Disadvantages of using DAQ Assistant

I need 2 analog inputs continuously at 5-10 kHz from the sample and then use a combination of producer consumer and State Machine for the processing of data in real-time.

In most parts of the example I've seen, people always use Subvi of data acquisition groups. Even though I know how to set up getting data using the Subvi, I like to use Express VI DAQ Assistant to perform data acquisition.

Known disadvantages of the use of VI express in my case (see 1st line)?

With the help of an express VI will slow down time of execution and, therefore, your time of iteration of loop due to the fresh general partner. If you are concerned about the timing of your program, then you should strongly consider using the DAQmx API screws.

Tags: NI Software

Similar Questions

-

Control relay with Boolean switch using DAQ assistant 9481 - problems

Sorry for what may be a stupid question but I'm stuck in quicksand.

I use a relay module 9481 and have two external relays connected lines 0 and 1.

When I create a digital output 0 line by line, I can run the test inside the express and activate the relay and turn off without problem.

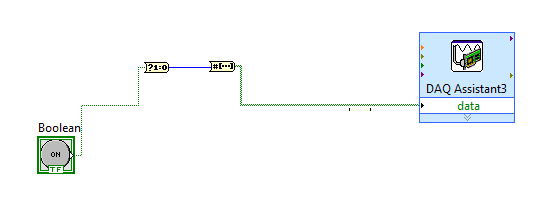

The generated block DAQ expressed expects a Boolean input of 1 d. (See attached photo).

I want to connect a Boolean switch relay line disk 0. You can connect live not because the switch is Boolean and the input is Boolean 1 d - I'm a conversation in the pict.

All plumbing lines display results, the relay never active.

Any bunch would be greatly appreciated! Thank you

Mr._Mechanical,

Welcome to the Forums of switch OR this forum is generally intended for products OR-SWITCH [such as the NI PXI-25xx & NI SCXI-11xx], I think I know the answer to your question.

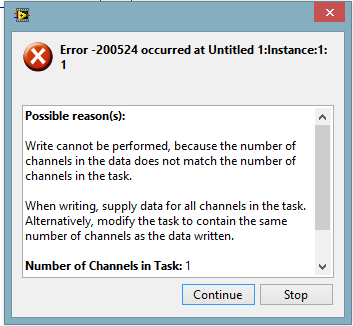

I think the reason why it's a failure is the conversion you make generates a table of 16 Boolean [as the 'boolean to (0,1)' function creates a data I16 type] with your data more false data points 15.

When you try to control the relay, he sees 16 datapoints are you Commander to a single port [channel] and so error out.

My suggestion would be to use normal DAQmx digital output screw [with, he set up as ' Digital > single channel > single sample > Boolean (1 line) "] rather than the DAQ assistant.

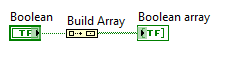

If you use the daq assistant, simply by using the function 'Building the table' will transform your simple Boolean data point in a Boolean array containing a single element.

While the DAQ assistant is very easy to use, I recommend that you use the DAQ assistant, because this reduces the features and increases the execution time.

-

Using DAQ Assistant with a system remotely

I'm new to LabVIEW and National Instruments hardware and I am trying to use an instrument with LabVIEW using the DAQ Assistant. I use a PC with Windows Vista and I am connected via a network to a PXI-8108 controller in a PXI-1050 chasiss chassis. The instrument is just a thermocouple which I use to become familiar with everything. The thermocouple is connected and the connection SCB-68 block which is connected to a PXI-6221 multifunction data acquisition in the chassis. I am able to create a task in MAX under remote system and everything seems to work. What I want to do is to use this instrument in LabVIEW, and it seems that for this I need to use the DAQ Assistant, but when I do it says no supported device is found. I wonder if there is a way to get LabVIEW lean on the remote system to see the acquisition of data and the thermocouple.

All advice is appreciated.

Thank you

Hi all

Ben is correct. RDA is no longer supported in DAQmx. We have another way to use DAQmx with a remote system. It is use DAQmx with an OPC server or simply by shared network variables. There is a section of the base of knowledge here that should help you get started. You should also take a look at the developer section area here. The basic idea is that you can use a variable shared within labVIEW that is bound to a variable shared on your networked machine. In this way, you can write and read values from a task DAQmx. Look at the instructions in the above two items and let me know if you have any questions.

