zedboard Xilinx Zync 7000 interface using labview

Hello

I'm doing my thesis in Zedboard for the development of a test for DDR3 memory and verification. For this I need to set up a base of dedicated on NI Measurement Studio LabVIEW graphical user Interface.

Theme: Algorithmic Szudy of test set-up for DDR3 SDRAM with a Xilinx architecting.

Here, I made my algorithm Xilinx SDK. But I need to create a graphical interface using labview. To run these programs. Please let me know how I can do this.

1 or is it possible to directly access the SoC architecting using Labview. If yes how?

2. or if I have to do the coding of Xilinx SDK and how do I run this code using Labview?

Please give me a detailed answer. As I am new to labview. I m not understanding how to start with. If you have any design example please share with me.

Thank you best regards &,.

Nithin Ponnarasseri

No you can not grow directly in LabVIEW and deploy this program to the Board of Directors Zync. NOR has their own material base platform Zync (cRIO and myRIO) but the tools to target these tips are specific to the hardware implementation OR and will not work with other hardware. Develop an interface for another hardware platform is a lot of work and must be adapted for each unique flavor to a new hardware platform. And NEITHER does not support this for other devices.

If your option will be to develop an application with the SDK Zync for Zync ARM controller and provide a form of communication interface (serial port, TCP/IP, or similar) to this application you can send commands to LabVIEW for your embedded application.

Tags: NI Software

Similar Questions

-

Control CMD (command line interface) using Labview 2011.

Hello

I'm trying to control software that has an interface to command line using LabView 2011 but I have problems when reading the information.

Is attached the VI I created so far, but it is not working properly.

Problems so far:

1 - if I use ReadLine(), it blocks showing no error and nothing else.

2 - ReadToEnd () same problem as the previous line, the software hangs just at this stage.

3 - if I compare the response of the "peek" in waiting for the - 1 indicating there is not more character, the hook of software as the previous steps.

You have some clues as to what might be wrong or another way to 'control' the CMD to send messages, read and send messages, etc...

Thank you very much for your help.

I've done it before - I posted about this on the forum here: https://forums.ni.com/t5/LabVIEW/How-to-open-close-and-monitor-a-application-xyz-exe-using/m-p/32511...

I did also wrap in a library at a given time and post it on the forums, but I couldn't find this particular post.

-

Interface using labview instruments

Hello

Can I interface a micropipette with PC using the LabVIEW DAQ module? This kind of micropipettes (electrically powered) available on the market?

Hi Aruvnam,

You must ask these manufacturers to check availability!

'Interface to a PC' should be a point in your list of requirements that you must discuss with these manufacturers!

-

Interfacing Ensenso SDK using labview

I am trying to Ensenso SDK interface using labview. The company provides a .net dll, however, all available functions are not accessible from labview. They also said that labview is not yet officially support for interface with the Ensenso SDK. But C, C++ are officially supported. Now my question is, is it possible to write code c or c++ to control the Ensenso SDK and then access the C or C++ works using labview? If so can you help me how can I do? Thank you very much for your support.

With sincere friendships.

Sewyew

If you can not get the .NET DLL to work with LabVIEW (for example the use of the call library function node), you could create a C/C++ DLL wrapper that allows you to access the functions you need. I don't know too much about the details, but it is certainly possible.

-

How to program using Labview to an accelerometer

Hello:

I got an accelerometer which has digital I2C/SPI serial interface, so I bought a USB - I2C converter for data acquisition. I would like to know if I can use Labview to acquire data of com port and also program for the accelerometer to capture the data of the axis z. I have a box of white myDAQ NOR but SB. says that it is not an appropriate device to acquire before I2C/SPI signals. The datasheet of the accelerometer is in the accessory and the specification of the converter is this link: http://www.robot-electronics.co.uk/htm/usb_iss_tech.htm .

I hope someone can solve the problem for me. It is best to use the software labview for me because most of my project work is based on that.

Best regards

The f

Good and bad news. You have an accelerometer that 'speaks' I2C or USB to I2C converter, so if you connect both of them, you can send 'orders' of your accelerometer easily of LabVIEW by using communication series live that's the good news. The bad news is that it seems that you need to address your accelerometer using calls very low level, a work, I certainly don't want to face! This crys on a 'pilot', a middle piece of equipment that does all the "hard work" to take a high level order ("Please tell me the acceleration") and he translates things your device includes (including the Setup program, records, calendar, packing and unpacking of the bits and bytes, etc.).

Bob Schor

-

tools for interfacing in Labview

My project is to create a multi parameter diagnostic tool to monitor the temperature, ECG waveform, analysis RVH, measure SPO2 and BP without a lapel. I would like to know the tools of different interface that I can use for my project

LabVIEW supports a large number of interfaces: series, Ethernet (TCP/IP, UDP), communicate with the driver dll, contact OR and Acquisition of third-party data (DAQ) devices (e.g. USB DAQ, cDAQ)

I suggest that the first thing to do would be to look at the material you want to use and what interfaces they offer (or to use sensors... analog? digital?) -You can then think about the use of this interface in LabVIEW.

