same task much hardware DAQ

Hello

I have a lot of test set-up each containing a device USB-6501. I wrote patches for the test set-up #1. Then I duplicated the test set-up, tasks for DEV #1 and I now DEV #2 (new USB-6501). I know that I can write or copy new tasks, but this means that each test set-up must be used with its own program. Is there a way that a task can be used with the USB-6501 connected no matter who he is?

Note: the reason for the reproduction is the production rate. I use labview 2012

Thank you

You can use the DAQmx API to search for the devices to see if they correspond to the device you want. You will then need to set up your tasks using this device name.

Tags: NI Hardware

Similar Questions

-

Hardware DAQ do not appear in the measures of e/s. I installed LabVIEW worm 2014 DS2 Developer suite and my request is not worked. I then uninstalled ver 2014 DS2 Developer suite and re-installed worm 2014 DS1 Developer suite that installs such as LabVIEW 2013. Now none of the DAQ screws are present in measures of e/s. I uninstalled all the software of NOR and remove this software OR who do not uninstall. LabVIEW worm 2014 DS1 Developer suite installs normally, but I get an "unknown error" when trying to install drivers for data acquisition from the CD and the CD device drivers maintains a loop with a message indicating "currently exectuing License Manager."

All return to work! I downloaded NIDAQ 9.8 on the site of NOR, and everything back to normal.

-

How to create a task in the DAQ Assistant of LabView for one of our modules cDAQ without actually being connected to the cDAQ module?

You can simulate a large number of instrument supported by DAQmx with Measurement & Automation Explorer.

Right-click on the NOR-DAQmx devices and then create new, then simulate and choose from the list of supported devices.

For the cDAQ chassis first then your module.

Excuse me, but I don't have an English version of MAX and so I did not have the correct translation of command...

When your simulated device is configured, ca use you it with the DAQ Assistant in LabVIEW.

-

Export hardware DAQ task created in Labview to MAX

Hello

Is it possible to export a task DAQ created in labview to make it appear in the "neighborhood of data / NOR-DAQmx of tasks" in MAX?

Thank you

-

James

Never mind...

He found as "DAQmx save task".

-

How can I draw dynamic data that I get a hardware DAQ against each other?

Hi all

I am trying to acquire voltage and current data of DAQ hardware. My goal is plotted against votlagein current a continuous path. As the votlage is increased at intervals of 1 Volt, every second I want to see how the current. However, this data is dynamic and I need help find how to draw in a single chart. Any thoughts on how to draw the two different dynamic data against each other in the same graph?

You help will be very appreciated.

Thank you

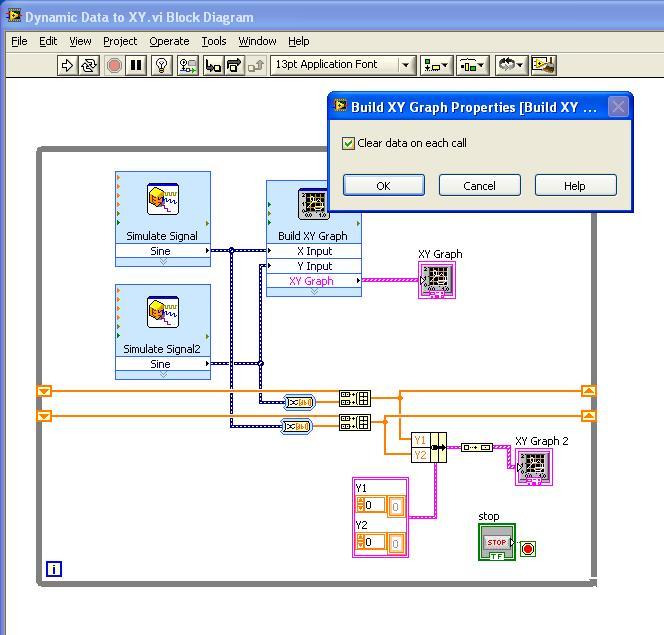

If I understand what you're saying, looks like you want to have the update of XY graph with each new data point (or points) acquired, but also choose to keep the previous data on the XY graph. If that's what you're after, I build on my previous example. For the method of use of the express VI build XY graph, you can simply double click on it and uncheck the "erase data on each call. For the other method of construction of the dashboard cluster, you will need to add a few records to offset to maintain the previous itterations table values. Here's the updated image:

-

AO. MaxRate, AO. MinRate, AO. Properties of voltage. RNGs for hardware DAQ USB-6008

Hello

in one of my report, I use the AO. Property of Voltage.Rngs to see if the selected DAQ card takes in charge the application voltage range. This works very well for my PCMCIA card as well as a PCI card. Now run the same VI with a USB-6008 device, this property gives all the return values. In addition, the report of AO.max.rate and AO.min.rate of the '0', the output is-200197 error properties. I use DAQmx as it is supposed to support the same functions for all DAQmx devices. Can someone please tell me what wrong here and how can I get around this?

Best regards

Gabs

AO.min.rate and AO.max.rate are 0 and error-200197 back because the USB-6008 case supports the outputs analog hardware timed. The description of error is "device does not support this property." There is an entrance to the knowledge base for this question.

By selecting 'Use Waveform' uses the synchronization of the sample clock. The waveform data type specifies a delta t, which is used to set the sample clock frequency. It is not supported on the box USB-6008. You shouldn't set your calendar of sample type or explicitly assign the "On Demand".

The DAQmx driver supports hundreds of different devices. Not all combinations of properties are valid for all devices.

-

Communication problem 6210 hardware DAQ with DAQmx 9.2.3 (Err 88302)

I would use NEITHER-USB-6210 with DIAdem 11.1 under Win 7 Home Premium. DAQmx software and supplied drivers are version 8.6, but does not support this DIAdem 11.1 (DAC-NOR-DAQ interface did not show any existing signal). So I decided to update software DAQmx on latest version 9.2.3 which should solve this problem. After installation, all previous configuration items, MAX moved well and DIAdem DAC block indicated all signals with success but start of acquisition and measurement is impossible since. After firmwareloader establishes the material connection seems to be running, but any attempt to transfer data or start any function Max raises failurie event-88302 "an internal error has occurred." Anyone help me please?

Dear Mr. Varga,

After that the PC was clean from previous installed everywhere DAQ and new installation repeated once more, problem has been resolved and now the system is fully capable to work with DIAdem, as well as with the Net. request.

Kind regards

Milos Riha

-

Need help with hardware DAQ in Labview

Hello

I'm new to LabView programming so I need some advice from you guys... My goal to use the labview is to calculate the dynamic mass or the apparent mass of the human subject in a rigid seat. The dynamic mass is calculated as the ratio between the cross of the spectrum between strength and signal acceleartion so that the autospectre of the Basic acceleration signal that LabVIEW can be done using FRF. I've attcahed the VI tht I created in order to calculate the FRF and spectrum of auto for the force and acceleration of Basic. Number of samples = 1024, rate = 100 Hz and the acquisition mode is continuous for the acquisition of data. Acquired signals were filtered using a lowpass with cut filter off = 25 Hz frequency as my frequency range is from 0.5 to 20 Hz. the number of averages = 6, with an average of mode = RMS average weight = linear mode. This basically the implementation that I use for my experiments. Now coming to my questions... I would like to record the time signal for both strength and Basic acceleration to do some post treatment how to do that in Labview? Here I have to say that getting two coulmns of data were only one column is for the moment and the next is for the data of force (or acceleration), with my setting I have 6000 samples for 6 medium.

For preliminary tests, I used a rigid seat to acquire the strength and the Basic acceleration signal in Labview DAQ. the stage in this case should be about zero, but the answer in step with the VI me different gives a value of 180 degrees. I would like also to say that for some of the iteration, the value tends to zero, but after only 6 average it shows me about 180 degrees phase. Iwould wish I had some comments from that aspect also.

