Pipes of LabVIEW, fluid?

Hello

I'm looking to simulate a pump RAM using Labview student 2012 edition. There is not much on the net about it, except that I saw that he said that I should maybe DSC module.

Currently, I use Labview for circuits electric, but not liquid and I am trying to download the DSC (800 MB) module.

It could be useful that I admit that I am no expert in using Labview (student rusty who has not used since last year).

Thank you

KeV.

The DSC module is not fake anything. It will provide commands that are similar to pipes and pumps.

Its benefits extend to the world real control and providing alarms and logging are present in control applications.

Tags: NI Software

Similar Questions

-

What is the best way to connect the pipes to Labview? DDE or OPC

What is the best way to connect quizix pipes to labview?

Pipes share data by using Dynamic Data Exchange (DDE), which is the best way? To use an OPC server between labveiw and pipes or DDE?

If the program manages DDE communication the best way is via a DDE, as LabVIEW handles this. Otherwise, you will need to add another instance (OPC Server) system that will make it more complex and causes more load.

See the previous link to the words 'to the help of LabVIEW as a DDE Client'.

-Tom

-

Named Windows (application OpenG)

Greetings,

I encountered some problems with the implementation OpenG Named Pipes (rolfk). I'm not sure how much this is due to my inexperience with pipes and how much is caused by aging OpenG (beta) implementation.

Use:

I want to take existing named pipes with LabVIEW to read the data on their behalf basic test case work (simple example .vi draws OpenG) (attached screenie 1).Problem:

If I try to pick up open hose separate .vi (or external for LabVIEW software) I get error 42, when you try to read (screenie 2)Issues related to the:

Is there a resource to determine what cover the error codes? (I've also seen error 8, screenie 3, but only found error description 6)

Are there reasons to believe that the implementation of the named pipe no longer works in Win7/LV8?Am I use butchering and appropriate procedure of channel named?

Thanks in advance for your review!

Nicolai

It is not trivial to debug the pipes. They sometimes behave a bit strange and I have not really understood where the problem lays. Sometimes, they seem to be missing the first element of data that was sent which is the only reason that I am never to the point of free software and to make an official of OpenG package. They worked well for what I needed to do and nobody else with enough knowledge on the side C seemed interested enough to make the tests more, so I left it there.

I wonder in your 5th case if you have a timing problem. The fact that you are running a VI or two screws separate really shouldn't make any difference at all (provided that you do not use the same name of channel of course). You can use a time-out on the playback feature to avoid running through 10 attempts you allow before stop the loop.

-

Show route of fluid through pipes?

Hi, host of back / AS amateur here...

I want to produce a series of training resources that symbolically see the fluid moving along a pipe. I have in mind something simple, for example content changes color as the liquid hose passes through it. I don't want to do it all at once, which would not be very easy. I want the fluid to follow the path of the conduct, which might have several turns.

I tried something like this in the past with text animated which was to simulate handwriting and finished just a mask along each character by interpolation. It was really painful and not convenient when I have many designs to animate. Some technique I use, it will be linked to AS logical to determine when the hose must be pressurized. I'll do the rate of parametric variation, and which will also vary according to the system requirements.

I see animations of the Comet trails, but that does not seem that it would be accurate enough?

see you soon

Colin

Sydney

You lost me at the break fluid in the pipes to dust in deep space.

If the pipe is fairly loose and without much overlap, you could do inside the transparent hoses (turning the complete layout of a PNG image with the inside of the transparent tube, or faking it with a corresponding mask inside the hose), then by program "fill" the pipes by turning on a sequence of individual blocks behind the pipes. The blocks themselves may have an animation loop showing the direction of the movement. This would result in the animation a little chunky initial flow according to the size of the blocks that you use, but I doubt most people would be bothered by it.

-

For a long time, I bought as add-on for LV had some renderings, 2D and 3D installation of pipes and pumps as custom controls Boolean. I can't find my 'old'. They are always available somewhere?

I think that the images were initially provided by the box tool (http://www.softwaretoolbox.com/)

You can still by the static symbol libraries or active controls, but they are all activeX controls if you buy directly from them.

-

Open built in the workspace Addons in LabVIEW application using the API

I do Veristand project who uses a lot o custom code for additional features (database Custom logging, several preconfigured stimulus profile running on action of the user, custom logging datafile, customized SCADA-like display of the State of the system (pipes, valves, pumps, etc.)). On any other user of hand interface for the control of the program must be simple, because operators use (the only options, no change in operation) and similar to the previous system solution (which was HMI, touch screen with multiple monitors).

