uberlegung, die jedes als TDMS zu speichern und sharp Test Messdatein in einer zu left data base.

Dabei ist mir aufgefallen, dass are probably sinnvoller alles in den TDMS-Datein zu organisieren und zu speichern.

Wie euer vorschlag das Ganze aufzuziehen ware? Meine Uberlegung ist:

I Testobjekt a TDMS file (Kanalgruppe defect den Tests, sind die gemessenen channels / berechneten values)

ICH kann die values von Testobjekten bei diesem Aufbau thank friendly/einfach um mit dem DataFinder/tiara?

Viele Dank as eure Hilfe!

If you have the choice, ALWAYS choose the database. It will give you the greater security and application/platform independence.

Mike...

-

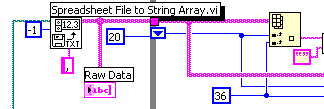

Write the spreadsheet in an array of strings on a different worksheet

Hello

is it possible to write the spreadsheet to a table of chains, but to an additional worksheet?

I am writing the results of the spreadsheet, but I want to create a different worksheet so that I can put the raw data.

is this possible?

If so, how?

You can't unless you start using ActiveX or report generation tool to connect with a real spreadsheet .xls file.

You are read and write a text file in the form in the way of a spreadsheet with delimiters between values in a row and the lines of text on the other. Text files have no understanding of the data being on a "sheet" and other data on another. It is a peculiarity of the format property of Excel file (and thus other spreadsheets) that allows Excel what data need to be put on what spreadsheet. It is not the kind of information that you can pass along the use of LabVIEW based text file i/o functions.

-

Excel sheet entry to 'setpoint' of the PID controller

Hello

I use this (attached) vi to control the thermostat of Lakeshore. I got the website vi OR. I want to change the vi as to the set value, it takes as input an excel sheet (could be any other form too). This spreadsheet contains a list of temperatures. The vi reads the first temperature and then that sets the value of the PID controller setpoint. Once the set point is 'set' the vi waiting for awhile (say 1 hour) before reading the next entry in the excel sheet set point. I want to wait that it is because I programmed a gamma spectrum software such that it counts for 1 hour and then starts a new count. The part of the spectrum is not very intelligent but its ok for now. The problem I have is that when I run this vi (attached), the indication of the set on the temperature controller (hardware) tends to zero and stays there. Can someone help me by pointing out the error that I do. This vi is Labview based 6.0 (it's a bad implementation!)

Thank you

Saurabh

Slim,

You could possibly have the calendar in step in the worksheet as well?

It would be a classic case where you could use state machines (or producer / consumer - events if the user input is critical), research of this architecture and examples on ni.com. Also for synchronization purposes, are looking for functional global timer or try to modify this example https://decibel.ni.com/content/docs/DOC-6523 to add 'elapsed time' (as in the elapsed time express vi) features similar to this code.

You have reports such as:

Initialization: initialize your control panel front/graphics etc. Read the spreadsheet file. Make sure that the comms exist between the software and the controller, etc..

Set the temperature: set the first value, start a countdown (depending on what you set)

State check: check the status of controller etc failure. Check if the user has pressed the stop button. Check if the timer in the previous state has expired?

In case of error stop the timer and take the measures necessary to correct, to report to the user

If the user has pressed the stop button, close all references, etc hard reset and exit the application.

If the timer has expired, get the next value and go on to set the temperature.

I hope this helps.

-

HIII all

I need to move an object from its height of roll and yaw data... I get data from serial port and his works very well... now I need to move any image in labview based on these values... I was able to draw a rectangle in picture 3D... but I don't know how to do it as I required...

the object can be anything...

Hello

as said above, you can do as below

Just change the values

Kind regards

-

I took Basic training courses so DIAdem Advanced and have been scripting for several months. I am interested in how to include specific lines of code based on the computer. Told me it would be similar to .ini in LabVIEW files, although I've never used myself .ini files.

Hi Karen,.

What do you mean by "includes the lines of code? Do you mean what happens when you run a command 'ScriptInclude()' or 'ScriptCmdAdd()' in a tiara VBScript? Or do you mean that you want to run several lines as DIAdem begins, similar to 'ScriptStart() '?

