RS232

I am trying to contact a micromanometre FCO510 from my PC using labVIEW. On the test Panel, measurement and automation open VISA explore gives me the followig error:

Error opening resource:

ASRL3::INSTR

VISA: (Hex 0xBFFF0072) the resource is valid, but the VISA cannot currently access.

Thank you

Something else holding it open? Don't forget to close the last reference time you used it, or you had an abortion a VI before having the opportunity to close the session?

Do a VI that rips through a range of COM ports and closes the VISA session, and then try again.

Tags: NI Hardware

Similar Questions

-

Series Tecra S2 and RS232 in MS/DOS

I have the problem that my RS232 does not work 100% in MS/DOS. In Windows XP, the RS232 interface works fine. What can I do?

Hello

I think that you need a proper BACK driver for the RS232 port.

At http://newsletter.toshiba-tro.de/main/index.html, you can control what material your Tecra S2 have a search a driver for it on the web!

TOK

-

Satellite M40X-189: how to connect RGB port to port RS232?

Hello

as you know the satellite M40X - 189 P - M 730/XP has a port monitor RGP and doesn't have a RS232 port.

I work with device of automatic titration requiring the RS232 port for connection!

No idea how I can connect my laptop on this unit!pls help

Thank you

OmranklHello

AFAIK the RS-232 port is a serial port and I don t think that it of possible to connect the RGB port to the RS232 port.

But I found the site useful:

http://www.Ontrak.NET/USB.htmYou will find a description how to connect the USB port to an RS-232 port.

You need an interface ADU.

Click on the link. -

PCMCIA card as a serial port RS232 on Satellite Pro 4200

I think to use a PCMCIA card as a serial RS232 port. The program that I need to use runs under DOS and needs two serial ports. My question is that I need to run the program and the serial port to be recognized by the system. I have a satellite pro 4200 laptop PC series.

Thank you

Why on Earth if you want that?

Your laptop computer with a serial port doesn't have it?Well for the serial ports are standard supported on Windows. In a back box that should be no problem.

But pure back could be a problem.

I guess you must also BACK drivers for your PCMCIA card... -

Satellite Pro M70 - compatibility USB to RS232

With the latest version of the BIOS and 2 RS232 totally different USB adapters, I can't get the RS232 interface to communicate with the laptop. The adapters are operating satisfactorily at least 3 other computers (1 of these loaptops was 2 door USB).

I am running Windows XP Pro.Any help would be appreciated gratefully.

Hello

I searched the net for similar questions and a lot of people say that the converter could not work because of the SP2.

I m not 100% sure about this, but it of possible.I found this page:

http://www.Sabine.com/Sabine-professional-audio/USB-connection.htm

On this page you will find some adapters tested and good work.Maybe it helps a little.

-

How to deal with the port RS232 of the SIN?

Hello

As my NAS does not restart because he tried to update to 6.5.1 I try to communicate with the RS232 port (four pins hidden near the kensington lock port).

Could someone tell me the settings please? (speed/bps, bits of data, stop bits, parity, flow control)? I get the information but I can't decode it.

Kind regards

Roman

Hello

Finally I had to return my chassis to the support team. I am currently waiting for a replacement chassis to return.

Thanks for your help guys

Kind regards

Roman

-

How to contact Compax3 via RS232

"We have a driver/Compax3 servo controller and need to communicate to via RS232 and the orders of the" object "(e.g."o680.5"retrieves the current position." However, I was unable to get the controller to really transform our engine. Someone has he done that before could provide examples of code?

LV 2009 SP 1

Windows XP

You should still be able to read and write objects while it is configured as a T30, but you would need to write a program of IEC which reacts to changes in your variables. I just did a project with a positioning more comms, and it was some time ago. My HMI would send '2O 1901.1 =' to define a position and ' $2O 6103CR "to move to the position. Note the space, and the Czech Republic is a carriage return. Unfortunately, Parker US doesn't have much experience with the communcations for this product, and the documentation is poor. You can call technical support of Parker in California. Rich Rittis would be your best bet to get answers on it.

-

I can collect data from a hygrometer in a text file using the RS232 port with the following T75.2F:H17.0% format, these data are collected using a data logger software. I was wondering if I can collect this data for later analysis using Dasylab. Any help is appreciated.