I plan to do LabVIEW custom application for GUI which communicates with the gateway Veristand and target using API functions.

However, I want to implement some already existing in the workspace tools in LabVIEW code, such as monitor of the alarm. There are "Open workspace tool" API functions in the labVIEW Veristand API function list. This function requires the toolpath to workspace as an argument. How can I set path for those built in the workspace tools? I'm not managing to find with the simple search.

You may want to consider this topic

http://forums.NI.com/T5/NI-VeriStand/open-workspace-tool/m-p/2253154

Concerning

-Eric

-

Integration of mastic in Labview

Hi, the serial port session LabView VIs are communicating well with my stepper motors (they do not meet 50% of the orders Stairmaster - stepper motor Excitron motor) I want to create a VI that incorporates serial port session manager PuTTY in LabView so I can use PuTTY in LabView to order my engines. Can someone please? I found some mentioning PIPES to do this, but when I try to add to my diagram it says its unavailable - this source made since 2006, that there may be another way now? I am running LabView 2010 for Windows Vista and I am not allowed to download anything on the internet by - cordially. Thanks EE people

-

Controlling the STDIN STDOUT of a legacy in LabVIEW application

I have a legacy DOS base program that runs in a command line interface in Windows. Normal use which is a type of operator in a command, look at the result, then type in another command based on the results. I need launch this application, KEEP IT OPEN and send/receive orders from certain TIME CMD line Interface IT IS ALWAYS OPEN.

Because I need to open this program, I can't use normal Exec.vi system that allows a single STDIN/STDOUT.

Has anyone else done this? I heard that it is possible using PERL, but I'm doing it in native LabVIEW, if possible.

Under Linux, you can use the LabVIEW VIs hose supplied with. For Windows, you can try the OpenG Pipe library.

WARNING: Only library Pipe works for me but it is not fully debugged software, so beware when using it in a production environment.

To install the attached package you prefer using the Manager of Package of VI.

-

Greetings,

I'm trying to send commands to 3rd party software, through pipes (Windows). The 3rd party software implements channels appointed for me this approach should be used. The 3rd party software returned data me through a separate set of named pipes. The pipe command accepts the following structure as input:

typedef struct _pipe_CMD

{

WORD wCMD

BYTE, Byte [2]

} PIPE_CMD;

An example of command shows the following values:

wCMD = PIPE_CMD_EXAMPLE

bYte [0] = 0 x 0001

bYte [1] = 0

Similarly, the exit pipe returns the following structure:

typedef struct _PIPE_OUT_PUT

{

Double x

Double y

Double z

} PIPE_OUT_PUT

Question:

What is the way to better/correct to imitate the structure of the typedef above in/to leave LabVIEW? Note that the channel named (OpenG application) for Windows takes string input (and similarly returns a string output).

In the below attempts, I use a named pipe created by LabVIEW to test what can be read as I wrote my order for the named pipe. At this point, I was not able to get the 3 rd party software to respond to one of these commands, so I set the channel control named and listen to the output of the channel named, but I can type a channel named, successfully providing information (read only) house-keeping.

Try 1: cast

See Screenie 1. I threw each of the values in a string and it concatenate to send through named pipe. One of the problems here is that, in my view, type casting 0 creates a NULL character, who does not intend. The other problem is that I can not actually the 3rd party software to recognize that I sent an order!

Attempt 2: Flatten the cluster chain

Screenie see 2: I create a cluster and flatten it into a string to be sent by the named pipe. Here a number of characters represented is apparent in the output. Again, I fear that these are not representative of what I'm trying to send (wCmd and bYte [2]). Yet once, none charged with receipt of the 3rd party software that I sent an order.

Thoughts:

Should I change the channel named call library function node to accept clusters/structs to send what I want? This will break something else down the line? My "gibberish" (Screenie 3) return attempt, but same "gibberish" regardless of whether I used method 1 or 2 above, indicating that maybe I don't know how to read what is returned? (Could say "fool you, stop this")

Thank you very much in advance for all your comments!

