Read/write port DAQmx questions

Environment

Windows XP SP3

LabView 7.1

NOR-DAQmx 8.7.1

(2) PCI-DIO-96 cards

I'm trying to move from the level of registry TDAQ programming DAQmx and give me an "intensive" in mx. I'm not sure about a few things.

I need to put in place 20 channels/tasks that will run a mix of single, large port (8-bit) bed and written. Some will be handshaking (82 c 55 mode 1) and some no handshake (82 c 55 mode 0).

The plan is to create all tasks during an initialization routine and save the names of global tasks. I open the task after creation and use the globals during the main part of the program execution, when I make the reads/writes on the port. The body can run for hours at a time. When the main is closed, the stop routiine close all tasks to exit ahead.

Regarding the task creation/destruction - is it safe to create tasks and leave them open, or should they be created and destroyed every time that a write is performed?

Regarding the port reads/writes, I suppose that when a port single read/write is made, there is no established buffer. Is this correct? Specifically, if I use the method above and leave task open, is it possible saturation of buffer or something similar to happen?

TIA

Charlie

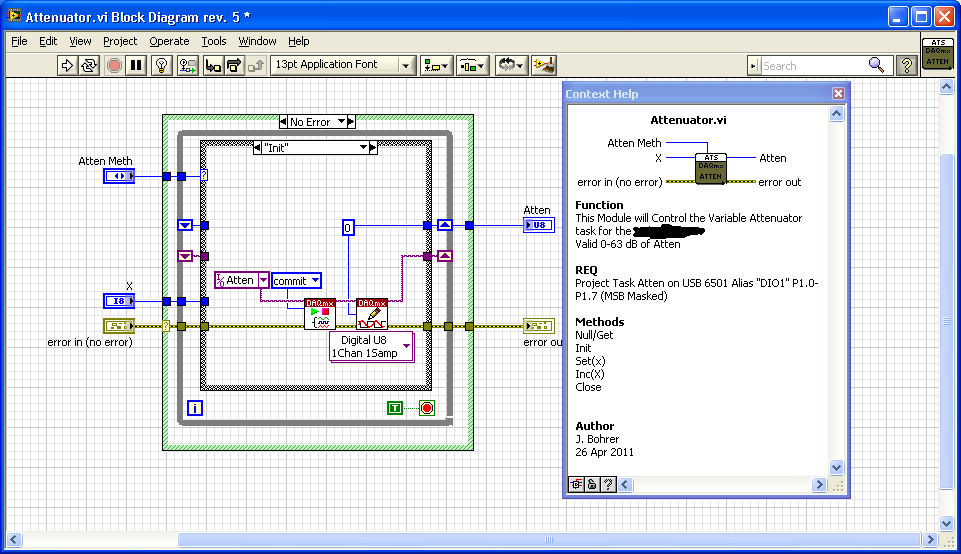

Regret - Yes, you said 7.1 - I can't keep back away, but here is a screenshot

And - the task is saved outside of LabVIEW, so it's not really 'Open' or 'Closed', even when programmatically, create and destroy jobs. Tasks exist or do not exist. If they exist and have no errors, they can be run.

Tampons are to move data to and from the device. For static DIO, this isn't a problem. You CAN run into problems with a task of acquiring buttons if it acquires data as soon as you read the data, but you can work around this by starting and stopping the task properly.

Tags: NI Software

Similar Questions

-

VISA from read/write to serial port - unable to implements several orders of writing!

Hello

I'm new to Labview and I'm reading from a pressure through a virtual serial port USB sensor. I am able to read the port when you use HyperTerminal

The code sequence that I should write to the port in order to obtain measurements using hyperterminal is the following:

' *' (2A hex)-online start and the responses of the port by asking 'Command', I should then enter

FF-online measurement select the port must ask the 'mode', so I should enter

0 has-online measurement of high resolution mode and it was then that I should start receiving action.

The port is always answer by errors when I write the start command or the FF one. I tried to establish a sequence stacked to write the three commands then read the port, I added some delay between the three of them, but it does not work.

Now I made really simple and removed the stacked sequence and just put the three commands one after the other and try to remedy not to not on the code.

