Motor, using analog signal

Hello world

I have a very simple problem that gives me a lot of trouble. I'm trying to run an engine on the analog output of a device of acquisition data NI USB-6211. I wrote a simple test code using the express VI and DAQ VI signal to control the motor. While the output graph displays the waveform that I need to control the stepper motor, the motor does not move. When I activate the program I can hear the motor buzzing, very faintly, that tells me that the program works and the engine is triggering correctly but there is not enough power for the engine to recharge the batteries. Given that my motor needs + / 3, 2V to trigger the so-called DAQ outputs hardware up to +/-10V (and) I don't think that the voltage is the problem. The only thing I can think is that the DAQ hardware is not really this output voltage, but I don't know of anyway to check.

If anyone has any ideas on how to solve my problem, it would be a great help.

I also downloaded my VI for reference.

Well, you check the voltage with a voltmeter.

Have you looked at the current requirements? You think there is not enough power and power is equal to the time of current tension. That said the spec 6211 is the maximum current output?

Tags: NI Software

Similar Questions

-

How can I use my PXI-6115 meter analog signal trigger to generate pulses of frequency

I work on a PXI-6115 DAQ card and want to using the analog signal to trigger the counter it's generating frequency pulses. The manual says the analog trigger is supported, but I can't use an analog signal to trigger the start of work, in the test, I use the counter 0 to generate pulses and use the signal input port analog trigger PFI 0, can someone tell me what it is? My test VI. & error message appears in the attachment.

Best regards

If you read the error you can see digital triggers are the available trigger only when you use the output of the counter.

You can work around this by setting up a dummy analog input task which will trigger an internal digital triggering when he sees the right analog trigger.

See this thread for more details:

-

Reading of analog signal using DAQPad-6016

I'm reading an analog signal using DAQPad-6016. An entry is on the ground, the other is Vdc. I can't operate at MAX and I'm confused becaue MAX alone gives me an option for differential reading, but the list of pins give enough information on how to connect in a different way. Is there a reference as well?

Hello, Bernadette.

This link should have what it takes to equip themselves properly: http://www.ni.com/gettingstarted/setuphardware/dataacquisition/analogvoltage.htm

After that you have put work in place, specifically see step 11 for check the connections of the device.

I hope this helps!

-

Problem when the PWM signal combinning and analog signal TOGETHER!

Hello everyone,

first I DAQmx 6212, and I need to run the water pump small (9V - 16V) that should be driven by a PWM signal; I also have a motor (5V - 13V) for a water supply which must be controlled by an analog signal and it has built in a force feedback potentiometer, I logged onto this potentiometer correction + 5V the DAQmx and used the output voltage of the third extremety as a value to diagnose to know the position of the engine.

My VI shows:

1 is a normal meter production to create my PWMout signal.

2 is an analog input, I use it as a PWMin to the LabVIEW to diagnose what is happenning in my pump water through the cycle and frequency.

3 is an entry of the third extremety of the analog potentiometer.

4 is an analog output that I used as power supply of the motor valve and I used an AC/DC amplifier for aplify signal the DAQmx and the motor road, between the two (3. 4.) I made a comeback with a few calculations, I had a P-controller to know the real position of the engine valve.

My problem:

When setting to 1. and 2. in the same VI only, I get an own PWM output with no problem.

also with 3. and 4. in the same VI only i can control the motor valve without any problem.

but when I put all these 4 set found in the attached VI, I have a problem as the engine valve turn continuously without stopping even if I change the position of the valve between 0 and 100%, I should mention that I see a PWM normal outside a signal on my oscilloscope, another thing to delete one of (1 or 2) and run the engine valve VI works fine without any problems.

so this my problem, if you can think of any solution please let me know.

Thanks in advance for your help.

Kind regards

Caliente

Here's your VI, slightly modified so the two analog inputs belong to the same task. This if only for purposes of illustration, I him have not tested. You will still need to do some debugging.

While changing your VI, I noticed another potential problem with your original configuration. You have configured the two tasks of AI for the same frequency, but read you 10000 samples of one of them and only 100 samples from the other (and throw it most of it). Data acquisition data are buffered, and if you read as fast as you acquire, the buffer fills eventually. If you read 10,000 samples of a channel, and the other channel acquires at the same rate, then when you read from the second channel you will get old stale data or an error full buffer.

-

How to generate analog signals?

Hi all

I'm trying to generate analog signals to simulate the position of the valve. I also want to simulate the position of the valve 0 - 5V (analog signal). I've implemented the numeric position of the valve by using the toggle switches, but I want to implement analog signals.