What do you mean by "computer-based? Do you mean you want to implement different batch files on different computers, but you are still using the same file (named) command on each target computer? Or do you mean that you want to implement the same command on all target computers file, but you want different commands to run this file based on the computer on which you are. In the latter case, how do you determine computer on which you are on - MAC address, logged in user name, or what?

Brad Turpin

Tiara Product Support Engineer

National Instruments

-

Need help with implementing DLL based on LabVIEW below call Lib

Here is the list of C functions in the doc that I have, but I don't get the right result.

I need help to understand how these features and how to configure it in LabVIEW

Parameters

voltType

[in] Specifies a voltage detector to get the value of. There may be flags

VCORE (1<>

V25 (1<>

V33 (1<>

V50 (1<>

V120 (1<>

VSB (1<>

VBAT (1<>

VN50 (1<>

VN120 (1<>

ATV (1<>

retval

[out] Points to a variable in which this function returns the voltage in volts.

Typesupport

[out]

If the value is specified as a (non-NULL) pointer to a variable, it will return the types of sensors available in indicators at the level of the ILO-ORed

Return value

TRUE (1) indicates a success; FALSE (0) indicates a failure.

Remarks

Call the function first with a typesupport non-NULL of the sensors available fan and a subsequent call to get the required voltage.Thanks to all...!

I solved this problem.

There was a problem in the configuration of the VoltType. We have a cluster of bits.

-

LabVIEW basics - Cahnging Boolean State question based on the input signal

Hi all

I would like the State to change the Boolean indicator based on a simulated sine wave signal. I have partially managed to do this but need help to develop it.

See the attached vi. At the present time changes Boolean false to true when the value of the signal is greater than 8 or lower than-8.

The focus I need is:

Once the signal passes more than 8 (and the Boolean value becomes true), I hope it becomes false again to a value of 9, but only after the peak value was passed or when the signal is down.

Similarly on the negative side of the graph, I want the Boolean value to become reality at 8-under, stay true until after the peak value was passed and then back to false when the value is greater than-9.

Any suggeastions?

Thank you

While Crossrulz responded, I had a little look.

Don't let me spoil your pleasure with the VI attached. Have a go yourself.

-

Communication between LabVIEW and MCU based on Modbus Protocol

Hello

I am a first year student in the port.and series applications see you, my projiect needs to communicate between LV and MCU based on Modbus Protocol.all configure it are correct, but the lv to send false information which is not suitable for modbus.i do not know how to fix it.

My programs are:

Why did you decide to write your own code instead of what is already available? If you had done a search, you would have easily found the modbus library. Just give a try.

-

Hi all

I use LV 2009 in Vista. I use a VI dynamic, in addition to higher level, to monitor the key pad. It works great except for the fact that when I have another application open during the execution of the LabVIEW application, it still meets the press of button. that is so that the use of the calculator and pressing the ESC key to clear the display, LabVIEW reacts as well.

LabVIEW will know if it is the "application of the update" in windows environment? I know he can tell it is windows that are in front, but what about other applications? I think to use this to filter keys when LV is not the front application.

Thank you!

Charlie

This is the vi registered under a vi 2009

Maybe you are looking for

-

Hello. I lost my iPad, bought a new one and all restored very easily except my pictures. Last time I bought a new iPad everything including the restored pictures. Advice anyone? Thanks, Frances

-

Satellite L70 - menu start does not work

I currently have a laptop L70 that so far has worked well. But today my Start menu does not work & I get a 'critical error msg"asking me to sign... help someone

-

Hello! My Iphone 5 is broken! I can't move it! The only thing I can see in my phone its Siri, but when I say something it doesn´t show the text! Ive tried to press home button and try to close the phone! It doesn´t work! PLEASE HELP ME!

-

CP2025: physically cleaning CP2025 ink roll

Ink red stripes sometimes my copies. Not the cartridge as I changed it out. The control panel cleaning cartridge does not. Notice that the horizontal roll back printer has accumulated red ink on it. Can I clean this roller with rubbing alcohol?

-

Reinstalled Windows 7 on PC now get a message saying that the key is not valid

I had to reinstall Windows 7 on my PC ot a message saying that my key was invalid. This is the same key I used because I got the PC in June and it has been activated then, but not now, why? Any help would be greatly appreciated, thank you Chris * ori