I'm really stuck at this point, could someone help me please? I read a lot fo articles on the forum, but I can't solve this problem

Thank you

I have attached my VI and the SCP1000 documentation (I can provide other versions of my demo if necessary)

The reason for your problem is a frequent misunderstanding even among experienced programmers. Take a look at this thread

http://forums.NI.com/NI/board/message?board.ID=170&thread.ID=417750

In your data sheet, then they return codes like 0xFF or 0x0A so has a single byte of average value. Then you in your-active code constant writing FF\n is so this equal to values in format hexadecimal 46460A and your instrument do not understand. But it will include FF0A. In order to solve your problem, you would type in \FF\n in your '-' chain helped codes. Remember too, if you type in \32 it will be converted to character 2 this being 0 x 32 50 decimals and code ASCII 50 is equal 2

Take the time and change the display format of string between '-' display and Hex display and you will see the difference

Hope this helps

-

Am about to buy DW. 2 quick questions before proceeding. (1) can I associate a DW created an EXTERNAL SQL Express database for the read/write site? Can be made safe? (2) am plans to use Contribute to allow non-technical end users EASILY change the sections of the web site. Can this work? Thank you.

I would like some ideas.

A CMS is the standard solution in the industry today. The most common environment is LAMP (LINUX, Apache, MySQL, PHP).

Some of us to write custom CMS systems for a living. I concentrate on CMS for retirement centers. There are all kinds of solutions CMS available ranging from generalist, off-the-shelf CMS like WordPress, completely custom, with a lot of opportunities in the meantime.

-

Stupid question... presentation layer "read / write" permission

I am curious to understand what exactly happens when you grant permissions users ' reading / writing "on objects of presentation layer? "Read" is self-explanatory... but what exactly 'writing' allows it to do?

Thank you!

ScottHi Scott,.

Used for writeback. Give read/write permission to enable writeback in the column of presentation.

Kind regards

DpKa -

A better way to make a continuous read/write on a NOR-6008

Hello

I use a USB of NOR-6008 module and have a loop of the software configuration where I acquire analog signals, digital signals, then, then put a digital high or low and repeat. I use digital multiplex outside the material so that I can use 6 of the analog inputs to read 12 signals. The digital inputs that I have are connected to the buttons on a panel that are used for the entry instead of the screen of the computer of the user. My loop is also to build a buffer zone of all the signals on the analog and digital lines that I read in so I can on average and this process elsewhere in the program.

The question that I am running is because this loop is very slow and on the final product is performed on a touch screen, XP Embedded PC and just this acquisition loop begins again as much CPU as the rest of my program. I would say that drops of loops on 4 or 5 cycles per second, which means that my update of 2 multiplex signals or longer than a second time. I would really like to better performance and does not use as much of my CPU resources.

I use a way simple enough to make the loop of the acquisition, by setting the parameters I, reading, deleting the task, defining the parameters DI, read, erase the task and then by setting the parameters, write about it and delete the task, which gives a slight delay and repeat.

Any thoughts on a better way to start the read/write that what I'm doing?

I have attached the code examples in the loop of the acquisition that I use.

Thank you!

First of all, the best plan is to move the chain DAQmx before the loop to create and use a start DAQmx, then write in the loop, then clear once the loop ends. This configuration must be done once, not every time you write the channel. This should speed things up considerably.

-

a speed of read/write DAQ card mode change will reach 200K

HEY, man,

I have a project needs to test two points I name them point A and point B, the first time, I should point A 5V DC input, voltage inductive test point B, sencodly, give point B 5V DC input and inductive point test output voltage, this means and two analog ports must read and write sharing mode , and the test speed must be 100 KB, if I have a 200 KB data acquisition card, can the speed of read/write mode change reach 100 KB for an analog port? or, please give your suggest for my this kind of situation, thank you.

Hi API,.

I see that you are trying to measure voltages using a single channel at a time on a data acquisition card.

Unfortunately, you cannot change the inputs to the outputs or vice versa on a map of data acquisition, they are static.

What I recommend is either using a switch like this: http://sine.ni.com/nips/cds/view/p/lang/en/nid/207130 where you will need a high chassis.

Or, having four channels, 2 inputs and 2 outputs and try to measure it. You should have the necessary speed as well.

If you have any other questions, I'd be happy to answer.

Thank you very much

-

Hello

I am writing a VI to control PWM with a microcontroller via a serial port. I wrote a simple code for the microcontroller that allows me to set the ratio of duty cycle on a scale of 0-65535. It works very well with Termite of Compuphase (RS-232 plug); The microcontroller invited me to an entry, expected that I would one, updates and expected another entry when I decided to send him. Now, I'm trying to get the same functionality on a LabVIEW vi but hit a snag.

