Modeling and Simulation occur error

I have established a model APEX PA78, but the simulation reports any error, please help me!

View report worksheet is followed:

-Audit netlist SPICE to PA78 - 2010-01-28 20:12-

Error of SPICE Netlist in schematic RefDes 'u2', item 'xu2': unexpected '15' found subckt - too many nodes or missing name value parameter instance online.

Error of SPICE Netlist in schematic RefDes 'u2', '

Error of SPICE Netlist in schematic RefDes "u1", item 'xu1': unexpected '1' found subckt - too many nodes or missing name value parameter instance online. Error of SPICE Netlist in schematic RefDes "u1", "

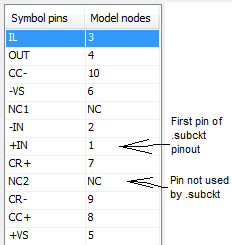

= SPICE Netlist verification completed, 4 error (s), 0 warning (s) =. --------------------------------------------------------------------------------------------------- The accessory includes three files, they are: PA78. TXT is the BERKELEY SPICE on PA78 model of http://Apex.Cirrus.com/en/products/Apex/design_software.html PA78U_B.PDF of page on PA78 of http://Apex.Cirrus.com/en/products/Pro/detail/P1163.html PA78. MS10 is a configuration of bridge-connected, but PA78 itself do not work a simulation. Hello I'll expand a bit what Angela said on the. ENDS and then try to clear up the pins. The SPICE model that you use for the PA78 includes several subcircuits and models. Best practices for creating a component in Multisim are having one. SUBCKT or. MODEL for each component. The point of this is to ensure that the additional models or models contained so that they do not interfere with each other in the final netlist. The best way to solve this problem is to move the. ENDS during the main subcircuit until the end of the complete draft - so, instead of simply add the. ENDS at the end, you must also remove the first. END of line in the file. For this circuit, you probably don't need to do it, however in general, it's a good idea to do by making a component like this. With respect to the pins, step 6 of the component wizard asking you order the pins will be used in the model. The (original) model that you have only 10 knots, so it isn't a problem if you have only 10 pins there. If you have 12 pins on your symbol, and only 10 model nodes, then you score just two unused pins as "NC"(vous pouvez également ajouter deux broches"fausses"pour le.) ". SUBCKT which is what you did, but you have not). For the rest of the pins, see the. SUBCKT line and comments just ahead of him: Comments indicating the order of broaching tell you the order in which the terminals must be indicated when you use the PA78. SUBCKT. As you can see on the. Line SUBCKT and comments, even if IT is pin 1 on the component, it should actually be listed third when you use the. SUBCKT. It's asking you to step 6 in the component wizard. Step 6 allows you to specify the order in which to use the pins to Multisim. The comment you indicates that + is the model node 1, - IN is model node 2, IT is the model node 3, etc., and then you say Multisim by setting the number of nodes of model Hope that helps! Tags: NI Software Models and simulation of collage/combination You can copy and paste slides between the projects, but to ensure that they have the same resolution. A model has nothing to do with it, you copy and paste between cptx-projects. Or do you mean that you are using a model (cptl) and a cptx project, which is a simulation software? How can I fix the following in "Scanner and Camera Wizard" error message an error occurred while setting scanner preferences. I have widows xp pro Hi Plumbbgp, 1. what brand & model of the scanner? 2. the scanner was working fine before? 3. don't you make changes on your computer before this problem? Please provide us with more information about the issue so that we can provide you with the necessary assistance. Whenever I try to update my iPhone 6 for the ios10 it is said it is impossible and that an error occurred during the installation? I ' have enough free space, so I'm not real why he keeps now. Try to update via iTunes. See you soon,. GB I can't sign on my icloud account, saying: "check failed and an unknown error has occurred." Hello buchionunwor, Thank you for using communities of Apple Support. I see that you are having problems connecting to your iCloud account. The following article provides basic troubleshooting for problems with your iCloud account. iCloud: Troubleshooting account Best regards. With the help of control and simulation module; e to get the time the MISO model Manager Hello Please can someone show me how to find the response time of the system below using the module control and simulation? (y (k) - 1,7407 y (k-1) + 0.6236y (k-2) + 0.1782y (k-3)) =-0.0932 u(k-1) + e (k) where there is out, u came and e is a white noise. I tried to enter the CD construct MIMO model, then connect it to CD response time. * s vi. But what I really need to enter the model coeffs every time? and I still don't see the