Thank you and best regards,

Suresh

-

Schedule of procedures of two or more in the same task?

Hello everyone,

I want to schedule a task using dbms_scheduler and I both procedures (one for serving newspapers AUD and the second for FGA). What is the best way to schedule only a single job that will run two procedures each month?

Thanks in advance

Honza

In my opinion create job like that is not good. Management jobs as this very uncomfortable. Because of this that I am recommended create a main proceeding and call this working procedure

----

Ramin Hashimzade

-

HP ENVY 120: scanning of multiple pages in one same task

I was able to scan multiple pages into a single PDF. Since last week when I replaced the ink cartridges (both HP) I can't do more. The ASNA creates two separate files: namesake, a _1 and the other _2. Two separate PDF files. How can I do the scan keep two pages (3 or 4 and so on) in a single PDF file?

I did not change anything else than cartridges.

Welcome @Tche2015,

Thank you for your participation in the forums! I see that you encounter problems, scanning of multiple documents in a file on Mac. I'd love to help you.

I have provided a few steps to check the settings of the scan to PDF.

Once the analysis is complete, click on send in the lower right corner.

Click the folder from the list.

Then down to the next window, click on the menu down next to Format and select PDF.

(if you want to save multiple files in a folder, uncheck Save all items in a single file next to content.

Select the location where you want to save the file.

And then click Save.

If you're still having problems, fix permissions of the drive on the Mac:

Repair disk permissions:

• Click on your desktop so that it is written next to the Apple Finder icon, and then click Go (you'll see it next to the Finder after file, edit and view).

• In the context of Go, click Applications.

• In Applications, select utilities.

• In the Utilities folder, you will see the disk utility, double-click on this icon to open the disc utilities.

• Click on your hard drive, and then click first aid. Click Run to allow it to run.

Reset the printing system:

Note: This will remove all printers in the print and Fax/Scan, any printer deleted can be re-added later by clicking the sign plus (+) symbol.

Click on the Apple icon and then click on System Preferences.

Click on printers and scanners.

Make a right click (or Ctrl + click) in the left white side panel, and then click Reset printing system.

Click OK to confirm the reset.

Type the name and the correct password.

Click OK to reset the printing system.

Then click on the sign to add the driver, highlight the printer +. (you may need to click the drop down menu to select the name of the printer) Then click the Add button.

Feel free to click on the 'accept as Solution' and the 'Thumbs Up' If this helped. Please let me know the results. Best regards

-

Can I use for the interface and control hardware DAQ win7 home edition

Will be home edition works for them, thank you.

If you really ask that if DAQmx and LabVIEW are supported on windows 7, the answer is Yes and Yes.

You are a long-time member. Did you research web site?

-

Error timeout when using hardware DAQ-6024E frequency measurement

-

How do I (send to) and (back of) my hardware DAQ OR-8451 using c#

I am writing a program that interacts with my camera of NOR-8451 using c# but I have problems to establish the interaction.

The error says that the dll is not available and is not a valid assembly or a COM component.

-

DAQ USB-6008 will be able to power and record voltage for UMS T5 blood pressure at the same time?

I would use my NI USB-6008 to power my blood pressure monitor UMS T5 (http://www.ums-muc.de/en/products/tensiometer/t5.html) but also to take readings of it, but I don't know if it's possible to do it properly. The power supply for the instrument can be as low as 5V, I can easily get the dedicated + 5V channel. I'm able to feed the instrument and connect it to an analog input on the 6008 and measure a voltage in differential mode. However, when you read the documentation of support for the instrument, I find the following:

"Potential pitfalls of data acquisition: the pressure transducer is configured in a full Wheatstone bridge, the input voltage and mV signal output can be connected to the same reference (mass)." Therefore, the mV output signal can be measured using a differential voltage measurement. Therefore, do not make an asymmetric measure of pressure transducer mV output. "(http://www.decagon.com/assets/Uploads/MeasuringUMSTensiometerswithnon-UMSControlandDataAcquisitionSystems.pdf)

My understanding is that the 6008 can take a differential measure if I attach the signal '+' and the signal "-" to the analog inputs of positive and negative terminals. However, it seems that all the ports of ground on the 6008 are grounded to the same reference, which would make my measure of invalid tension according to the above paragraph. So my real question is: if I try to record the voltage with one of the analog inputs on the 6008 in this way, is the valid measurement? Or I need to find a separate power supply, with a different reference field to ensure that the measure is accurate?