You can help.

Thank you

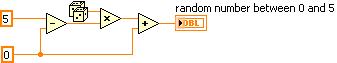

You can just use a random number generator.

Since you have no generator hardware signals of NOR, I'm not sure why you are posting to this Board. Generic questions of LabVIEW. Post to this Board.

-

control of DC motor using myDAQ

Hello

I'm building a DC motor using myDAQ command, that I ran into a couple of problem with the STOP button and the Max speed Min. For some reason, the diagram of waveform becomes crazy I will attach my file VI.

Description of the project:

-An engine-engine-OFF button

-A control for fast / slow

-A switch left / right

-A speed once button maximum (100)

-A speed once button minimum (10)

-An indicator of instantaneous speed (0 - stop, maximum 100)

-An indicator that signals the directionCould someone tell me why it happens and how to solve the problem?

Thank you very much!

Best,

Istrael

Hi Istrael,

You use a lot of CPU resources by not including not calendar in your loop. I think that your questions can be resolved if you place a timer 'Until the next ms Multiple' in your 'pulsegenerate.vi' in a loop. This will actually load on your CPU if you set it to 1 ms.

I hope this works,

Paul

-

Hi all

I'm still new to LabVIEW, but I played a little enough to create a simple analog signal generator. Product signals appear staircased when displayed on an oscilloscope, but are smooth, when I read the signals in an entry (as shown by the graph on the waveform) analog. How can I change my program settings so that I can see this staircased signal?

I run LabVIEW 2010 and use a data USB X Series multifunction acquisition.

Thank you

-Olivier

-

Can I have the user enter a variable that will be used to Signal Express?

We seek to use the Signal Express to collect data of analog sensors and load cells. We would like the user to be able to enter a variable that the program Express of Signal can act on. Is it possible within Signal Express?

Hello

When you select 'Change destination', it will fill with all stage settings that are supported for the given control used. Not all the steps or step settings are able to be adjusted when the operator mode. That is why you were only able to bind controls to step DAQmx Acquire and filter (they are only available to bind in your configuration steps settings). The forumla node is not able to reference an entry of order of the operator interface. You must manually configure the formula tab of configuration step for that particular step.

I would recommend if you want that more customized the user interface and approach programming using an application development environment. Signal Express is ideal for acquisition of signals and perform analysis and basic treatment, but if you want more functionality LabVIEW would be a better option.

-

How to create an analog signal of a text or a binary file?

I'm trying out an analog signal of a file on a map of NOR-DAQ 6251 with labview 8.5. I found examples on the construction of a waveform, but I'm stuck at how read a text file and do a 1 d table to enter my amplitudes in the buildwaveform.vi and I can't find all the information on how to do it. Help or direction is appreciated.

Thank you

David

What if all you want in the file corresponds to the values of Y, then a text file with a value on each line can be read. Read from a usable spreadsheet file. It will return a 2D you can then use array index to get a column or if you select Transpose, the array returned by 1 d would be used.

If you want to create an example, use a 1-d array constant in a VI and pass it to the writing on a spreadsheet file.

-

Generation of the trigger (or TTL) analog signal

Hello world

Well I look at the droplet, riding on the vibrating bath. In this case I have to synchronize the device with the accelerometers.

Accelerometers are connected to the vibrating plate vibrating sinusoidal with frequency of 80 Hz. I am the acquisition of acceleration using NOR-DAQ USB 6212. A camera (Camera Link Basler, NI PCIe-1433) is used to acquire images of the vibrating plate. The frame rate of the camera is 20 Hz which controlled by external signal (TTL) or camera attributes.

I would like to generate a trigger of data acquisition (signal HAVE) to the camera at the first minimum acceleration in the attachment. I've also attached the file vi. Could if it you please let me know if is there anyway we can generate the trigger of the analog signal.

See you soon

NGO

Hello, NGO,

Can you post the update VI?

-

generation of digital, analog signals read snap SMU-6358

I have two SMU-6358 card and I want to send control signals to my camera and read the analog signals from the device with them.

For the digital control signals, I tried to set up a system where I specify the identifiers of the pins, bring them into arrays of strings - the respective waveforms would be collected in the tables too - and I transfer them to a VI of inputs/outputs multiples that puts digital waveforms for the cards output pins.

I developed this code here, but it doesn't seem to work. I can't understand how I can convert the string and form table wave to meet the requirements of the input/output VI or which another VI I could use to do the job. Or is there a smarter way to do it?