answer! Help, please... Kind regards ruser Hello you have the correct image... I used the Toolbox ID sys (Assistant)... to estimate the system model... and I tried all week last get the model of my system in labview for use the control on this module. Alhamdulillah... I ended up doing... I saved the template to a file from the Toolbox id sys... (my model is in discrete form) then I loaded it in labview using load file pattern... so now I in labview... now for control parts... Thank you again... ruser. my copy of CS4 is not allowing me to open it, whenever I have it try state that the license is no longer works and gives an error code: 6. this problem occurs on my laptop works fine my office copy [from the same CD, etc.] Exit code: 6, Exit Code: 7 Installation error - http://helpx.adobe.com/creative-suite/kb/errors-exit-code-6-exit.html The problems with the Setup logs. CS5, CS5.5, CS6 - http://helpx.adobe.com/creative-suite/kb/troubleshoot-install-logs-cs5-cs5.html for more information on how to review your Setup logs Downloaded a trial Lightroom and got "an error occurred when attempting to change modules." Macintosh. Created another user and it market. This will happen if I do a total of purchase? I want to use my administrator user. Hi ecl44, This is perhaps due to incorrect preferences / permissions issue on the Mac. You might want to refer to the KB Doc: http://helpx.adobe.com/lightroom/kb/error-changing-modules-lightroom.html External template function (control and Simulation Module) on Linux using target Hello I am trying to run the 'EMI_Integrator.vi' for example on one OR cRIO-9024 (nor a myRIO). I moved the file 'EMI_Integrator.so' to the ' / or-rt/system ' on the cRIO and the .so file added to the target in the LabVIEW project. I can not navigate to the .so file directly so I specified the .so path manually, but the VI is not able to run and an error of-2366 'reissue model '. "You can find the original version of VI in the Finder for example OR", but I've included my modified version that has a LabVIEW project and targets already loading. Thank you Mitch Hello Mitch, If you want to use the external model on a 9024 node, you must copy the appropriate VxWorks library (.out) file to the/or-rt/system folder of the target. The .out file is located in LabVIEW\Examples\Control and Simulation\Simulation\External model Interface\EMI_Integrator\RT-Lib\vxworks. In LabVIEW, have the external model node refer to the file of the library appropriate for your operating system. In my case, I use a .dll for Windows file located in the folder EMI_Integrator, above. When I run the VI on the cRIO target, referring to the library on my host computer, it will automatically search the folder to/or-rt/system for a file with the same name with .out. Kind regards System ID: estimated incompatibility of response and simulation I use the VI express Estimation of transfer function SO to model a system plant transfer function. The actual data are a step response, where the stimulus is a flow rate report, and the answer is the size of the droplets resulting (it is a system of generation of Fluid emulsion, decreases of drop size as pump ratio increases). My problem is when I compare the response data simulated that I see in the "preview" when configuring the express VI, a plot of the simulated response using the model TR Simulation.VI - they do not match, the form of the response is quite different. I'm relatively new to the design and the system id modules command, so I guess I'm doing something wrong. A screenshot of the vi express overview as well as Panel frontal/block is attached, as well as the file data and vi. TIA After puzzling on this for two days, I finally understood the error on mine, obviously only a few hours after I posted this question! (I should have posted earlier For the sake of posterity. error #1: I use the data in a table, and I forgot the model IF Simulation.vi wire in the sampling rate I have a mac Pro 13 "model and its making funny nose and get hot around 11:00 area when she is facing you. sounds like wearing out but it happens only intermittently. The genius bar people are especially good to physical problems and power problems. MacBook Pro my son got in because he was behaving strangely, and I run diagnostic and written tests the error code. The genius powered on the MacBook, made a terrible face, picked up over his head and held the keyboard close to his ear. "You have bad fan!", he said. "And you have also run diagnostics and got an error code? What was this error code? » The error code has turned out to be basically "Bad fan". Your visit for assessment is free, guaranteed, or rear. If you decide to do the work, it's all fixed-price, no surprises. Model does not work error-307702 I am trying to run a fairly simple model created in Simulink and compiled to a target 9081; VeriStand returns a code of 307702 error at the start of the model. The cRIO can run another