-

Instrument interfacing in Labview

Hello

I would like a Luxtron m600 optical fiber probe so that I can use it to receive entries analog signals to control the heating of the samples of the interface.

My obstacle becomes the sensor FOT to contact my office. In MAX, I tried to configure the NI PCI-6229 I use under "Devices and Interfaces" with the probe attached to the block connector with wire bare but couldn't create the task. My understanding is the sensor FOT being a third-party tool, I also need to connect it to one of the serial ports on the computer by using a VISA interactive control. In addition, I also need to download the driver specific to the probe.

I downloaded the mentioned software and managed to obtain data on the temperature of the sensor with the driver. But my goal is to integrate these data at a higher level VI which will use the PID toolkit. Before, I used a USB DAQ Mbps key and had to use the explicit input function DAQ helps acquire signals. But for this application I use assistant DAQ and the Assistant of the Instrument, or is it a different thought process that will allow me to interface with the PCI-6229 FOT sensor lead? I've only been using Labview for a few weeks to get the detailed procedure would be greatly appreciated. Thank you for your time and patience.

I have attached the driver I downloaded for reference.

If you are unsure how to add devices to the connector pane in LabVIEW, you really start the tutorial from LabVIEW. Very basic task which should not take more than 60 seconds.

Throw the instrument if you want to instead use the DAQ card to read the sensor. Makes no difference to me. Always plug your DAQ card for what will be the heating element. Your reading of the temperature is only half of the installation. Since you already have this part done with driver, I don't quite understand why you focus not on the part of output control.

-

AKM21C using LABVIEW servo motor control

Hello

I'm controlling only 3 engine AKM21C using LABVIEW. I want a user to enter a certain length and width to move the motor in x-y-directions, and through the GUI LABVIEW on the façade. Two of the engines must evolve synchronously in the direction, while the third engine moves in. x I have a query UMI-7774 interface connected to the reader of the AKD engines.

Could someone please guide me on how to proceed with this?

Hello

Assuming you are using one of our motion controller cards, follow-up guide will be an excellent aid step by step to get you started: http://www.ni.com/pdf/manuals/375543c.pdf.

-

to create a terminal using labview

Hi can someone tell me how to emulate the serialterminal window in labview? or give me a simple code to do?

Basically, I want to create a hyper terminalprogram using labVIEW? I have search for labview as an example but I wasnot able to find anything.

I am able to send a bite at a time to themachine, but I want to have the interface of terminal as a window. You can pleasehelp?

Another sidenote: use rs232, buad rate is 9600.

Have you tried a Search?

First success.

-

Possible to use labview with daq system not of NOR?

Hello

I have a daq system and the software from another company that NEITHER. But I want some changes in the software. If the opportunity was to make a new program with Labview.

Is it possible to use the old system of data acquisition? Is this compatible with Labview? Or I have to buy new hardware?

Thank you.

Hi VIassaks,

Good afternoon and I hope that your well today.

Thanks for the post.

LabVIEW can communicate with 3rd party hardware using the library function call is located in the tip under the functions Palette palette. If your equipment is equipped with a DLL at the driver level LabVIEW can communicate with the hardware. However, you must obtain documentation of the DLL so that you can create your own interface for the material of the part 3.

Another option would be if the hardware manufacturer provided LabVIEW VIs that control their material. You will not be able to use the screws (National Instruments Data Acquisition DAQ) because these screws use the DLL OR-DAQ, which is our software at the level of the driver for our DAQ cards. Other companies use their own software to the driver level to control their own material. Only the National Instruments hardware uses the NOR-DAQ driver that allows you to use LabVIEW DAQ screws.

Hope this helps,

-

Screenshot of Tektronix MSO4104B using LabVIEW

I am trying to acquire a screenshot of an oscilloscope Tektronix MSO4104B using LabVIEW. I am currently able to collect data from the device and have a waveform displayed on my front of VI. However, for various reasons, our preference is to capture the actual screen shot of the scope.

I have reviewed the reference for programmers for this camera and have done countless searches on Google for an answer, but have not been able to find a solution. It seems that a few people were able to reach on OTHER Tek scopes by sending a hard copy through the port of communication (GPIB, USB, Ethernet, etc.), but according to the reference of programmers for this particular device, it seems that he will send a paper copy of an installed printer, rather than simply as a stream of data to the port which can be read using VISA controls.

The other solution I've seen is to record the screen turned to a flash drive, and then copy the file via the port to the PC. However, none of these solutions seems to be available on this device... it's one of the more advanced scopes makes Tek... I can't believe it's so hard! Help, please!