Nicolai

If your named pipes pass binary data - and it seems that they are - so don't expect to get an ASCII string. You will also need to send binary data. The wCMD is setting a WORD (2 bytes, or 16 bits) - so why do you send 15 bytes (PIPE_CMD_EXAMPLE length)? Moreover, since the data is an array of 2 elements of fixed size, it would be preferable to use a 2-element cluster for byte element, and not a picture of LabVIEW. Who's going to flatten properly, while a painting may not (depending on whether you set the flag to prepend to the size of the array). For data read back, you will need to unflatten it in a cluster of 3 values double precision, and it is possible that you will need to reverse the order of each element byte to get the correct values.

-

NOR-845 x driver Labview 2011 SP1

Hi all

I faced problem,

I have a LabView program that is used to communicate with devices SPI-NOR-8451. Program worked perfectly, on PC with LabView 2010. After that, I moved the program to new PC where f1 LabView 2011 SP1 has been installed. And now, I am not able even open - LabView program stuck on the white block diagram (not responding).

Program is complex and includes 10 ~ SubVis, which is packaged in the .llb file. I tried different things - to decompress from .llb, or run subVis themselves - for all the subVis, which include a part any communication NOR-8451, I've got stuck LabView. In addition, after the removal of NOR-845 x pilot, I can't ignore everything and load the program successfully, with '? ' instead of screws of NOR-845 x pallete.

In addition, when I'am tring from white VI and set NEITHER-845 x ref Device link (see attachment for details Link_on_ref_.jpg) on the block diagram, I'm LabView stuck - see the attached Stuck_.jpg.

I use NEITHER-845 x driver 2.0, I tried to reinstall several times.

So, it's my suspicious that NEITHER-845 x driver 2.0 does not work for LabView f1 2011 SP1 - is it possible? Or maybe I'm doing something wrong?

Hi RangerOne,

Thanks for the trace, as LabVIEW is suspended, it is what I expected but hoped a different error code. If you could go to MAX and reset Configuration data, and then create a MAX Technical report and attach it.

If you open the test Panel, you run a query, it works or hang? Try to run a trace when you try to query.

I see the same error with the camera on my machine under interrupt in Pipe status is not abnormal.

I also noticed that your computer input for findlist, retcount and SrcName parameters have not the & on the non-working paper. I will continue to examine the reason why the & is not there and if it has an effect on the shot.

DylanC

-

How to read the data from a channel named in windows using labview

Hello

I need to read the channel named in windows data. The pipe is created by python by another application. This application post permanent data on the pipe. But I don't know how to read data using labview. is it possible to read the data from different application? If possible, how to start?

Thanks in advance

concerning

RJ

Hi Rolf,.

It's just, because of driving is not initialized completely, pipe read returns error 42, I added 2 seconds late, then its work perfect.

Thank you very much.

Concerning

RJ

-

This is not directly related to the LabVIEW but he wanted everyone to be aware of something that could dramatically change this and all the forums software such as we know them today. I was going to post this on breakpoint , but I wanted more people to see if it please forgive me.

I read this thread on copyright on the lava and the posted queue Aristos a same scenario frightening about what could happen SOPA becomes law. (This is a link to Wikipedia that will be down in the world later today to protest these laws)

Basically what is happening now, is that if someone posts the code under copyright on this forum, that person is legally responsible. The copyright owner can sue that person and the order NOR to take down the offending content. This applies to screws, clips, screenshots, etc. If SOPA become law then NOR will inspect any code and determine if it is legally displayed. If someone illegally post another code under copyright of people and someone download it then OR would be legally responsible. It would be more convenient for this forum to exist. Same for any forum that allows attachments.

Here is a good list of reasons why you should oppose to SOPA and PIPA. What can do you? It is probably fatalist, but I don't have a good feeling about the future.

36 years ago, I raised my right hand and swore as God as my witness that I will defend the constitution of the States participate.

The authority to implement and accept the Constitution was derived from the declaration of independence which reads in part;

When, as part of the events, it becomes necessary for one people to dissolve the political groups which have connected them with another and to assume among the powers of the Earth, the separate and equal station to which the laws of Nature and of the God of Nature entitles them, a decent to the opinions of mankind requires that they should declare the causes which push them to the separation.

We hold these as obvious truths, that all men are created equal, that they are endowed by their creator certain inalienable rights, that among these are life, liberty and the pursuit of happiness. - that to secure these rights, Governments are set up among men, deriving their just powers from the consent of the governed,--that whenever any form of Government becomes destructive of these ends It is the right of the people to change or abolish it and to institute new Government, its foundations on such principles and organizing its powers in this form, as to them is apparently the most likely to perform their safety and happiness. Prudence, indeed, will impose that established Governments for a long time should not be modified for causes slight and temporary; and accordingly all experience has shown, that humanity is more likely to suffer, while evils are sufferable, rightmost themselves by removing the forms to which they are accustomed. But when a train of abuses and usurpations, pursuing the same subject long manifested a design to reduce them under absolute despotism that is their right, it is their duty, to get rid of this Government and to provide new guards for their future security. -.

emphesis and font size adjusted by me.