model without problem, but this model still fails. I already tried this model running SE, update the template in Solution Explorer system, insertion or removal of the inputs and outputs and definition of the parameters of model instead of the target scope range. So far, nothing has led to a different result. I'm running SP1 2013 VeriStand, and the target is a chassis 9081. I have attached the defective model and the DLLs below for reference. The model was created in MatLab/Simulink 2009 b. Thanks in advance! Problem has been resolved. After I restarted my computer, load correctly pattern on the target. Should have tried before posting. Control and Simulation in a loop / while loop with TCP/IP reading / writing of synchronization Hello, I have a problem with reading TCP/IP and written in two loops. The problem is NOT to get the two loops to read and write to and from the other. This has been accomplished. My problem is when I run control and the loop simulation on my laptop and the while on a RTOS remote on the controller on-Board of LabVIEW in a remote PXI chassis, the while loop the remote system running on four 4 times faster than the loop control and simulation on my laptop. In other words, for each iteration of the loop control and simulation on my laptop, there are 4 four iterations of the while loop on the remote system. I need to know how to get a degree of kinship (1:1) with these iterations of the loop. When I run a longer simulation in real time, say 10 seconds, the control and Simulation loop begins to slow, i.e. the simulation time slows down until it is no longer in real time and the "Late Finish"? Parameter is set to true and the LED lights and continues to stay lit. At this point, the system destabilizes due to what I believe is being well sampling rate too discreet and I have to end the simulation. How can I get a ratio of one to one between the loops and also to avoid slowing the loops causing destabilization? To give an overview of my application, I implement a control system in a network, seen in "image2.png". This is achieved using my laptop as a subsystem 1. Reference signals are generated from the laptop and the error signal is produced. Control measures taken and the control signals are sent via TCP/IP to the remote system. Position feedback is returned, and the process repeats. My system has Core I7 Procs w / 3 GB of RAM, up to 1 GB/s speed via ethernet and LabVIEW 2011 installed with all necessary modules and networking tools. The attached VI Custom_Wireless_Controller works on my laptop. The remote system I'm working on that has the 7830 NI R Series with FPGA card. OTN runs on the PXI chassis with an enbedded controller that has networking capabilities of up to 100 MB/s via ethernet. I use the FPGA for the acquisition of data and apply control signals to my plant. The plant is the PCE twist connected to the FPGA through the cable of the ECP - RIO of NOR. Subsystem 2 is this side of the CNE. The FPGA collects position, he sends to the controller via the network, receives signals from the network drive and writes signals to the plant power amplifier that operates the plant. This process is repeated and the VI and is titled Custom_Wireless_Plant. I appreciate the help really and look forward for her and for any question! Well, the first step is to understand what you have set up right now. Your control and Simulation loop on the side of the controller is configured as 'Runga Kutta 4' and you have a loop timed on the other side. In addition, you have the primitives of TCP/IP on the control and the Simulation diagram and means he will perform (a message) on the size of each minor step, which in your case is 4. So, you have two options: 1. replace the Solver side controller Runga Kutta 1 (this must synchronize loops) 2. hold RK 4, but create a Subvi around two primitives of TCP/IP and configure from the VI to run than the major (continuous) step-size. If you do it right, you should see a 'C' on the upper right part of the VI you have created. Please let me know if what I said is not clear... Control and simulation and data acquisition Hello I am applying to motor control in Labview. I'm sampling speed from DC engine in real time through an acquisition of data. (my sampling time is 1000 samples per second) Then wrap speed as input to a Simulation (simulation and design of the order) and inside the loop simulation, I have a PID controller. The PID has the actual speed of the engine for the acquisition of data and the engine reference speed as input. Reference engine speed comes from the generator of signals (control design and simulation-Simulation) and is a waveform. My step in the engine size is 1000. I am running this application real-time and drawing the reference signal and the motor real signals. I run into several problems with regard to the calendar. 