The technical details of this device is very poor. The manual is not much better. Companies that want to sell scientific equipment should publish decent cards or get out of business.

In section 3.4.3 General requirements the device is described as a "bridge not amplified circuit. This information along with the impedance of the bridge should be in the specifications, because it is essential to apply the device under any circumstances other than the nominal behavior in 10.6 V.

The answer to your question is:

You can use it with the box USB-6008. The 5 V supply will result in output voltages a little less than half (5/10.6) the voltage specified in nominal conditions. You can use the differential input mode on the box USB-6008. The absolute input voltages will be approximately 2.5 V with the 5 V power supply. This voltage is in the range of the aircraft. The differences are likely to be less than 100 mV. The resolution of the USB-6008 on the + /-1 V is located about 0.5 mV so your resolution of pressure will be about 1% of full scale. The voltage input impedance and termination of the USB-6008 will present a few errors. These can be in the order of 5 to 10%. I can't predict much better without the missing bridge impedance specification. These errors should be relatively constant and systematic. A calibration of the whole system - sensor and together hardware DAQ should allow you to compensate for a large part of this error.

Lynn

-

Do you need 'DAQmx start task' vi read from a device NI DAQ (NI 9205)?

I have a NI 9205, which I use to get a waveform data. To get started quickly, I used the wizard DAQ Vi. The code below (FIGURE 1) is the acquisition of data help VI looked like when I convert LabVIEW code and made some minor adjustments.

When I looked online to see how to get hardware DAQ data, many sources use the task start DAQmx in figure 2.

DAQmx start using VI makes another? Materials using DAQ assist in loop gives you a lack of performance? If so, figure a will have a lack of performance too as it is basically the DAQ help code?

FIGURE 1

Hello sticyfinger,

Help for the Start Task function:

"If you do not use this VI, a measurement task starts automatically when execution of the reading DAQmx VI. Automatic start of theDAQmx VI entry write determines if a build task starts automatically when the execution of the writing DAQmx VI.

If you do not use the DAQmx start task VI and VI task DAQmx stop when you use DAQmx Read VI or VI to write DAQmx several times, as in a loop, the task starts and stops several times. Start and stop a task repeatedly reduce the performance of the application. »

Hope that helps!

Maybe you are looking for

-

Not discoverable - Bluetooth HP Pavilion 15 p001tx

Hello. I have a HP Pavilion 15 p001tx. I was not able to get Bluetooth working since I bought the laptop. I want to say that it detects any device around her or himself detect everything. Its really frustrating even if I have installed the latest dev

-

How to detect the resource (find) information?

Hi all I'm trying to detect programmatically information resource name for devices HSDIO PXI and PXI-4130. How can I do? System DAQmx property does not include these devices, and I can't find a way to convert a resource VISA name in name of reso

-

product shredder 64 msi 1706 error

I tried everything, including my virus program to get rid of this pop up every time I open my computer. Help, please! Send me directions and I'll y tr to get erased situation. I am 76 and I don't need this problem, because it is very frustrating f

-

Original title: I will take a phone call from "Windows Care" telling me that my computer was sending Windows messages. He wanted to access my computer to solve the problem. Is anyone aware of this company? Does anyone got a call from 213-221-3528 "

-

Categories of Palm Desktop (Centro)

installed Palm desktop (6.2.2) on mobile home, hot sync. the categories are all the same color on the desktop. computer desk & centro phone colors are available. advice much appreicated.