When I tried to send my orders with a series read base and an example of writing, everything worked fine. I could see the prompt entry, write an entry and if I was quick enough, check out the update message. Even when I was not fast enough, I was able to check the update by monitoring the PWM pin with a Logic Analyzer. The problem with the basic example, however, is that I need to update the report to aura cyclical ratio, so I went for an example of reading continues writing. The problem I've met; is that I have to switch between reading and writing to make it work. When I do that, either I don't hold write it down long enough and nothing happens, or I get several updates when I switch to reading. Some of these updates don't even match and produce updates to defective upgrades for example; 16000 16000, 16000, 16000, 6000, 600, 60, 16000, 1600, 60, 0, 0, 0, 16000, 60, 0, 0 etc.

I tried which allows characters of endpoint in the hope that the writing would end at the end and go to reading where he would receive a termination character and wait for me allow writing once again, but nothing helped. I still have to alternate between the two and either get no response on reading several updates of variable accuracy. I tried to remove her allows read/write and their structures of matter in the hope that the loop flow, associated with the characters of endpoint would the case, but then the updates don't register at all. The funny thing is I did a VI like this before with an Arduino and that there not even no need to switch between writing and reading (I'm now using a Board of Freescale FRDM).

I was also the frequency of timeout errors; Error-1073807339 at VISA Read, reason Possible: VISA Hex 0xBFFF0015. I removed the option to stop the while loop if there is an error so I can run but always pops up an error on the judgment occasionally. Could the problem of synchronization always cause me problems?

Would appreciate all advice really, I am providing my slightly modified example screws and can provide the code for microcontroller on request, even if it's very simple.

Thanks in advance, it is

Yusif NurizadeIn other words, frankly, a good bad example you according to your code. Also, you have the order of writing and read upside down in your amendment if the instrument requires a command to return something. It should really be using a structure of the event. The structure of the event around a write and read and use a value change event. I have attached a quick change. This mod is still a reading after writing. If necessary, you may have two separate events to write and read.

-

In the target FPGA read/write control function?

Hi people,

I learn a lot from the sample project FPGA, including how you can easily retrieve and set controls and indicators in an FPGA using the read/write control function running in an RT target.

However, I can't find a way to do something similar in a FPGA target. I've been down this road before - that is, trying to move the data in/out a looping VI FPGA (void) to a (parent) FPGA VI - where my memory points to reach what I needed use.

So I was happy to see the palette FPGA enabled me to drop the control functions to read/write on a FPGA vi target. But alas there where tons of errors (not compatible son for target, etc.) and I guess now it's not possible.

So, just to be sure, I'm not missing something, is there something like control functions to read/write to use in an FPGA for read/write in an another FPGA (looped)?

In addition, why would I be able to read/write on a FPGA vi control functions if they are not supported? (Sorry for the n00b question)

Thank you

Steve

maherhome wrote:

You're right that I don't have this knot in my palette. However, I also do not seem to have a Refnum Occurrence in the palette is in the FPGA (see below), but I need to synchronize several loops of FPGA and added research using the textfield in the VI editor (and if compiles and runs). So 6 months to Labview and I'm fuzzy on how the palette is restricted

I don't know what you're trying to prove here. There is no control of refnum in search in your image. Occurrences are available in FPGA, and for control of refnum for one you just right click on a function of the instance and create a control. If you can create a valid thread of a certain type of data, then you can create a control or the indicator for it, regardless of the question to know if this type of control or indicator appears in the palettes. However, the functions that you can use in the block diagram are limited by what is available in the palettes.

maherhome wrote:

Regarding orders read/write for the FPGA/lights, I'm surprised that the infrastructure developed to allow read/write between RT and FPGA has not mobilized to allow read/write between FPGA and FPGA. The elements of memory function, but they are less convenient.

You may have noticed that you cannot compile the individual parts of an FPGA VI and combine them later; This is because when you compile an FPGA VI, all its subVIs are essentially merged to create a single block diagram (with additional logic if one not reentrant Subvi is used in multiple locations, this is why it is not recommended on FPGA). The subVIs no longer exist in the FPGA compiled; reading and writing a control on them would make no sense. If you want similar behavior, use global variables - but understand that global variables store values in FPGA logic resources. Using the elements of memory (or FIFO, which can also store in memory) leaves more fabric available FPGA logic by storing data in resources specially designed for this purpose.

-

Effective use of the FPGA read/write

I am writing an application for a CompactRIO real-time and I am looking for ways to simplify my code and reduce the CPU usage. I use FPGA to do much CAN e-mail and signal processing, then I have a VI running on the real-time processor that reads values in the FPGA, does some processing and outputs data in the FPGA. My code running on real-time parallel uses several loops running in a master/slave architecture. A single loop reads all necessary information in the FPGA in indicators and writes the values of the controls in the FPGA. The other loops read entries and manipulate the outputs via local variables.