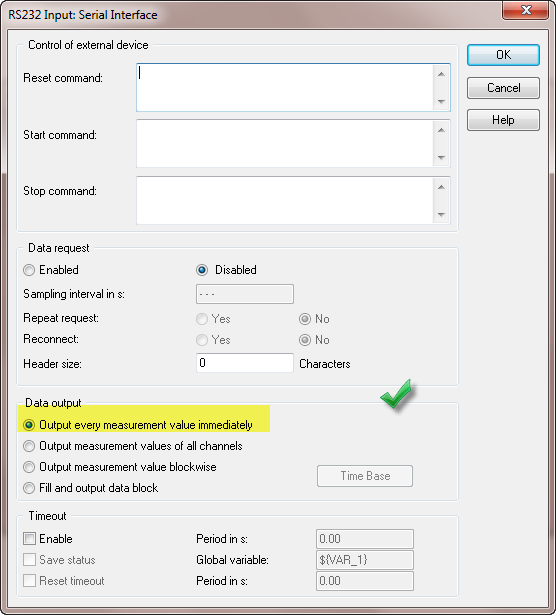

The setting below causes the error. Change for the second selection, output values of all channels.

-

USB RS232 "is connected Port" "invalid property value".

I'm quite new to this so if all the below is not clear or needs more explanation Let me know and I will try to provide information.

I'm trying to integrate a device in my LabView program. Of its guides, that I could find on the site OR mentioned most NI MAX goes first and then working them down. My camera is an RS232 port, so I connected via a USB converter, and I know that I'm looking at the right port (COM5) to look at the section "manage devices" on the control panel.

All series settings are set up properly, I would say (the user manual ishere, with 17 being the party and my setup herepage). I tried to test commands, he gave me on the input/output section, but constantly came up with the error "VISA: (Hex 0xBFFF0015) timeout expired before the operation is complete." Initially, I thought I entered orders incorrectly, I find instructions in the manual that is confused, especially compared to the things other users have posted on orders ('\r' and '\n' instead of what I am told to write, but I agree that mine are not always literal characters).

But when I went back to "Display attributes" connected "East Port" final attribute has an error with the "invalid property value" and the warning Hex 0xBFFF001Derror. Because of my inexperience with all this, I don't know where to start really trying to solve this problem, or what measures are in place, I need to do to start working properly.

All advice is appreciated. Thank you

The property "is connected" is only for devices of NOR so if you have another brand of converter, you would ignore the error.

-

DASYlab RS232 analysis need help

Hi, I'm running DASYlab 13 and have implemented an RS232 input with a single channel (0) for a USB sensor which can be read normally via the COM port (port COM 13 in this case, to 115200 8 - N - 1. I can read very well with the RS232 monitor data, I have a problem with the analysis of the data using the format in the "Measurement data Format" field of the configuration input RS232 in order to get data to display box using the meter digital, recorder, etc..

To get the data from the probe (apart from DASYlab) I can close DASYlab (which closes the COM port) and issue a command to the sensor from the command prompt in a terminal program: B followed by the Enter key. For example, "B\r\n" (without the quotes).

The sensor reacts with 'AA 3 b xx xx xx xx' hex, where "AA 3 b" is a header, and x is the data. Data format an INT32 (IEEE 754). However, apparently so he can convert correctly with a converter to int32, France must be reversed. I.e. If the sensor reports data as 12 34 56 78 (it is a data point made), I have to change to get what I expect as output for 78 56 34 12. So, I'm not a Data Format to measure '2 x f' or '2 x fy' because neither one takes into account the reverse bytes format.

How can I analyze the data, so I ignore the two-byte header (that would be x 2 or x 4?) and to reverse the order of data byte, so that the display on the digital output is correct? I have tried all sorts of things, looked in the help files, forums, etc. and a short entry. I am a novice user of DASYlab, so I don't know how to do the script, and I don't understand why there are several channels in each RS232 input. I think that they allow to separate the data of a 'package' of RS232 in the individualized data points, but strings do not appear in the examples I've seen, to allow you to reorganize the data... e i. using my previous example, 12 may enter the channel 0, 34 can enter channel 1, etc., but I can't put 78 in channel 0 , 56 in channel 1, etc. In addition, I do not understand how the data in the channels of result in the output that is displayed on the output (meter either digital, etc.).