-

waveform, with an average of results using labview to O-scope

Hello fellow engineers! I'm a first-yeargraduatestudent in CHEE at the University of Houston. Basically, I know nothing about labview. I am trying to program an application that looks like this - I collect a waveform of the signal of O-scope. This waveform does not change its characteristic shape. I need to find the wave form average of waveforms of N (100 for example). Thus, the slight changes (or noise) in the feature of form during the period mustbeaveraged out and I need to have a resultant waveform that represents the average waveform over a period. So, basically, I'm collecting the wave several times (for example 100) on a single period. The O-scope that I use now is Tektronix TDS 2024 B. It communicates with the computer via USB. The version of labview is 8.5. For now, I am able to communicate with the computer using our o-scope through labview. I already downloaded the driver of instruments of your Web site. It turns out that the program can give me only the average result I can get directly from o-scope manually. I need to have more say on average (100) using labview. I wrote a program that relies on the instrument driver that is downloaded on your website (for loop part is average, the waveform). The program that I modified and an instrument driver are attached. The program cannot be fully open, if the driver is not put in the right place in the labview (under lib inst.) When I run the program, the average waveform does not appear on the front panal and signal waveform file is not saved correctly. Is there someone can find where I did wrong and it develop for me? Because I barely know Labview, it will be even better if you can add an image or program that you have changed. I'm waiting for your creative ideas.

With the best regards,.

--

Weiye

-

I want to send data using labVIEW to arduino using write visa and the process and to take action using arduino. After that, I want to arduino to send out necessary via a serial port to labVIEW which should be read using visa read and store in a chain. While I am able to write or read both individually, I can't do it consecutively. I used advanced read and write vi for checking my code, but nothing is helping. The wrong bed 'time delay before execution. " Please let me know where I can go wrong. Also is it possible to write code for hx711 using labVIEW

1. you need not "\n" on your orders println(). This command adds an end of line character already in the message.

2. you get the error because you have a loop around your reading. After the first reading (well technically, the second because of you add an extra line end character), there is nothing left in the port. As a result, you will get the timeout.

3. you should really consider using a Structure of the event. This way you just don't write and read when you press the Write button and you can also use the structure of the event to make the loop to stop. I also go up to close the port inside the stop-> value Change event.

-

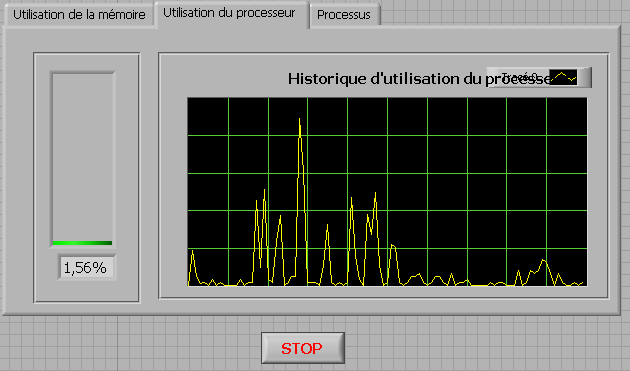

How to check the CPU usage and paging using LabVIEW

Hi guys,.

I build an application that is used to check the CPU usage and paging using LabVIEW. How can I do?

any help, suggestions or advice will be greatly appreciated...

Kind regards

Prashant

Hello

If you plan to build your app for Windows, you can use .NET classes. (System.PerformanceCounter), there is a simple example with LabVIEW:

C:\Program NIUninstaller Instruments\LabVIEW 2010\examples\comm\dotnet\SimpleTaskMonitor.llb

Also, you have several screws that you can use to verify information about the processor.

Kind regards

-

Programmatically insert step of ActiveX/COM using LabVIEW

Hello

I would like to be able to create sequences like the one set using LabVIEW.

This sequence has only 2 steps, a LabVIEW VI call and an adapter of ActiveX/COM call.

I was able to do using an adaptation of the code here: https://decibel.ni.com/content/docs/DOC-36337

However, I am struggling to add the step of the ActiveX/COM.

Any help would be welcome.

Thank you

Of course, there is a way, if you look for it

Since you have an existing 'Step' class object, you can also get a 'Module' object for her. Subsequently, you will need to specify that it is an ActiveX module. If you do not know which - probably you need to get the object 'map' somehow... Our case is simpler, so just cast to the ActiveX module and... to set certain properties like ServerId, ActiveXReferenceExpr and so on.

I've attached an example for you. Interesting thing is the ServerId - I just read this chain of the TS for similar action and reused it here so do not ask me how to get automatically

You will need to complete your 'properties' as 'file' - but I'll gracefully leave this work for you =.

Best regards

Maybe you are looking for

-

How do I set the home page for new tabs?

When I open a new tab, it opens as a blank page. How to set Firefox to open new tabs in my homepage? locked by a moderator due to the age and Firefox 13 has a new feature for a new tab

-

NOR-9264. How can I get specific frequency between 48 and 52 Hz output

-

5700 sucks not start windows cannot use recovery CD

I have an Aspire 5742 running Windows 7 Home Prem When I try to start windows I get a message from windows Startup Manager File: \windows\system32\config\system Status: 0xc000000d Info: Windows does not load because the system registry file is missin

-

I have a sandisk sansa fuze v02.03.33 and want to downgrade or less v02.02.26. is this possible? and I may have a link. and if not, why?

-

Hi my hp c309 photosmart will not print any document message that the printer is offline

Hi my hp photosmart c309 doesn't work when I print a document a message come and tell the printer is offline but the work of fine print. Thant for your help Angie