My question if it would be more effective to get rid of the loop which is dedicated to the communication of FPGA and has of each loop to read and write directly on the FPGA. If I use a reference block FPGA open and use the reference of the output in several loops, each read/write operation block others until it's over? Each output is changed only in one place in the code, but there are several entries that are used by multiple loops. It is even more effective for each loop of read/write for the FPGA on request? How will this affect determinism?

Thank you

Jon

Jon,

Read/write controls is not deterministic, but I think that your previous method should work just fine, as long as you have that unique writers. If you have multiple writers, you start affected by race conditions.

I don't think you will see a significant improvement in the performance/CPU in the alternative method. You would see big performance gains if your master loop reads more slowly indeed, but it's always a compromise.

-

Possible timeout in VISA read/write in While loop

As the title says, I have a while loop that is constantly written followed by reading using VISA read/write. I'm waiting for buffer correspond to a certain one, which the true value would end the loop. In this loop, I have an indicator showing how many times he runs. All of this is repeated in another while loop.

My problem comes the counter arrives at 10, then stops at the "write" command. Do not know why. I tried to increase the time-out of the instruments, but nothing has changed. I added a delay of 10ms in loop, which also has not changed anything.

For reference, I use a tektronix scope series 3000 of the MDGS and checking its state of relaxation.

You said chill to read earlier!

But it is not supposed to have to write it either. Experimentally, access all VISA nodes, right-click and choose the Mode of synchronous i/o. Make it synchronous instead of asynchronous. The watch symbol will disappear from the top right corner. See if that changes anything.

What kind of serial port are you using? What is an integrated in the PC? A USB to serial port adapter? Makes the chips on that, Prolific and FTDI? You can try with a different serial port or a brand of adapter? A lot of people have had problems with prolific chips. And I have also heard of people having problems using adapters who had fake chips in them.

-

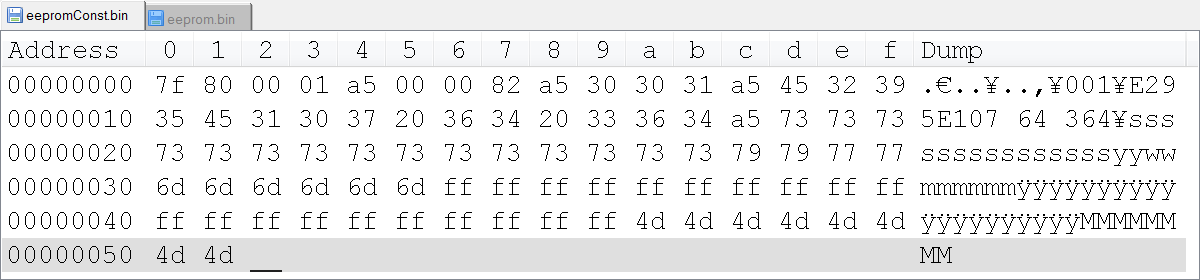

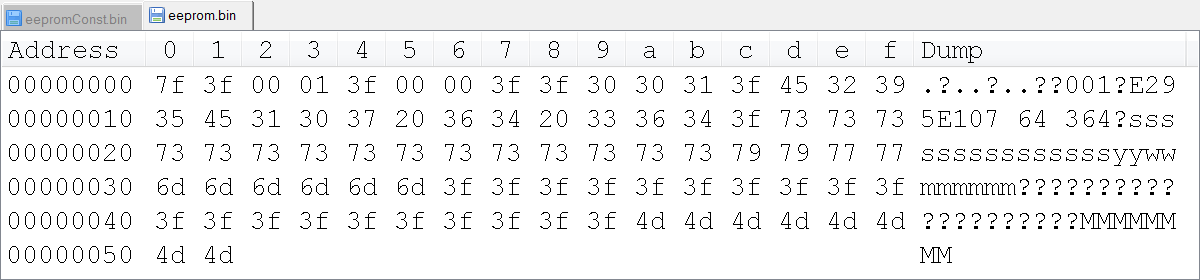

Read/write file binary change greater than 128 bytes.

Hi all, maybe a strange question, but I'm scratching my head on this one. There is undocumented behavior in the function of read/write binary file, where U8 a value greater than 128/0 x 80 get automatically converted to 0x3F value?