DASYlab1.png image shows a screenshot of my setup. You can see the COM port monitor and the release of data by the sensor. In this case it's 3 b 74 94 62 41 hexagonal AA. Removing the header and reverse bytes give me 41 62 94 74 hexagonal, which is 14.16 when I convert it with http://www.h-schmidt.net/FloatConverter/IEEE754.html. This reading (after manipulation) is correct. However, with a '2 x f' measurement data Format parameter I get 00000000000000000000000000001110 on digital playback, which does not match anything significant.

Your help is very appreciated.

Thank you

If you configure the analysis chain to assume a fixed length, then Yes, this is an expected error.

Often, we can compensate for chains of variable length using line end or the end of data point delimiter... is the analysis of flexible length for an ASCII string. With the delimiter, we always end up at the end of the line, starting on the following.

Always at the beginning of the anchor chain is to use a search string, if the data always starts with 3 b AA, you could try a search string to use it...

l '\xAA \x3B '.

You must the \x notr is hexagonal. Note also that we are not them jumping with 2 x more, but looking for them. This should keep anchored so that you get a bad data point periodically, but of legal data points are fine.

-

In 30 years of developing LabVIEW I saw such a strange problem. Maybe someone can help out me.

Here's the problem:

Ms 1 000 large delays occur intermittently in two instances of an executable of LabVIEW with exact system. (SEE ATTACHED time STAMP of SCREEN CAPTURE FOR 11 and 14 COM COM where there was a > 1000 ms delay)

- Subrotine RS232 communication loop were brought in the course of a program of 'C' that has held rock solid and did not have this same problem.

- No record on the hard drive is in this subroutine, communication comes standard.

- The executables are running on the same high performance server DELL 7910 communicating with satellites in Earth orbit, 24 x 7. (RS232 115 200 Baud, Windows 7, 6 son of processor).

- An executable uses COM 11 and the other uses COM 14.

- The executable has the critical loop "subroutine" that injects data REVIEWS, if there is more than a 100ms delay.

- The subroutine is not reentrant, because it is the only case used throughout the program.

- I placed the time markers in the loop of the subroutine which tell me exactly where in the code the delay occurred. In most but not all cases, that the delay occurs at the 'WAIT MS' or 'WAIT until the NEXT MS MULTIPLE', I tried them both, and they both have the same intermittent problem.

- What gets me, is that the executables that are run independently of each other are logging the delay at EXACTLY the same moment. This leads me to believe that it is a question of operating system. Or a problem that the two executables have when competing for time to critical system resources.

- This problem of intermittent delay occurs on other computers and on windows XP

- The large delay occurs even when there is only one executable file running.

- This problem is particularly bad , when the user resizes or drag the window to the executable.

- If the system is left alone, the problem of > 1000 ms delay can happen only once or twice a day.

- I have not yet attempted to set the priority or affinity processor running in the Task Manager

- The executable runs as well some other non-critical time loops that perform SQL database entries, you connect the hard drive, then state machine management.

Would like to hear from someone about it.

Thank you

Brad Whaley

@ Boeing electrical engineer

-

How interface bronkhorst RS232 communication flowmeter in DIAdem DAC?

Hello

I am Thiyagi.I am working in WABCO INDIA Ltd. I bought Bronkhorst Flowmeter. I use the tiara DAC Professional version. I want the meter to DIAdem.Flowmeter of the interface have a RS232 communication. In my pc, I have a COM1 port. DIAdem DAC which icon I want to use to connect the flow meter.

Hello hmongz

You can already succeeded, but still, here's what I used to do:

I could do this with flowmeters mass Bronkhorst and Brooks, and had a pretty good success using their method of DDE (dynamic data exchange). To do this, download their software from FlowDDE of Bronkhorst.com, start the DDE driver and he can communicate with the MFM. Once it works, insert a DDE lockk in CAD DIAdem, configure it appropriately and it should work.

Greetings

Michael

-

Reading from the sensor to LabView via rs232 or Subvi problem

I'm quite new to LabView and not too experienced with instrument control so I was wondering if someone could help me to solve my problem?