1. when I change the size of the step of the simulation loop, the frequency of squares of reference also seems to change. For example. What step size = 1000, duration of pulse = 1 s. What step size = 100, pulse width = 0.1. (My pulse frequency is 1 Hz, Simulation clock - 10 kHz). How step size can affect the pulse width. 2. can you explain the relationship between the DAQ, the Simulation step size loop sampling time, Loop Simulation period. 3. If I want to collect different sets of data using sampling different hours, it's OK to change the sampling DAQ time without changing the size of the step of the simulation. Would also like to emphasize that the DAQmx calendar under sample clock mode is placed in front of the simulation loop and the output is connected to the loop simulation. Appreciate any help. Hello Maybe some screenshots of your code would help. Furthermore, what you have read your samples together with your DAQ screws? (1) If you have a waveform, the output is specified as: For example, if you change the size of the step of the simulation loop, you change the simulation time which are introduced into the signal generator and affecting the waveform that you see if you do not have a size quite small step to characterize the waveform that you generate. (2) sampling DAQ rate is the speed at which samples are taken on the acquisition of card data itself. The size of the simulation step, help. "Specifies the interval between the time when the ODE Solver evaluates the model and updates the results of the model, in a few seconds." Simulation loop, still using, "Indicates the amount of time that elapses between two subsequent iterations of the loop of control & Simulation.". " "Step size determine the value of t that is introduced to the functions you use in the loop simulation while the loop simulation period controls simply to how fast you change the following t value. The sampling rate of DAQ hardware is a clock of completely separate hardware controlling the analogue-digital on the DAQ card converter so that you can get a deterministic dt between the samples being acquired. (3) you can change the schedule for the acquisition of data, but you will need to restart each time the changes take effect. If you change the calendar of data acquisition and want your values to correlate with your simulation, you will need to change your size of step as well. -Zach -Zach Hello I'm trying to generate a report using a template. In my model, I use cross references to refer to a bookmark. For example, in the first page, I created a bookmark for my name, and in the header, I've created a reference refer to my name. The problem is when I start my VI the bookmark update perfectly but the reference to refer to the bookmark cannot refresh with the same value and generates an error: ' error! Reference source not found. " NKI Unfortunately, since this is a mistake in the word, there is no we can do about it. But you found a great workaround solution - good troubleshooting. The use of Global Mapper SDK with LabVIEW I am really new to the use of any SDK with LabVIEW.The basic idea behind this is to trace the lat and long coordinates in global map cutomized app via Labview.I mean I'm labview data acquisition, but I want to display coordinates in global map. For w problems with on movie maker file extensions... How can I get my film extension is avi, during the publication of my film on movie maker? I don't see any option to do this, and it does not work when I just "Rename". box 'aid', said that "when youpublish a movie, she becomes either an avi file or o HP 19-2113w: password must be rentered. HP 19-2113w I need to keep back my password if the computer is idle for a short time. {about 120 seconds} I have tried all the settings in order to increase the length of time that it remains open, but nothing makes no difference. My stop button for Windows 7 has always a shield orange with one! indicating that an upgrade is required, but it is never done. Why? Fireworks CS6 with a subscription of the CC. Hi fans of fireworks.Just before I invest a lot of time:I need to install Fireworks to revive some pictures that use the data for Adobe Fireworks. As I have a subscription to the CC, I have access to the program CS6 Fireworks and I don't need a seria

* PINOUT ORDER +IN -IN IL OUT +VS -VS CR+ CC+ CR- CC-* PINOUT ORDER 7 6 1 2 12 4 8 11 10 3.SUBCKT PA78 7 6 1 2 12 4 8 11 10 3

Similar Questions

Is it possible to paste or import a software simulation that has already been completed as a project in another project that was created by using a project template? I tried just copy / paste, but it did not work. Any help is appreciated. ..

.. )

)

error #2: the transfer functions did not correspond to the preview of express VI and on my front panel because I had not specified the type of realization in convert it IF transfer Function.vi - default value is 'minimum' and it was therefore minimizing States. Change in full sets this inconsistency.

Can someone help me please!Maybe you are looking for