Kind regards

Paul C.

-

Outbreak of DAQmx N-sample and the Acquisition using DAQ Assistant

Hello!

I'm still fairly new to LabVIEW and I am working on all the points of connection. I would like to acquire a finite number of samples of analog data from a CompactDAQ system when a Boolean event of internal software (like a button of VI). I followed the examples to implement the acquisition with the DAQ Assistant, which works very well. I don't understand how I can use a software trigger, but I don't see how hardware triggers are configured in the trigger tab in the DAQ Assistant.

I don't know that this should be very simple; Maybe I'm just ignorant of the configuration used for this sort of thing. Also, I could find soon I need to go beyond the DAQ Assistant for some of what I want to do, so any pointers to good references or tutorials on programming DAQmx are welcome.

Thank you!

Ryan

You can simply put the acquisition within a value of the Boolean control change event.

-

PID control using DAQ assistant

Hi, I'm generating sine wave using acquirng and function generator cela DAQassitant in my computer using USB6211 DAQ and labview. I want to manipulate this singal granted using the labview PID command and use the result of PID to generate an analogue of singal feedback (similar to that of entry). But when I run the code, it gives me an error that the buffer size is less. How can I increase the buffer size so that I can generate the singal output continuously. I have attached the file .vi

Thanks a ton.

Krishna

Hello Krishna,

get rid of the DAQAssistents and use the plain DAQmx features!

It is never a good idea to use the son of DDT in combination with points of constraint: what kind of data does it not provide your DAQAssistent and expect your PID?

-

Using DAQ Assistant to read voltage of 9205

I am new Nock in it and I tried to read the voltage level of 9205 relating to 9172. I use it in XP mode virtual because windows 7 does not have labview 8,9. I installed the drivers for data acquisition.

When I check the meter in automation and Explorer, it works very well which means it reads im DC voltage supply. When I created a VI facilitate data acquisition, I chose the right channel, the entry as analog voltage, the numeirc indicator shows it is-10 to 10. I noticed he did the same thing, even once the USB is disconnected, which means that the function helps daq was not save the data of the 9205.

Can someone help me?

Hi aaclabview,

The way in which you have added the device to MAX makes the device act as a simulated instrument. Simulated instruments only generate sine wave data to test a piece of code without using any material. A simulated device has the icon yellow as shown in the screenshot you provided and are completely dissociated from any material, so add or remove the usb device has no effect.

The problem with the help of Windows XP mode as mentioned in the above KB is the USB transfer must be enabled for the measurement and Automation Explorer inside the Virtual Machine detect the device. Using the unit in this way is not supported or recommended by National Instruments and can lead to instability and the latency of the errors in the acquisition of data even if a connection is established.

It is a more sure bet to try and install LabVIEW and hardware drivers DAQ as described above on the real Windows 7 machine to try and run inside the XP mode.

-

Using the DAQ Assistant. can I create a VI that measures continuously during a fixed time?

I use LabView to an NI USB-6009 enclosure, with two accelerometers like my analog input. When you use DAQ Assistant to build my VI I have not seen an option to measure continuously for a set amount of time. I need the test to run for two seconds and then stop.

Is there anyway to specify the exact duration of each test?

It's about as simple as you can get. Set the number of samples to be twice the sampling frequency (or whatever the multiplier that you want). That's it - a simple DAQ Assistant and nothing else on the block diagram. If you need it to be variable, just wire a control of the number of input samples.

-

Task of naming of the DAQ Assistant

I not bad by using DAQ Assistant to create a task to do what I want, but I can't understand how to give a meaningful name to the task. The name of the task seems to be assigned arbitrarily to something like "Assistant_1 DAQ", which is not very useful for me.

Please advise on how, in the "convert to NOR-DAQmxTask", procedure I can assign a different name to the task. If not, is it possible to rename an existing task?

Hi wildcatherder,

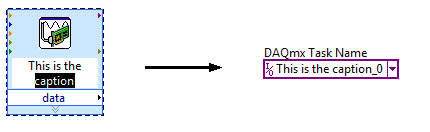

There is already a way to set the name of the task in the present case, but it is not quite obvious and has a little whim. If you change the legend of VI DAQ Assistant express before selecting "Convert to the NOR-DAQmx task", he uses the legend that you specified as the name of the task in Max... and then he adds "_0" at the end:

If you have a suggestion to improve this feature, perhaps you could post it to the Exchange of ideas, information Acquisition?