There is part of me saying that it's time to rise and meet the oath that I swore.

This sweet lady that I swore to defend is be sullied by those who claim to represent.

Ben

-

How to draw tanks and valves in labview 6

Hi all

I am a beginner in LabVIEW. As a newcomer, I made small programs on the flashing LEDs and check the water level in the tank and so on. Now, I am doing a project on the mixer. While exploring through the examples that I've seen a more or less similar to the HELP option example. In the GUI there are tubes and tanks and valves. Now my question is how I'll be able to draw these pipes, valves etc. in the façade of labview?

Thanks in advance

Rohini

NB: I enclose the photo of the façade.

You asked essentially the same question in July 2010, and it was stated that valves and tanks came the DSC module. If you can not buy it then you need to use Control Editor of LabVIEW to customize the controls. The LabVIEW help describes how to customize controls. You can also search the site FOR examples, like this:

-

Hello

I use Linux in LabView 2009. I want to use named pipes. I am unable to create a channel named with mode = 1 (write).

I am getting an error, but I do not see the pipe being created.

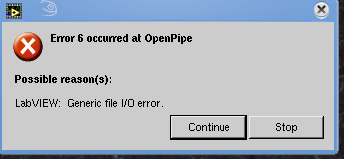

"

Error 6 took place in OpenPipe

Possible reasons:

LabVIEW: File generic i/o error.

"

Thank you.

Kind regards

H

H P,.

If you are looking for open pipes to ni.com, the third document 6 error is this basis of knowledge (http://digital.ni.com/public.nsf/allkb/FB7A1B9D8C1A558186256CAA0083C290). It is said that you must open a channel mode reading first before you can open it in write mode. Do you think this could be the cause of your error? Which Linux distribution do you use? You see another error with LabVIEW under Linux?

-

Sorensen XEL power is compatible with labview

What Sorensen XEL power compatible with labview? I'm in the automotive field of vehicle dashboard. I want to test and simulate different transient conditions that may generate noise in the pipe I needed of a programmable power supply. Currently I have a NIcompactRIO configuration. I needed voltage output cards higher simulation and test requirements and special conditions.

I was told that the Sorensen XEL series is compatible with Labview. Is this fair? The other question I have is NIcompactRIO uses IP Ethernet, but Sorensen communication RS 232 communication. Can I have some possible parallel communication with Labview frontend Protocol, controlling all the two from the same unique computer.

Third, what are the function blocks required in the VI for Sorensen.And programming last but least, where can I get a drivers Sorensen RS 232?

Nothing in this VI with Ethernet communication so I don't understand what you're asking.

Rather than add a \r\n with each entry, I recommend you set up VISA to automatically add and I would also recommend that you enable the character to stop playing as well. Then, there was no need for the VISA to the Serial Port bytes and these expectations. Look at the example of advanced series to learn how to set the VISA property to add a termination character.

Maybe you are looking for

-

Parameters to win 8 and SSD drive

Just bought a h9 - 1440t with windows 8 pro and an SSD. Can you tell me: 1 - is the motherboard SATA 2 or SATA 3? 2. are there additional parameters I should do to ensure the best performance of the SSD drive? I was led to believe that I had to disab

-

I have a HP PAVILION DV7T - 4100 NOTEBOOK with 6 GB of RAM running Windows 7 Edition Home Premium. This laptop will be Windows 8? I know that the touch screen option would not work.

-

Don't want my static Z2 homescreen background

Hello! I recently reset my Z2 and now my homescreen background is static, I want that it move as well as each screen. How can I make 'non-static?

-

Problems with Windows Error Reporting

I have Vista Home Prmium with SP2 on a dual processor computer heart. wermgr.exe is running in the background and when he does he can linger around for awhile while using 50% of my CPU all the time. He passes in and out the Task Manager, so that the

-

continue the print job after adding paper

Cannot find directions for: If the printer is out of paper in the middle of printing, how to make so that it can continue the work after paper is added? I always end up having to cancel, and then restart. Impossible to find a button back.