I try to use LabVIEW to generate a binary file custom that we'll load in an EEPROM, so all data in the binary file is stored as values of U8. I have a "template" file, and eventually I'll take the logic implemented to replace the fields with the data from the true value. However, I am struck by the anomaly that when I just read the file in LabVIEW and then réécrirait, all the values 0x80 and more are truncated to 0x3F value. Has anyone seen this before, and is there a solution?

I noticed writing the value 0 x 80 directly to one generates a binary file (such as a U8) 0 x 90, 0 x 70 being written in the binary file. It is also rather undesirable, as it adds additional bytes in the bytestream, and the bytes of EEPROM must be in exact locations.

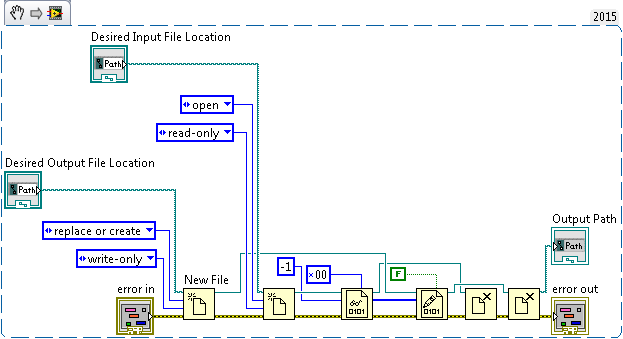

Join your data file.

This program is to give the images below? Are you sure that LabVIEW is to write the bytes differently? I really doubt that.

-

CD / dvd drives will not read / write to any disk

Hi, can someone help (first timer) I have two cd/dvd drives will read / write to disk get them all is a window pops up asking me to insert the disc. all my drivers are up to date, my Device Manager shows two active drives and works correctly, I use service pack 2 and I have installed a new software/hardware. my computer is a dell XPS 420 that is now three years old and this is the first time that I had any problem that I have not been able to solve. Help!

Hello

Its not unusual for the same problem have an impact on both drives, in fact its very common.

Step 1: Please do all the same underneath if you did some before as is often total

a process that solves the problem.Try this - Panel - Device Manager - CD/DVD - double click on the device - driver tab.

Click on update drivers (this will probably do nothing) - RIGHT click ON the drive - uninstall.

RESTART this will refresh the default driver stack. Even if the reader does not appear to continue

below.

Then, work your way through these - don't forget the drive might be bad, could be a coward

cable or slight corrosion on the contacts (usually for a laptop) and other issues.Your CD or DVD drive is missing or is not recognized by Windows or other programs

http://support.microsoft.com/kb/314060 - a Mr FixitTry this fix manually if the Fixit 314060 does not work

http://www.pchell.com/hardware/cd_drive_error_code_39.shtmlYour CD or DVD drive is missing or is not recognized by Windows or other programs-

a Mr Fixit

http://support.Microsoft.com/kb/982116The CD drive or the DVD drive does not work as expected on a computer that you upgraded to

for Windows Vista

http://support.Microsoft.com/kb/929461When you insert a CD or a DVD, Windows Vista may not recognize the disc

http://support.Microsoft.com/kb/939052Your CD or DVD drive cannot read or write media - A Mr Fixit

http://support.Microsoft.com/GP/cd_dvd_drive_problemsCD/DVD drive does not appear in Windows Vista, or you receive this error in Windows

Vista installation after booting from the DVD (AHCI)

http://support.Microsoft.com/kb/952951

Drive CD - R or CD - RW Drive is not recognized as a recordable device

http://support.Microsoft.com/kb/316529/Hardware devices not detected or not working - A Mr Fixit

http://support.Microsoft.com/GP/hardware_device_problemsAnother possibility is that the cables are loose. Remove ALL power, then make sure that the cables in both

ends. Remove and replace, do not just tight. For laptops, you can often clean power and

contacts data with a pencil eraser.Some DVD players do not use the Windows default drivers so check with the manufacturer of system and

manufacturer of device to see if there is a firmware or drivers for your drive if necessary.===============================

Step 2: You have disc problems as the CD/DVD is actually 4 discs in 1 case (CD & DVD

Burn and CD and DVD read). So it is not unusual for 1 or 2 operational so that other parts

do it right.Did you follow the Troubleshooting Guide for the reader who still does not work? There are

the entries in registry that the troubleshooter does not solve and those who "might" be the cause.Check with your Maker system and a device for the two possible firmware updates and

the correct registry entries for your car.Here are the keys that I of course are those in question - for the subkeys of the CD/DVD drive

as there will be other subkeys in these keys. Do not forget to ask specific keys involved as well as

the parameters.HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Enum\IDE

HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Hardware Profiles\0001\System\CurrentControlSet\Enum\IDE

HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Control\Class\ {4D36E965-E325-11CE-BFC1-08002BE10318}

-----------------------------------------------------------------------

You can probably find more info here and maybe even the exact registry for your CD/DVD settings

drive from someone with the same model.Forums - a lot of expert real help

http://Club.myce.com/CD/DVD units

http://www.myce.com/storage/Use DevManView to locate the CD/DVD in the registry (be careful and do a prior Restore Point)

nothing change) - find the DevManView device and then make a right click on it free in RegEdit.DevManView - free - an alternative to the standard Windows Device Manager, which displays all the

devices and their properties in flat table, instead of the tree viewer

http://www.NirSoft.NET/utils/device_manager_view.htmlI hope this helps and happy holidays!

Rob Brown - MS MVP - Windows Desktop Experience: Bike - Mark Twain said it right.

-

I have three users who have no problem with read/write & record readers records secure network access. I have two users who can read some files and save in some files, but cannot save or access certain folders even after receiving full access read/write for all files in the network drive. Help, please. The computers running Vista Ultimate and server access to Windows Server 2003. Thanks for your times * address email is removed from the privacy *.

Problems related to access to the files on a server networked in a business environment are a produce little for Windows answers Forum. I recommend you repost the question either in the Technet Forum to the:http://social.technet.microsoft.com/Forums/en-us/winserverfiles/threads orhttp://social.technet.microsoft.com/Forums/en-us/itprovistanetworking/threads.

I don't know that someone there can help you.

Good luck!

Lorien - MCSA/MCSE/network + / has + - if this post solves your problem, please click the 'Mark as answer' or 'Useful' button at the top of this message. Marking a post as answer, or relatively useful, you help others find the answer more quickly.

-

Sony ILÇE-7R - what is the speed of read/write in the camera

I have several Sony ILÇE-7R cameras used for a given application where more than 80 panes in a row with 1 second interval occur.

When you are taking pictures on a 1 sec shutter time / 1.2 s, then the camera tends to slow when writing the buffer on the SD card. (A suitable high-speed sdcard has been used). When the buffer is disabled on the SD card, then the camera accepts no any command of the shutter (IR Led or cable gives the same question), so I'm missing components/images.

What is the read/write speed in the camera?

What are the compensation of buffer time?

Are there settings that can improve the buffer time on the SD card, while taking still pictures of compensation?

Is there firmware settings that have been implemented to improve the write speed camera?

Thank you very much

Kind regards

-

Driver: driver USB embroidery personalization VIP v6.2 system d/card reader/writer

I use the system software embroidery personalization VIP v6.2 that I need a new driver for the card/d USB drive to run on windows 7.

I was running the program under windows XP, everything seems to work fine on win7, I can't it the usb card to operate. With a labour

card reader/writer usb I can't transfer my designes for my Husqvarna Designer II sewing. The software company will not answer all

one of my emails. All advice from someone sure would be useful.

Thank you

Hi JMiller,

I imagine the inconvenience that you are experiencing. I'll certainly try and help you in the matter of fixing.

To help you to propose measures to solve the problem, I would appreciate if you could answer the following questions:

1. what happens when you try to use the card reader? You get the error message?

2 are you able to use other USB devices without any problem?

You can run the FIXIT and check if it helps.

You can also update the drivers and check if that helps.

Hope this helps and let us know if you need more assistance. We will be happy to help you.

Maybe you are looking for

-

Equium M50: State of battery power remains on 12% and will not load

Hello. I bought my M50 about 6 weeks knowing that I had a few years of work in Goa in India. My problem is since I got the bloody thing works with the charger connected. The battery shows that 12% full and go any higher. I put a meter on the charger

-

Hello It might make me totally distracted, but in the password protocol, it seems all sites want one and then somehow I've now changed my passwords? IE: Google, Microsoft... Some people say that I need only a pswd for all sites? Some say all change e

-

"Error code: 80070002 0 x ' OR"0 x 80070003"Windows updates failed?

" Error code: 80070002 0 x ' OR"0 x 80070003"Windows updates failed? Regds, 'a journey of a thousand miles begins with a first step."

-

I know this may seem a stuid question but I just you'd be grateful if someone could help me

-

Cannot select "Tray 2" which is dimmed. How to fix?