Brad

-

DAQ Assistant don't update the buffer size to change the frequency

Hi all

I use DAQ Assistant inside a loop to write a signal in a module output best 9262 OR a cDAQ-9174. I generate the signal with the express vi simulate Signal or with a simple loop using indexing. The problem is that when I change the frequency, using the same sampling frequency, I have a different number of samples to write the cDAQ does not seem to update the size of the buffer, so no my signal gets written in. The result is the first sine wave is nicely written, but each after that gradually get cut off on the edges. I traced imput signal that I generate, so I know that it is generated with the right size and frequency of departure, what ever it is, still works, it is those more later in the loop who have the wrong size aparently buffer. I tried to reset the cDAQ by adding a different DAQ Assistant at the end of the outer loop with the stop bit the true value, it makes me just the error "resource not available.

Any ideas?

I'm using LabVIEW Base development system new V12.0 32 bit.

Thank you

Matt

Idea:

Get rid of the DAQ assistant and use the DAQmx API. The DAQ Assistant is there to support the limited functionality and base up a dirty experience and running quickly. The report of the API offers more funcionallity and DAQmx property nodes allow greater flexibility. DAQ Assistant is just too limited for your needs. (you can't paint a masterpiece with crayons)

-

Recovery of the DAQ Assistant data acquired

Hello

I'm currently dealing with a continuous data using NOR cDAQ-9174 proposed acquisition and recording of analog input signals of a built-in three-measuring probe.

I built a simple vi using DAQ Assistant to acquire data and write to an output .txt - rather than .tdms using Signal Express.

On a day 10 cycle of data acquisition computer was mistakenly turned off - leaving the empty output .txt file. LabView recovered the VI cut and I wonder if there is a way I can access the data that has been saved by the DAQ Assistant which can be saved in temporary files etc..

I have no idea where that might be, since you cannot delve deeper down into the 'levels' of DAQ assistant as you would a sub - vi.

Just as a note aside to apologize my stupidity - I realize that all the data at the end of the writing task is stupid and completely avoidable... but I worked for a date limit.

Thanks in advance for any help you can provide.

Dan

The most likely answer is not, unfortunately. It looks like you were a table of data at every point of the construction and then measure he writes at the end. In this case, unless you have explicitly recorded data in a temporary file, it is located right in volatile memory, waiting for you to do something with it.

I realize that this isn't what you want to hear, as it comes to the time of submission of draft / year...

If you post your VI (preferably version LV2012 or below), I can have a look to see if there is anything obvious.

-

Calibration of thermocouples in the DAQ Assistant, using data from spreadsheet?

Hi all

For my first application LabVIEW, I'm looking to automate the calibration of thermocouples by measuring their response at different temperatures in a dry well Sizer. I get temperatures of thermocouples six by SCXI 1303/1102/1600 and have six channels put in place in one of my subVIs in the DAQ assistant.

I compare these values to temperature calibrator that I am acquiring by VISA series in an other Subvi. All these values are written in a .csv file.

Can I import these data into the DAQ Assistant to use for calibration? Is there a simpler way to associate with the channel calibration data? Currently, I could manually copy - paste the cells on the worksheet in the calibration sheet, but that seems just silly.

If there is everything that I could provide to help solve the problem, let me know!

Thank you!

Hi Zoysiamo,

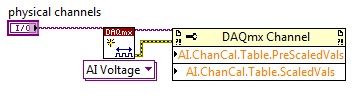

It is possible to automate the calibration screws DAQmx at a lower level, in particular the DAQmx channel property node. Using you can specify advance nationwide and the values on the scale for your channel. I recommend you take a look at this example of the community. The property node configuration will be similar to, as illustrated below:

-

I use several DAQ assistant but it seems impossible...

Hello world

I'm on a project for some time.

To summarize, I had 3 modules for the project: Anolog, digital, input resistance meter.

My main program works, but now I have to connect with an excel file.

I found an easy way of this solution, but now my problem is bigger. The fact is that I use my screws and screws with this how to link my data, but according to LabVIEW Sub, I can't, in the same program, do something in relation to 2 modules different. Obviously, each module works with a DAQ Assistant.