Currently, I'm using LabView 2011 and I'm trying to read pressure DualGauge of Pfeiffer (TPG 262) pressure sensor and display the readings of two pressure on LabView. However, when I run my program, the pressure readings are not displayed - what is displayed are default 0.00 if same mBar pressure reading a reading of the display of the DualGauge probe. To connect the sensor, I use a RS232 cable and have managed to find the device on my device manager, so I don't think that the connection is the problem (I've also seen the port appears in the Device Manager, when I connected the sensor via RS232 and USB in my computer). I also use Subvi Pfeiffer in my code, and I suspect that the problem may be in there.

Attached is my code and here are links to the manual of the DualGauge and the driver of the software LabView of Pfeiffer

Double manual gauge - p. 23 and 68 are probably the only things related to the RS232 connection.

http://www.idealvac.com/files/brochures/Pfeiffer_TPG262_Operating_Instructions.PDF

DualGauge LabView driver - software Pfeiffer double gauge LabView driver 2009

Any help is very appreciated!

-Candice

You have not tested really do anything. Devices and MAX Manager displays only the com port that you added to the computer. It does nothing to verify that an instrument is truly connected. You might have the wrong settings of com or the wrong type of cable serial (null-modem is required). I suggest that you start with program such as hyperterminal, PuTTY or MAX and try something simple. It seems that you will receive an acknowledgement returned by the instrument when a correct command is received. Make sure that this simple step that happens.

-

PSC-2 2220 connected to the same Bus RS232, using turns

I want to do using two PSC-2220 experience which, in turn, use the same RS232 cable (I intend to fill the cable). I manage the turns with shared variables. Is this possible? I mean, is that of the interface RS232 can be shared if a CFP2220 does not use it?

Hi ggarza. RS - 232 is not designed for more than two devices to communicate. It might be possible with enough

diodes and prudent to programming, but I expect it would be a challenge.

A better approach would be to use RS - 485, which is designed to support more than two devices.

Ago RS485 to RS232 converters available which will allow you to connect your device; controllers of-2220

already have a RS-485 port.

Matt

-

cRIO 9067 to hired 7fh USB RS232

Hello

I have a cRIO 9067 and would like to interface with an instrument that has a converter USB-RS232 from SiLabs. I can't comminicate with this instrument easily on a Windows PC. I am able to see the device in MAX when its the cRIO connection. IT appears under "Devices and Interfaces" as "USB0::0x1FB9:0 x 0100: 121A00A:RAW ' with model number and description of the device.

I followed the description at this link, but I don't get a ttyUSB # devices.

https://decibel.NI.com/content/docs/doc-34827

Is it possible to get this working on the cRIO as a serial port?

Thank you.

After some research, talk with people, NOR google and to talk with people to lakeshore.com (provider of the device) this is what I have reconstitute on how to make this work:

- Under Linux, usb devices are listed automatically, and by default, will appear as a USB RAW device

- Once the USB device has been identified, it can then subsequently be linked to a driver

- Linux determines if and when to link each device USB-based device Vendor ID (VID) and the model identifier (MID). It is usually 3-4 digit hex string.

- In the case of the Lakeshore 121 power source, VID = MID 1FB9 = 100. I could see in MAX for the Raw Device USB.

- There are two levels of USB-serial device drivers. The first pilot: usbserial.ko is a generic driver that handles all USB-serial devices. This should be loaded for any USB-serial converter.

- The second driver is specific to the chipset for the USB-serial device. For the cRIO, there are three options which are pre-installed (DFT, 7fh and a few others)

- The drivers can be found at /lib/modules/3.2.35-rt52-2.0.0f0/kernel/drivers/usb/serial/ (where the kernel version directory may vary)

- Lakeshore 121 uses the TR labs CP210x chipset, so we chose this one.

- Records of the device first of all need to be loaded by Linux. Linux can automatically do this by adding files of length zero in the module.autoload.d directory. To do this run the following:

- CD /etc/modules.autoload.d

- Touch usbserial

- Touch cp210x

- restart cRIO

- run dmseg. grep usbserial to confirm that usbserial driver is responsible

- run the dmesg | grep cp201x to confirm that the driver for cp210x is loaded

- The next step is to associate the cp210x of our device USB device driver. Don't forget that linux associate unit to a pilot from the VID and moy. anyone installed linux cRIO base, I'm sure, knew nothing of the VID 121 Lakeshore and MID.