Thank you

Kriváň

Dear Kriváň

Please find attached the VI in LV 8.6 format. Also, I HIGHLY recommend to rearrange the front panel and which makes it neater, your code is very hard to read and not structured at all. I hope this helps!

-

Output of different analog signals through 4 outputs

Hi all

Exit 4 different analog signals from the PCI 6711 map: I need help. I intend to use the waveform function from the palette of analog generation vi. My goal is to be able to enter the 4 necessary functions, it sampling information and then leaving four available analogue outputs available to the Board of Directors. I saw the code example for the output on multiple lines, but it doesn't seem like he is able to create unique waveforms through the exits, they are all the same waveform. I've attached what I thought work, but I can not get my number of rows in the data to match my number of rows in the task.

Specifically, choose instance polymorphic Analog-> multiple channels-> multiple samples-> 1 D wave.

Your current instance you chose is for just a single line.

-

Problem using analog feedback on pix7340

Hello

I try to use analog ForceFeedback on one of my lines on pxi 7340. The problem is that MAX always use encode as your comments even though I have set up as analog. MAX I disabled the encoder and activated the ADC suitable for axis and set the position to a few hundred charges so that the controller stops the axis when force is superior to a low value (around 1 v). If I start the movement, she spends the same as if the response has been to encoder (for a few hundred charges). I don't know what is happening. I red the manual of the motion and if I understand it the axis should pass at the speed configured until the force is larger as the value, I put in the position field.

Thank you

OK, that explains the behavior. To use analog feedback properly, you should configure the axes as axes servo with analog output. Mode step closed-loop the jury does not run a loop of PID, but it checks at the end of the move, if the position of the target has been reached. If not, he made a gesture of pull-in.

It works very well for the positioning of the stepper motors, but it does not at all with analog feedback.

Please configure your player in current with the analog input control if possible.

Kind regards

Jochen

-

How to control the mouse cursor using EEG signals

Hello world

I am doing a project of cursor control using EEG signals. The idea is to find a way to all signals in a specific period of time in order to find the signal Ridge. Then, the highlight will be a parameter to control the position of a cursor.

Can someone tell me the function that allows you to control the mouse cursor?

I also found an old topic asking about it (http://forums.ni.com/t5/LabVIEW/Moving-Mouse-using-Labview/td-p/1285842) and I run an example of this link ( smercurio_fc) program. My cursor is stuck in the upper left corner of the screen, I can't control it again. Can you tell me how to run this program and to use the windows API?

Thank you in advance.

Sorry, but I can't do it for you.

As I advised, you should take the free online tutorials. You clearly lacks the basic concepts of LabVIEW, as data flow.

Things more: in your real applicaton does not use DAQ Assistant, screw Express are generally not optimal for data acquisition. It is safer and better use good DAQmx live. What is the equipment you use? Sampling rate, etc.?

Why do you need to read data files? For testing? I thought that you will acquire data active, right? In your VI generate you some signals and write in a data file. Is this also for testing?

There are several constructs in your VI which simply don't make sense.

So again, I really suggest to go through online Core1-2 teaching material, which is accessible if you are a student, or if you have shared services provider license... It will really help.

-

How to convert an analog signal into digital signal

Hello

How to convert an analog signal into digital signal, such that each sample of the analogue signal corresponding to 1.2V will be represented as '1' digital signal and other samples of the analog signal (which are not 1.2V) will be represented (converted) ' 0' in the digital signal.

And how to view the wavefroms or graphical indicators signals.

Thank you.

If you have 1000 samples and you want to convert to digital, you get 1000 digital values. Attached, that's what I mean.

Maybe you are looking for

-

In a club and audio on snapchat works fine but the audio on real videos * and is more often just static. Are there ways to recover the audio real video?

-

How to change the thumbnail size, return to the original size.

How to restore the list of download and my folders of images, the size of the thumbnail to the original. I was remove several photos and old downloads folder now hold the control button when everything went in miniature and now I can't get the origin

-

Unable to send email using windows mail

I use windows mail and can receive by e-mail. When I try to send emails to anyone, I get the following error: An unknown error has occurred. Object "answer if you receive a ', account:"Amy Logan', server: 'smtp.verizon.net', Protocol: SMTP, server r

-

Silverlight has install problem-64 bit PC with win7 32 OS installed

Trying to help a friend with Silverlight. She has a portable 64-bit with Win 7 32 installed on it. Websites with Silverlight request installed Silverlight even if it is installed. I did a number of installs / uninstalls. I removed the registry and

-

can I get an installation for my hp officejet 4500 cd

can I get an installation for my hp officejet 4500 cd