To be more specific: I want to put the data from the 2 (thanks to the analogue of the module), and wire different sensors 1-> 0 or 0-> 1 (thanks to the digital module)

And when I link 2 DAQ in the same file or 2 screws secondary who got 1 acquisition of data in entry of a measurement file, it does not work. The error that I can not launch the DAQ second after the first... so...

I hope you understand my problem.

You have a solution for this problem? Should I change a large part of my program to do this or is it just a small detail?

Thank you in advance! I'm really disappointed-_ - I'm for several times... and I'm late for my project...

Best regards.

ML

-

How to create different types of analog inputs without using the DAQ assistant?

Hi all

I would like to create multiple entries multiple analog channels of type... I mean I want to have the voltage of 5 and 2 channels of temperature...

However, I am not using the DAQ assistant. I use "create channel" vi.

Can anyone suggest me please how to do / I submit my VI for reference... I have 5 tensions, and 2 temperature characterized as showing these 2 two separate graphics...

-

Using the DAQ assistant voltage vs time graph

I'm relatively new to all Labview and terms and everything which affects programming. I've read tutorials and everything trying to understand things. One thing that I have a problem is the DAQ assistant. Now, if I wanted to place the DAQ assistant on the block diagram of labview and I have everything set up so that the voltage will travel in the DAQ hardware, how would I set up my block diagram so that I can get a graph of voltage vs time in which data begin recording until the voltage reaches a certain tension I was inputing and change such as 30 or 40 volts. The data will also stop recording when the voltage reaches the same number. I also want to be able to multiply the number of voltage coming out a number that I can change myself before it is graphed over time. Example, I mean the voltage to start recording when he reached 40 volts. Now when the voltage comes out of allows it to DAQ assistant say he is somewhere read 10 volts and the number I want to multiply by 5. So, I want to be able to multiply the voltage by 5 and then since it will be 50, it would begin graphing this number over time.

You would need to have a Boolean value which controls whether the (amplified) voltage is greater than N.

If so, he would send this value to a graph, if not, the tension would not get graphically.

Here is an example: (do not try to copy this code exactly, because it does not use a signal, but rather a whole number that is being created)

-

How to use generate multiple signals on a single DAQ Assistant

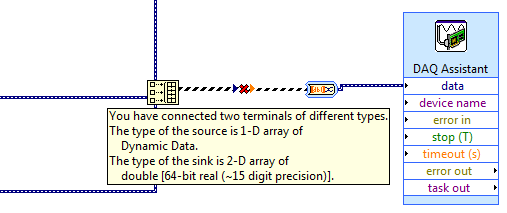

I am trying to generate several AO on my DAQ card, but I kept getting an error. I looked at the error and he said that I had to use a single DAQ Assistant. So, I created one, but I can't understand how to connect the signals. I get lines that don't connect. Is attached a picture of the installation. Thank you!!!

If you want to use the type of dynamic data, you must use the appropriate function. Do not use the construction. Use the Signal to merge. Then wire you the output of said directly to the Assistant.

Maybe you are looking for

-

Pavilion dm3-1170es: 04 HPQ00/ACPI driver for HP Pavilion dm3-1170es

I need the driver ACPI/HPQ00 04 for HP Pavilion dm3-1170es, please.

-

Equium M50-192 - upgrade to Windows 7

I have an Equium M50 - 192, model No. PSM59E-003008AV, running on XP.My PC is Windows 7 and I have two machines on the same OS. Windows 7 Advisor on the Microsoft website shows that this M50 - 192 is suitable for an upgrade.I have already increased t

-

The Windows media player 11 does not work correctly

My windows media player 11 does not work properly whenever I go to open a video with it, it appears on the taskbar, you can here the sound, but the player himself does not appear on the destop I tried to reinstall the drive, and I get the same thing.

-

V515w all-in-1 printer suggest a new please

My printer dell all in 1, the head has an error. Seen a number with the same problem and we only printed perhaps leaves 200 and had it a year. So do not you are looking to buy this new model Any suggestions on another who is all in 1 printer and wire

-

I'm trying to transfer photos from my Blackberry. I don't have a data plan or a micro sd card, so the usb mass storage option is (I think) the only way for me to get my pictures on my computer and my phone. I plug the usb cord into my computer and th