- Lakeshore recommended to read the source code for cp210x, adding the VID and MID to the list of recognized devices, recompile the cp210x.ko file and install it on the cRIO. It would work, but it is beyond my current Linux capacity.

- Linux offers the possibility to dynamically add MID, VID, so that a device can be recognized on the fly

- When the driver CP210x is loaded, a struchture of the entire directory is created. There is a file because the directory structure called new_id where you can dynamically added VID, mid

- Create a startup script to run the following command. Be aware of the problems of termination of cr/lf line between operating systems. It is generally easier to create the script on the cRIO with the VI editor to avoid any problems.

- echo 1FB9 100 > / sys/bus/usb-serial/drivers/cp210x/new_id

- Startup script Info: https://decibel.ni.com/content/docs/DOC-38960

- Now, restart (or running the script), you will get a device/dev/ttyUSB [0-9]

- Unfortunately, the creation of default of the unit ttyUSB [0-9] does not permission to write, so we have need create a UDEV rule to automatically grant writing

- Add the following lines of code udef.conf in the folder/etc/udev

#typical devices

ttyUSB [0-9] * root: ATS 666

- Create a file named 99 - ttyUSB.rules in the /etc/udev/rules.d folder

- Add this line of code in this file:

KERNEL == "ttyUSB [0-9]" * ", OWNER ="admin", MODE ="0666""

- Restart the cRIO. This should be it! It worked for me.

-

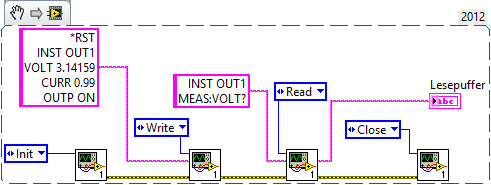

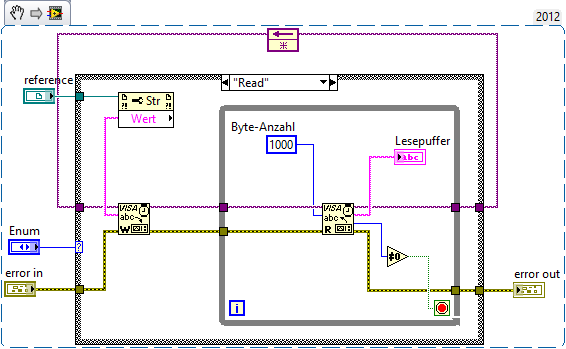

Problem reading Hameg 4040 via RS232 VISA

Hello guys!

I'm trying to control my Hameg 4040 power through sustainable intensification of CROPS more than VISA (RS232).

Writing works well, but the return values of reading do not work.

Tried to do a simple Test.vi that puts just in voltage and current.

After that, I want to review my real tension.

I took the example of SCPI codes from the manual, so should work (I think...)

Here's my VI and FGV

Maybe someone could understand my problem?

BR

Sagi

Hi Sagme_Mi,

I have a few questions for you:

1. what "timeout in ms' did you put in my vi?

2. how many bytes you are waiting and how do you get? Do anything at all?

3. maybe the hameg waiting fo a character of endpoint as 0x0A. You send one?

First of all, I would like to try to establish communication with a Hyperterminal as HTerm.

There are also several free tools to monitor communication on your COM-Port. With such a tool has you might observe that the expressVI made differently from your VI.

Kind regards

Heinz

Maybe you are looking for

-

need to view the source code in version 7 doesn't have a place in the view menu

upgrade to version 7, teaches at a high school on HTML class and we use the source of the page all the time, he disappeared in version 7. Where is it?

-

This may sound stupid, but how do you enable 32-bit 64-bit Mac browsing?

I need to run a 32-bit program but a 64.

-

has dropped iPhone 5s: touch screen no longer works

I recently left falling m 5s iPhone and when I pressed the home button to turn on, I noticed a horizontal row of white squares to the bottom of the screen and a big white vertical line near the right side. There was also a lot of other smaller lines,

-

Problemas con el operation del Messenger y el Live mail 20011

No puedo entrar al del Messenger Mail. In the pantalla del cat appears unos numbers y letras Québec no puedo clear. Cuando estoy Live mail en el y quiero answering machine messages me returns: "no to is the application. What debo hacer?. (el equipo l

-

I want to change the view and see all the files. Reason is to move files from one hard disk to another instead of doing the method of file transfer.